Forming method and forming device of perovskite layer film and use method and application thereof

A molding method and molding equipment technology, applied in coating, metal material coating process, gaseous chemical plating and other directions, can solve the problems of affecting film properties, unable to achieve continuous production, film properties differences, etc., to improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Please refer to Figure 7 As shown, the application of the forming equipment of the perovskite layer thin film of the present invention in the field of making solar cells specifically includes the following steps:

[0066] (1) Clean an ITO glass plate of 2.5×2.5cm by ultrasonic cleaning for 30 minutes with detergent, deionized water, acetone and isopropanol, and then use N 2 After drying, it was treated with UV O-zone for 10 minutes;

[0067] (2) Spin-coat PEDOT:PSS, dry at 90°C~150°C for 5min~20min;

[0068] (3) PbBr 2 Dissolve in DMF with a concentration of 1M, stir at 70°C for 2h, and spin-coat PEDOT:PSS to obtain PbBr 2 For thin film, anneal at 70℃~100℃ for 5min~60min;

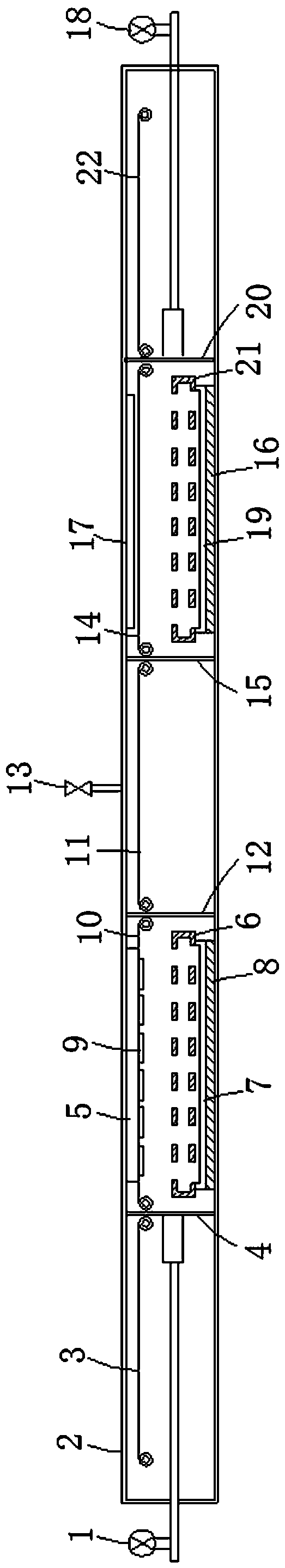

[0069] (4) will be deposited with the precursor PbBr 2 One or more substrates 9 are placed on the substrate frame 24, the partition 4 is opened, and the substrate is transported to the deposition chamber M2 through the substrate entering chamber M1 through the conveying device 3 and 10, and the...

Embodiment 2

[0080] The molding equipment of the perovskite layer thin film of the present invention is applied in the field of making LED, specifically comprises the following steps:

[0081] (1) Clean the 2.5×2.5cm FTO ethylene glycol phthalate board with detergent, deionized water, acetone, and isopropanol for 20 minutes, and then use N 2 After drying, it was treated with UV O-zone for 15 minutes;

[0082] (2) Spin-coat CuSCN and dry at 100°C~200°C for 5min~20min;

[0083] (3) PbCl 2 Dissolve in DMF with a concentration of 1M, stir at 70°C for 2h, and spin-coat CuSCN to obtain PbCl 2 For thin film, anneal at 70℃~100℃ for 5min~60min;

[0084] (4) will be deposited with the precursor PbBr 2 One or more substrates 9 are placed on the substrate frame 24, the partition 4 is opened, and the substrate is transported to the deposition chamber M2 through the substrate entering chamber M1 through the conveying device 3 and 10, and the partition 4 is closed;

[0085] (5) Open the partition 12...

Embodiment 3

[0092] The forming equipment of the perovskite layer thin film of the present invention is applied in the field of making thin film field effect tubes, specifically comprises the following steps:

[0093] (1) Clean an ITO glass plate of 2.5×2.5cm by ultrasonic cleaning for 30 minutes with detergent, deionized water, acetone and isopropanol, and then use N 2 After drying, it was treated with UV O-zone for 10 minutes;

[0094] (2) Spin-coat PEDOT:PSS, dry at 90°C~150°C for 5min~20min;

[0095] (3) PbBr 2 Dissolve in DMF with a concentration of 1M, stir at 70°C for 2h, and spin-coat PEDOT:PSS to obtain PbBr 2 For thin film, anneal at 70℃~100℃ for 5min~60min;

[0096] (4) will be deposited with the precursor PbBr 2 One or more substrates 9 are placed on the substrate frame 24, the partition 4 is opened, and the substrate is transported to the deposition chamber M2 through the substrate entering chamber M1 through the conveying device 3 and 10, and the partition 4 is closed;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com