Special clamp for circular saw cutting machine

A cutting machine and clamp technology, which is applied in the field of special clamps for circular saw cutting machines, can solve the problems of waste of tailings, long sawing time of workpieces, and long length of sawing tails of circular saw cutting machines, so as to reduce waste, The effect of avoiding manual misoperation and reducing the input of manpower and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The special tongs for the circular saw cutting machine of the present invention will be further described in detail through specific embodiments below.

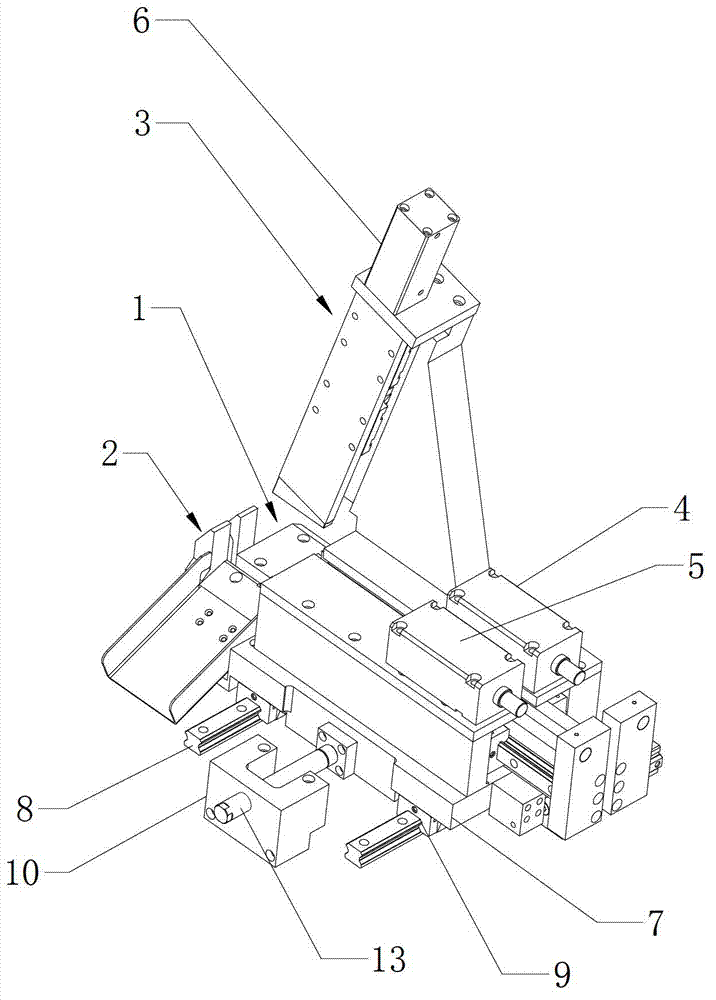

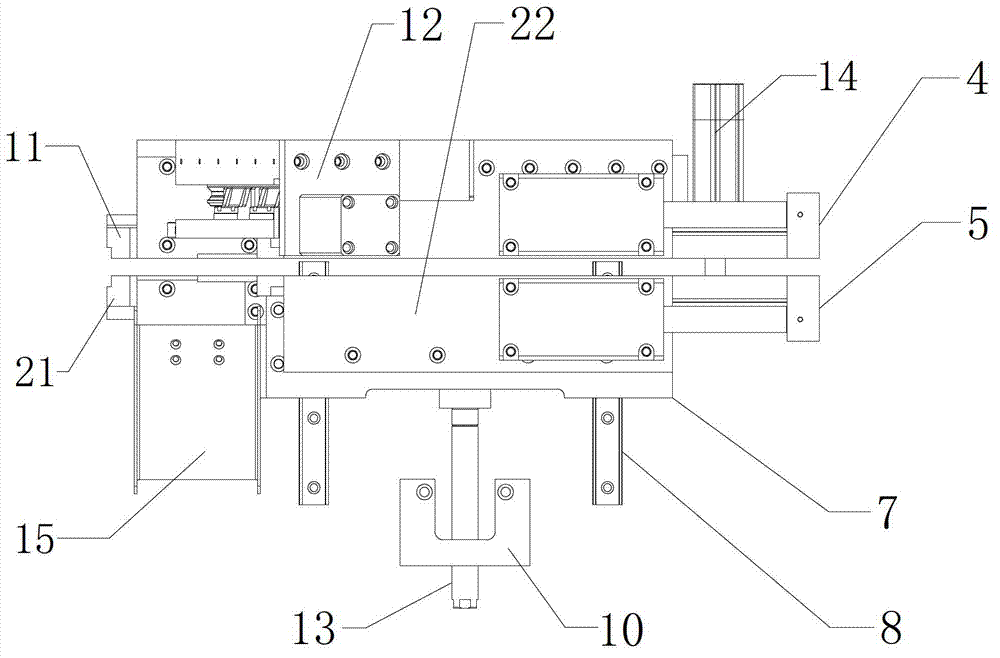

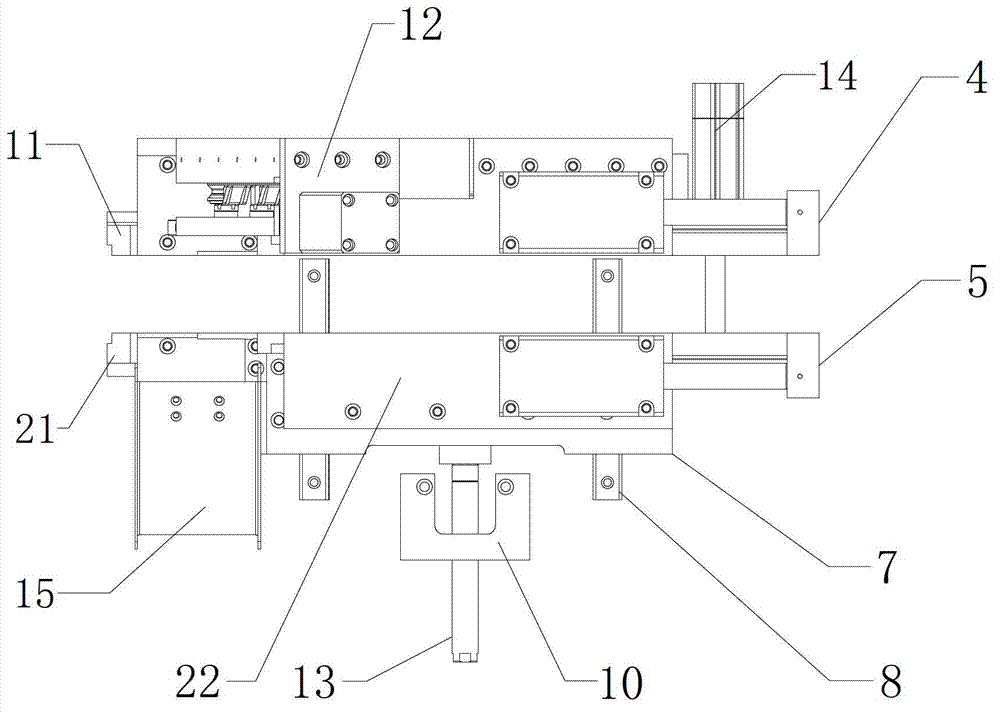

[0022] Such as Figures 1 to 4 As shown, the special clamp for the circular saw cutting machine includes a frame, an inner clamp 1 and an outer clamp 2 installed on the frame, and the inner clamp 1 and the outer clamp 2 are respectively located on the saw blade of the circular saw cutting machine. Upstream and downstream; the inner clamp 1 includes a fixed jaw 11 and an inner moving jaw 12, the inner fixed jaw 11 is fixed on the frame, and the inner moving jaw 12 is powered by the inner moving jaw power device 4 Cooperate with the internal fixed jaw 11 to clamp the profile delivered from the upstream from both sides, the outer clamp 2 includes the outer clamp working platform 7, the outer fixed jaw 21 and the outer movable jaw 22, the outer clamp working platform 7 is slidably installed on the frame along the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com