Adjustable wood board cutting processing device

A cutting and adjustable technology, which is applied to wood processing equipment, feeding devices, sawing components, etc., can solve the problem of difficult control of cutting length, achieve simple structure, low equipment cost, and prevent debris from splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

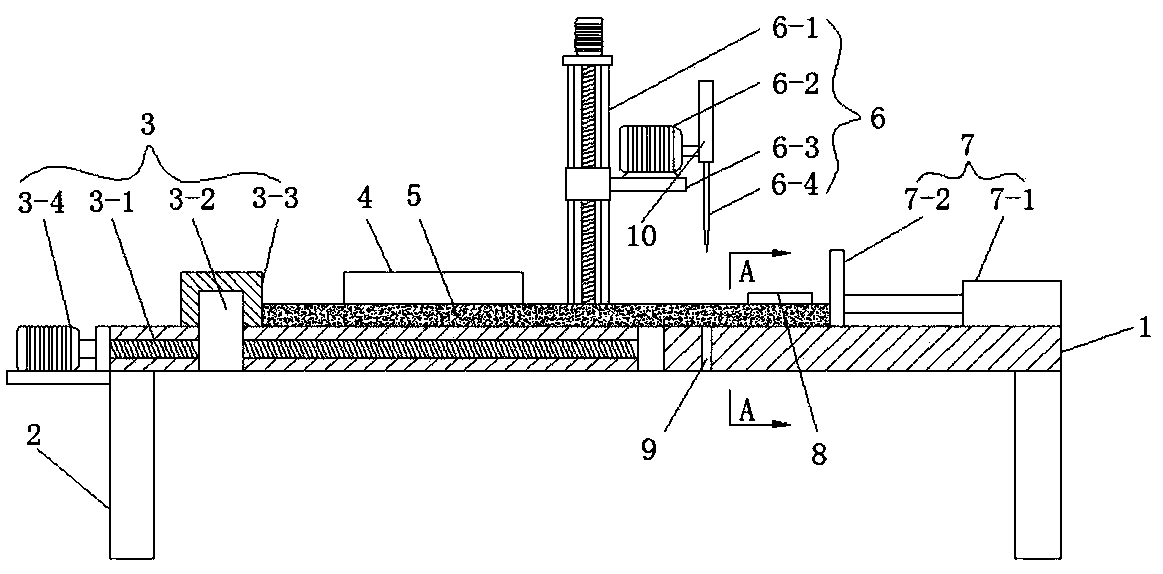

[0024] Such as Figures 1 to 3 As shown, the present embodiment provides an adjustable wood board cutting and processing device, including a workbench 1, brackets 2 are provided at the four corners of the lower end of the workbench 1, and a pushing mechanism 3 is arranged on the workbench 1 from left to right. Based on the two side plates 4 of the positioning plate 5, the cutting mechanism 6, and the limit mechanism 7, the pushing mechanism 3 includes a screw rod 3-1 arranged inside the workbench 1, and a screw nut seat 3-1 is arranged on the screw screw 3-1. 2. A push block 3-3 that can slide on the workbench 1 is socketed on the screw nut seat 3-2. The screw rod 3-1 is connected with a stepping motor 3-4 arranged on the outside of the workbench 1. The cutting mechanism 6 includes The lifting mechanism 6-1 that is arranged on the workbench 1, the lifting mechanism 6-1 is connected with the supporting plate 6-3 that can move on the lifting mechanism 6-1, the supporting plate 6...

Embodiment 2

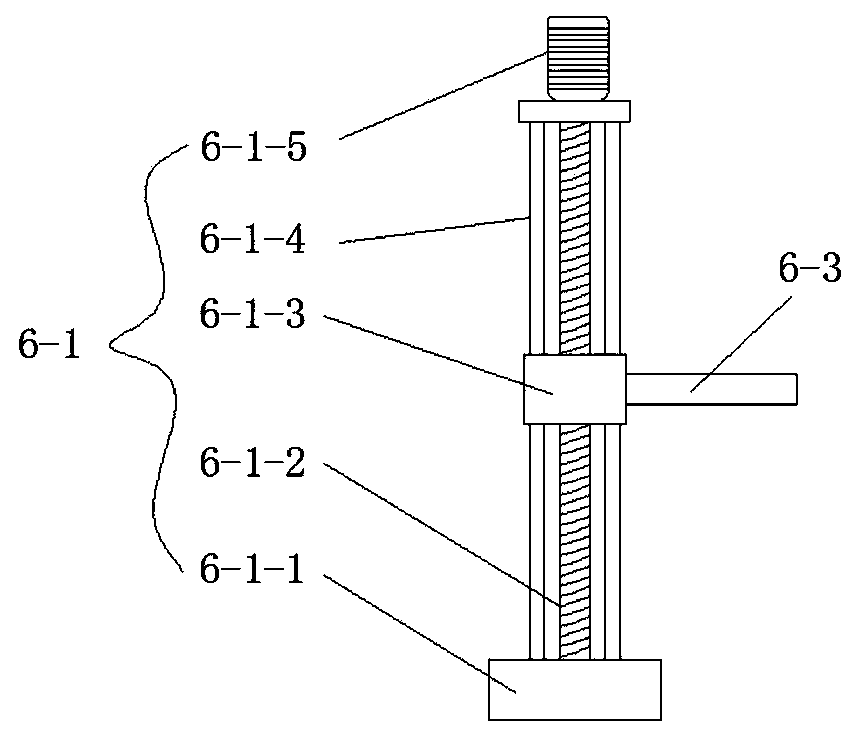

[0027] Such as figure 1 and 3 As shown, this embodiment is further optimized on the basis of embodiment 1. Specifically, the lifting mechanism 6-1 includes a bearing seat 6-1-1 arranged on the workbench 1, and the bearing seat 6-1- 1-1 is provided with a screw rod A6-1-2, the screw rod A6-1-2 is provided with a screw nut seat A6-1-3 connected with the supporting plate 6-3, and the top of the screw rod A6-1-2 is provided with Stepper motor A6-1-5 is arranged, and two guide slide bars 6-1-4 for guiding the screw nut seat A6-1-3 are arranged on the bearing seat 6-1-1.

[0028] In this embodiment, by controlling the forward rotation and reverse rotation of the output shaft of the stepping motor A, the nut seat A on the screw rod A drives the supporting plate to move up and down.

Embodiment 3

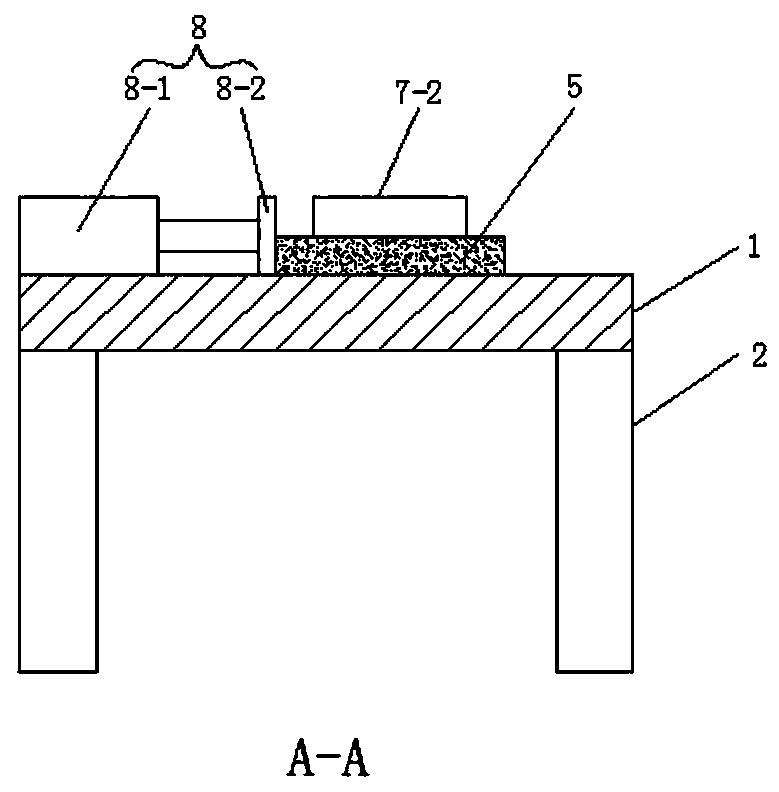

[0030] Such as figure 1 and 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the workbench 1 is provided with a pusher mechanism 8 for pushing the processed planks, and the pusher mechanism 8 includes a push cylinder 8-1 and the push plate 8-2 that is arranged on the piston rod of pushing cylinder 8-1.

[0031] The inside of the workbench 1 is provided with a processing slot 9 corresponding to the position of the saw blade 6-4.

[0032] A protective cover 10 is arranged on the saw blade 6-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com