Full-automatic transverse and vertical cutting device for furniture decoration veneer

A technology of decorative veneer and cutting device, applied in the directions of transportation and packaging, metal processing, coiling strips, etc., can solve the problems of low processing efficiency, poor cutting effect, unreasonable and so on, and achieve the effect of automatic cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

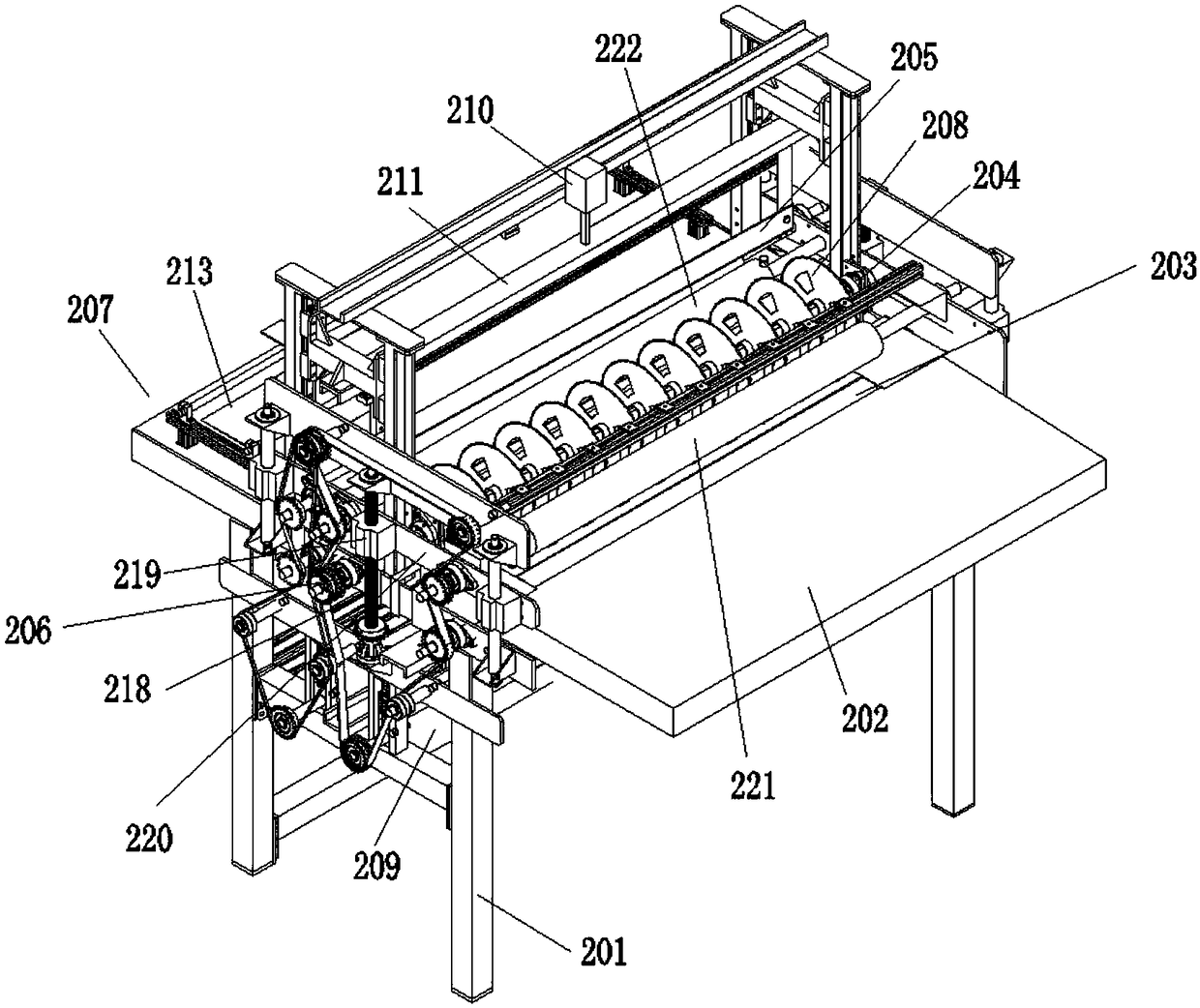

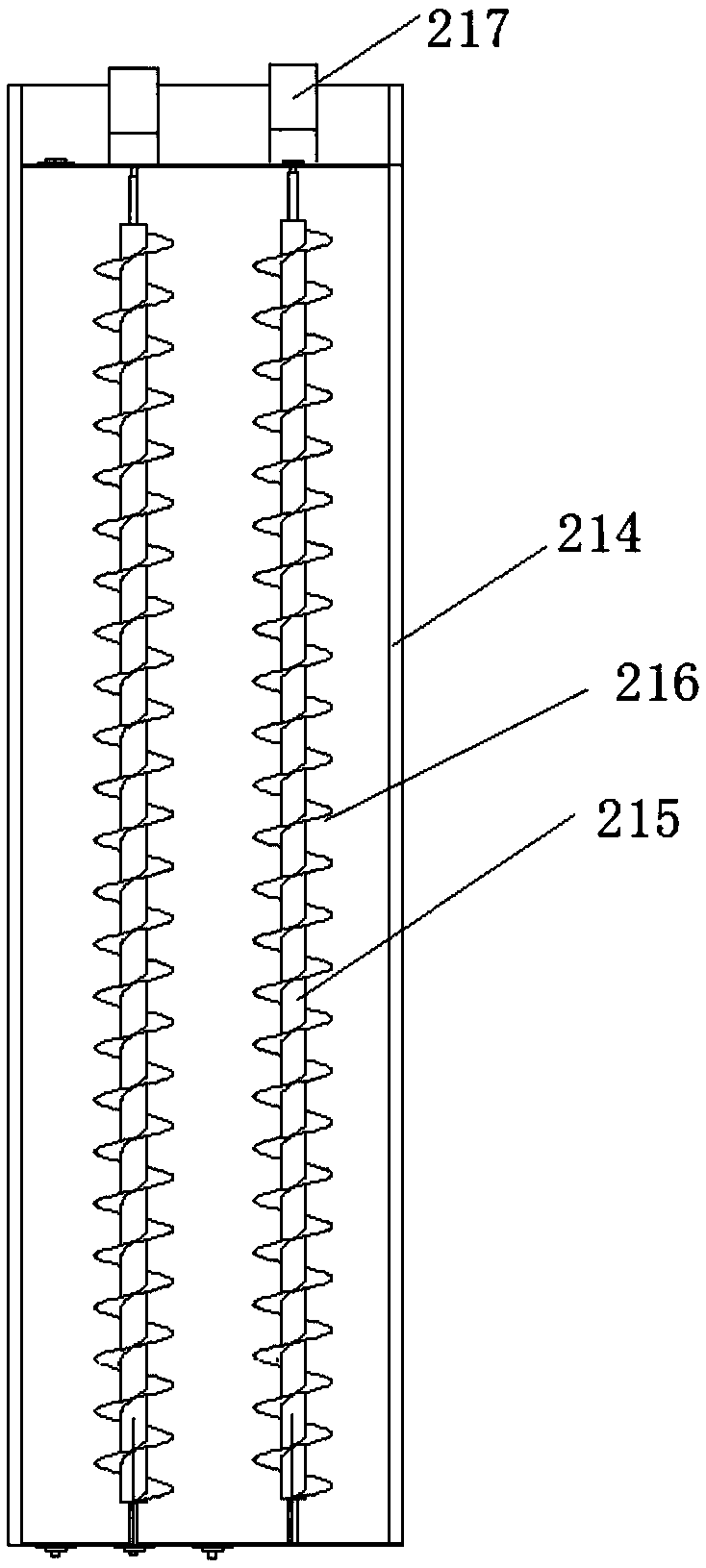

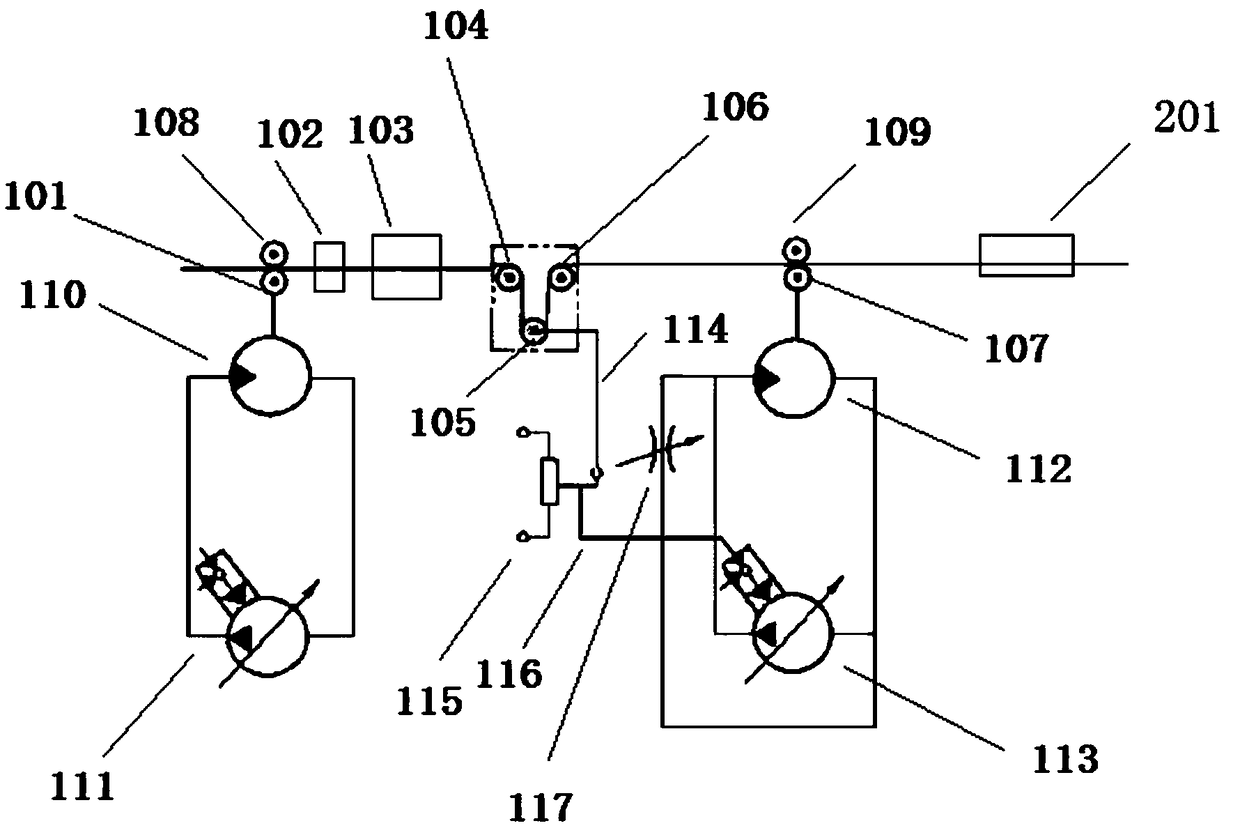

[0011] Example: Full-automatic horizontal and vertical cutting device for decorative veneer of furniture, as attached Figure 1-2 As shown, the frame 201 is included. The frame 201 is provided with a feeding table 202, a feeding roller 203, a vertical cutting shaft 204, a horizontal smashing sheet 205, a discharging roller 206, and a discharge port in sequence along the feeding direction of the material. 207; the vertical cutting shaft 204 is provided with a vertical cutting blade group 208; the bottom of the frame 201 is provided with a motor 209, the motor 209 through the chain and the feed roller 203, the vertical cutting shaft 204 and the discharge shaft 206 Connected; above the frame 201 is provided with a lifting hydraulic cylinder 210, the extension end of the lifting hydraulic cylinder 210 is connected with a horizontal smashing frame 211, and the bottom of the horizontal smashing frame 211 is fixed to the blade 205;

[0012] The discharge port 207 is provided with a dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com