Automatic grinding production line

A production line and automatic technology, applied in the direction of grinding machine, grinding feed movement, grinding machine tool parts, etc., can solve the problems of tool wear, increase labor, reduce production efficiency, etc., achieve high integration, realize full automation, improve Effects on production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

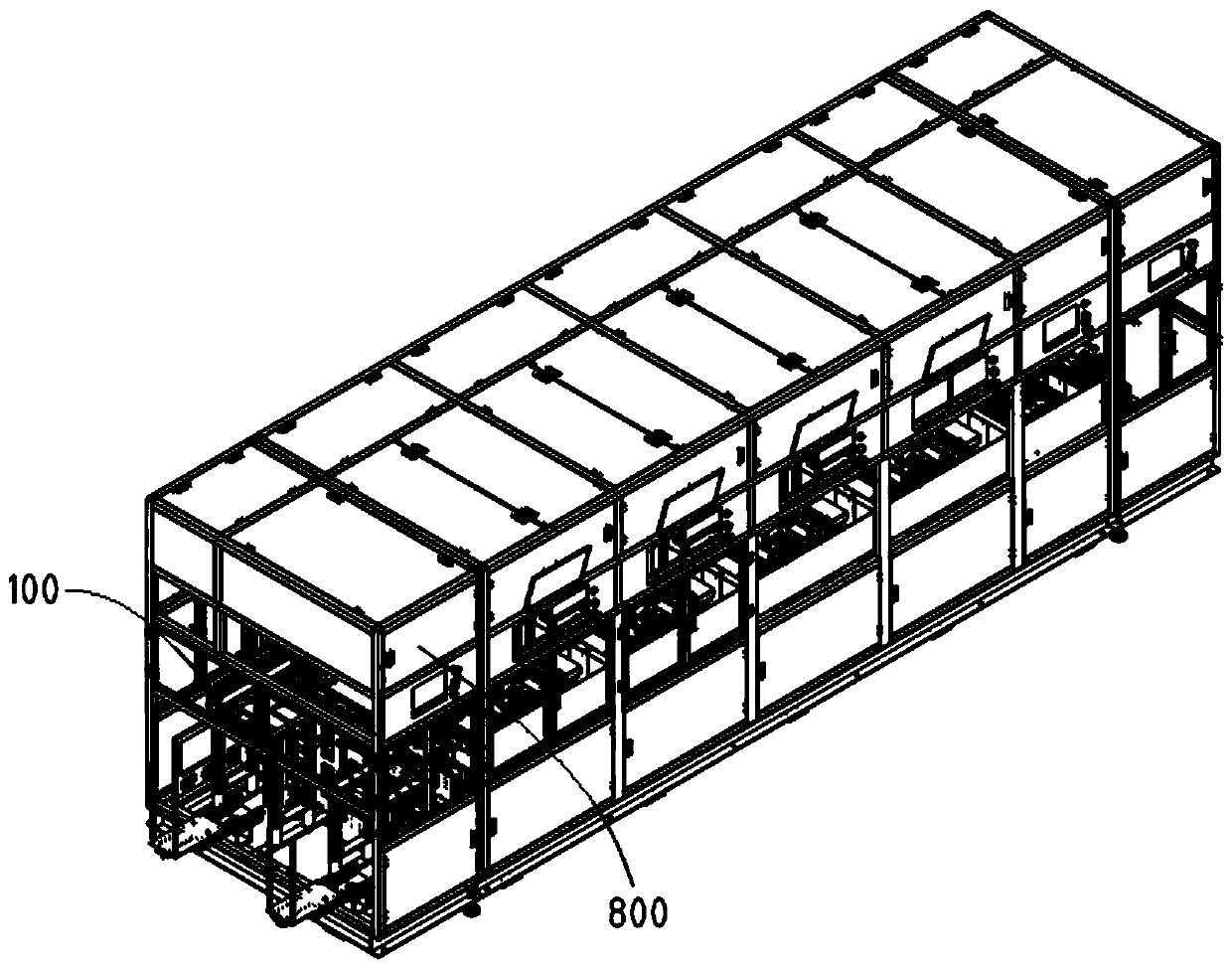

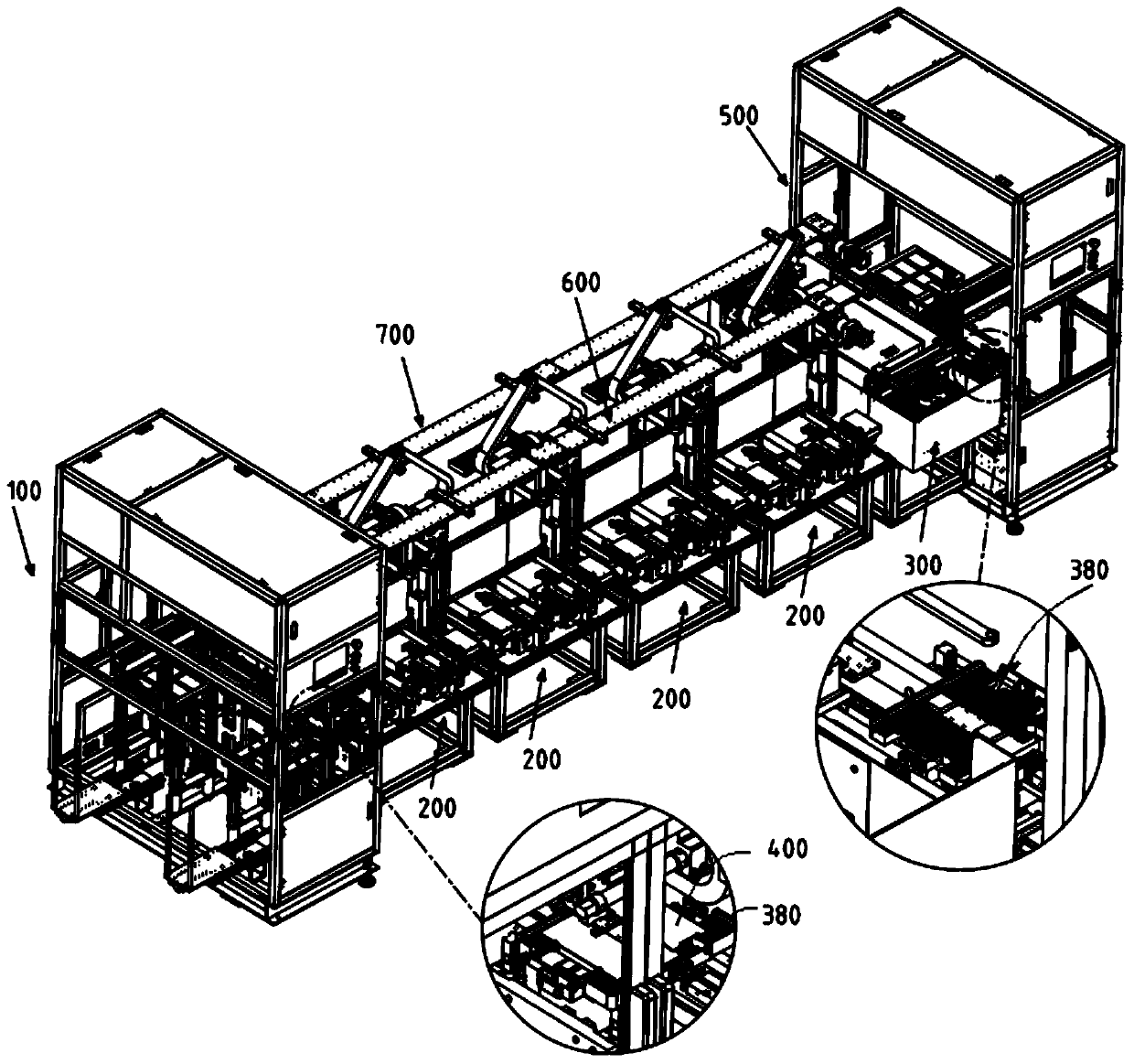

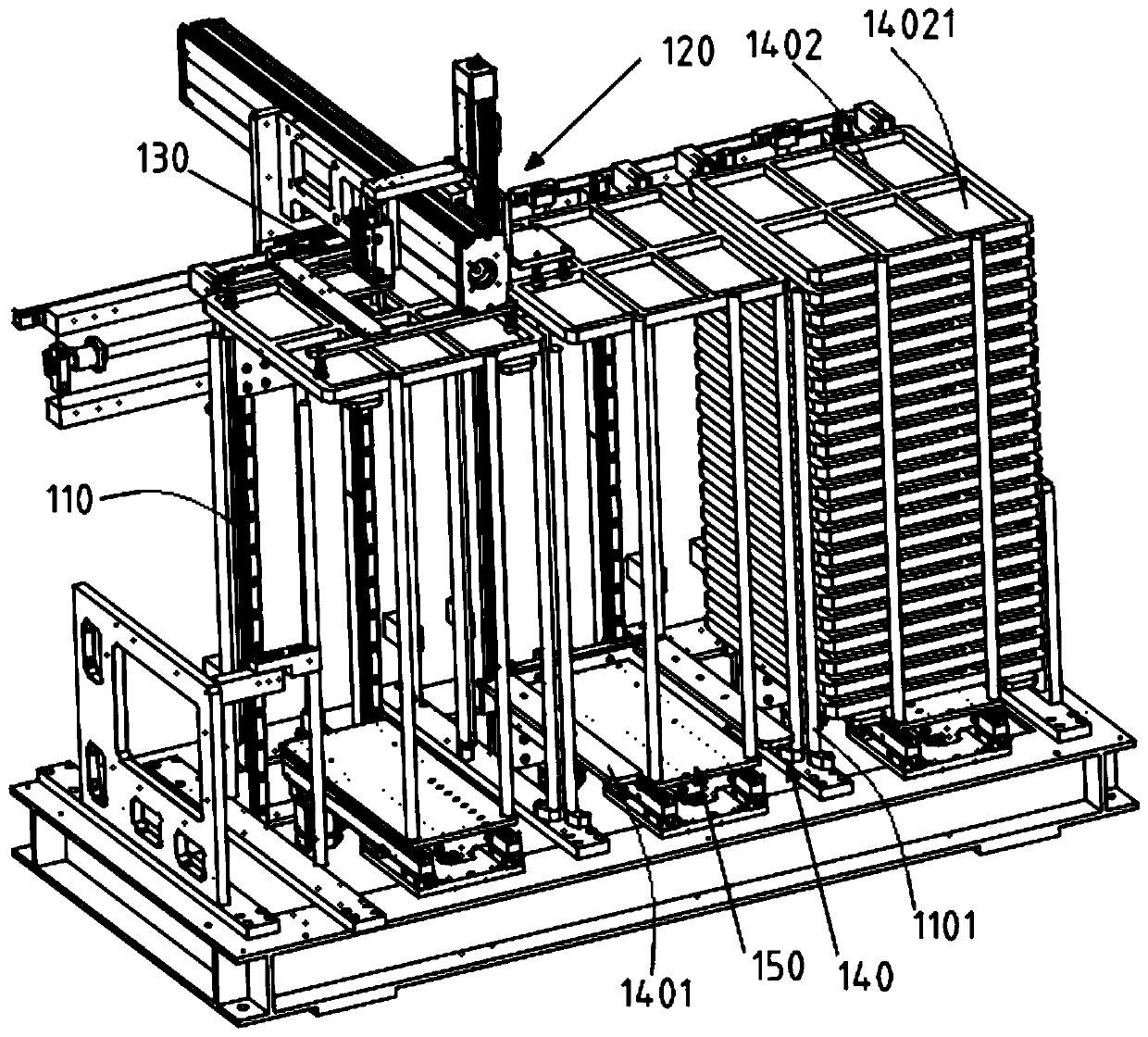

[0062] Embodiment: a kind of automatic grinding production line, as figure 1 with figure 2 As shown, it includes a feeding device 100, several grinding machines 200, a washing machine 300, a feeding device 500, a first conveying device 600 and a second conveying device 700, and the grinding machine is located at the downstream of the feeding device, and the The cleaning machine is located downstream of the grinding machine, and the unloading device is located downstream of the cleaning machine. The workpiece 400 to be processed is transported from the feeding device to the grinding machine by the first conveying device, and the workpiece 400 is transported from the feeding device to the grinding machine by the first plate feeding device. The processed workpiece is transported to the washing machine;

[0063] Such as figure 1 As shown, the production line also includes a control system and a control cabinet 800, the control system is located in the control cabinet, the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com