Wood plate cutting equipment and implementation method thereof

A technology for cutting equipment and wood boards, which is applied to sawing equipment, unloading equipment, sawing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 A kind of wood cutting equipment

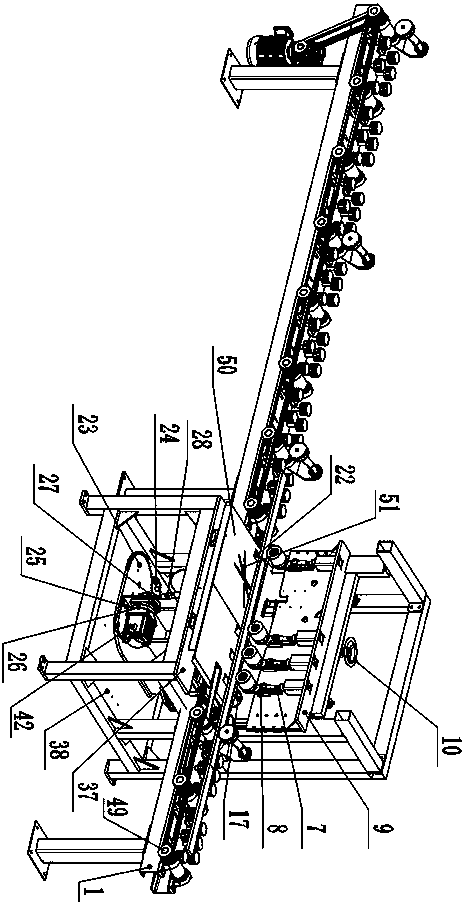

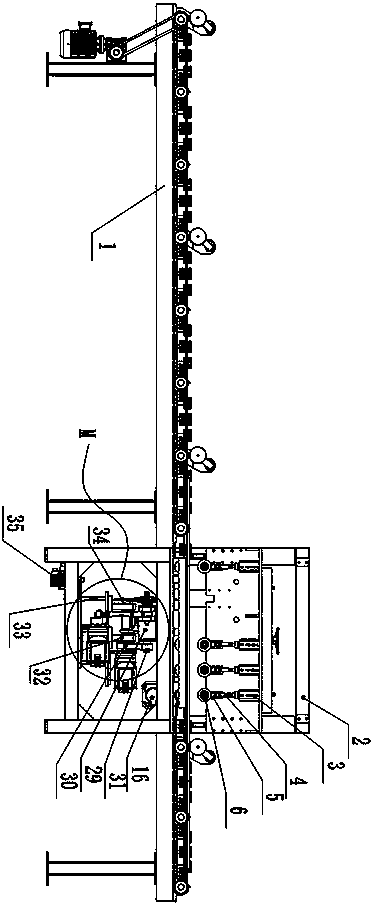

[0049] see Figure 1~14 , the present invention provides a kind of plank cutting equipment, comprises material conveying frame 1 and cutting equipment, and described cutting equipment comprises frame 2, and described frame 2 is h-shaped structure, and described material conveying frame 1 is arranged on the h-shaped structure On the middle platform of the frame 2, the feeding frame 1 is used for conveying wood board materials.

[0050] The front end of the frame 2 on the conveying frame 1 is a wood material feed end 101 ; the rear end of the frame 2 is a wood material discharge end 102 .

[0051] Both the bottoms of the wood material feed end 101 and the wood material discharge end 102 are fixedly connected with a transmission bracket 52, and the transmission bracket 52 is fixed on the ground.

[0052] A plurality of first gear mounting plates 53 are arranged on the discharge end 102 of the wood material, two adjacent fir...

Embodiment 2

[0099] Embodiment 2 A realization method of wood cutting equipment

[0100] The present invention also provides a method for implementing wood cutting equipment, including an adjusting step, a feeding step, a cutting step and a discharging step.

[0101] Adjustment steps: Rotate the handwheel 10 to adjust the height of the mounting plate 9 to the required height of the wood material;

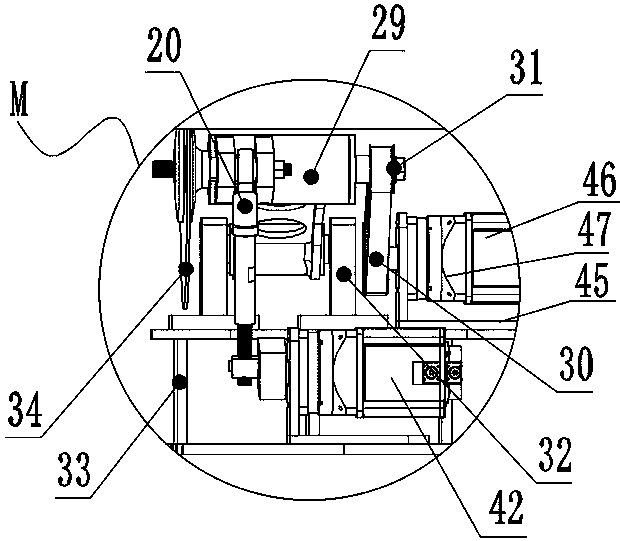

[0102] Feeding step: place the plank material to be cut on the plank material feed end 101 of the feed frame 1, and under the action of the transmission spindle drive motor 16 driving the transfer spindle 19 to rotate, the feed drive on the plank material feed end 101 The shaft 49 conveys the plank material to the cutting device; during the process of conveying the plank material to the cutting device, the first row of gears 74 and the second row of gears 75 can assist in conveying the plank material and limit the plank material to prevent the plank material from running Partial;

[0103] Cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com