Lifting type material supporting mechanism and material collecting device of conducting film assembly

A lift-type, conductive film technology, applied in stacking receiving devices, transportation and packaging, sending objects, etc., can solve problems such as messy, achieve the effect of improving the efficiency of receiving materials, keeping the position neat and consistent, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

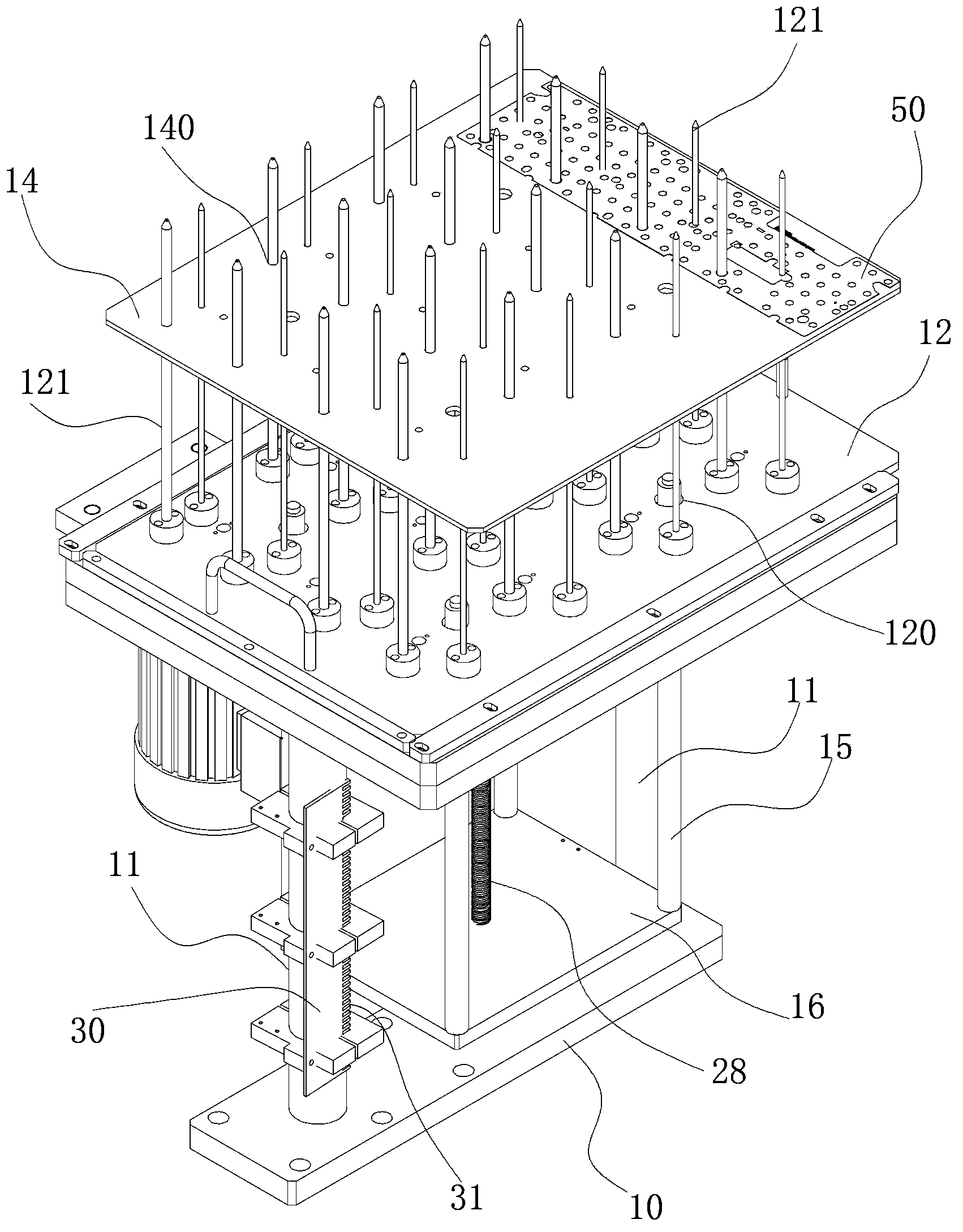

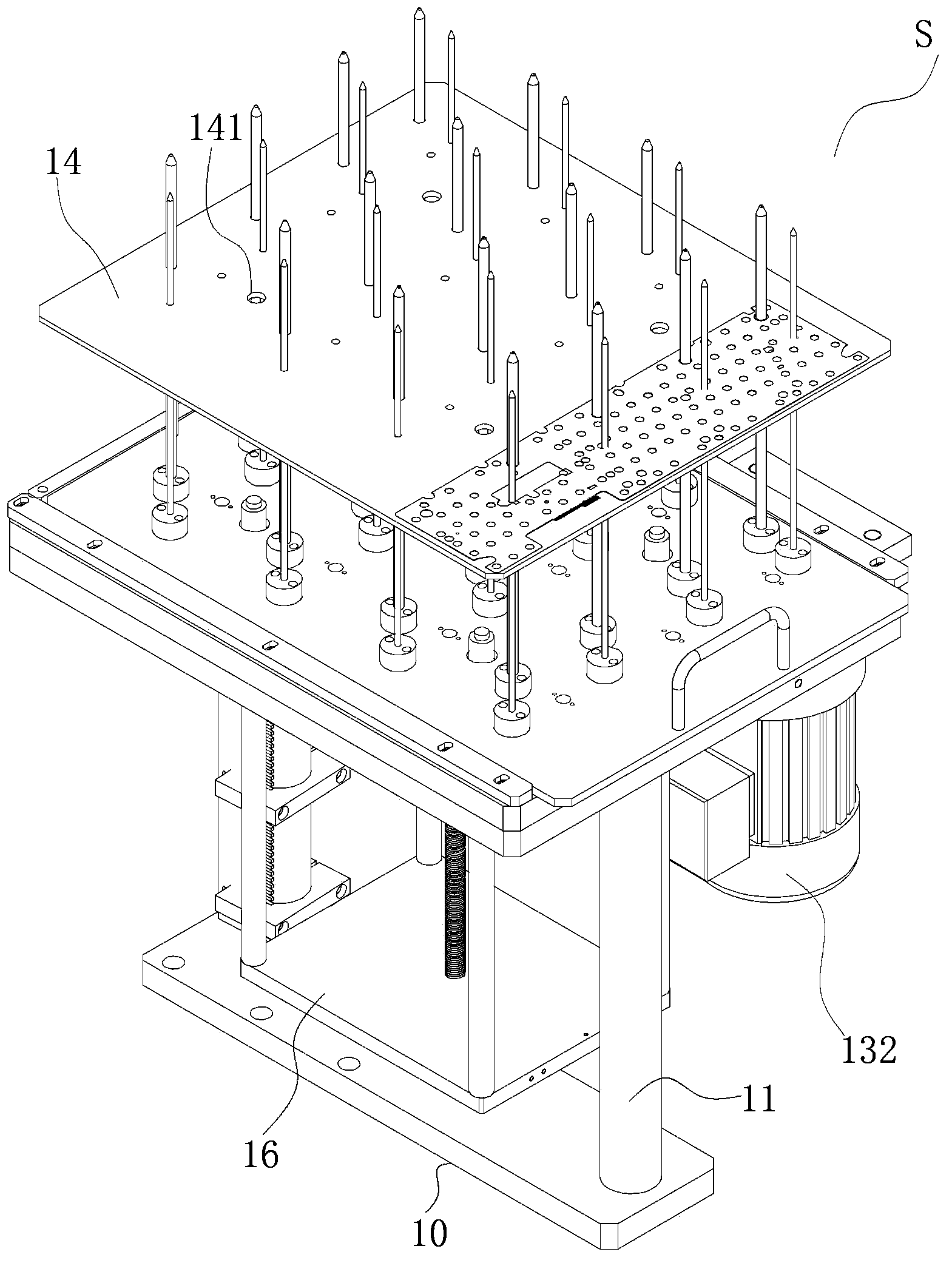

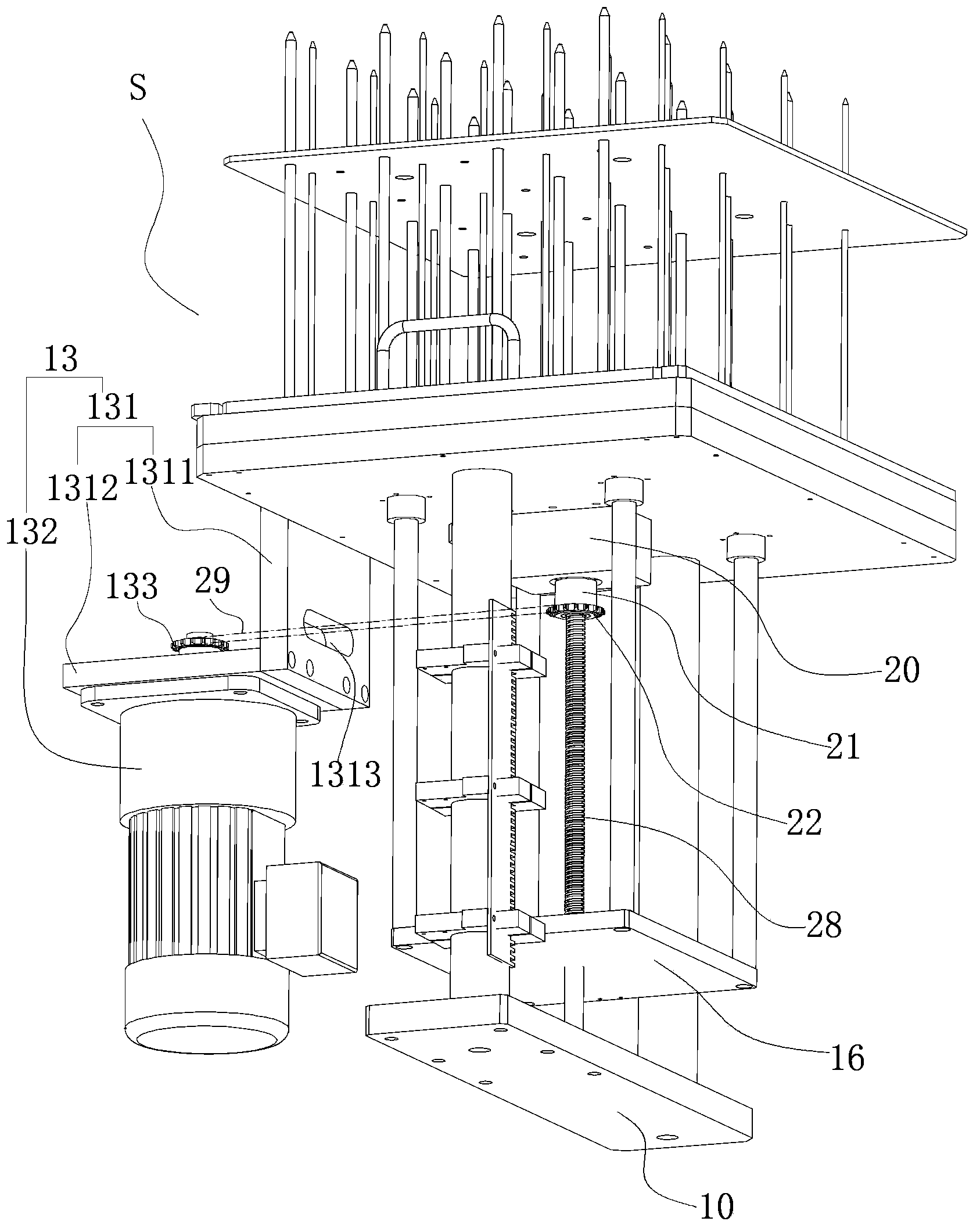

[0039] Such as Figure 1-3 As shown, the lifting type support mechanism S of the present invention is used for the support collection of the FPC conductive film assembly 50 of the keyboard, and includes the following components:

[0040] Base plate 10, two columns 11 are arranged above the base plate 10, and the two columns are fixedly connected with the base plate by screws, and the base plate is also provided with screw holes for installation and fixing;

[0041] The fixed plate 12 is fixed on the upper ends of the two columns 11 as an upper support structure, and a cavity for the movement of the lower connecting plate 16 is formed between the fixed plate and the bottom plate; the fixed plate 12 is provided with 32 upwardly extendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com