Water jet cutting manufacturing method for chip prevention plate

A technology of water jet cutting and manufacturing method, which is applied in the direction of manufacturing tools, used abrasive treatment devices, abrasive materials, etc., can solve the problems of high cost and low time-consuming efficiency of chip plates, and achieves improved production efficiency and good economy. Value, the effect of increasing first-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

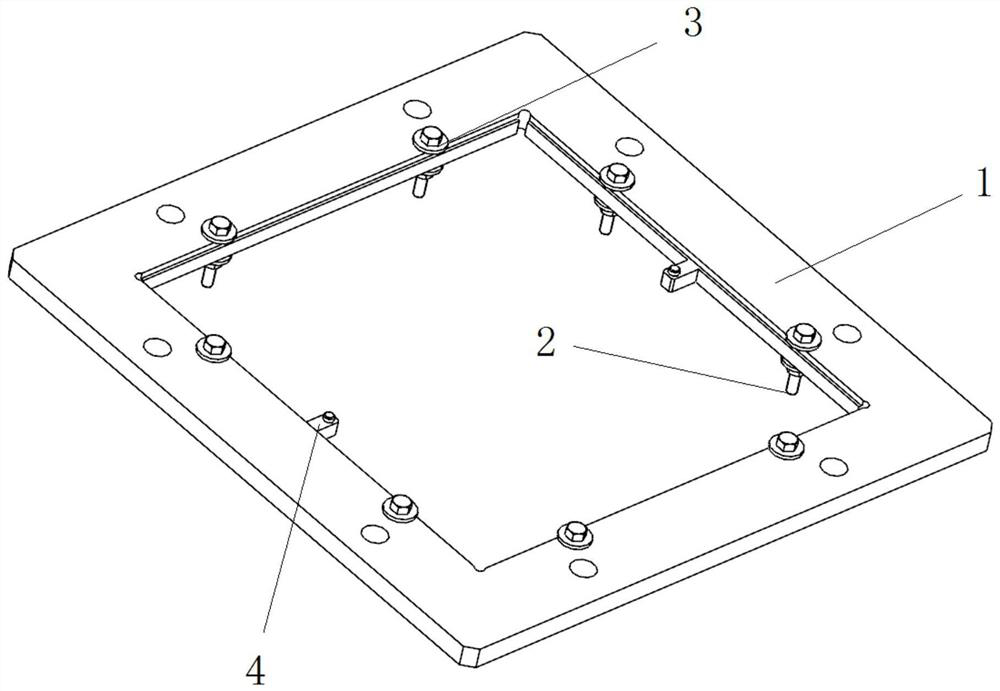

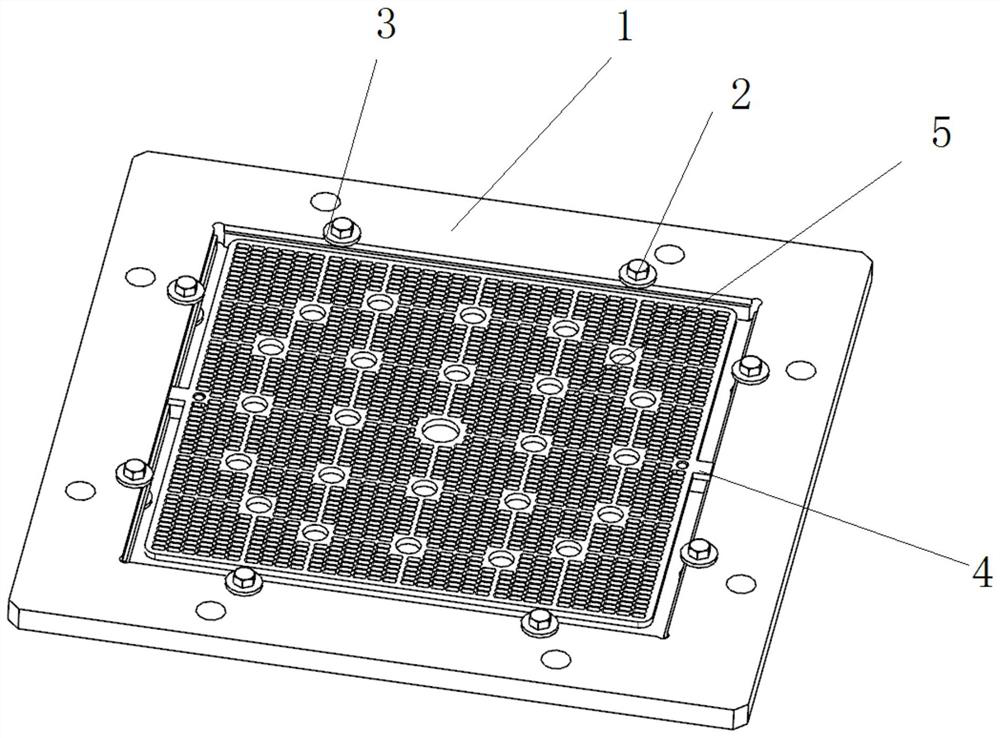

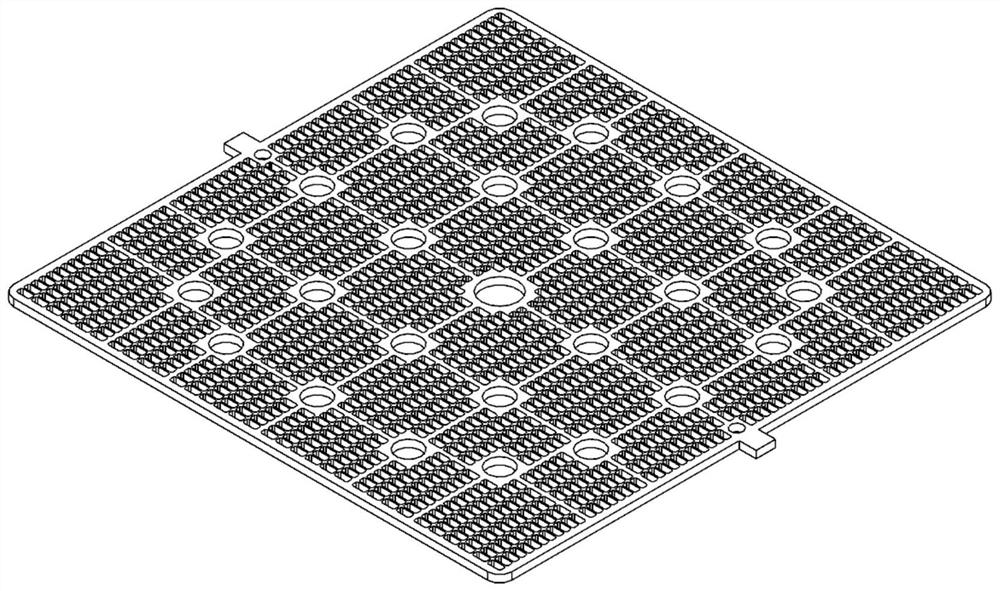

Image

Examples

Embodiment Construction

[0034] A water-jet cutting manufacturing method for an anti-chip board includes water-jet cutting pre-treatment, water-jet cutting process, water-jet cutting post-treatment and water-jet cutting quality process control method.

[0035] The method for manufacturing the chip-proof board by water jet cutting specifically includes the following steps:

[0036] Step 1. Re-inspection of raw materials and profiles: 100% inspection of the appearance quality and size of the cutting blank; cutting small samples on the cutting blank for re-inspection of its chemical composition; cutting standard tensile samples on the cutting blank, standard tensile test Age-hardening heat treatment is carried out after mechanical processing of the sample; tensile test, grain size determination and corrosion resistance test are carried out on the standard tensile sample after age hardening.

[0037] Step 2. Mechanical leveling of the cutting blank: Use mechanical methods to perform mechanical leveling on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com