Automatic cutting device for bobbins and cutting method for automatic cutting device

An automatic cutting device and bobbin technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as low production efficiency and uneven workpiece incision, and achieve improved blank pass rate, smooth workpiece incision, and Dimensional Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

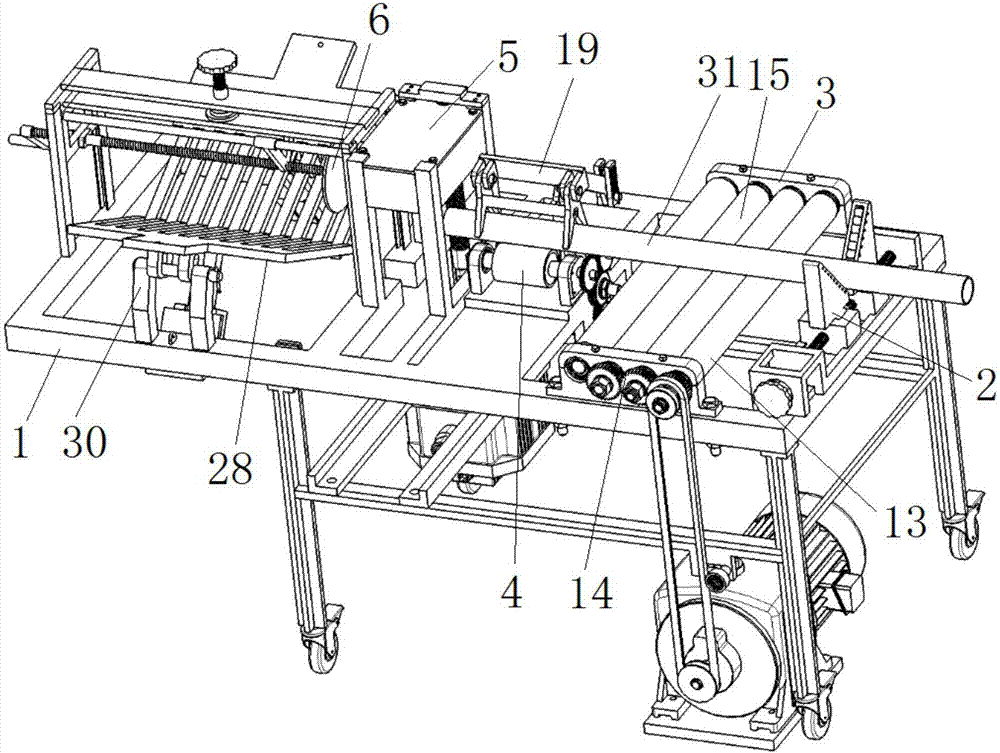

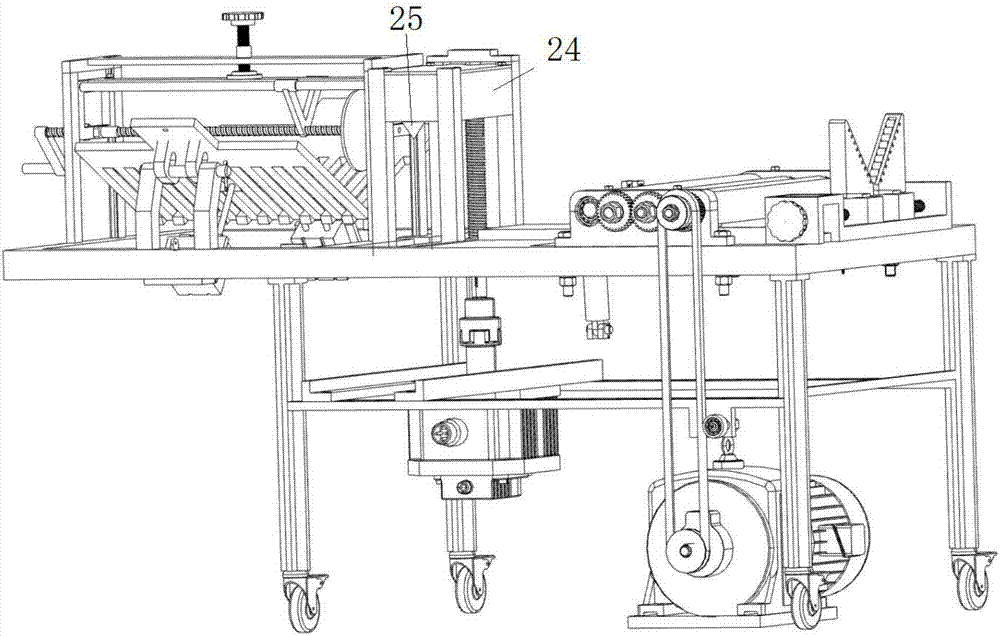

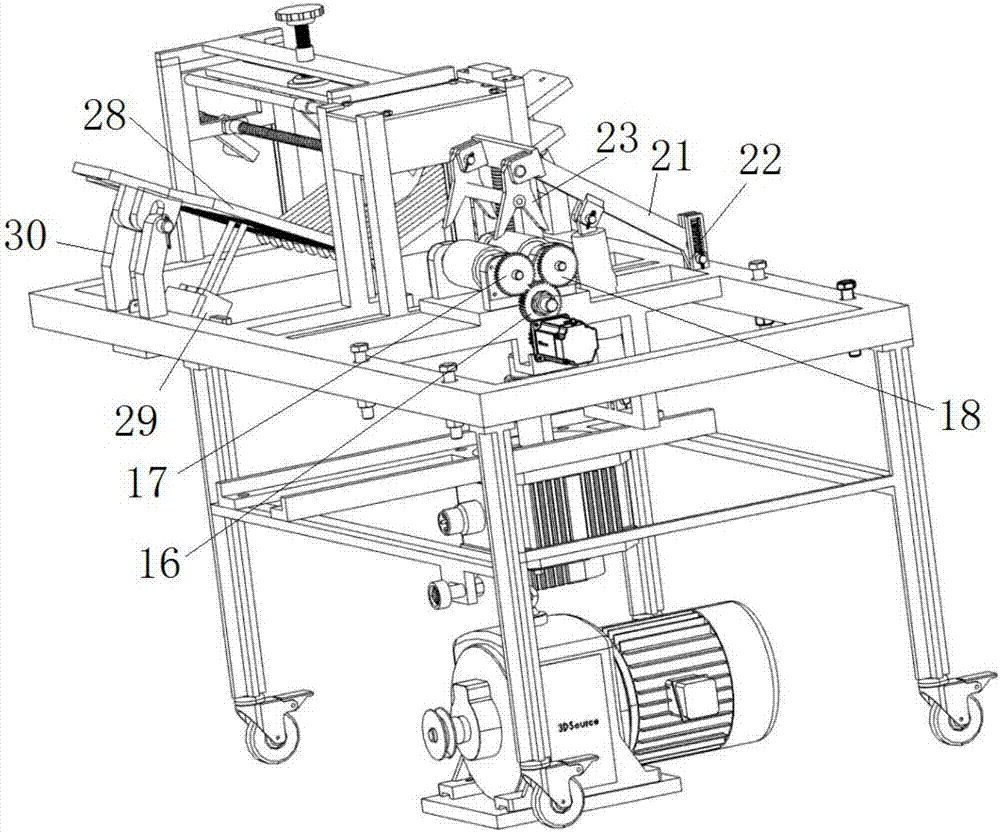

[0031] Such as Figure 1 ~ Figure 5 A bobbin automatic cutting device shown includes a frame 1, on which a feeding axial roller mechanism 2, a feeding transverse feeding mechanism 3, a feeding rotary feeding mechanism 4, and a cutting mechanism 5 are sequentially arranged on the frame 1. , Unloading floatation mechanism, a limit baffle 6 is arranged above the unloading floatation mechanism.

[0032] The distance between the limit baffle 6 and the cutting point of the cutting mechanism 5 is the length of the tube to be discharged. The feeding axial roller mechanism 2 includes two sliders 7, a double nut screw mechanism 8 that drives the two sliders 7 to slide. The two sliders 7 are respectively provided with support blocks, and the support blocks include a left support block 9, The right support block 10 and the left support block 9 are provided with a left support slope, and the right support block 10 is provided with a right support slope symmetrically arranged with the left su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com