Longitudinal and transverse saw cutting device

A sawing device and cross-cutting technology, which is applied in the direction of sawing components, sawing equipment, feeding devices, etc., can solve the problems of affecting the accuracy of plate cutting, poor plate flow and connection, and difficult control of the production process, etc., to achieve Labor saving, high production efficiency and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

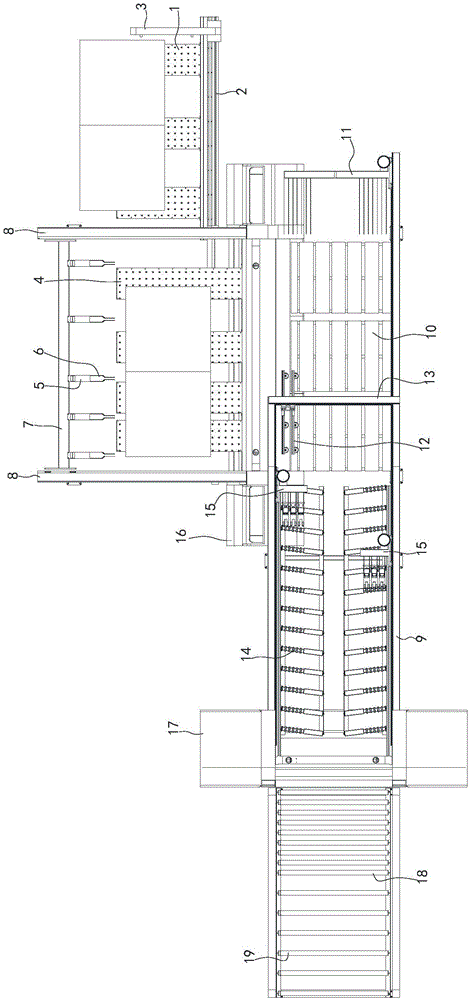

[0022] Such as figure 1 As shown, the vertical and horizontal sawing device proposed by the present invention includes a cross-cutting mechanism and a longitudinal cutting mechanism. The sheet material is processed by horizontal sawing. There is a conveying mechanism between the cross-cutting mechanism and the slitting mechanism. The final plate enters the slitting mechanism, and the slitting mechanism performs longitudinal sawing on it; the feeding mechanism includes a primary supporting platform and a secondary supporting platform, and the primary supporting platform is connected with the feeding device. The feeding device supplies sheets to the primary supporting table, and the secondary supporting table is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com