Radix astragali slicing device

A slicing device and the technology of astragalus, applied in metal processing and other directions, can solve the problems of uneven thickness of astragalus slices and uneven distance of astragalus, and achieve the effect of uniform slice thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

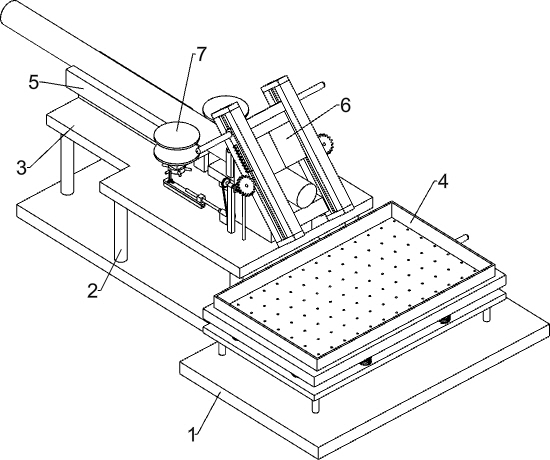

[0024] An astragalus slicing device such as Figure 1-3 As shown, it includes a base 1, a first support column 2, a workbench 3, a collection screen 4, a pad 5, a slicing mechanism 6 and a feeding mechanism 7, and the rear side of the top of the base 1 is provided with a first support column 2, and the first support A workbench 3 is arranged on the column 2, a collecting screen 4 is arranged on the front side of the top of the base 1, a spacer 5 is arranged on the upper and rear sides of the workbench 3, a slicing mechanism 6 is arranged on the upper front side of the workbench 3, and a The feeding mechanism 7 is located between the slicing mechanism 6 and the pad 5 .

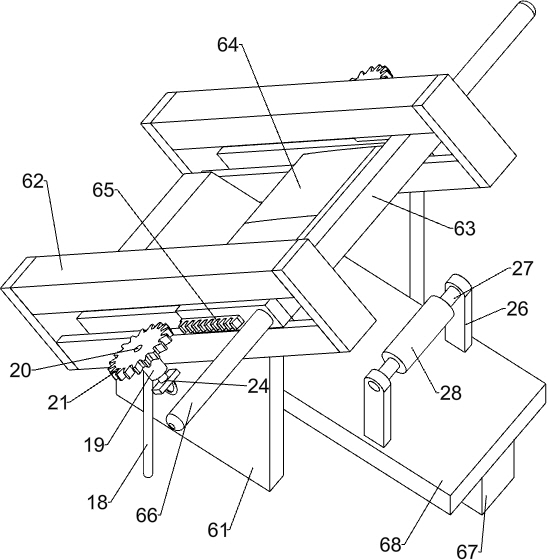

[0025] The slicing mechanism 6 includes a first support block 61, the first slide rail 62, a slide bar 63, a slicing knife 64, a rack 65, a handle 66, a second support block 67 and an anvil block 68. 3. A first support block 61 is arranged symmetrically on the left and right sides of the center line. First sli...

Embodiment 2

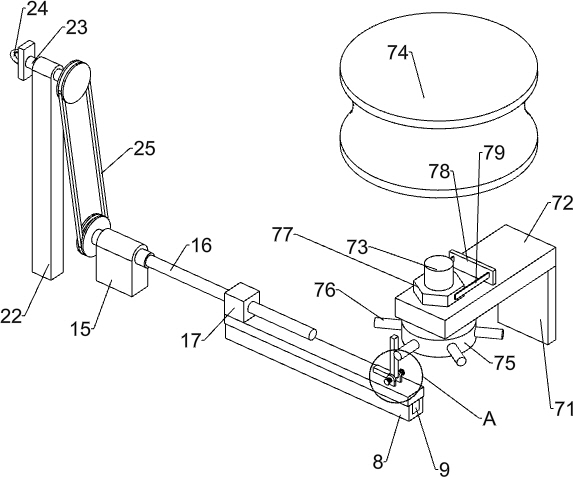

[0029] Such as Figure 2-5 Shown, on the basis of embodiment 1, a kind of astragalus slicing device also includes second slide rail 8, slide block 9, sector block 10, second rotating shaft 11, L-shaped push rod 12, round block 13, the second One elastic member 14, the first bearing seat 15, the screw mandrel 16, the nut 17, the support column 18, the axle sleeve 19, the third rotating shaft 20, the gear 21, the second bearing seat 22, the transmission shaft 23, the coupling 24 and the belt The transmission device 25, the middle part of the workbench 3 is symmetrically arranged with the second slide rail 8 with respect to the center line of the workbench 3, and the inside of the second slide rail 8 is provided with a slide block 9, and the upper and rear sides of the slide block 9 are all about the center line of the slide block 9 There are fan-shaped blocks 10 symmetrically arranged on the left and right, and the second rotating shaft 11 is arranged in a rotating manner betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com