A film sample automatic cutting method and device

A fully automatic, thin-film technology, applied in the direction of measuring devices, test sample preparation, sampling, etc., can solve the problems of difficult processing technology, easy wear of the knife edge, cumbersome cutting steps, etc., and achieve good dimensional consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Attached below Figure 1-6 The specific implementation content of the present invention is described in detail:

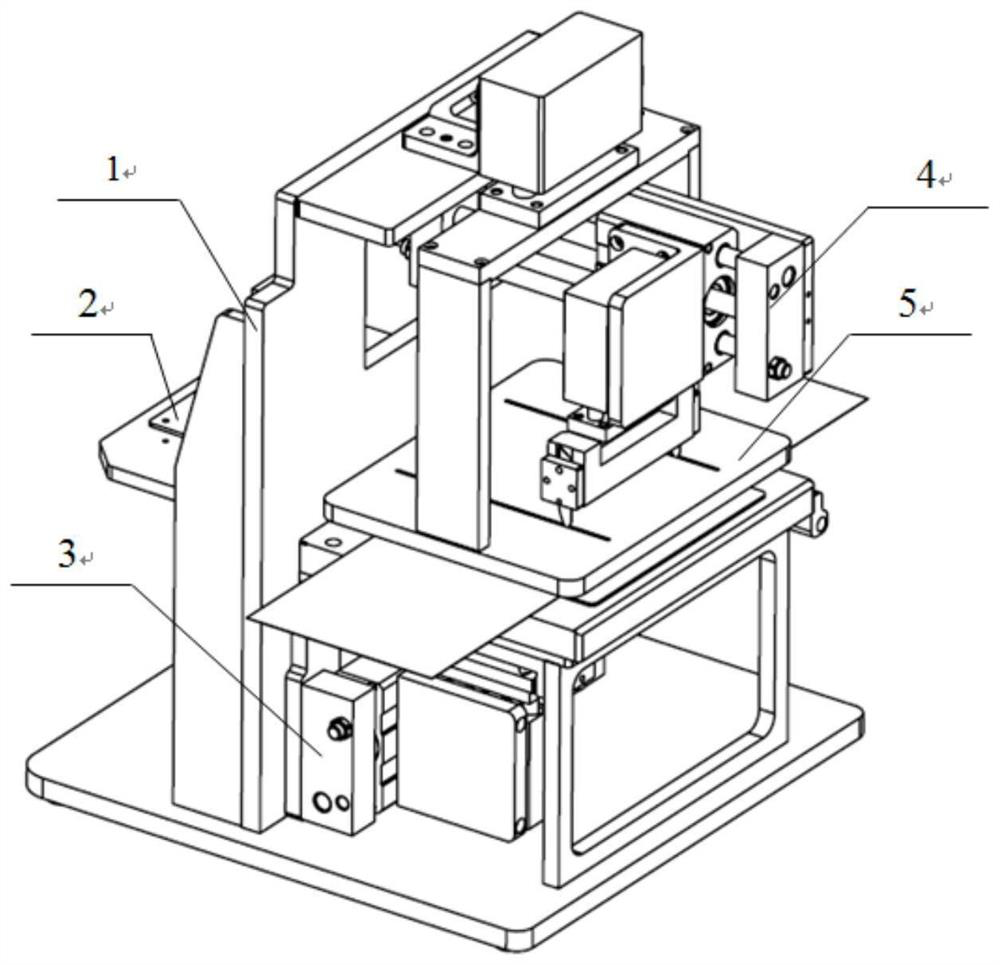

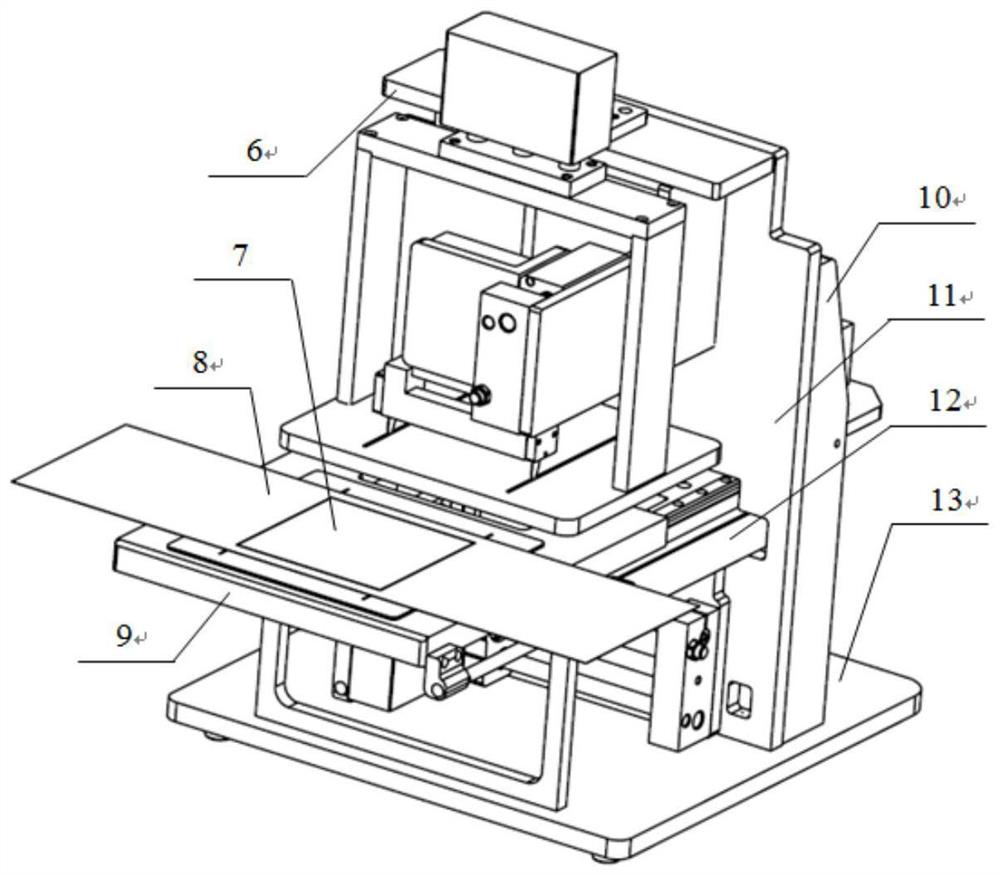

[0041] The film sample automatic cutting device of the present invention comprises a film pressing system 5, an upper sliding platform system 4, two upper and lower film cutting systems 24, 30, a film fixing platform system 9, a lower sliding platform system 3, a control system 2 and Fix the supporting part 1 etc.

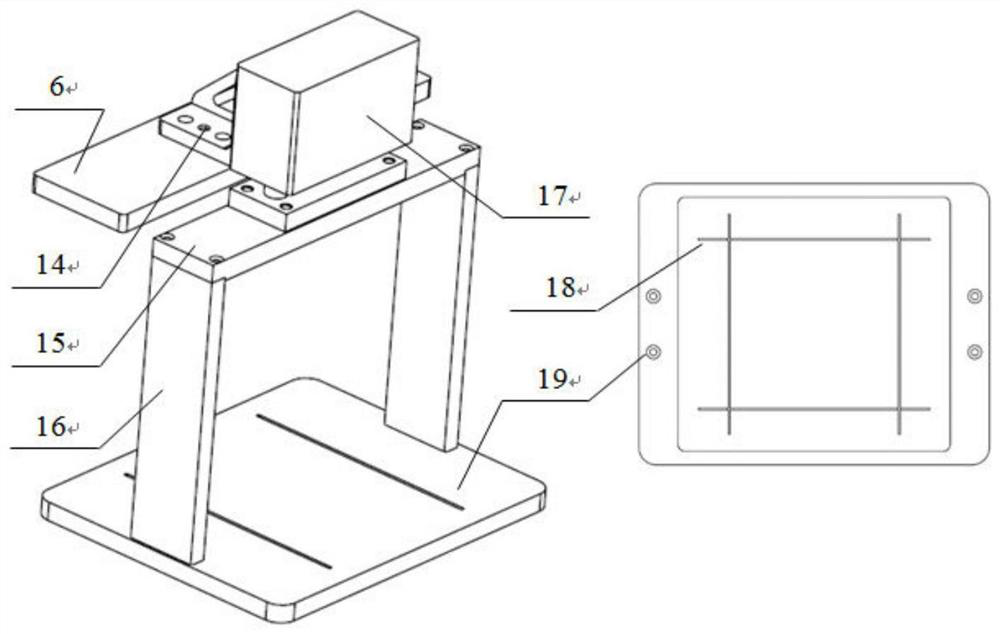

[0042] The film pressing system 5 of the present invention includes a film pressing system fixing frame 14, a pressing adapter plate 15, a pressing vertical block 16, an upper pressing cylinder 17, a film pressing pad 18 and a film pressing plate 19, etc. . The upper pressing cylinder 17 is fixed above the film fixing platform system 9 through the film pressing system fixing frame 14, pressing adapter plate 15 and pressing vertical block 16, and the upper pressing cylinder 17 pushes the film pressing pad 18 and the film The up and down movemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com