Wood thin-board machining process and wood thin-board automatic machining equipment

A technology of automatic processing and processing technology, which is applied in the direction of wood processing equipment, unloading equipment, sawing equipment, etc., can solve the problems of large labor and low efficiency, and achieve the effects of reducing production costs, high versatility, and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

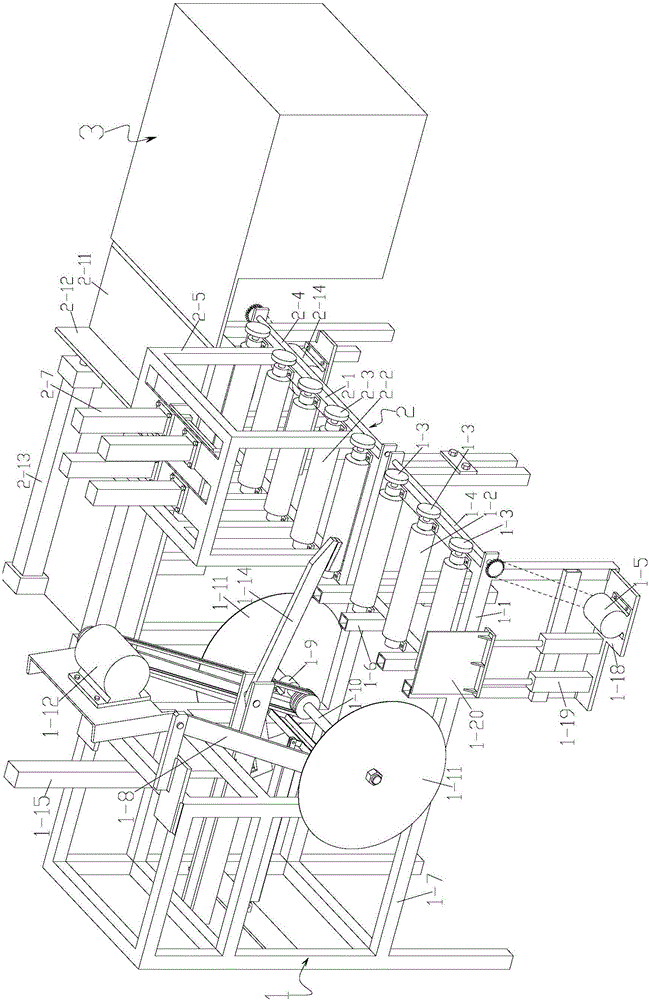

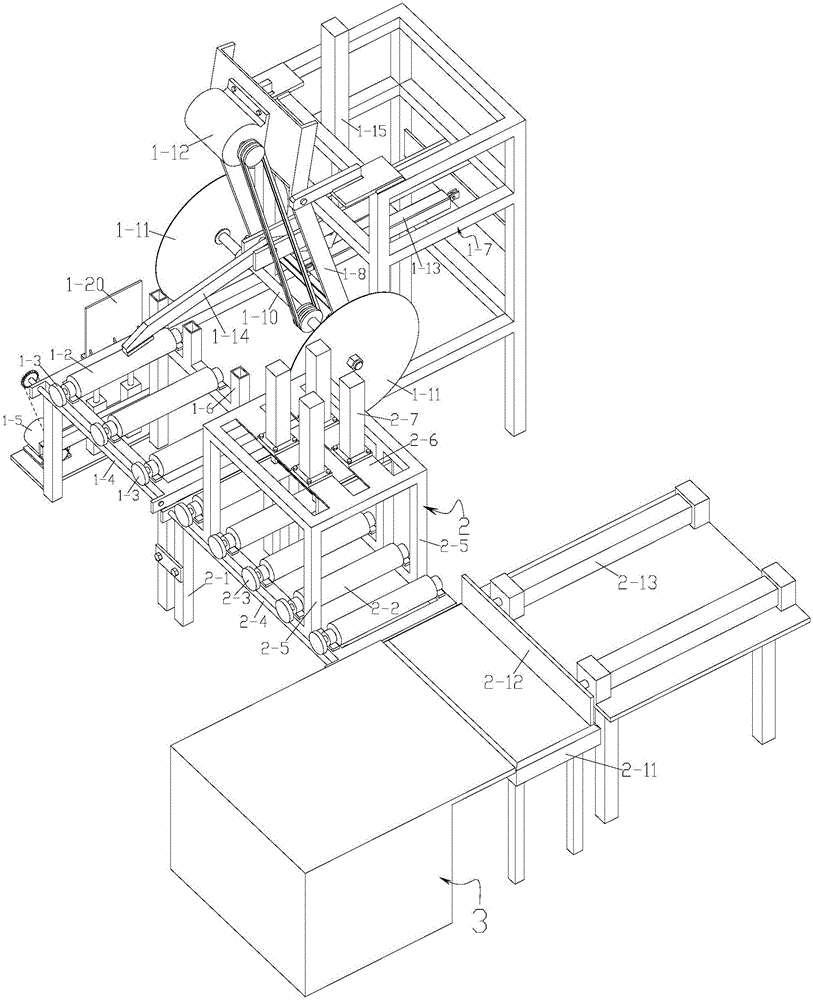

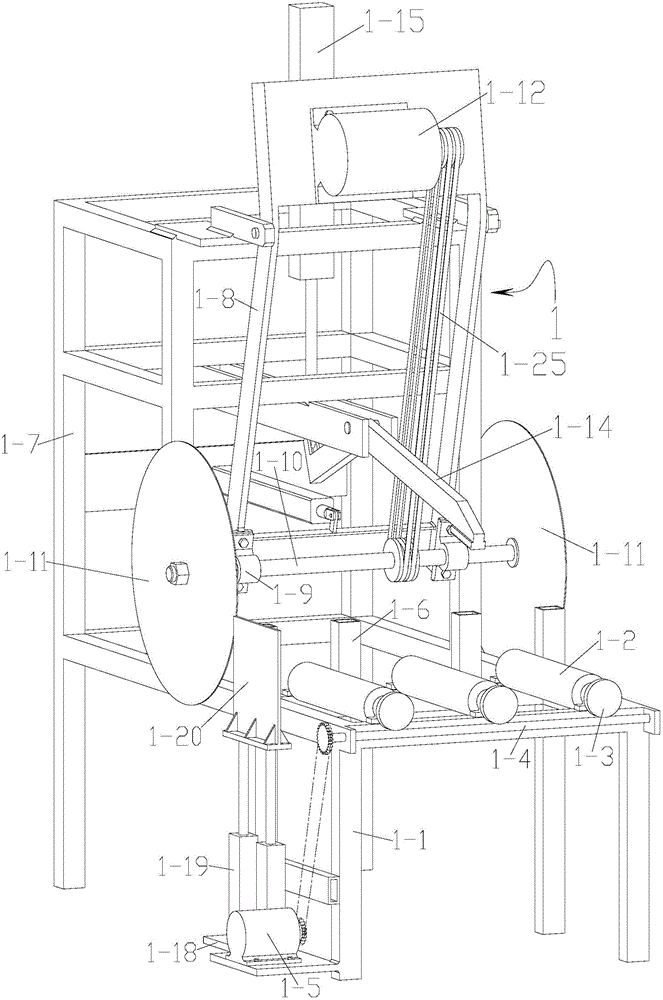

[0030] The present invention will be further described below in conjunction with accompanying drawing:

[0031] With reference to accompanying drawing: this wooden veneer processing technology comprises the following steps:

[0032] A. Log clamping: place the log 4 whose length is greater than the distance between the two saw blades 1-11 on the support roller 1-2, the sixth cylinder 1-19 drives the vertical plate 1-20 to rise, and the log 4 One end is aligned against the vertical plate 1-20, and then the second cylinder 1-15 is activated to drive the pressure rod 1-14 to rotate in an arc, and the bottom surface of the front end of the pressure rod 1-14 presses on the log 4 and drives the log 4 Move towards the limit rod 1-6 direction until the log 4 leans against the limit rod 1-6 and cannot move, at this moment the pressure rod 1-14 compresses the log 4 on the support roller one 1-2;

[0033] B. Cutting at both ends of the log: start the drive motor 1-12, drive the saw blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com