Automatic wood slicing device for building materials

A slicing device, wood technology, applied in the direction of clamping device, feeding device, wood processing equipment, etc., can solve the problems of inconvenient operation, low efficiency, easy injury, etc., and achieve the effect of preventing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

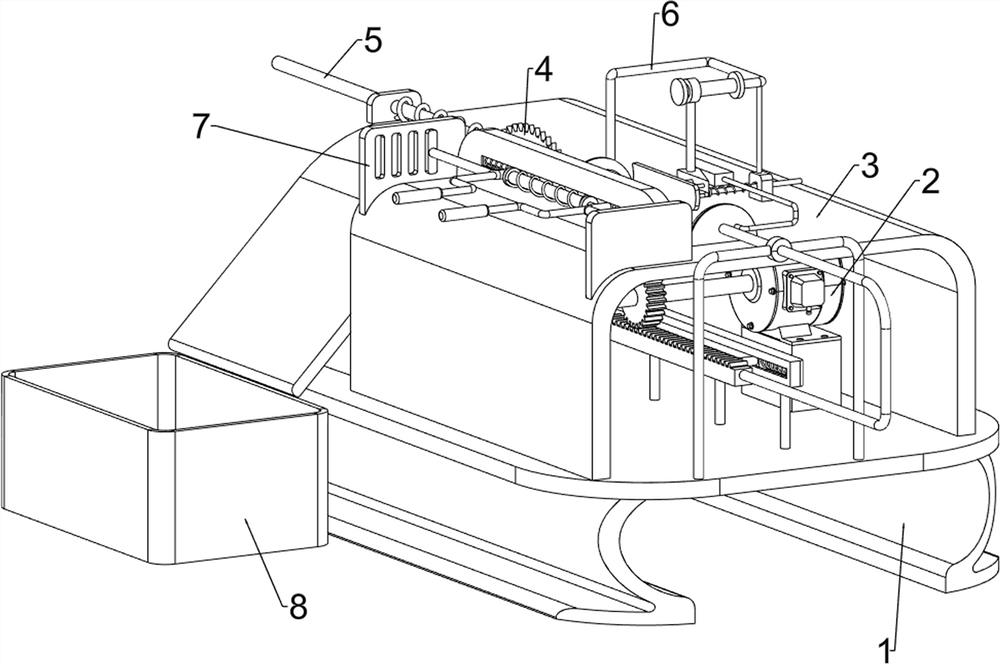

[0023] A kind of timber automatic slicing device for building materials, such as figure 1 , figure 2 and Figure 5 As shown, it includes a first workbench 1, a motor 2, a second workbench 3, an electric saw 4, a pushing mechanism 5 and a pressing mechanism 6, and the upper right side of the first workbench 1 is provided with a motor 2, and the first workbench 1 is provided with a second workbench 3 , a chainsaw 4 is rotatably provided on the second workbench 3 , a pushing mechanism 5 is provided on the first workbench 1 , and a pressing mechanism 6 is provided on the second workbench 3 .

[0024] When people prepare to slice the wooden block, the wooden block is first placed on the second workbench 3, then the motor 2 is started, and the output shaft of the motor 2 will drive the pushing mechanism 5 to rotate, and the pushing mechanism 5 will push the wooden block To the chainsaw 4, at the same time, the pushing mechanism 5 will also drive the pressing mechanism 6 to move, ...

Embodiment 2

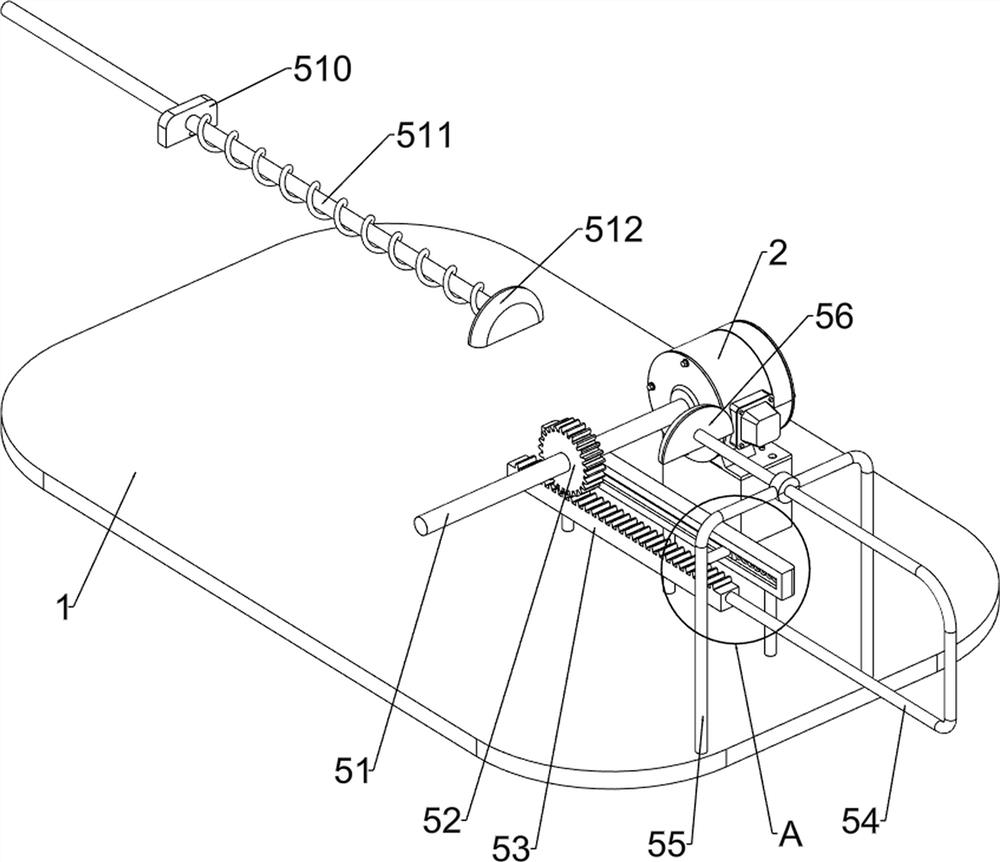

[0026] On the basis of Example 1, such as figure 2 , image 3 and Figure 4 As shown, the pusher mechanism 5 includes a first rotating shaft 51, a missing gear 52, a rack 53, a push rod 54, a first sliding sleeve 55, a first push plate 56, a first slide rail 57, a first telescopic assembly 58, The first slider 59, the first fixed plate 510, the second telescopic assembly 511 and the second push plate 512, the output shaft of the motor 2 is provided with a first rotating shaft 51, the first rotating shaft 51 is provided with a missing gear 52, and the first working The front side of the upper part of the table 1 is provided with a first sliding sleeve 55, the upper front side of the first workbench 1 is provided with a first slide rail 57, and the first slide rail 57 is slidably provided with a first slide block 59, and the first slide block 59 The first telescopic assembly 58 is connected between the first sliding rail 57, the left side of the first slider 59 is provided wi...

Embodiment 3

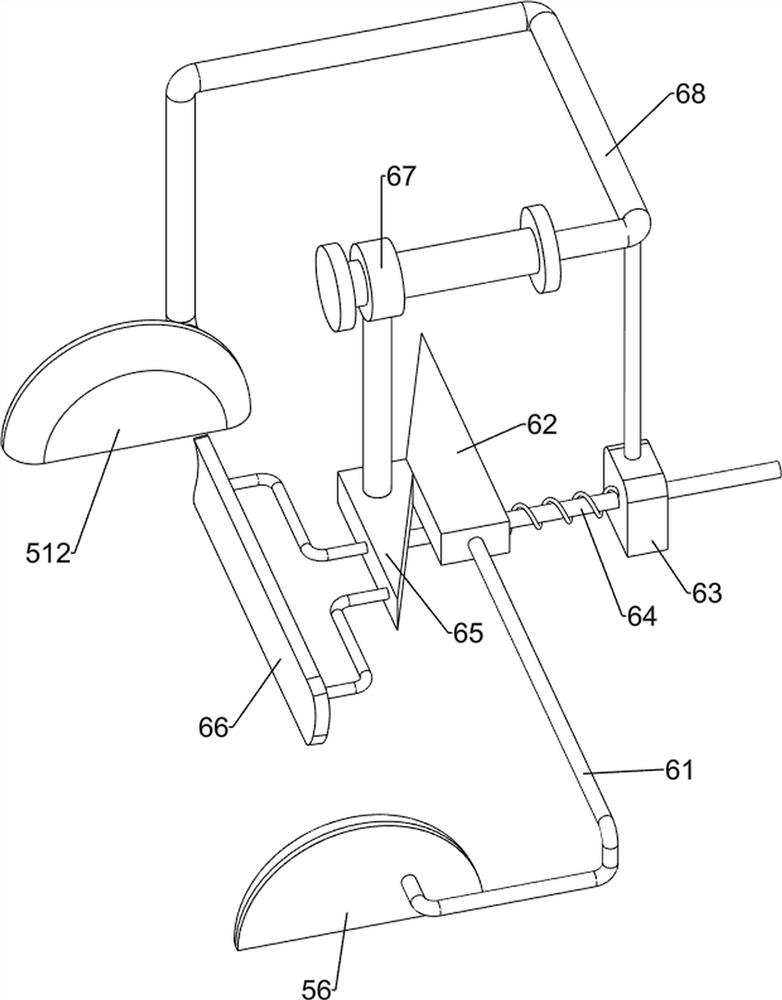

[0029] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 and Figure 6 As shown, the pressing mechanism 6 includes a first connecting rod 61, a right wedge block 62, a second fixed plate 63, a third telescopic assembly 64, a left wedge block 65, a pressing plate 66, a second sliding sleeve 67 and a second connecting rod 68, the first connecting rod 61 is provided on the front side of the first push plate 56, the right wedge block 62 is provided on the rear side of the first connecting rod 61, the second connecting rod 68 is provided on the rear side of the second pushing plate 512, and the second connecting rod The upper part of 68 is slidingly provided with a second sliding sleeve 67, the bottom of the second sliding sleeve 67 is provided with a left wedge block 65, the left side of the left wedge block 65 is provided with a pressing plate 66, and the right side of the second workbench 3 is provided with a second fixed plate 63 , the second fixed plate 63...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com