Cone yarn packaging device

A bobbin and station technology, applied in the field of automation equipment, can solve the problems of increasing production costs, low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to demonstrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

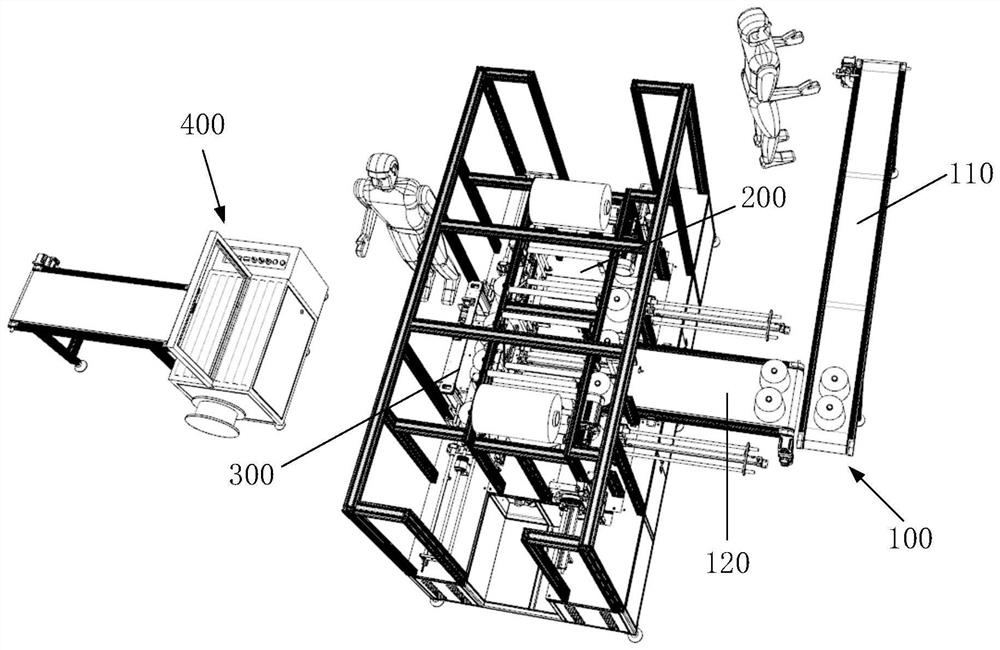

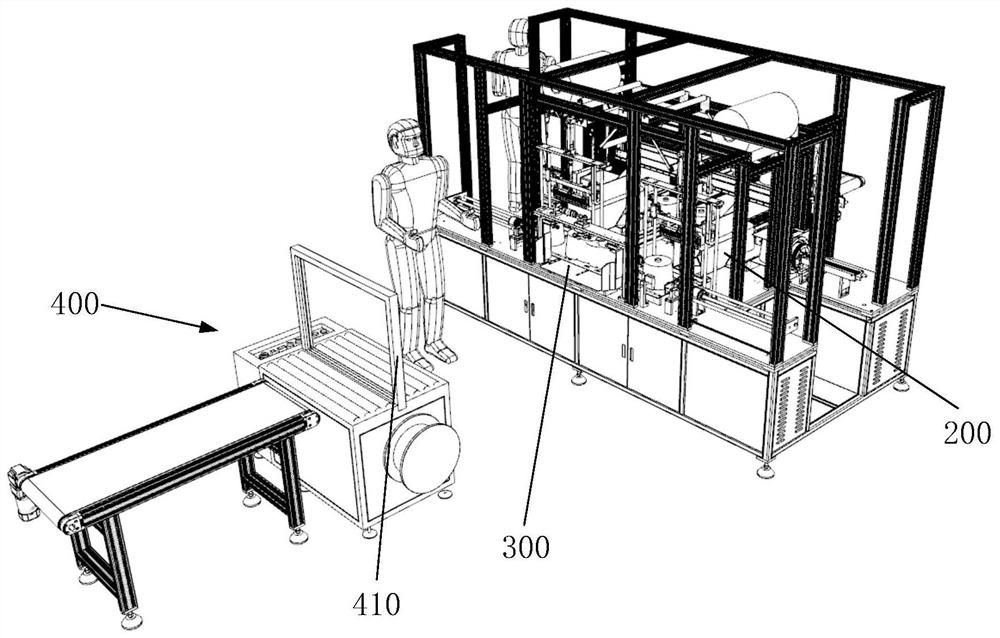

[0024] The bobbin packaging device provided by the invention, such as Figure 1 to Figure 6 As shown, it includes in turn: a feeding station 100, a film covering station 200, a bagging station 300 and a sealing and binding station 400 to form a complete bobbin packaging production line.

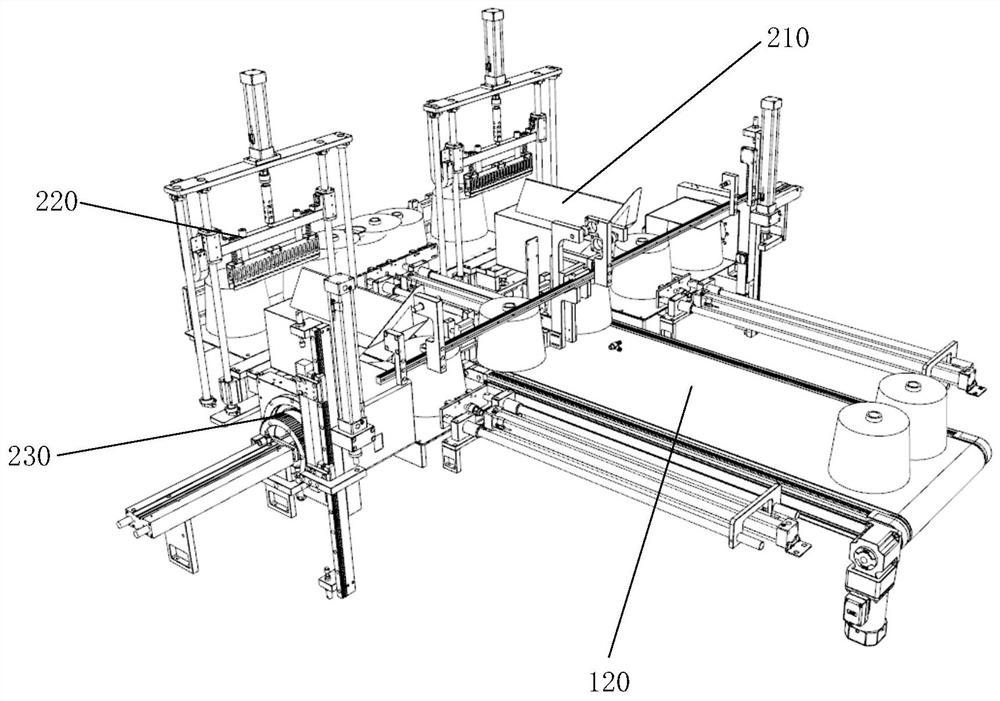

[0025] The feeding station 100 includes a feeding belt 110 and a diverting belt 120 connected in sequence, used to transport the package yarn 001, and divide the flow according to the specifications of the package yarn 001, for example, only one specification of the package yarn 001 is allowed to flow in Laminating station 200;

[0026] The laminating station 200 includes a film forming mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com