A fully automatic cement brick cutting machine

A brick cutting machine, fully automatic technology, applied in the field of fully automatic cement brick cutting machine, can solve the problems of cement brick vibration, instability, falling, etc., and achieve the effect of stable cutting process, high cutting efficiency and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

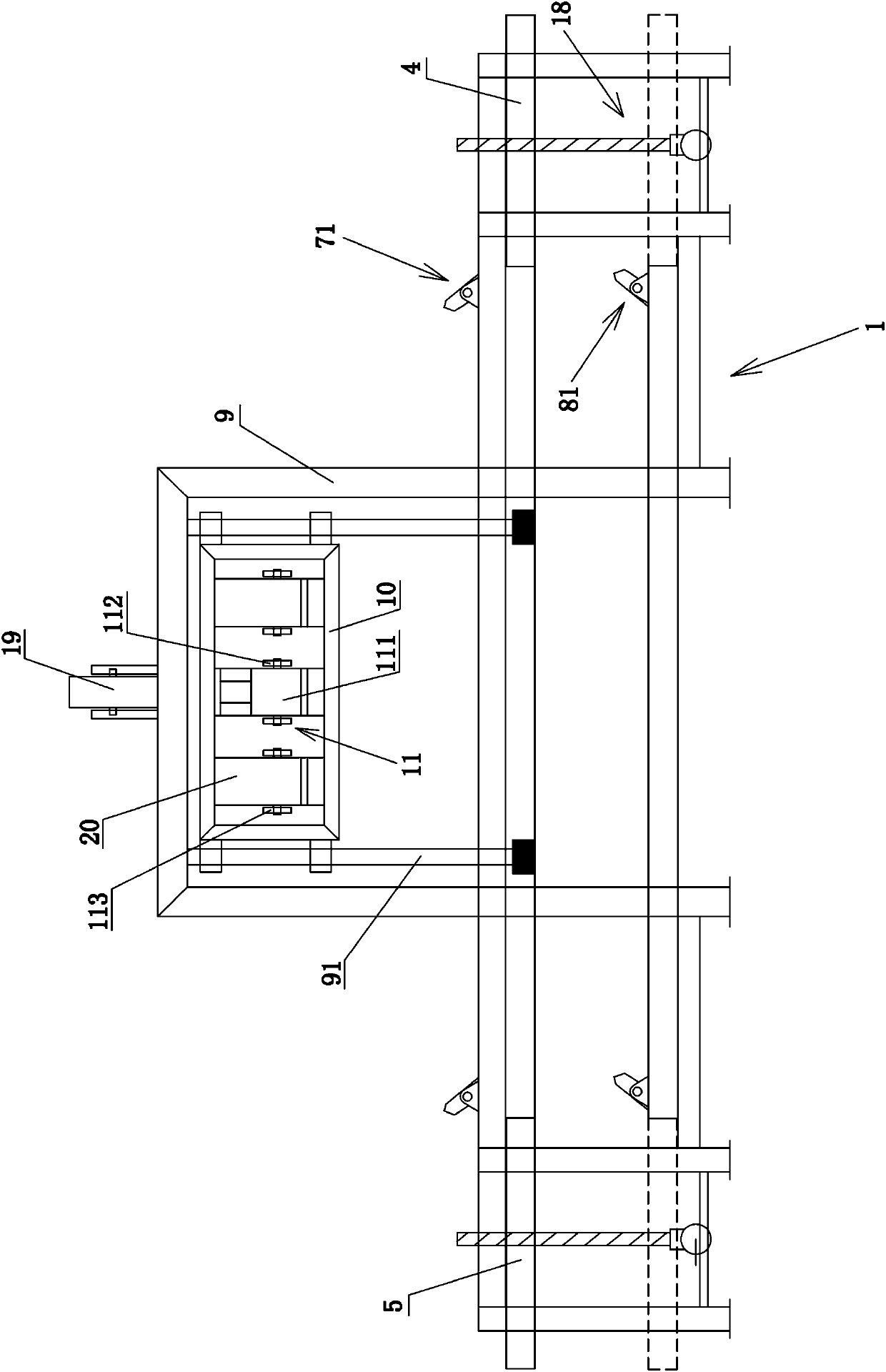

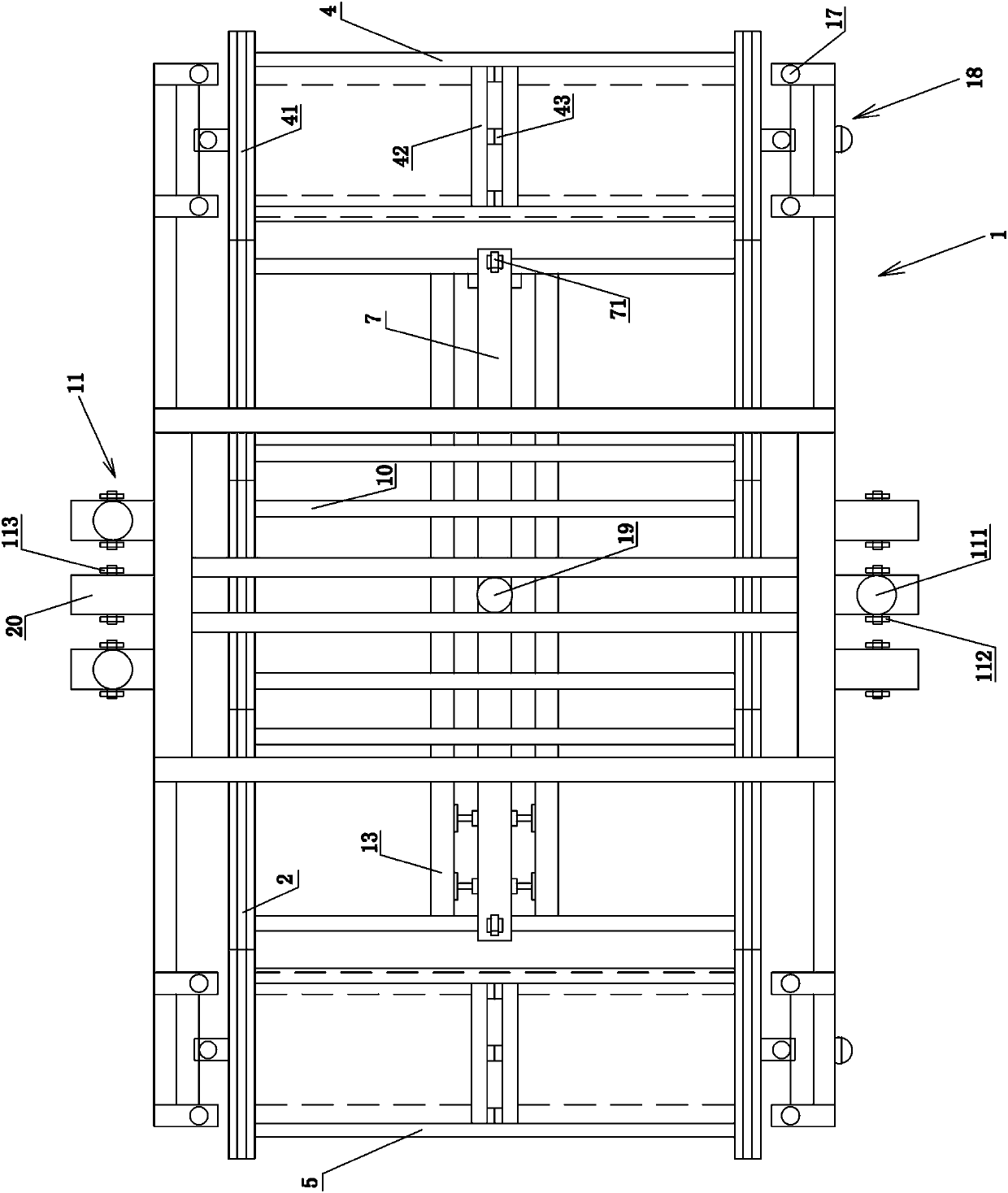

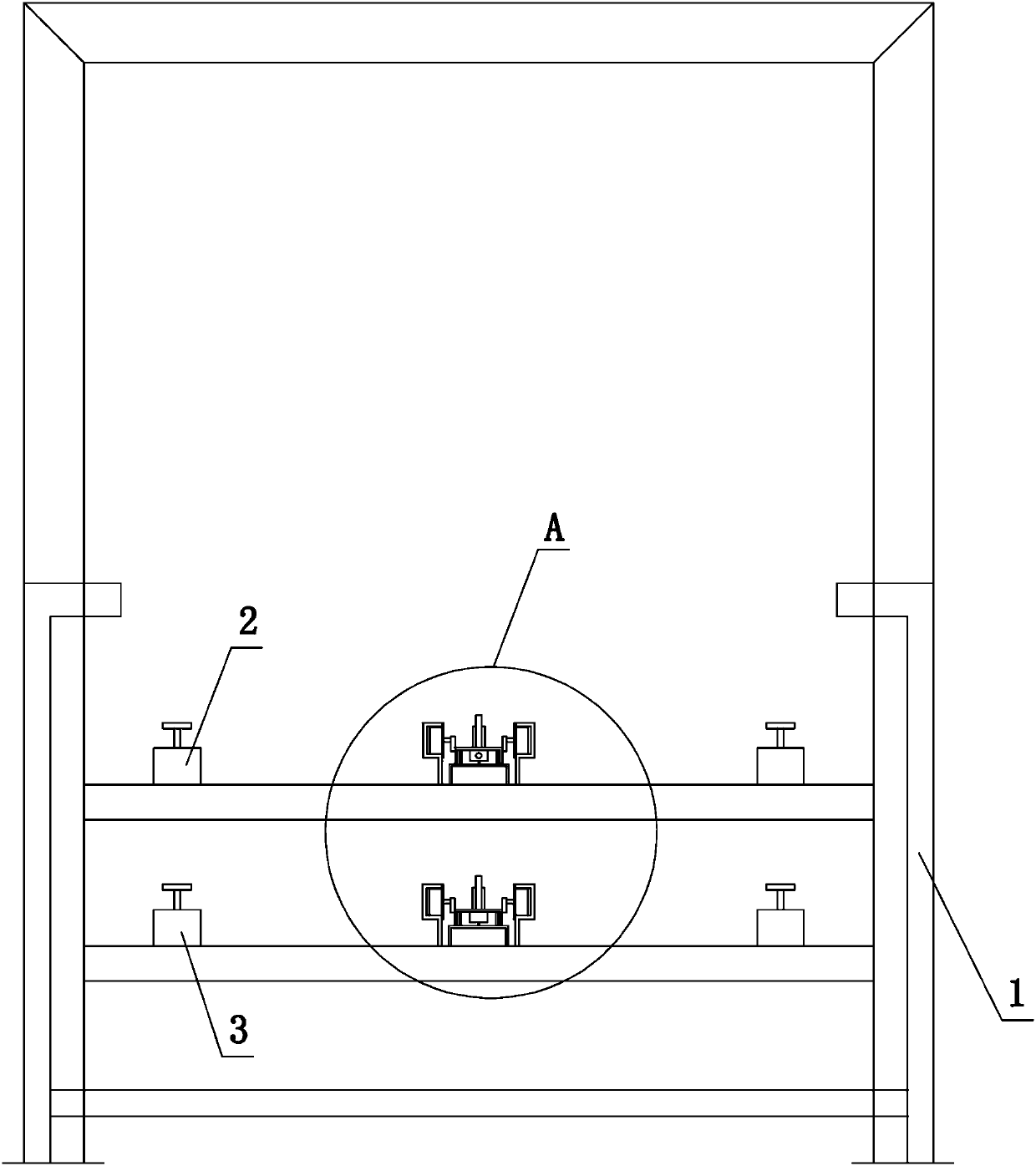

[0024] refer to figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 . A fully automatic cement brick cutting machine comprises a frame 1, on which two upper slide rails 2 arranged at intervals from left to right and two lower rails 3 arranged at intervals from left to right are arranged on the frame 1. The front and rear parts of the frame 1 are respectively provided with a front lifting frame 4 and a rear lifting frame 5, and the top surfaces of the front lifting frame 4 and the rear lifting frame 5 are respectively provided with two front slide rails 41 and two rear slide rails. (not marked in the figure), the structures of the two front slide rails 41 and the two rear slide rails (not marked in the figure) are the same. After the front lifting frame 4 and the rear lifting frame 5 are raised, the two front slide rails 41 and the two rear slide rails (not shown in the figure) are connected with the two upper slide rails 2 and are flush with each other. After the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com