Double-end rip sawing device

A longitudinal saw and double-ended technology, which is applied to feeding devices, clamping devices, circular saws, etc., can solve the problems of limited use range, small adjustment range, and insufficient positioning efficiency and accuracy, so as to ensure timeliness and smoothness, and improve The effect of high processing efficiency, versatility and adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

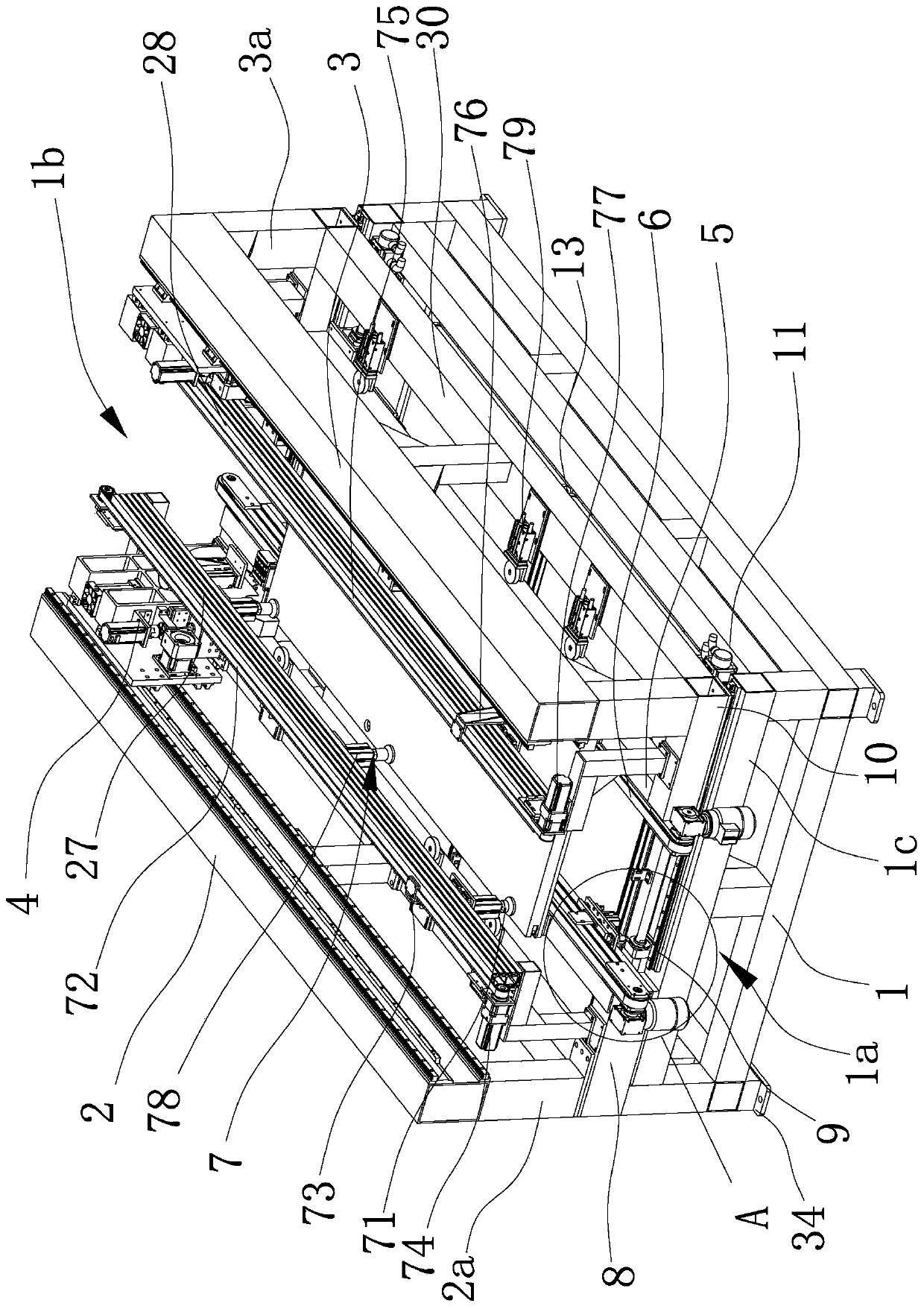

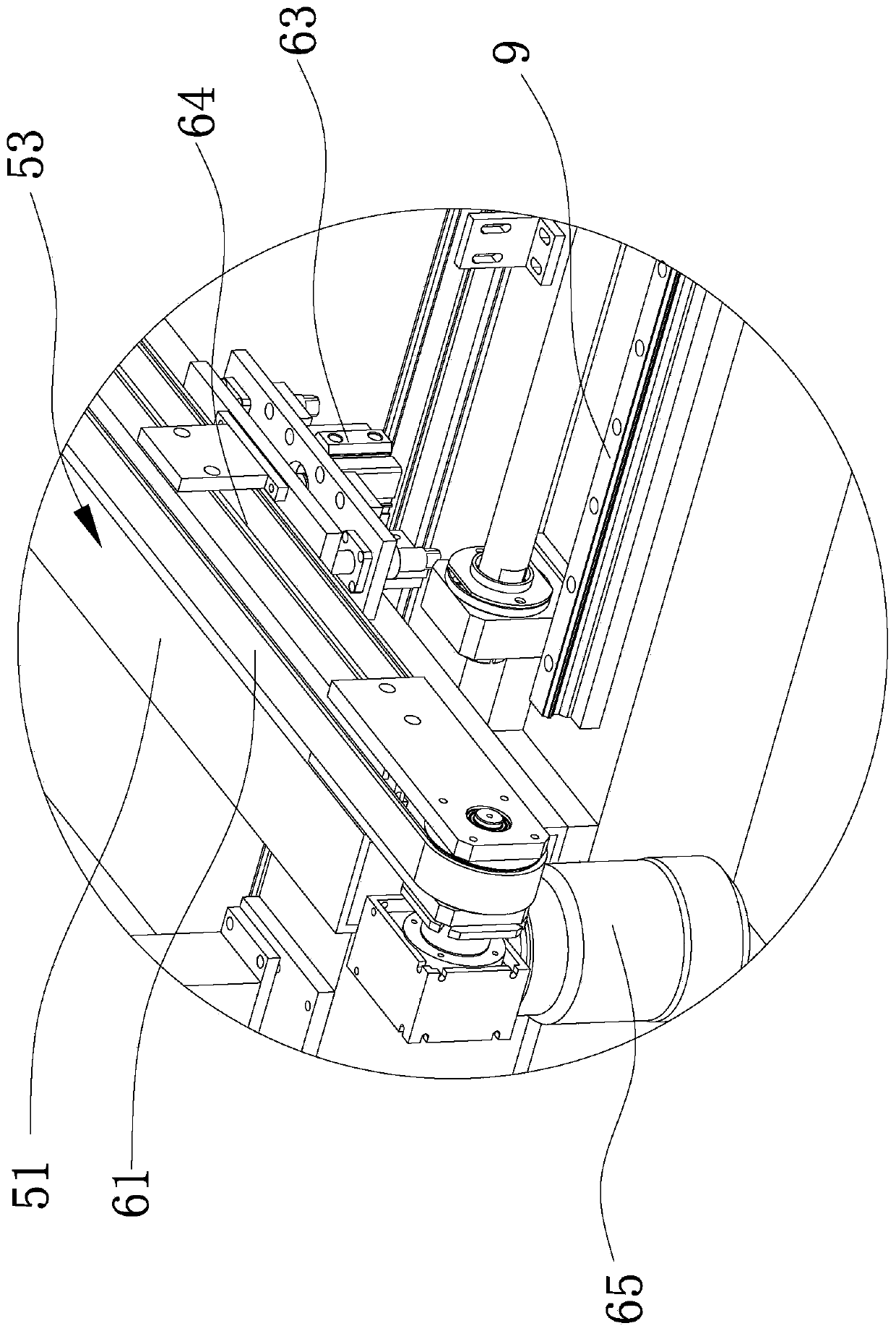

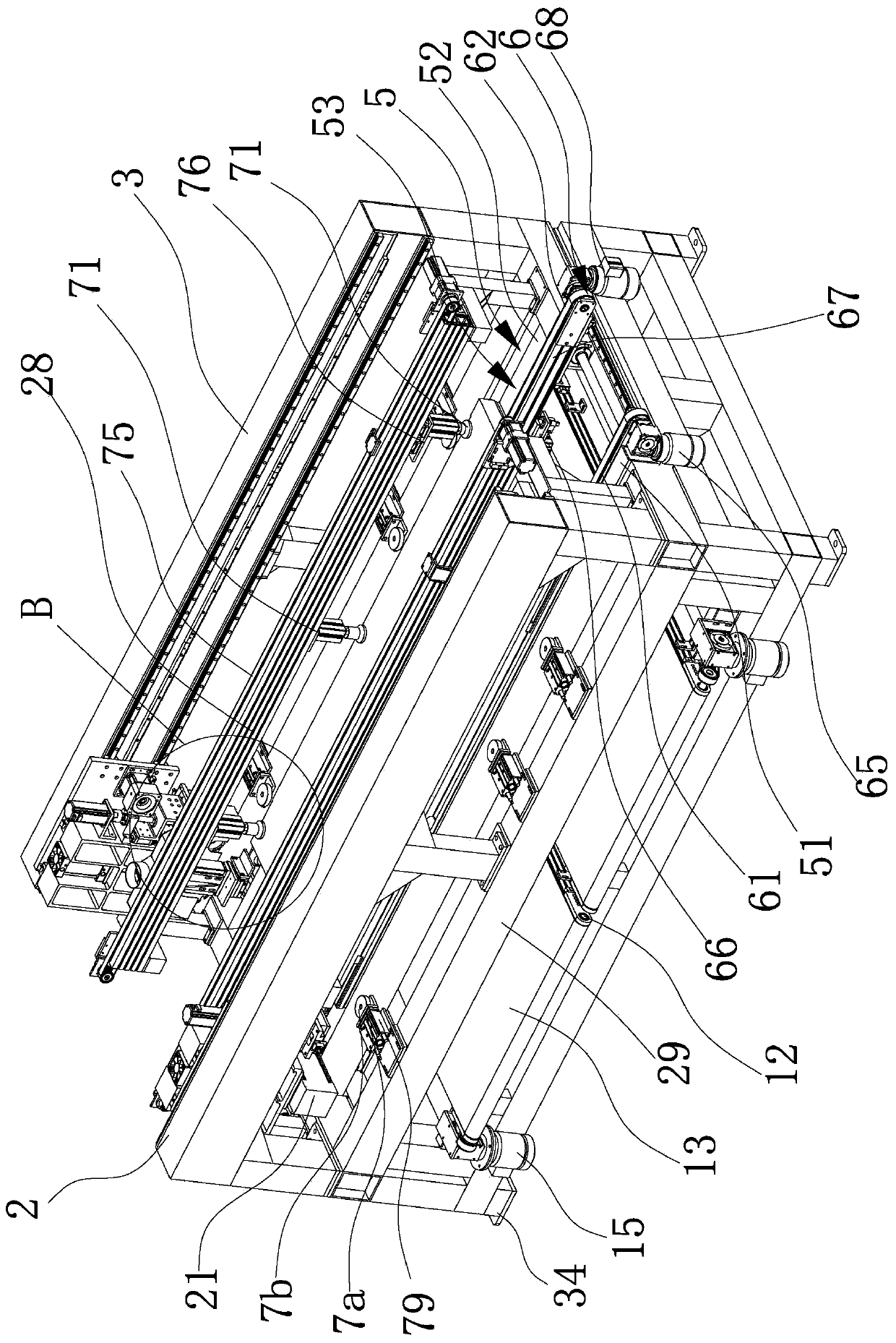

[0036] like Figure 1 to Figure 7 As shown, the double-end longitudinal sawing device includes a frame 1, the frame 1 is a long rectangular frame structure, the bottom of the frame 1 is fixed with several supporting feet 34, one end of the frame 1 is the input end 1a, and the other end is the input end 1a. On the output end 1b, one side of the frame 1 is fixed with a fixed frame 2, and the other side of the frame 1 is provided with a movable frame 3 that can move along the width direction of the frame 1, and both the fixed frame 2 and the movable frame 3 are provided with A processing head assembly 4 with a saw disc 41, the processing head assembly 4 can move back and forth along the length direction of the frame 1 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com