Automatic bamboo pole sawing device

A bamboo pole and cutting device technology, which is applied to feeding devices, circular saws, sawing components, etc., can solve problems such as low efficiency and slow speed, and achieve the effect of overcoming slow speed and realizing automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below by specific embodiment the present invention is described in detail as follows:

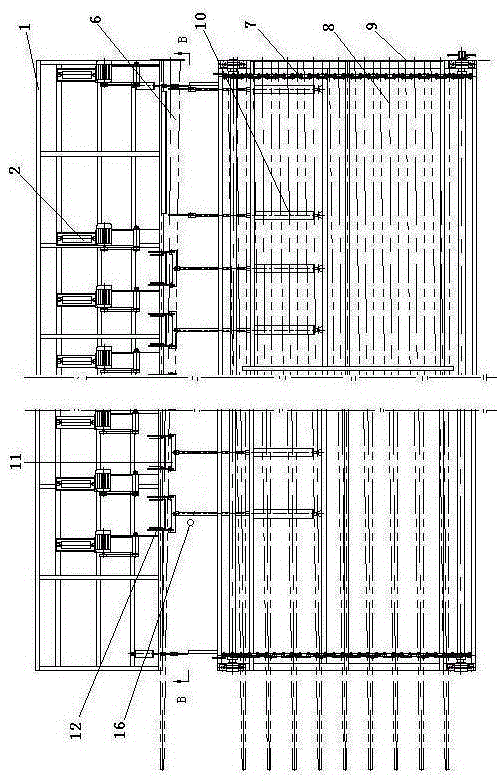

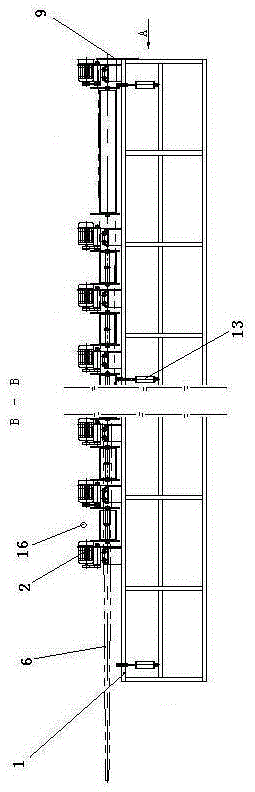

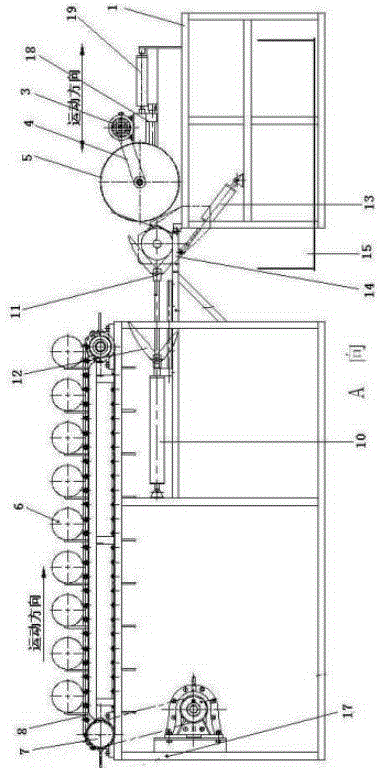

[0018] exist figure 1 figure 2 with image 3 In this automatic bamboo pole sawing device, a plurality of cutting devices 2 are arranged in parallel on the saw table 1. The cutting device 2 includes a cutting motor 3, and the cutting motor 3 is connected to the saw blade 5 through a cutting conveyor belt 4. The material device 2 is movably installed on the material cutting frame 18. There is a material cutting cylinder 19 behind the material cutting device 2 to push the material cutting device 2 forward or backward. The cutting device 2 is located on the same straight line, and the distance between the saw blades 5 of the cutting device is equal to the length of the bamboo section that needs to be cut. The device 2 is installed on the saw table 1 by bolts, and the distance between the cutting devices 2 can be adjusted according to the length of the sawn bamboo section.

[0019] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com