Strip cutting machine suitable for regular plate

A strip cutting machine and board technology, applied in the direction of sawing components, sawing equipment, wood processing equipment, etc., can solve the problems of inconvenient collection of wood strips, irregular wood strips, etc., to improve cutting efficiency, improve cutting accuracy, good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

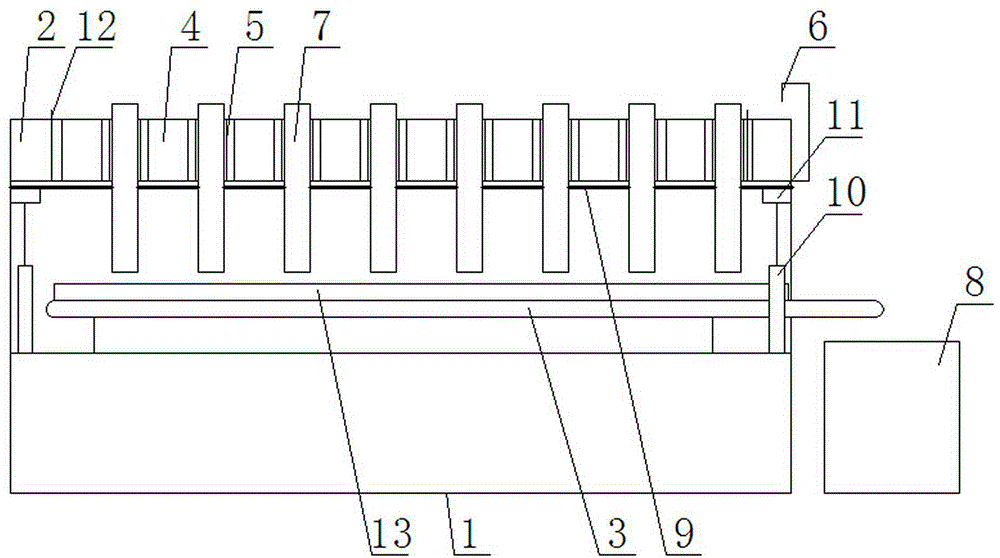

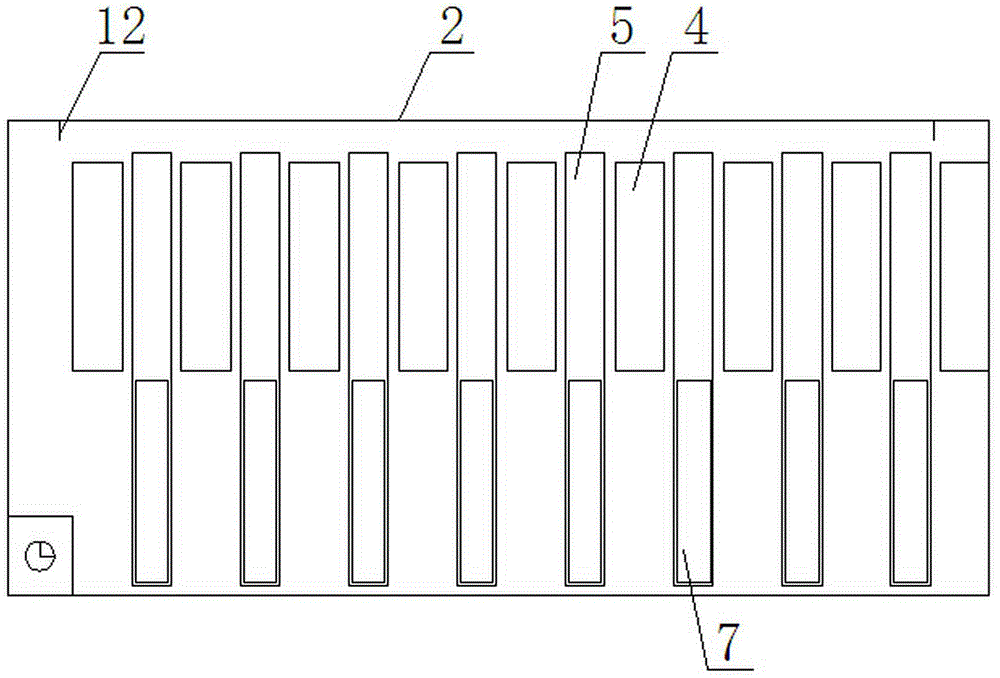

[0017] A strip cutting machine suitable for regular plates, comprising a support 1, on which a workbench 2, a cutting mechanism, a receiving box 8 and a conveyor belt 3 driven by a motor are arranged, and the work surface of the workbench 2 A plurality of blanking holes 4 are evenly arranged on one side, and a cutting groove 5 is provided between any two adjacent blanking holes 4, and the width of the blanking hole 4 is greater than the distance between the blanking hole 4 and the cutting groove 5 , the length of the cutting groove 5 is greater than the length of the blanking hole 4, the two ends of the workbench 2 are provided with a positioning piece, the positioning piece is located on the side of the blanking hole 4, the end of the workbench 2 The top of the blanking hole 4 is provided with a positioning baffle 6, the distance between the positioning baffle 6 and the workbench 2 is less than the thickness of the plank to be cut, and the positioning baffle 6 and the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com