Patents

Literature

75results about How to "Feed realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

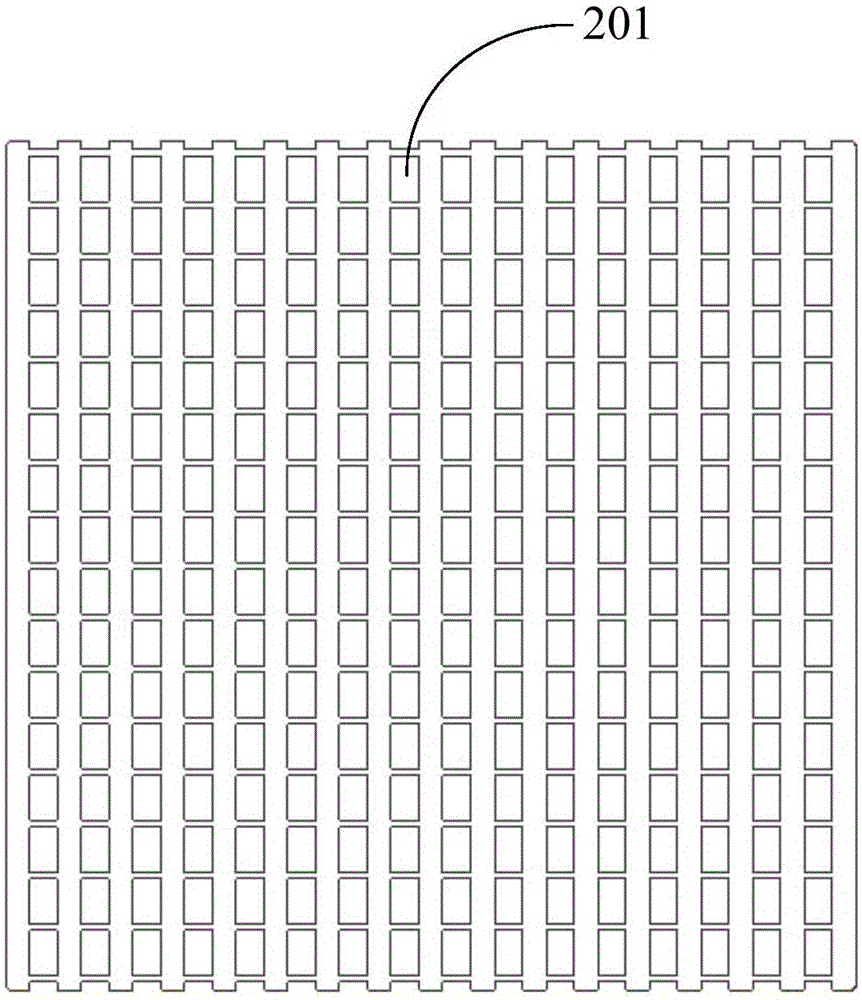

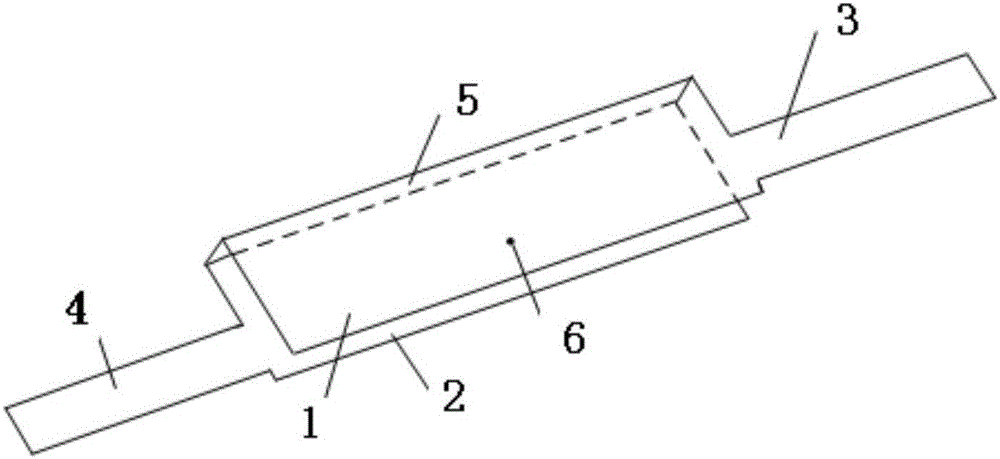

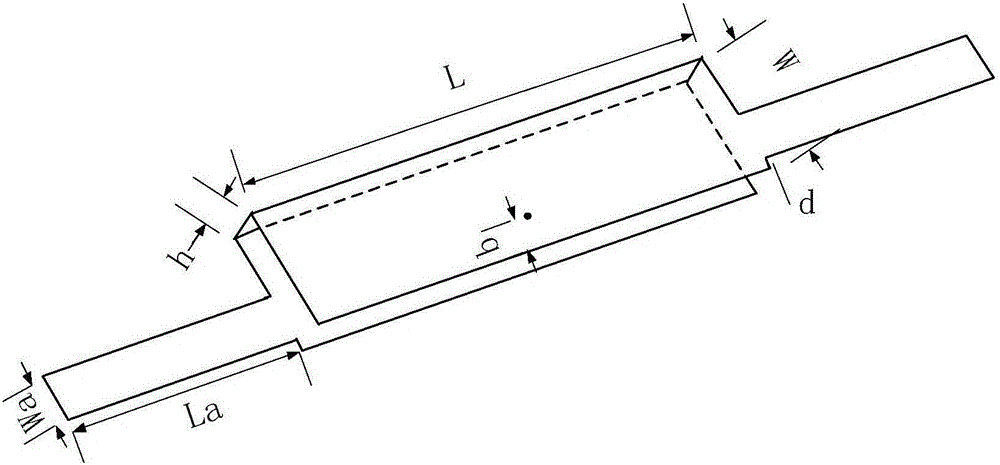

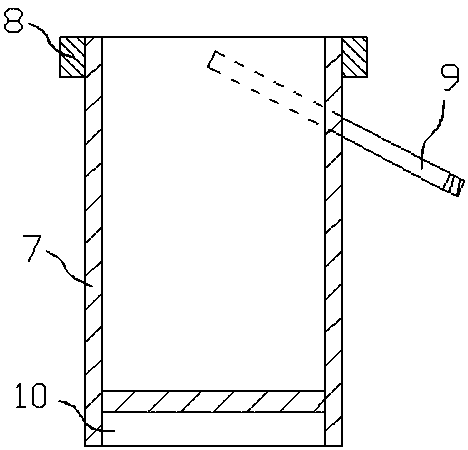

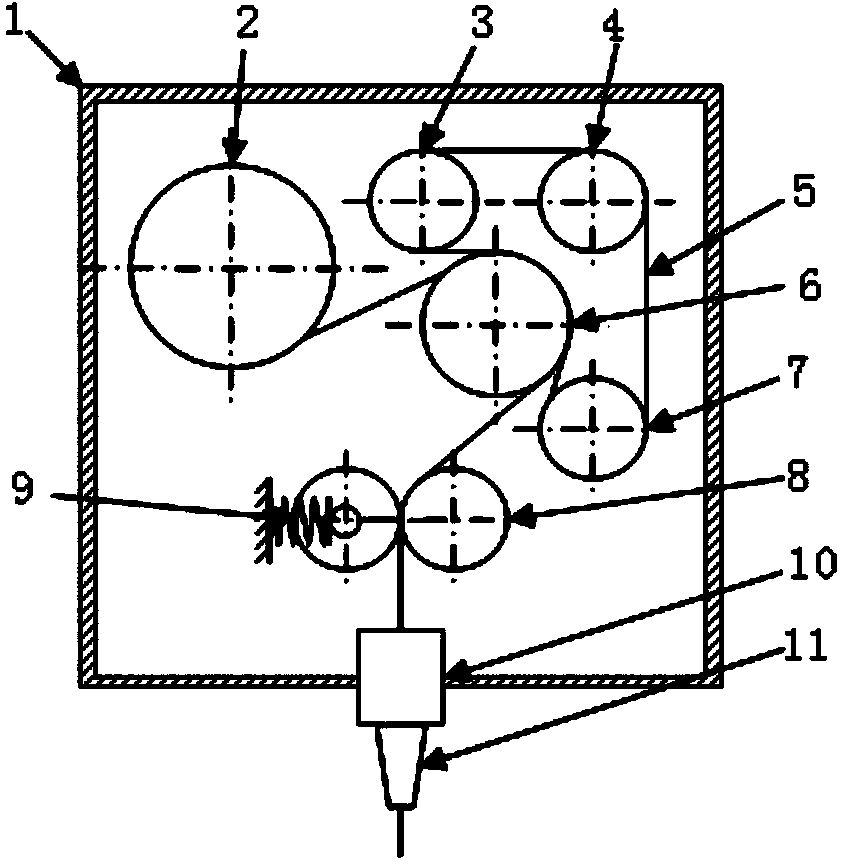

Conformal low-sidelobe waveguide slotted array antenna

InactiveCN107086362ASide lobe lowHigh sensitivityAntenna arraysRadiating elements structural formsCoaxial cableCoupling

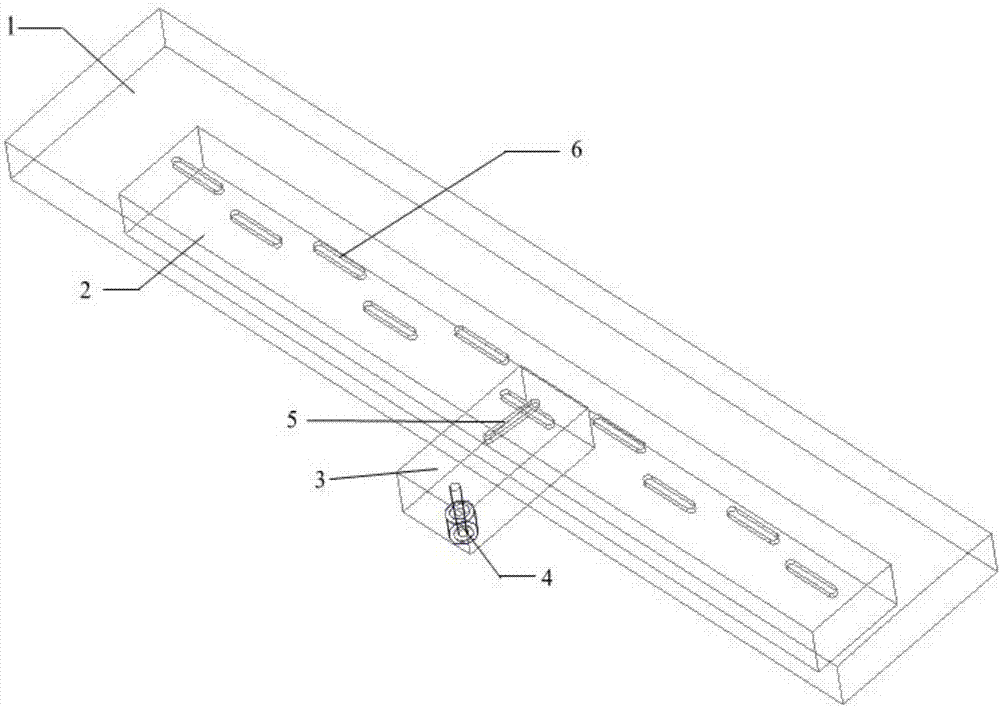

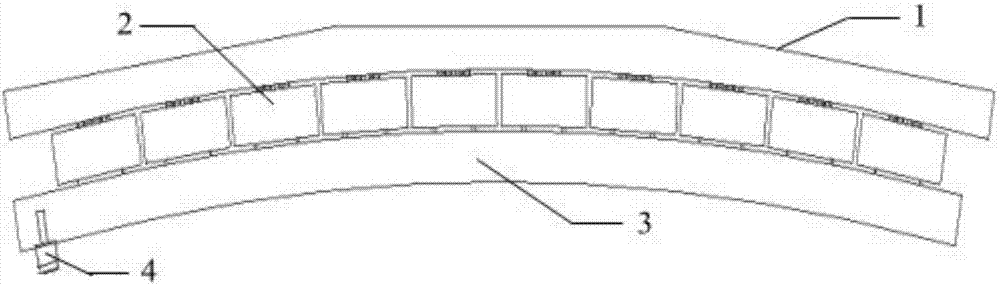

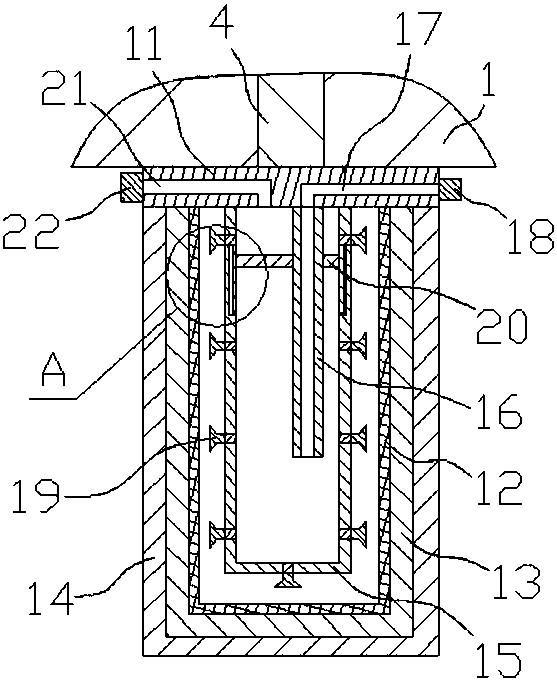

The invention discloses a conformal low-sidelobe waveguide slotted array antenna. The antenna is characterized by comprising a radiation rectangular waveguide array, a feed rectangular waveguide and a coaxial feed unit; the wide side of the radiation rectangular waveguide array is vertical to the wide side of the feed rectangular waveguide; bias radiation slots are formed in the wide side of the radiation rectangular waveguide array in the top, and inclined coupling slots are formed in the wide side of the feed rectangular waveguide; and the end portion of the feed rectangular waveguide is provided with a coaxial feed interface. Feed includes two levels; in the first level, coaxial cables in the bottom feed the feed rectangular waveguide in the middle; and in the second level, the feed rectangular wave uses the inclined coupling slots thereof to feed the radiation rectangular waveguide array, and the bias radiation slots serve as an antenna radiation array plane to complete antenna radiation. According to index requirements for the anti-interference capability of antennas and sensitivity of micro signals, the antennas characterized by being easily conformal, low in sidelobe, high in gain, easy to design, compact in structure and the like are designed.

Owner:HEFEI UNIV OF TECH

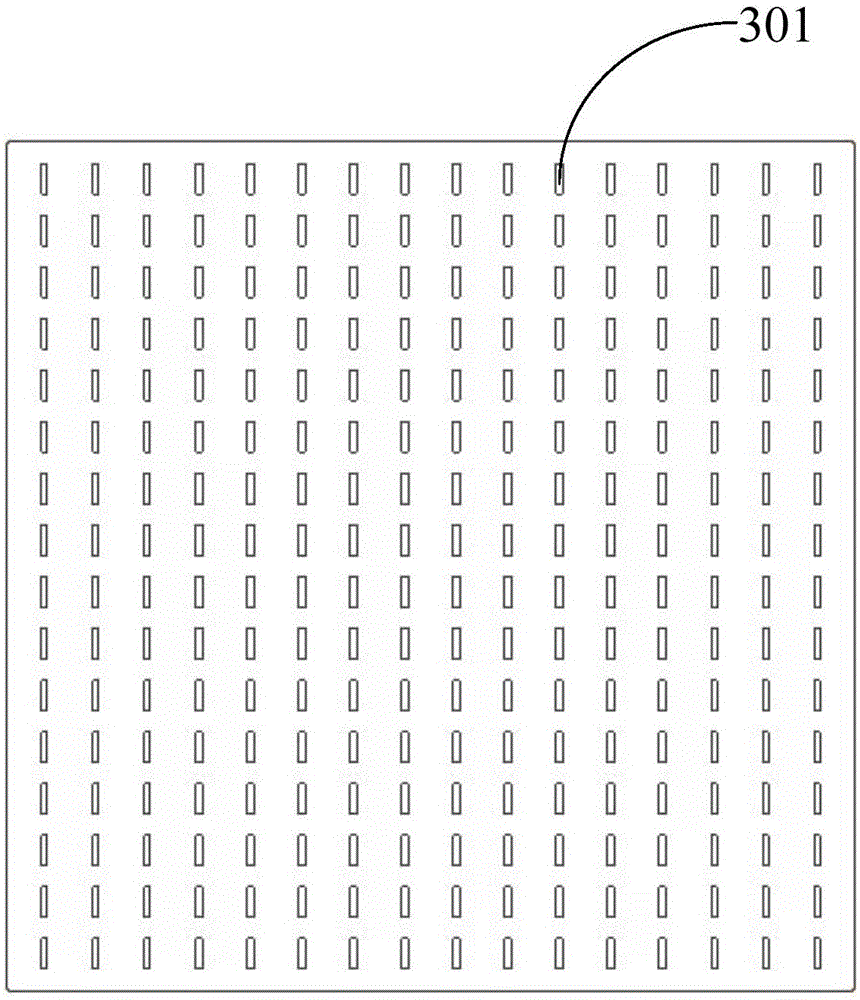

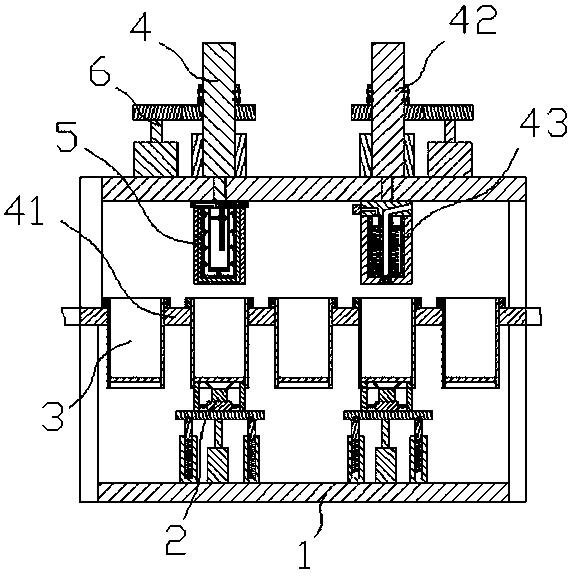

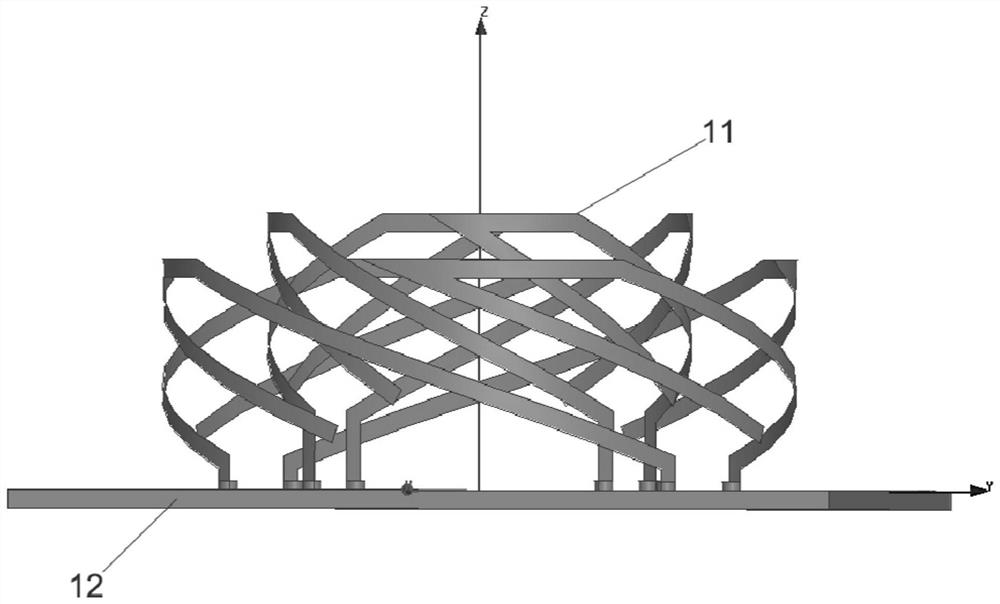

Ridge waveguide planar array antenna employing mechanical center feeding

InactiveCN105098366AReduce mutual couplingImprove out of roundnessAntenna arraysAntenna supports/mountingsElectricityCoupling

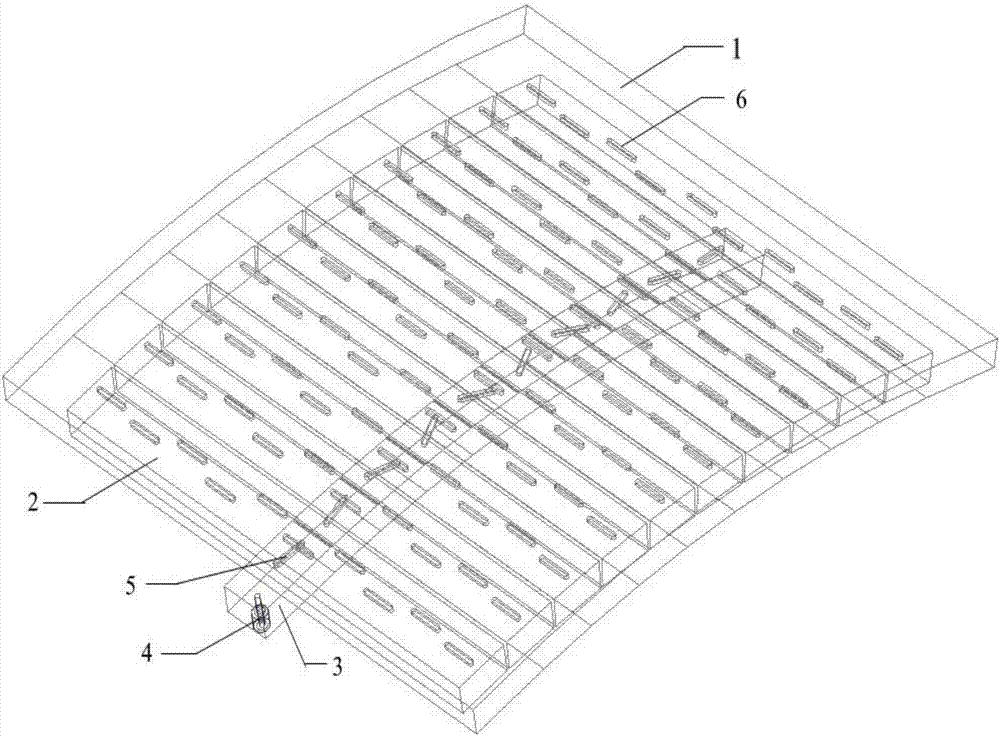

The invention discloses a ridge waveguide planar array antenna employing mechanical center feeding. The ridge waveguide planar array antenna comprises a grid layer, a radiation layer, a coupling layer, a feed network layer and a center feed layer, which are sequentially stacked, wherein the mechanical center of the center feed layer is provided with a feeding opening which is vertical to an antenna array and is used for inputting and outputting a signal; the feed network layer is composed of a single ridge waveguide; and ridges are arranged at the centers of narrow sides of various branches of a ridge waveguide power divider on the feed network layer. Through introducing the grid layer and the center feed layer, adopting the design of a ridge waveguide power dividing network, and successfully combining with other structure layers, the targets of improving the out-of-roundness of an antenna radiation pattern, improving the antenna standing wave bandwidth and realizing mechanical center feeding of the antenna are achieved.

Owner:西安三维通信有限责任公司

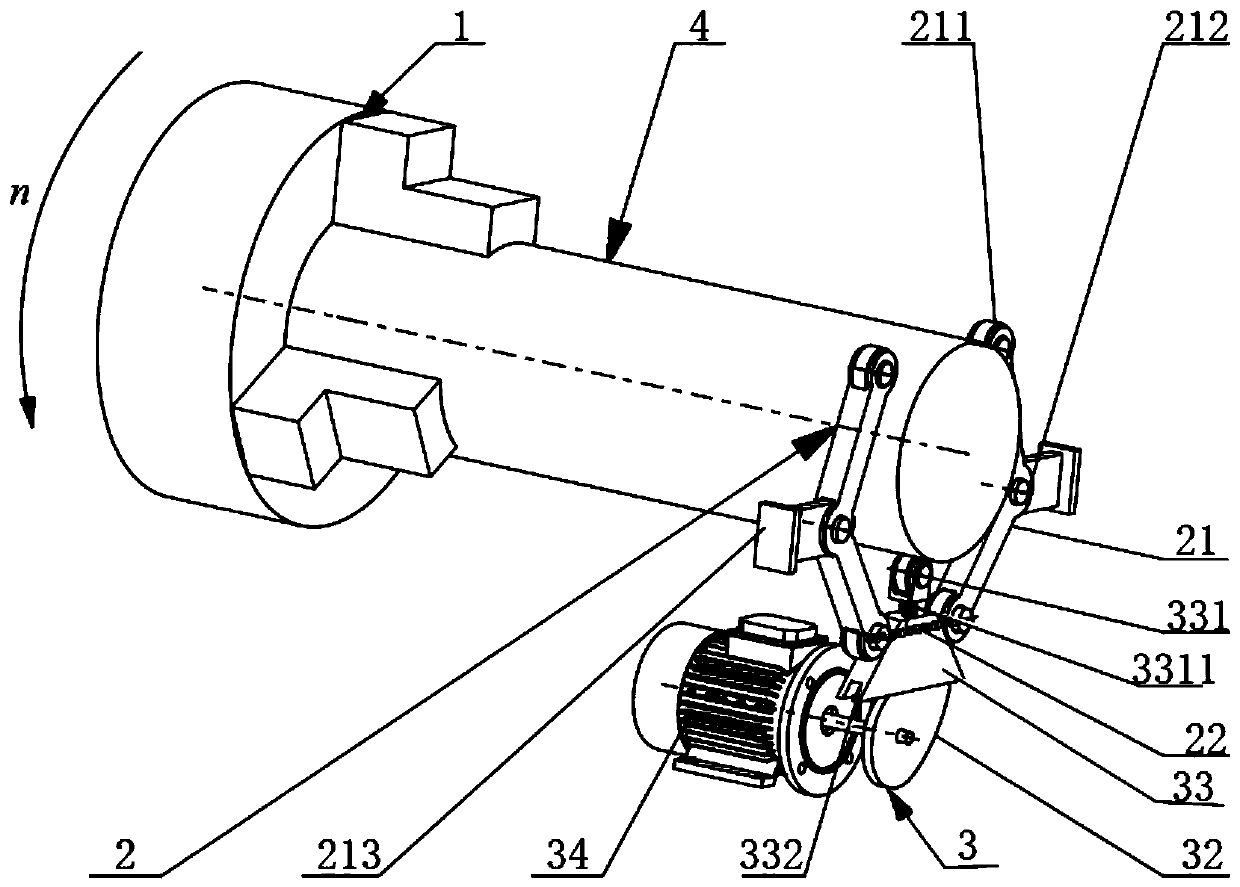

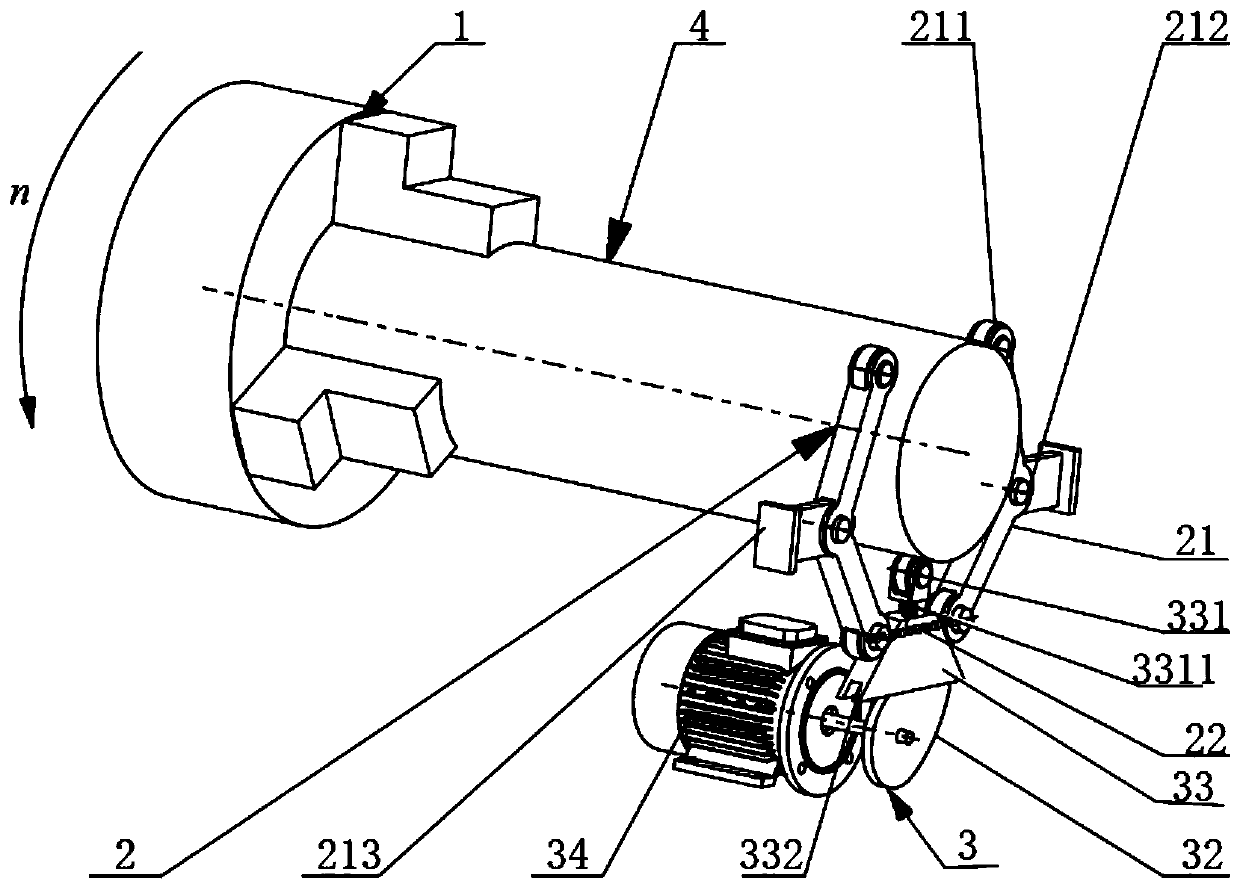

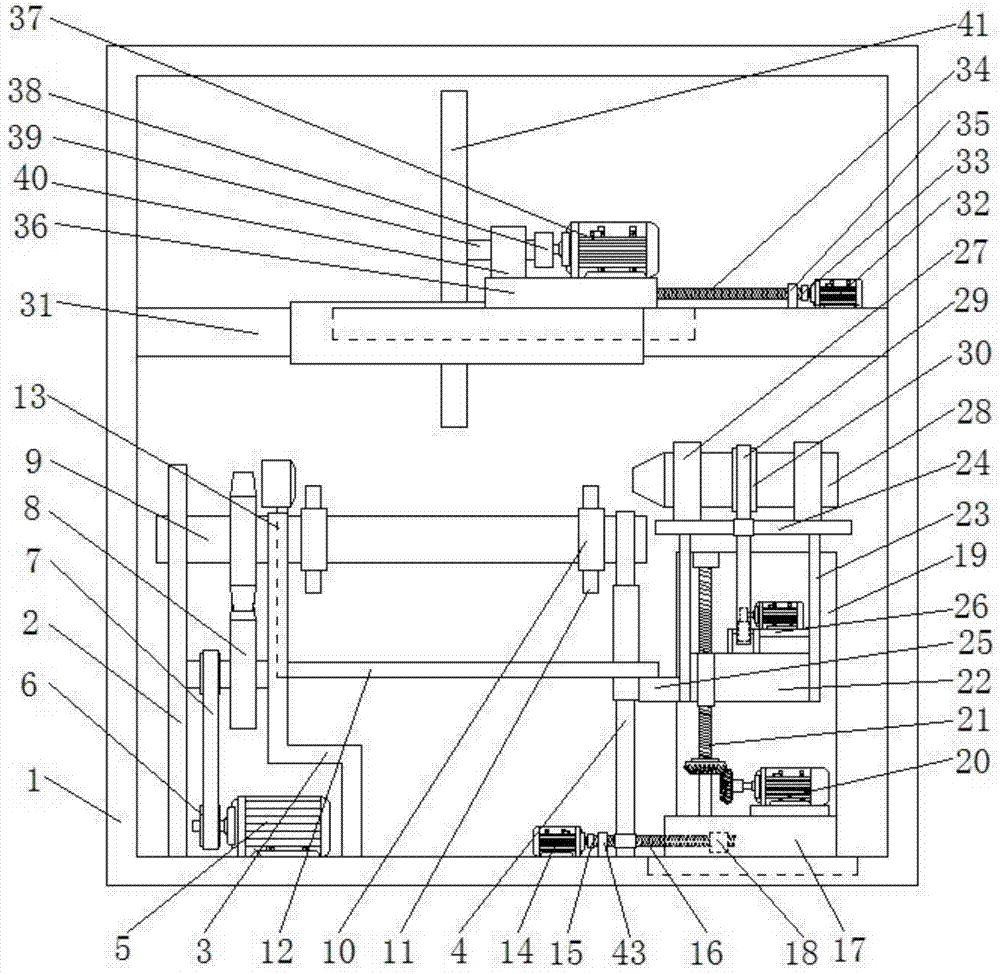

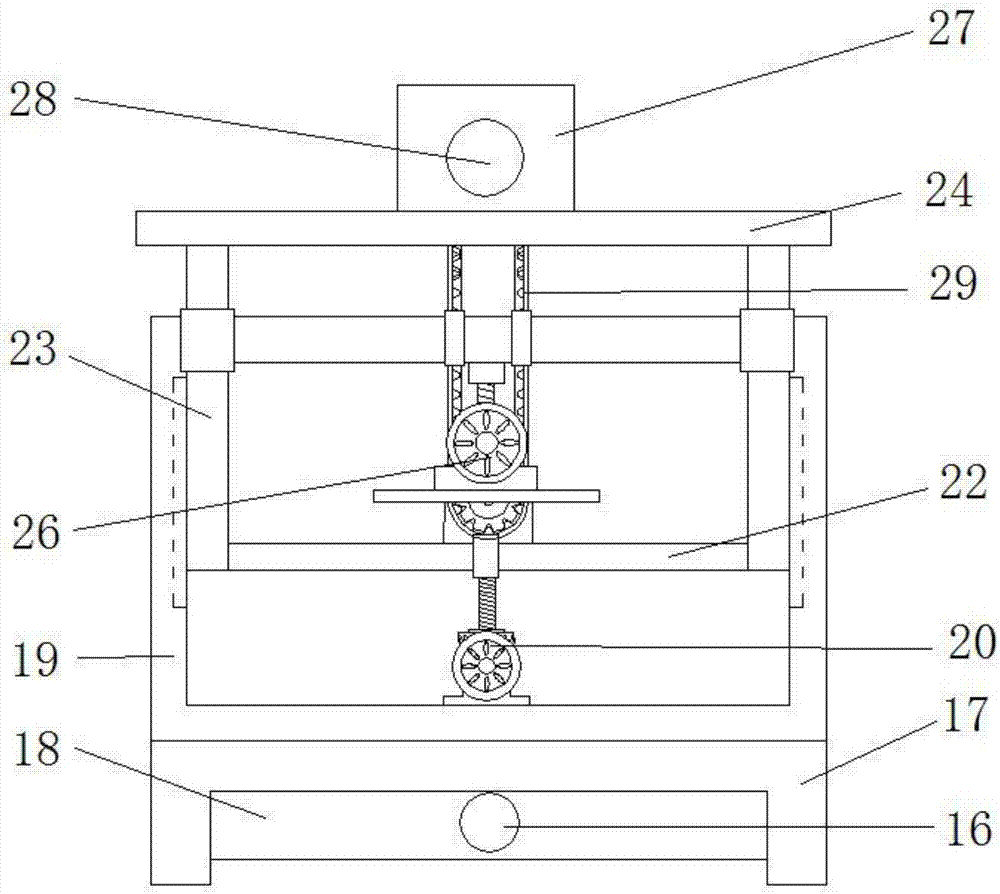

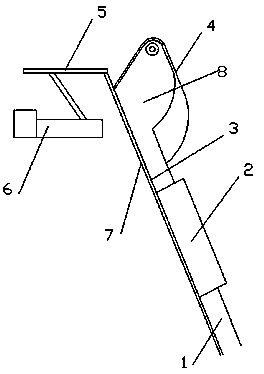

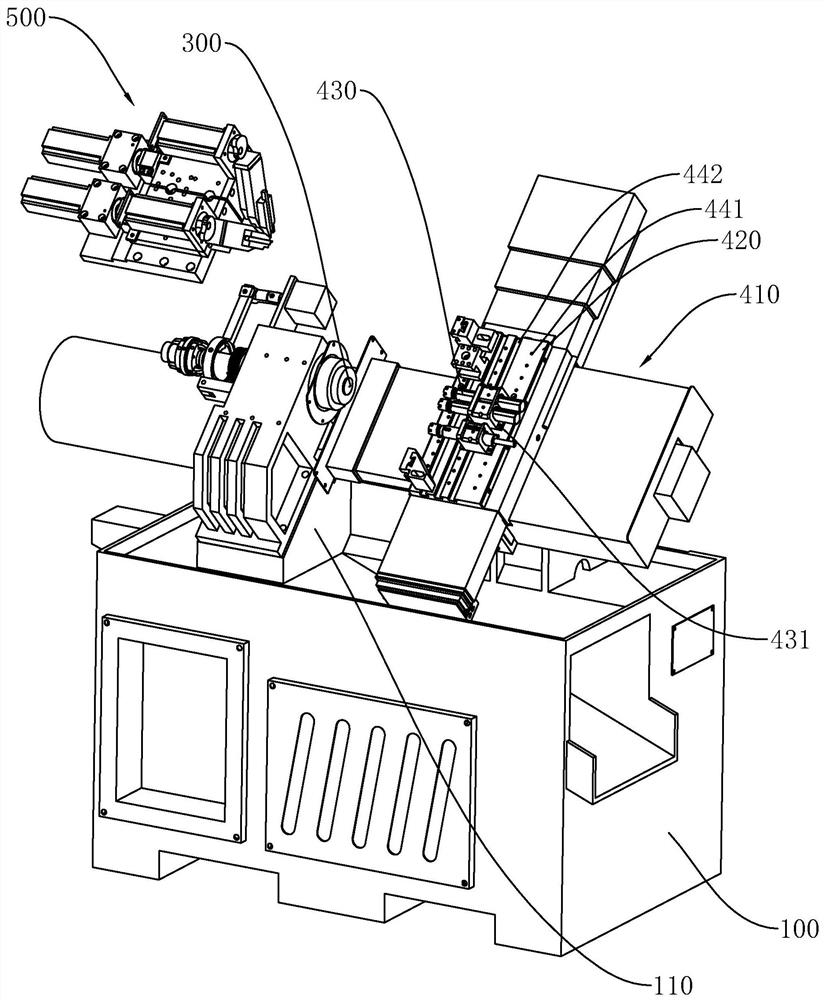

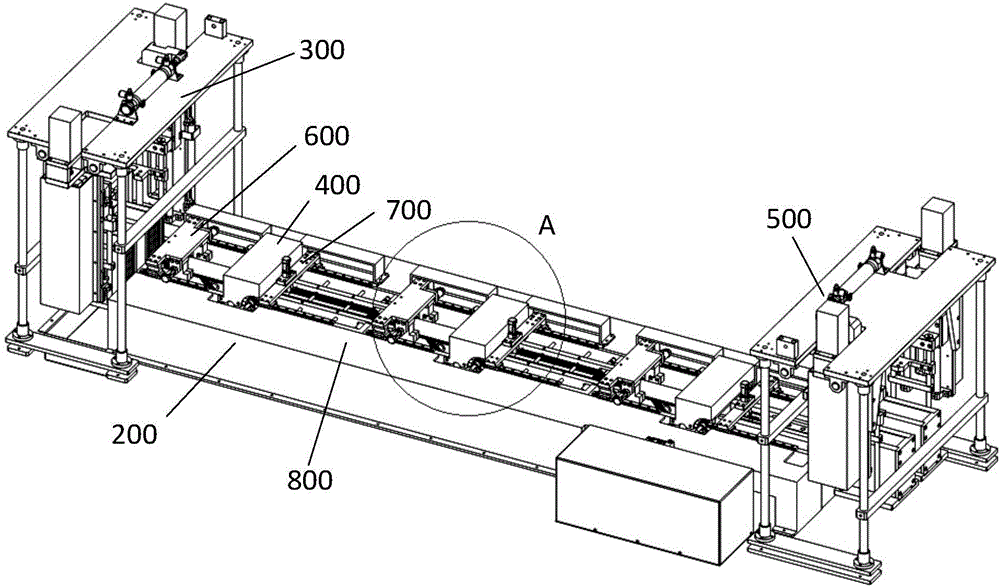

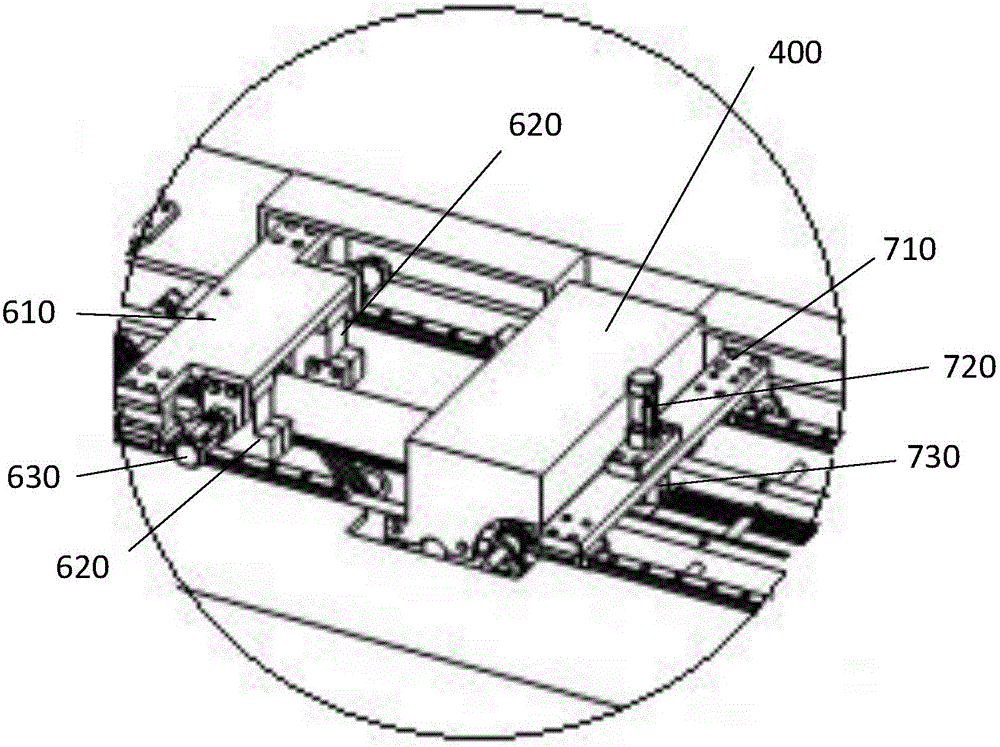

Long shaft part center adjustable quick clamping and machining device and operation method thereof

PendingCN109848735AGood supportReduce processing size and shape errorsChucksPositioning apparatusDrive motorCam

The invention provides a long shaft part center adjustable quick clamping and machining device and an operation method thereof. The device comprises a chuck, a fixture and a force applying device. Thechuck is used for fixing one end of a shaft part. The fixture comprises two V-shaped rods used for clamping the other end of the shaft part. The V-shaped rods are fixedly connected through a spring.The tail ends of the V-shaped rods are provided with rolling wheels. The force applying device comprises a cam, a bevel push block and a driving motor. The two bevels of the bevel push block are arranged in an inverted-V shape. The upper end of the bevel push block is arranged in the space formed by connecting the spring and the V-shaped rods. The lower end of the bevel push block is connected with one side of the cam. The driving motor is arranged on the other side of the cam. The long shaft part center adjustable quick clamping and machining device provided by the invention can implement quick clamping and dynamic clamping and machining on different diameters of shaft parts, is fast and convenient to operate, firm in clamping, integrates the functions of centers and follow-rest devices during traditional shaft part machining, saves the cost and optimizes the machining process.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

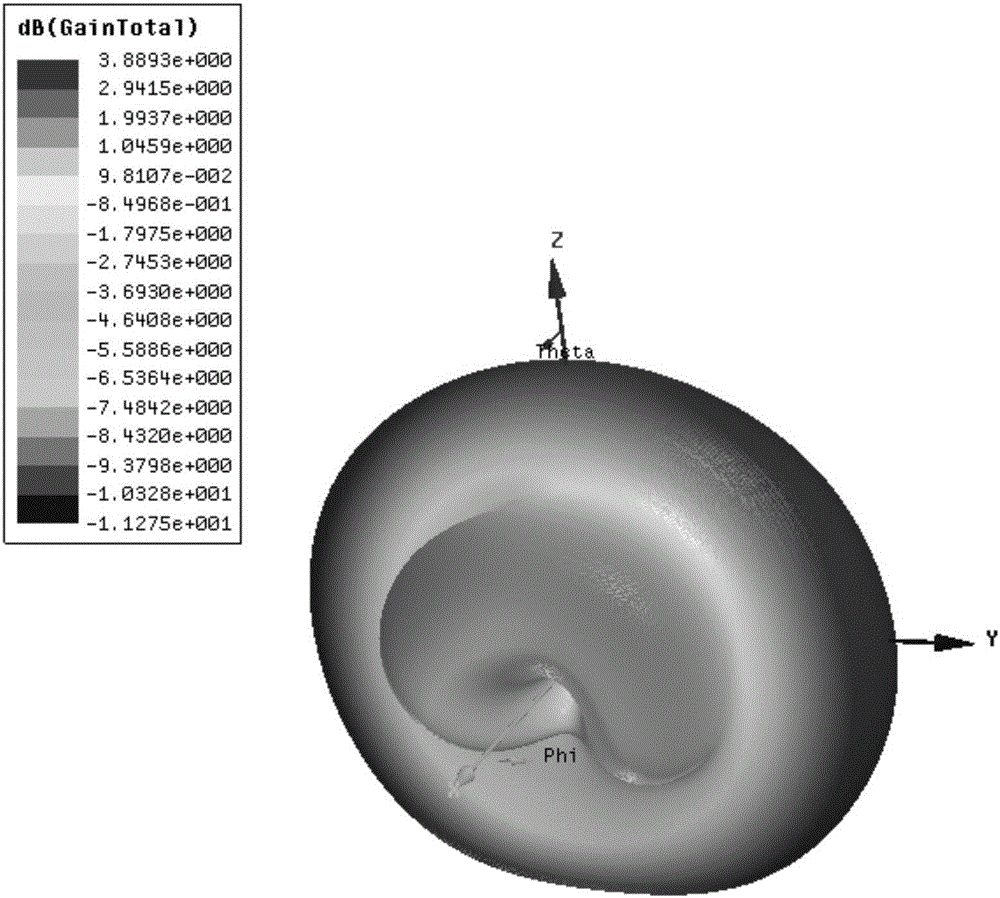

Omnidirectional circular polarization plane antenna based on electrical/magnetic dipole

ActiveCN105048080AFeed realizationHas a "broadcast" featureRadiating elements structural formsAntennas earthing switches associationOmnidirectional antennaMiniaturization

The invention discloses a circular-polarization omnidirectional antenna based on an electrical / magnetic dipole. The antenna comprises a microstrip antenna and a dielectric substrate supporting the microstrip antenna. The microstrip antenna comprises a first rectangular metal paster and a second rectangular metal paster which are located on upper and lower surfaces of the dielectric substrate. Sizes of the first rectangular metal paster and the second rectangular metal paster are the same, and the first rectangular metal paster and the second rectangular metal paster directly face each other and are in a parallel relation. Along a length direction of the first rectangular metal paster and the second rectangular metal paster, a first rectangular metal arm and a second rectangular metal arm which are in the same size are led out in reverse directions respectively. The first rectangular metal paster and the first rectangular metal arm form a first surface of the dielectric substrate. The second rectangular metal paster and the second rectangular metal arm form a second surface of the dielectric substrate. The first surface and the second surface are connected through a short circuit wall. A width of the short circuit wall is equal to a thickness of the dielectric substrate. A length of the short circuit wall is equal to a length of the first rectangular metal paster. A main radiation portion of the antenna uses the paster and does not use a reactive component. Miniaturization advantages of a low profile, a small size, easy coplane and the like are possessed. The antenna can be realized on a single layer board.

Owner:SYSU CMU SHUNDE INT JOINT RES INST

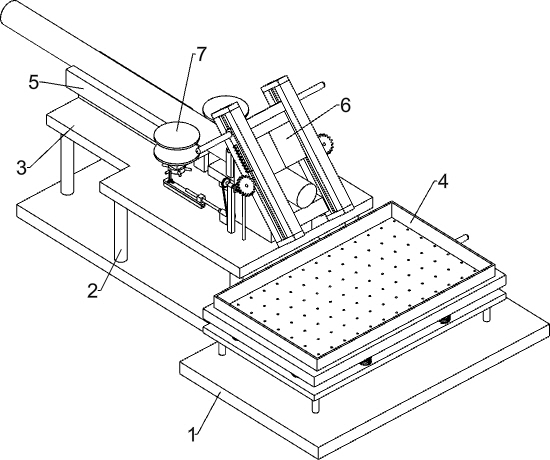

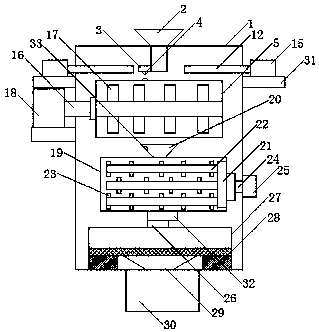

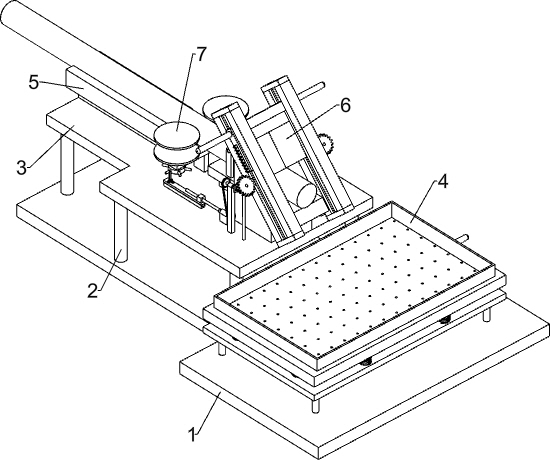

Polishing machine used for machining automobile crankshaft

ActiveCN107336121AFeed realizationRealize automatic feedingPolishing machinesGrinding drivesCouplingControl engineering

The invention discloses a polishing machine used for machining an automobile crankshaft and relates to the field of machining of automobile parts. The polishing machine comprises a box. A first motor is fixedly connected to the bottom of the inner wall of the box. A first belt wheel is fixedly connected to one end of an output shaft of the first motor. The surface of the first belt wheel is in transmission connection with a feeding device through a first belt. A second motor is fixedly connected to the bottom of the inner wall of the box. A first lead screw is fixedly connected to the output shaft end of the second motor through a first coupling. A sliding table is slidably connected to the bottom of the inner wall of the box and located on the right side of a third vertical plate. A supporting rod is fixedly connected between the two sides of the inner wall of the sliding table. The first lead screw is connected with the supporting rod in an engaged mode. A third motor is fixedly connected to the top of the sliding table. A lifting device is fixedly connected to the output end of the third motor. By adoption of the polishing machine for machining the automobile crankshaft, the problems that traditional crankshaft polishing equipment is complex in structure, and manual clamping is needed are solved, cost is reduced, labor is saved, and production efficiency is improved.

Owner:湖州五左机械有限公司

Feeding habit domesticating device and method for carnivorous fish

ActiveCN105594646ALow input costTo achieve the purpose of domesticationClimate change adaptationPisciculture and aquariaFish oilFishery

The invention relates to the field of fish breeding, and mainly relates to a feeding habit domesticating device and method for carnivorous fish. The feeding habit domesticating device comprises an aeration device, a fish oil feeding device, and a bait containing component disposed in water, and outlets of both the aeration device and the fish oil feeding device are communicated with the bottom of the bait containing component. When the feeding habit domesticating device is in use, the bait containing device containing bait is put in water, and normally formula feed cheaper than living bait is selected as the bait; airflow is pumped into the bait containing component from the bottom thereof through the aeration device, then the bait positioned inside the bait containing component is raised with the airflow to be in the status of vertical floating motion, at the same time, fish oil with strong fishlike smell is fed into the bait containing component from an air inlet through the fish oil feeding device to be evenly fixed with the bait so as to further make fish take the fed bait for swimming live fish, and the fish are promoted to eat the non-living bait so as to achieve the purpose of feeding habit domesticating.

Owner:安徽长江渔歌渔业股份有限公司

Washing and wipe dry integrated machine for coating barrel

InactiveCN108746126AImprove cleaning and drying efficiencySimple structureDrying solid materials without heatHollow article cleaningEngineeringMechanical engineering

The invention relates to a washing and wipe dry integrated machine for a coating barrel. The washing and wipe dry integrated machine comprises a rack and a conveying carrier band, the conveying carrier band is provided with a carrying opening matched with the coating barrel, the upper portion of the rack is sequentially provided with a washing mechanism and a wipe dry mechanism, and clamping devices are arranged at the positions, at the lower portions of the washing mechanism and the wipe dry mechanism, of the rack; the washing mechanism comprises a washing lifting air cylinder arranged on therack, the lower portion of the washing lifting air cylinder is connected with a washing device matched with the coating barrel, and the washing lifting air cylinder is matched with an air cylinder rotating device arranged on the rack; and the wipe dry mechanism comprises a wipe dry lifting air cylinder arranged on the rack, the lower portion of the wipe dry lifting air cylinder is connected witha wipe dry device matched with the coating barrel, and the wipe dry lifting air cylinder is matched with the air cylinder rotating device on the rack. According to the washing and wipe dry integratedmachine, the conveying carrier band tightened for conveying is used as a carrier of continuous movement of the coating barrel, the washing mechanism and the wipe dry mechanism are used in cooperationto achieve continuous and automatic washing and wipe dry, and the washing and wipe dry efficiency of the coating barrel is greatly improved.

Owner:DONGGUAN UNIV OF TECH

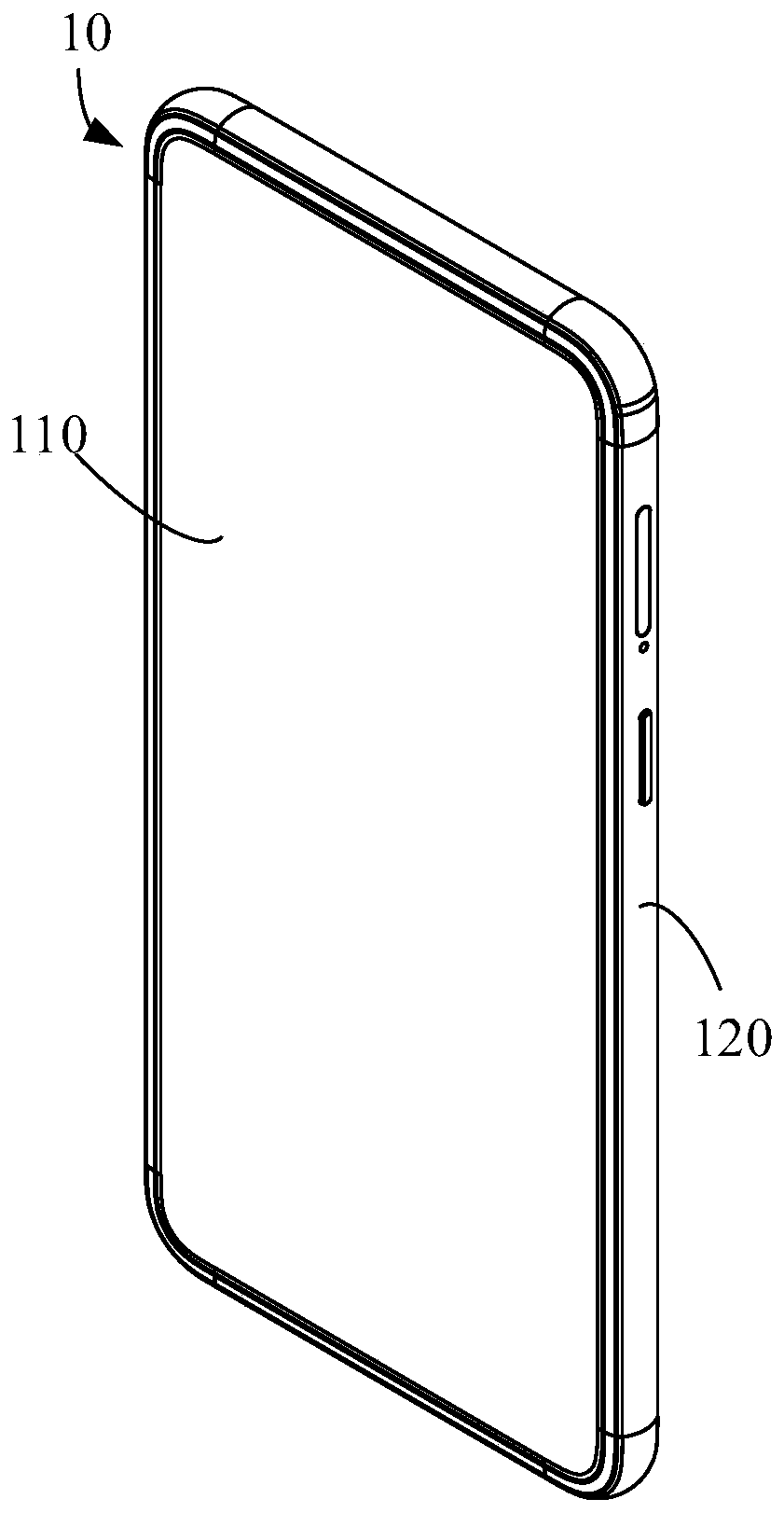

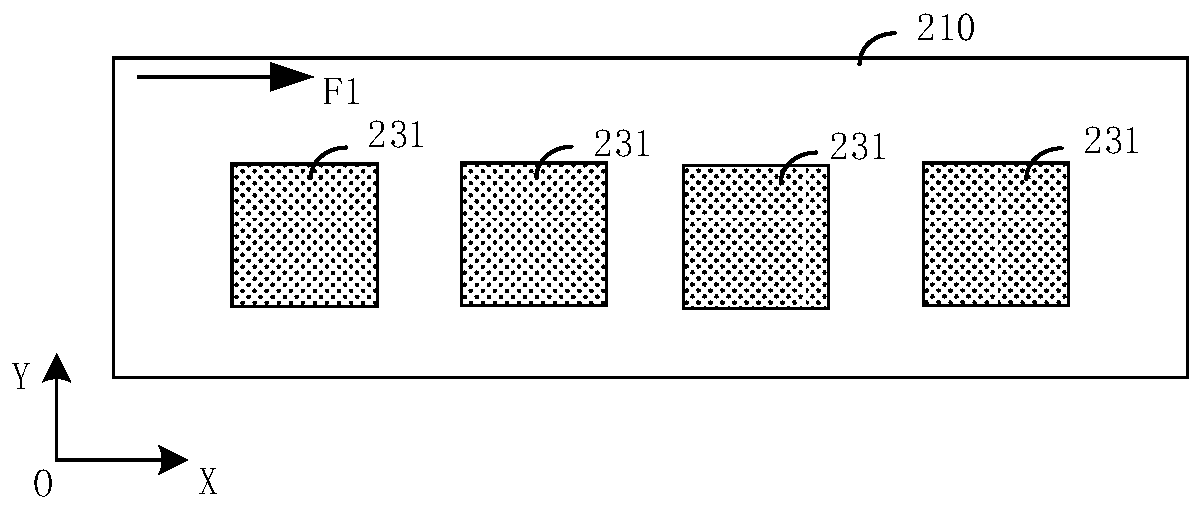

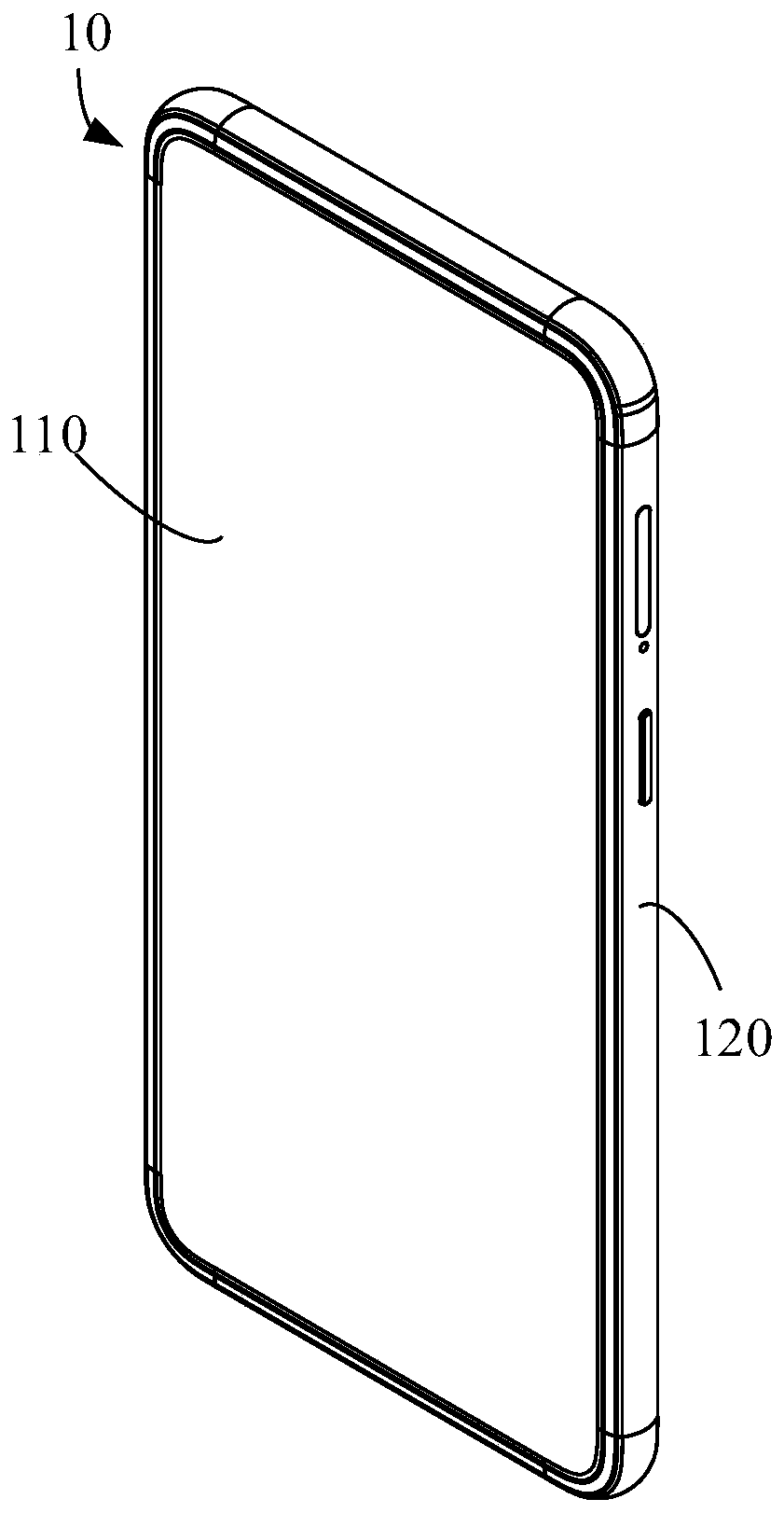

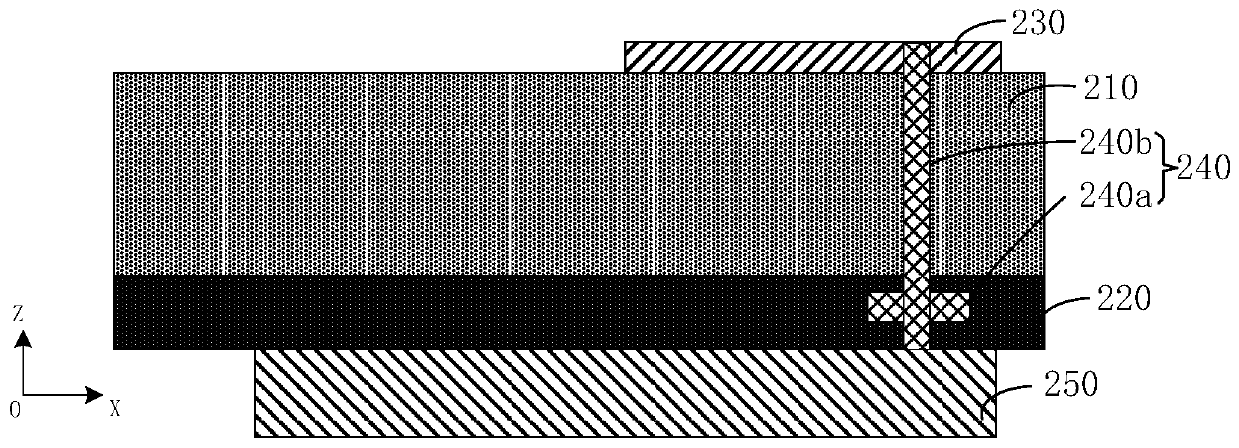

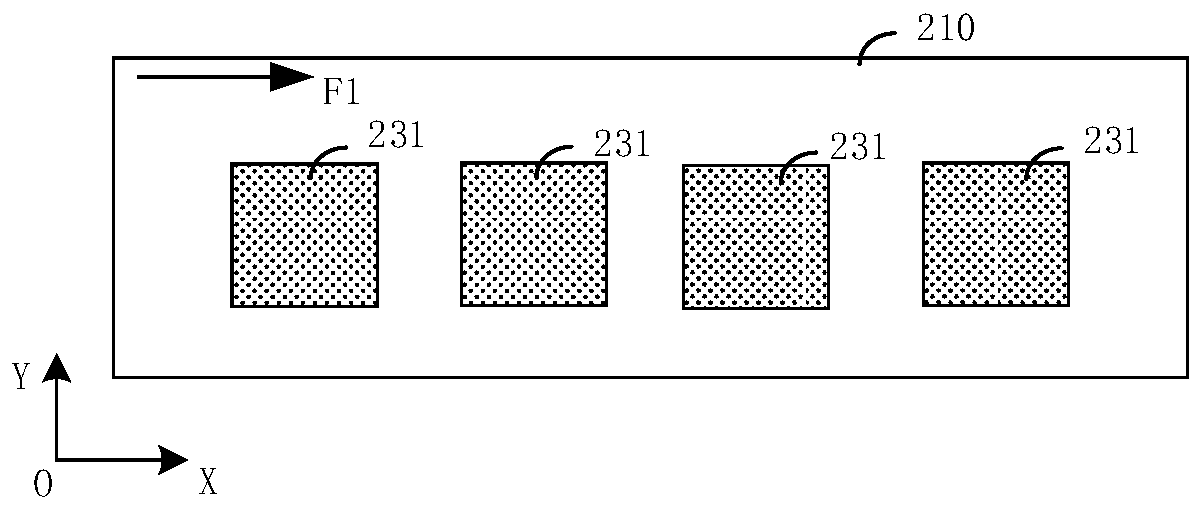

Antenna packaging module and electronic device

ActiveCN110867662AFeed realizationAchieve circularly polarized radiationParticular array feeding systemsAntenna supports/mountingsHemt circuitsAntenna substrate

The present application relates to an antenna packaging module and an electronic device. The antenna packaging module includes: an antenna substrate having a first side and a second side disposed opposite to each other; a first laminated circuit disposed on the first side of the antenna substrate and having a side away from the antenna substrate used for holding a radiofrequency chip; a radiationstructure disposed on the second side of the antenna substrate; and a feed network including a 90-degree directional coupling structure disposed in the first laminated circuit and a transmission linepassing through the antenna substrate and the first laminated circuit. By introducing the 90-degree directional coupling structure and connecting the radiofrequency chip and the radiation structure through the transmission line, it is possible to feed the radiation structure so that the radiation structure realizes circularly polarized radiation, and improve the degree of isolation between feed ports and reduce mutual coupling between antenna units.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Antenna packaging module and electronic equipment

ActiveCN110854507AFeed realizationRadiant realizationAntenna supports/mountingsRadiating elements structural formsAntenna substrateRadio frequency

The invention relates to an antenna packaging module and electronic equipment. The antenna packaging module comprises an antenna substrate which is provided with a first side and a second side which are arranged oppositely, a first laminated circuit arranged on the first side of the antenna substrate, a radiation structure arranged on the second side of the antenna substrate, and a feed network comprising a 180-degree directional coupling structure arranged in the first laminated circuit and a transmission line penetrating through the antenna substrate and the first laminated circuit, whereinthe side, deviating from the antenna substrate, of the first laminated circuit is used for arranging a radio frequency chip. The antenna packaging module is advantaged in that by introducing a 180-degree directional coupling structure and respectively connecting the 180-degree directional coupling structure with the radio frequency chip and the radiation structure through the transmission line, the radiation structure can be fed to realize dual-polarized radiation, the isolation degree between feed ports is improved, and mutual coupling between antenna units is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

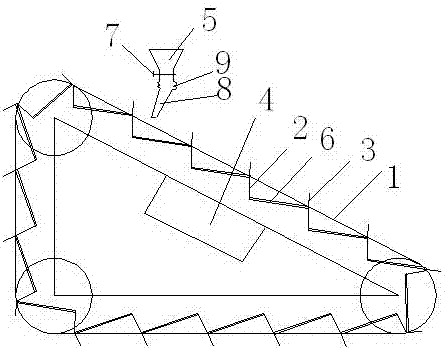

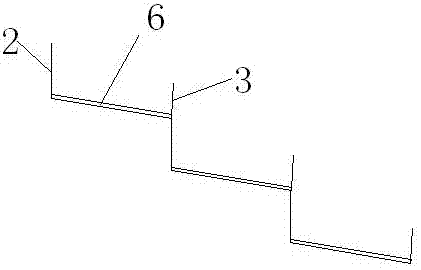

Stepped vibration feeding device

InactiveCN107336948ALay evenlyImprove impact performanceConveyorsGrain treatmentsMechanical engineeringEngineering

Owner:NANTONG LIYUANHENG MACHINERY

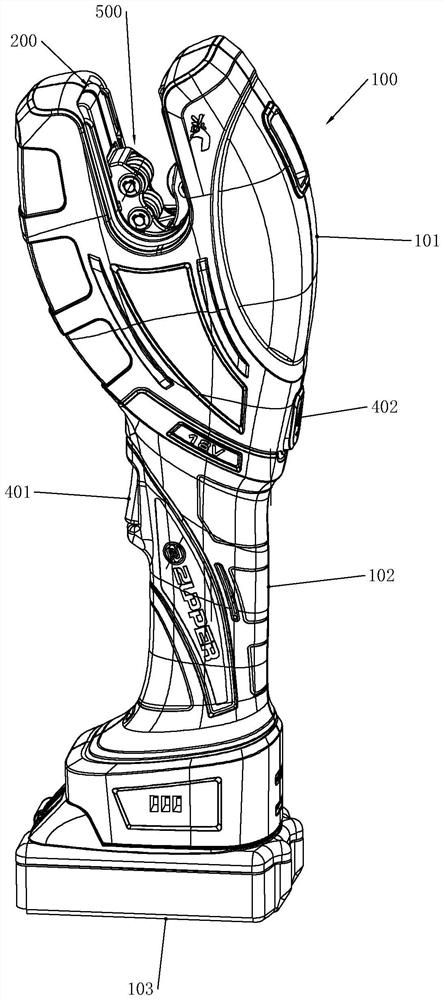

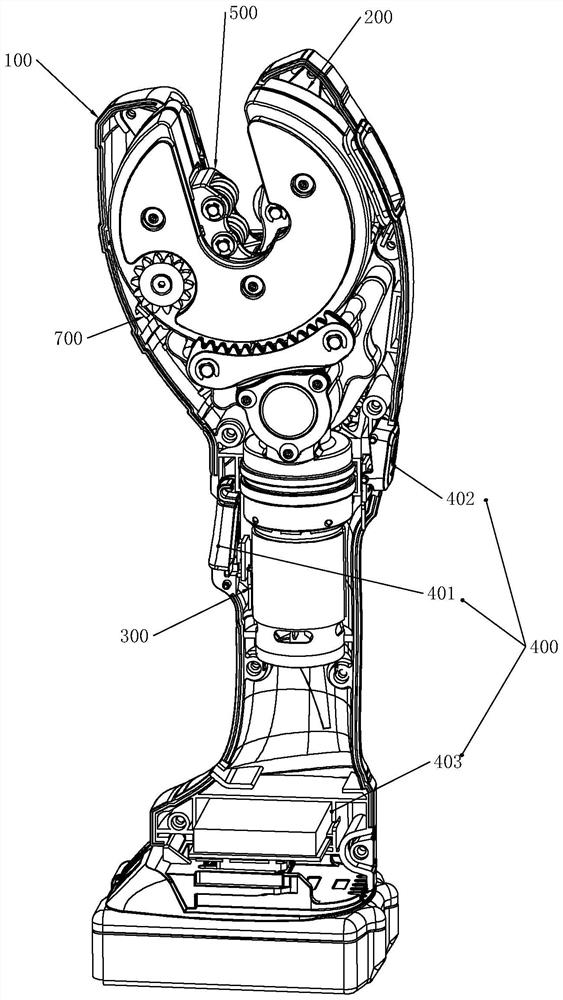

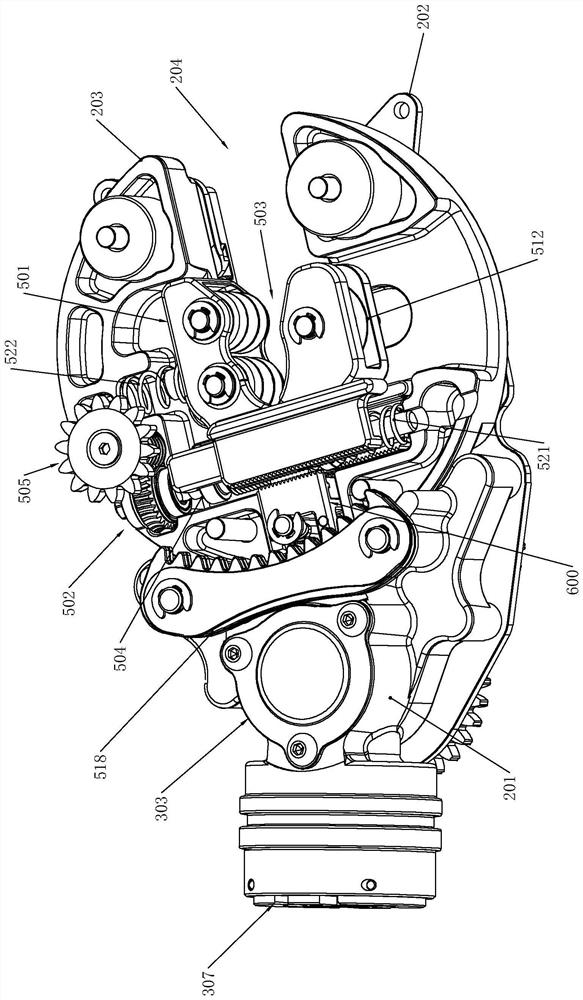

Handheld electric cutting tool

The invention relates to the technical field of electric tools, in particular to a handheld electric cutting tool which is used for cutting a pipe and comprises a shell, a handle and a handle. The cutter feeding device is rotatably mounted in the shell; a clamping position is arranged in the cutter feeding device, and a cutting knife is arranged on the peripheral side of the clamping position; when the feeding device rotates, the cutting knife executes a cutting action; and the driving device is used for providing power for the execution device. The driving device is used for driving the cutter feeding device to work, cutter feeding is achieved, cutting force is generated, pipes are cut, and the problems that in the prior art, due to the fact that the elastic force of an elastic piece is limited, the cutting force is small, high-hardness and thick pipes cannot be cut, and use is inconvenient are solved.

Owner:TAIZHOU JULI TOOLS

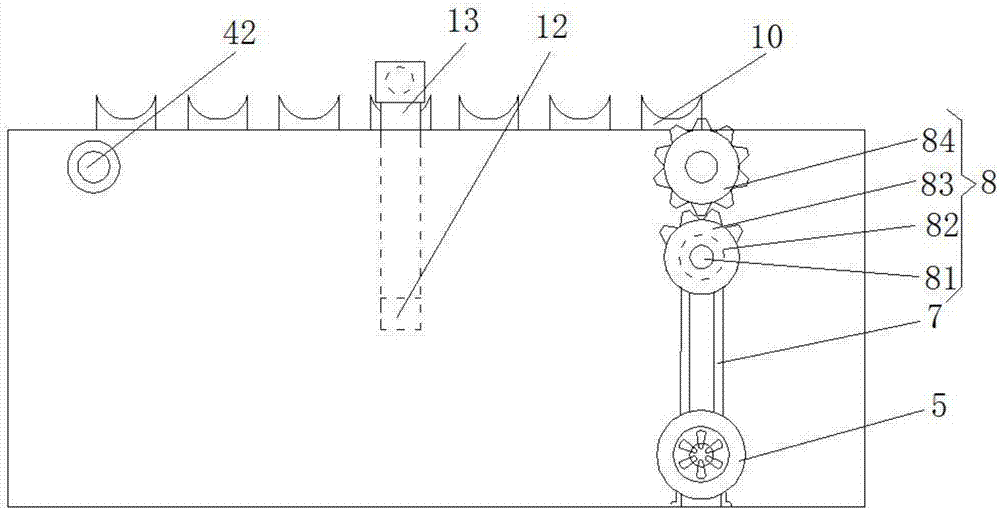

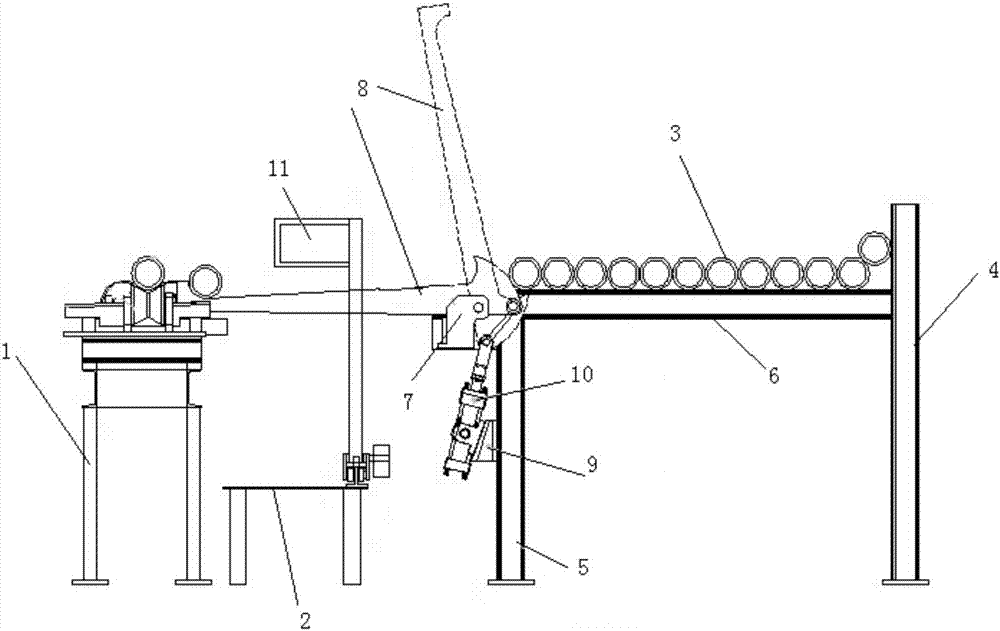

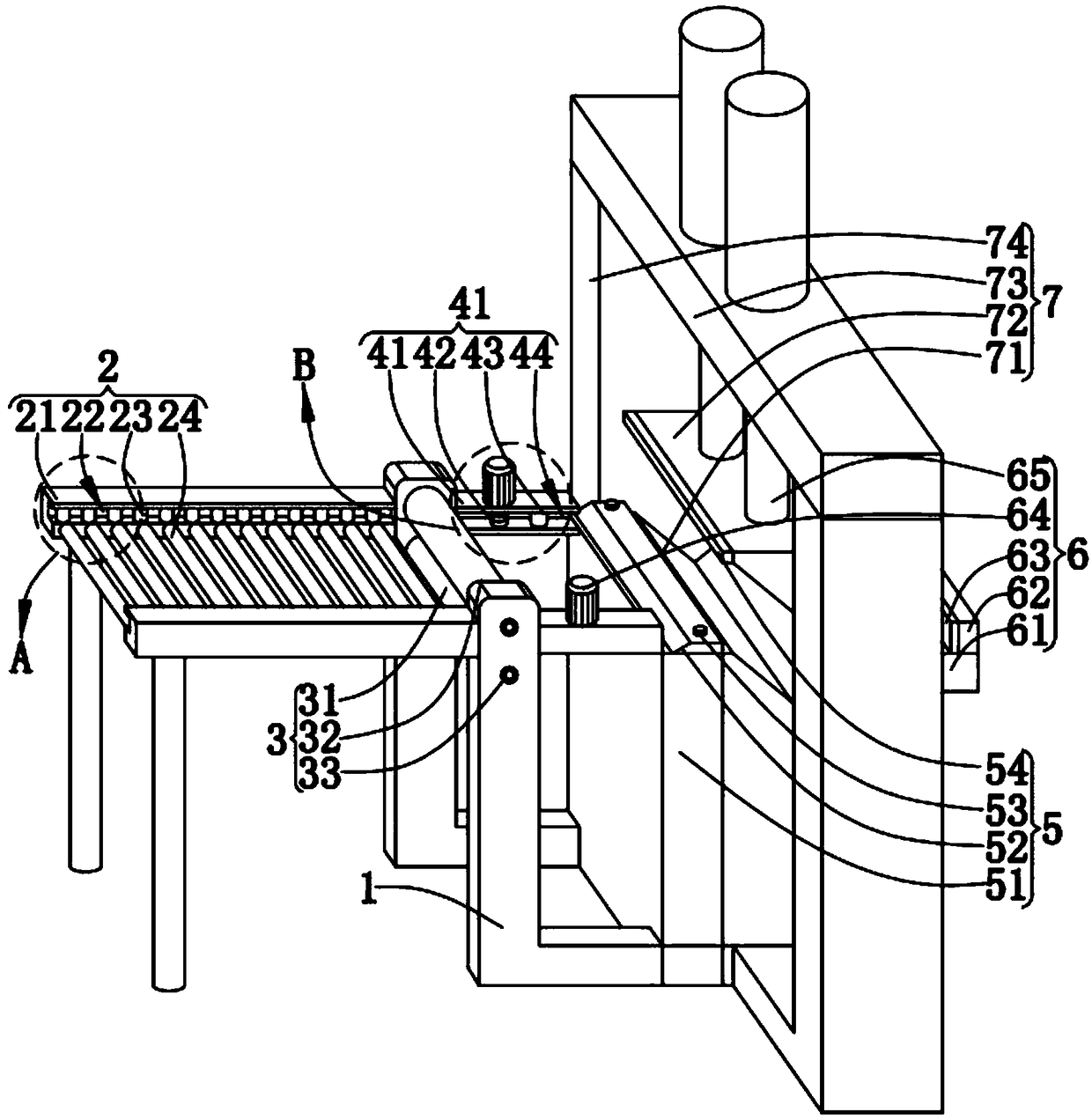

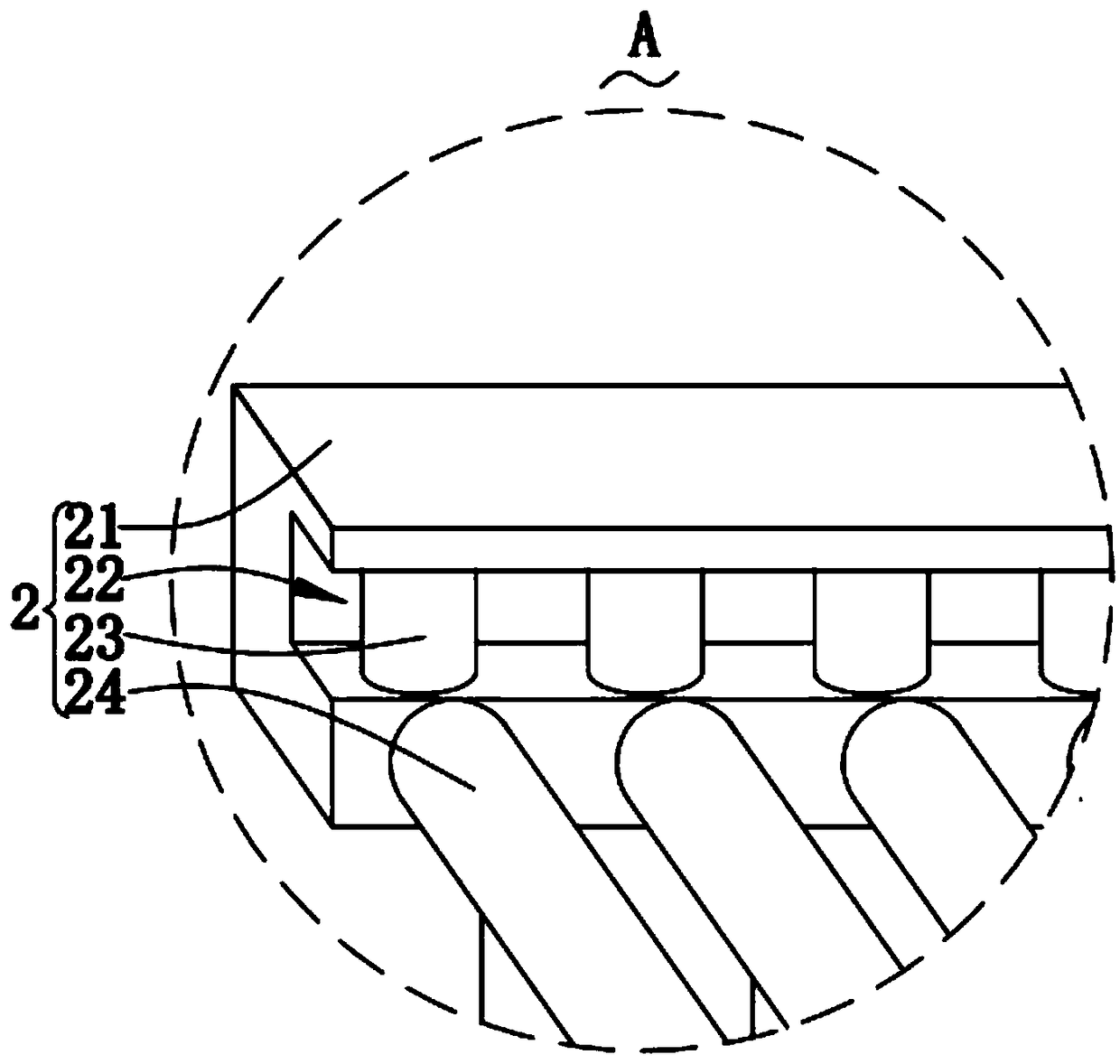

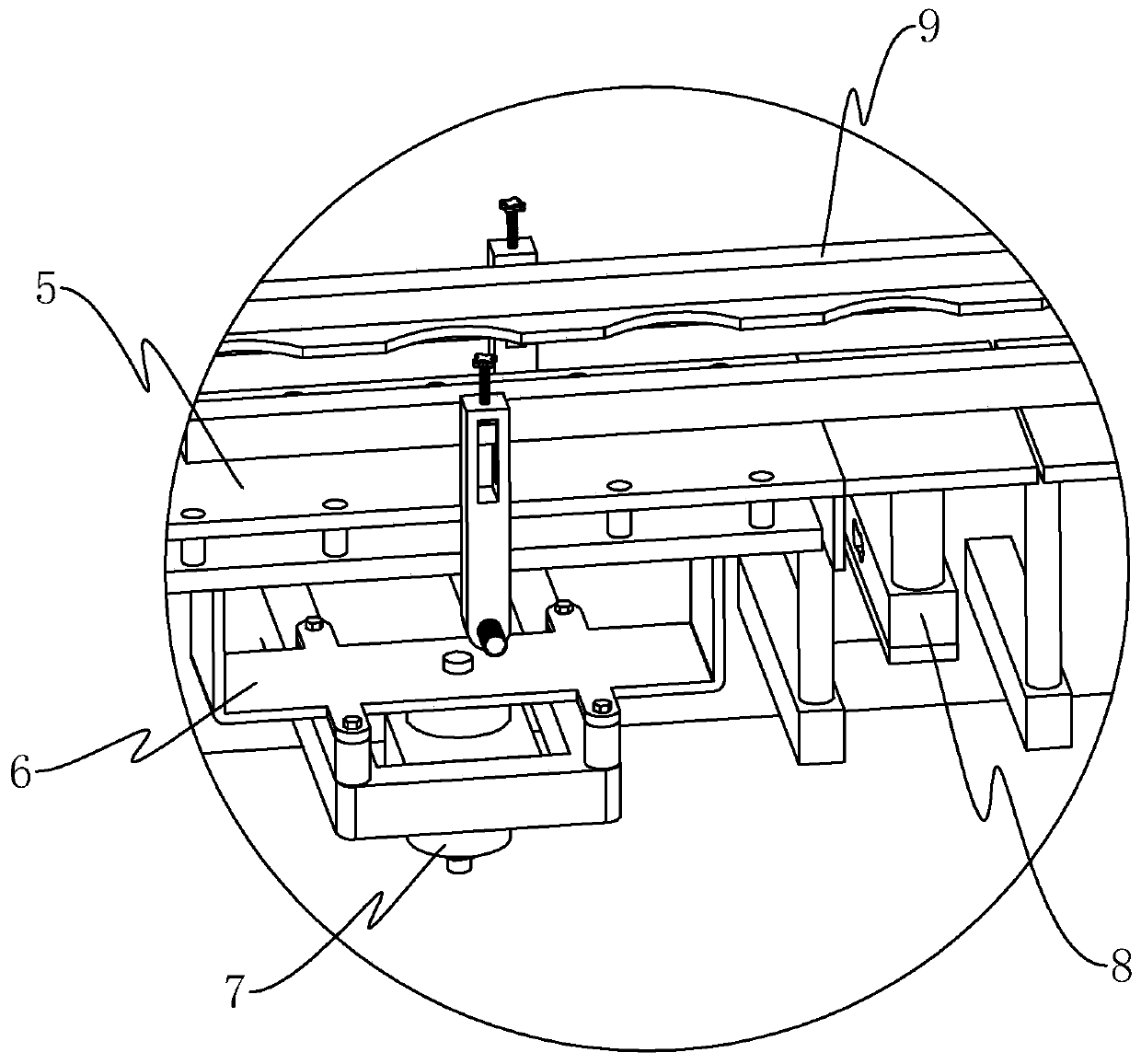

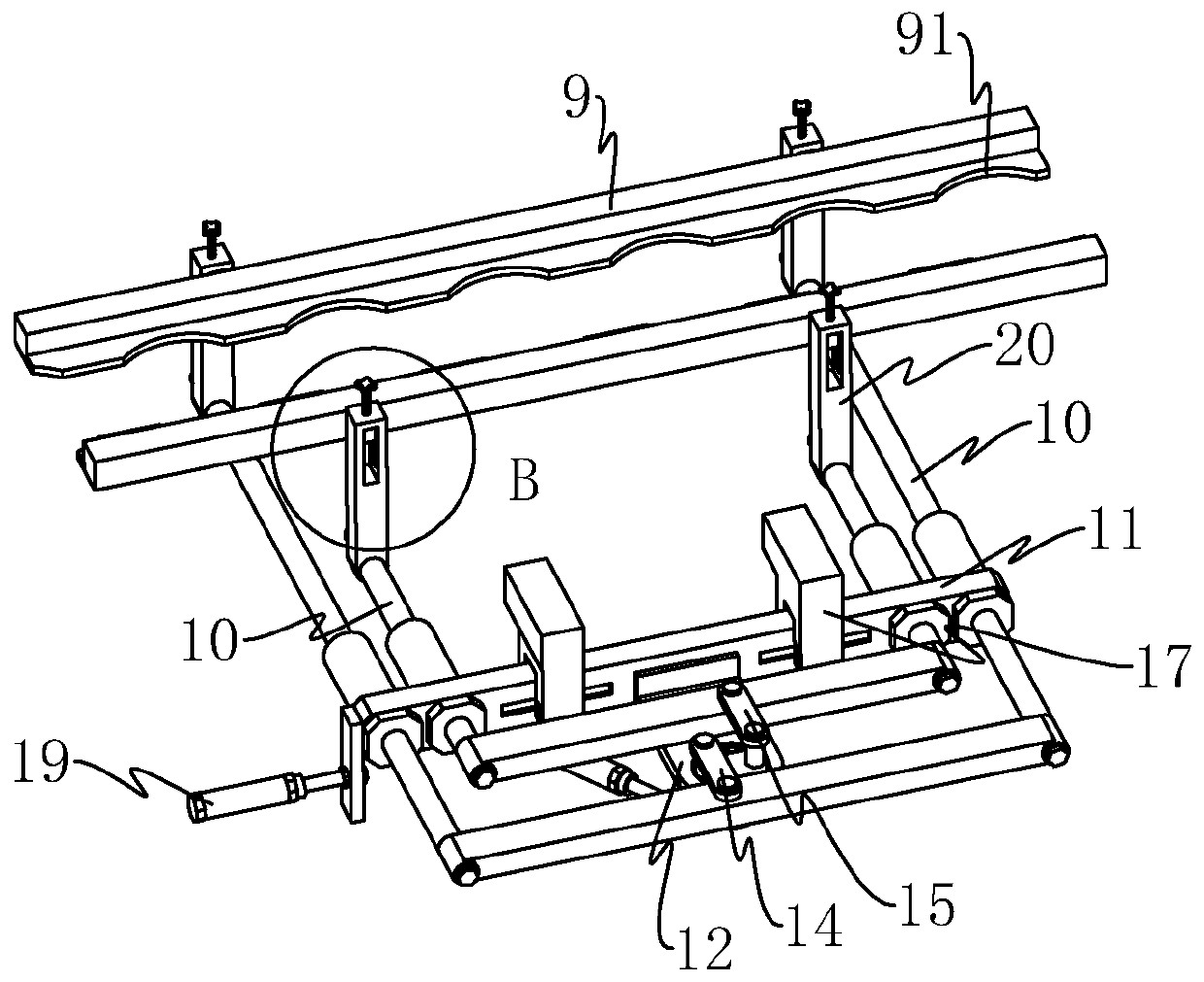

Automatic-feeding pipe fitting flaw detection device

PendingCN107515308AFeed realizationReduce frequency of useMaterial analysisPipe fittingPetroleum engineering

The invention relates to an automatic-feeding pipe fitting flaw detection device. The device comprises a detection mounting rack (1), a detection working rack (2), a detector, a storage rack and an automatic feeding unit, the detection working rack (2) is arranged between the detection mounting rack (1) and the storage rack, the storage rack is used for placing a pipe fitting (3) to be detected, the detector is arranged on the detection working rack (2), the automatic feeding unit is movably connected with the storage rack, the automatic feeding unit is connected with the detection mounting rack (1) and the pipe fitting (3) is conveyed to the detection mounting rack (1) during feeding, and after the feeding is completed, the automatic feeding unit automatically disengages from the detection mounting rack (1), and the detector on the detection working rack (2) automatically runs to carry out flaw detection. Compared with devices in the prior art, the device provided by the invention has the advantages of simple structure, and stability and reliability in running.

Owner:上海瓦姆石油天然气管业有限公司

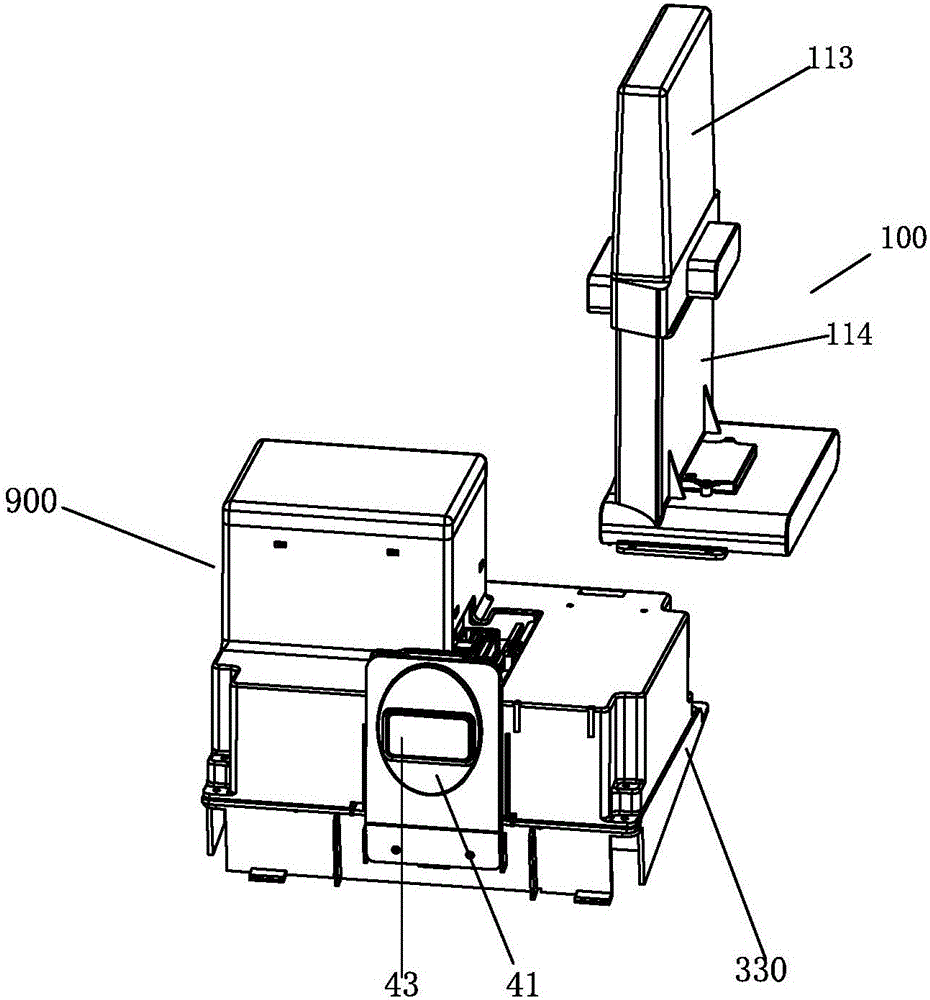

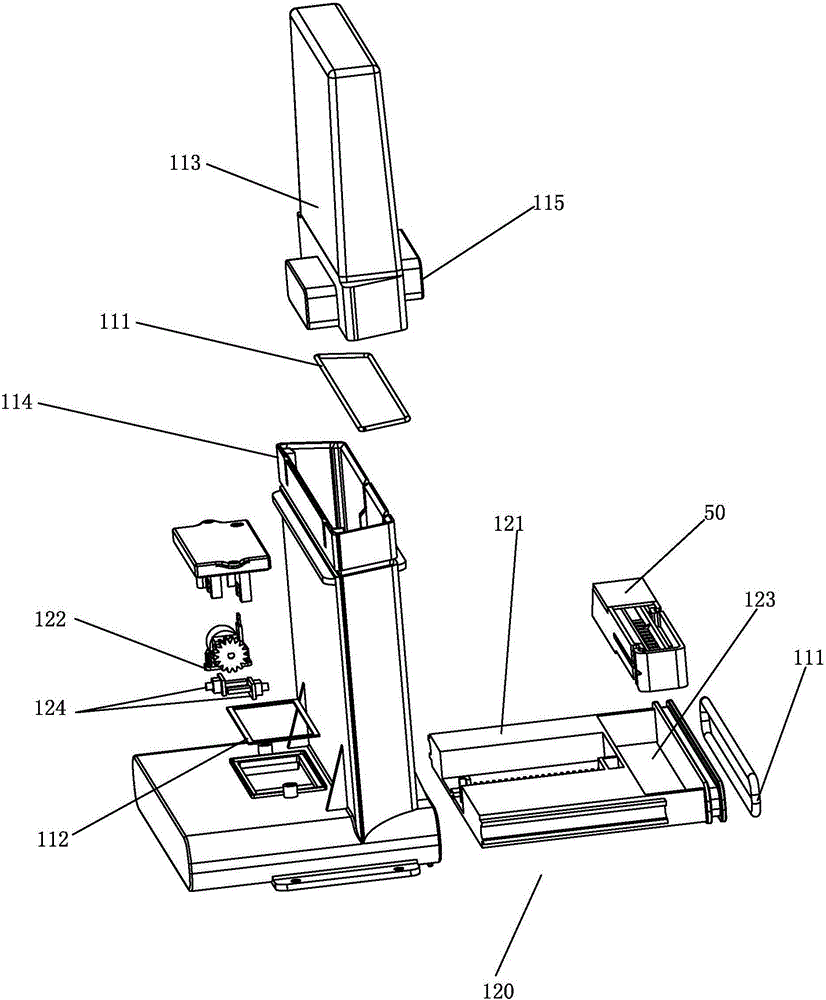

Feeding mechanism arranged at back part of color sorter slide

InactiveCN103658053APrevent splashPrevent the phenomenon of dustSortingEngineeringMechanical engineering

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

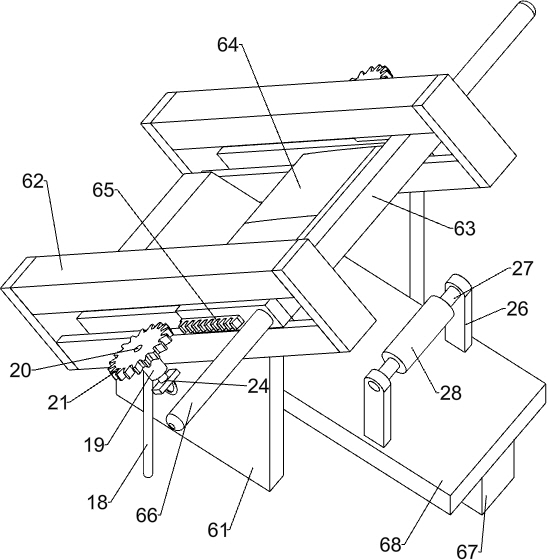

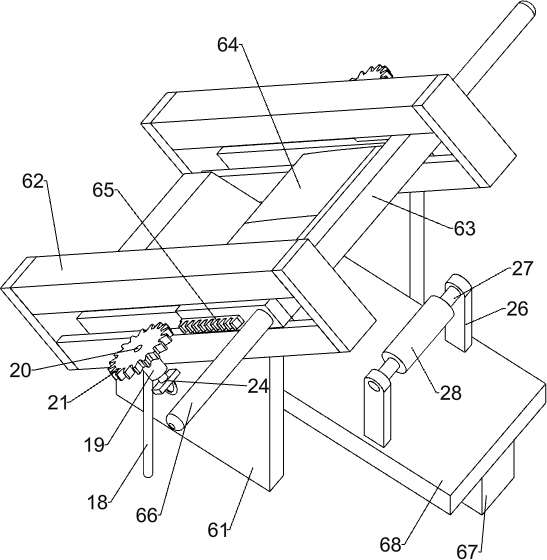

Radix astragali slicing device

ActiveCN111873006AAchieve automatic feedingUniform thicknessMetal working apparatusRadix Astragali seu HedysariEngineering

The invention relates to a slicing device, in particular to a radix astragali slicing device. The technical problem to be solved is to provide the radix astragali slicing device which is automatic infeeding and uniform in slicing thickness. According to the technical scheme, the radix astragali slicing device comprises a base, a workbench, a collecting screen, a cushion block, a slicing mechanismand a feeding mechanism; a first supporting column is arranged on one side of the base; the workbench is arranged on the first supporting column; the collecting screen is arranged on the side, away from the workbench, of the base; the cushion block is arranged on the side, away from the collecting screen, of the workbench; the slicing mechanism is arranged on the side, close to the collecting screen, of the workbench; and the feeding mechanism is arranged on the workbench, and the feeding mechanism is located between the slicing mechanism and the cushion block. The radix astragali slicing device achieves the effects of being automatic in feeding and uniform in slicing thickness.

Owner:王发云

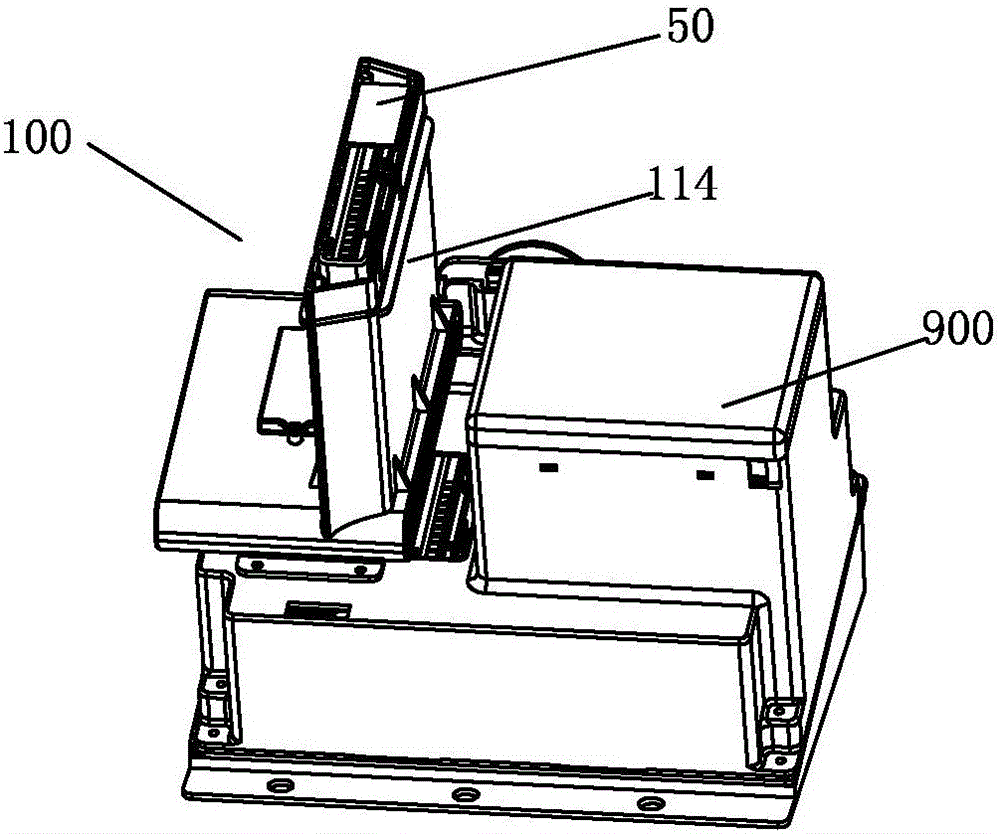

Intelligent urine detector, urinal and urine detection method

ActiveCN106198516AAchieve readAddressing deficiencies in manual urine testingMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesArtificial urineEngineering

The invention relates to an intelligent urine detector, a urinal and a urine detection method. The intelligent urine detector comprises: a feeding mechanism comprising a storage box and a pushing unit, wherein the storage box is filled with a plurality of test paper boxes, and the pushing unit is used for pushing the test boxes to a two-dimensional conveying mechanism; the two-dimensional conveying mechanism which is controlled to move along a first direction to realize feeding or discharging or is controlled to move along a second direction to realize urine taking or supplied urine information reading; a scanning mechanism used for reading the urine information in the test paper boxes; and a control mechanism connected with the feeding mechanism, the conveying mechanism and the scanning mechanism to control coordinative work of all the mechanisms in order to realize intelligent urine detection. The intelligent urine detector, the urinal and the urine detection method effectively overcome the disadvantages of artificial urine detection, and realize feeding, automatic urine taking, urine information reading and discharging through adopting the cooperation of the feeding mechanism, the two-dimensional conveying mechanism, the scanning mechanism and the control mechanism.

Owner:JOMOO KITCHEN & BATHROOM

Metal sheet punching and folding composite forming machine

ActiveCN109500155ACut offRealize the integration of punching, folding and cuttingMetal-working feeding devicesPositioning devicesPunchingMetal sheet

The invention relates to the field of metal sheet punching and folding equipment, in particular to a metal sheet punching and folding composite forming machine. Stand columns, feeding structures, limiting structures, guiding structures, a cut-off structure, a control structure and a punching and folding structure are included. The cut-off structure is fixed to the ends, deviating from the stand columns, of the guiding structures. The punching and folding structure is fixed to the end, deviating from the guiding structures, of the cut-off structure. When the punching and folding structure conducts punching and folding on metal thin materials, the metal thin materials can be cut off, punching, folding and cutting-off integration can be achieved, independence of the cutting-off procedure is reduced, and the machining efficiency is improved. The ends, deviating from the feeding structures, of the stand columns are provided with the guiding structures. Through the arrangement of the guidingstructures, the metal thin materials can be guided and can accurately enter the machining area. Through the arrangement of the guiding structures, the metal thin materials can be automatically conveyed to the machining area, manual feeding is not needed, automatic feeding can be achieved, and the machining efficiency is improved.

Owner:佛山市沧水天泽科技有限公司

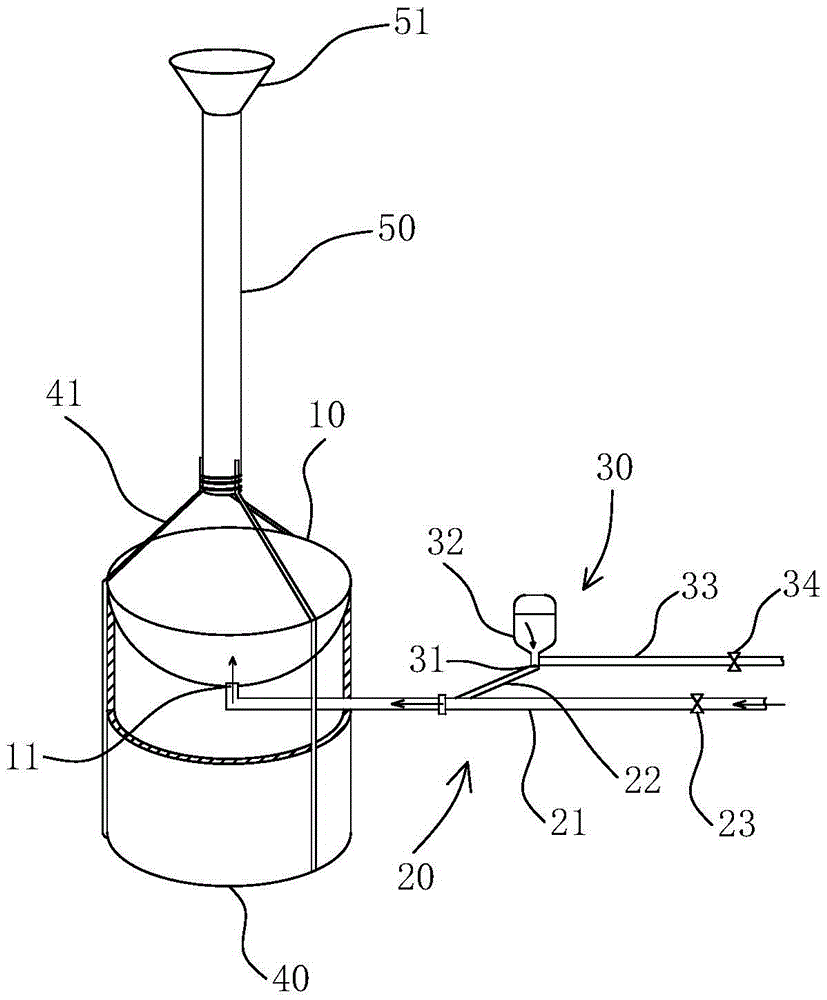

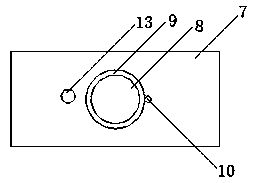

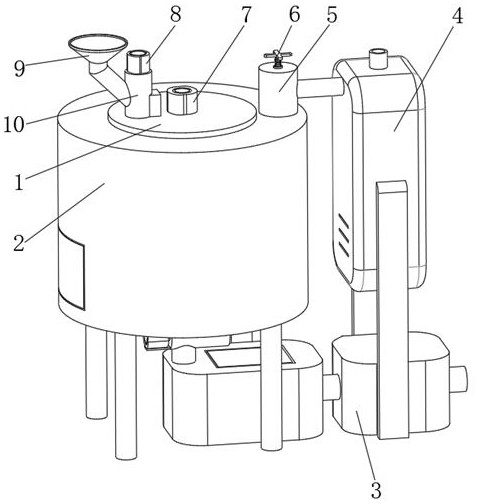

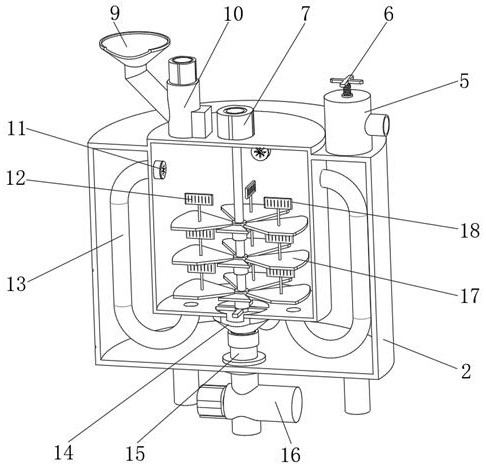

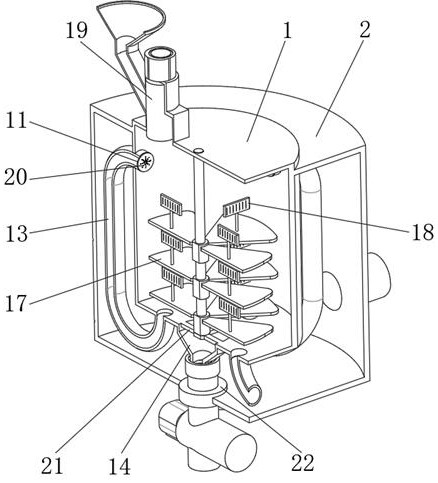

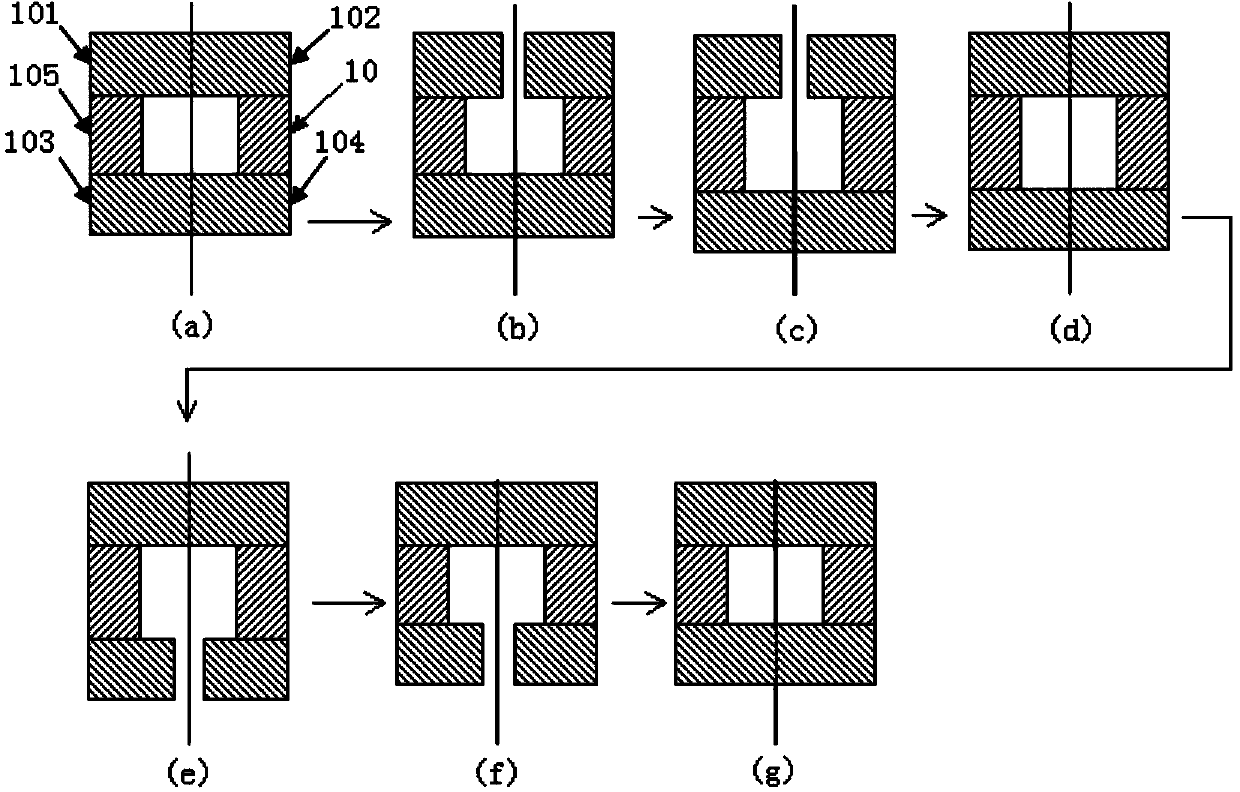

Sliding box feeding type mixing tank

InactiveCN105344280ACause poor qualityFeed realizationRotary stirring mixersTransportation and packagingEmulsionEngineering

The invention belongs to the field of coating equipment, and discloses a sliding box feeding type mixing tank which comprises a tank body. A stirring paddle is arranged in the tank body. A horizontal sealing cover is arranged at the upper end of the tank body. A plurality of vertical feeding pipes are arranged on the sealing cover and distributed in a straight line. The outer wall of each feeding pipe is provided with a marking layer. The sliding box feeding type mixing tank further comprises an inserting plate. The inserting plate penetrates through the feeding pipes in sequence from left to right and extends out of the rightmost feeding pipe. Each feeding pipe is divided by the inserting plate into upper and lower independent spaces. The inserting plates are in sliding fit with each feeding pipe. The right end of the inserting plate is provided with a gear and rack mechanism capable of driving the inserting plate to do rectilinear motion. According to the sliding box feeding type mixing tank, the technical problem that a feeding sequence is likely to be mistaken during emulsion paint preparation at present is solved.

Owner:CHONGQING BAIQIJU MATERIALS

Graphite raw material mixing device for lithium battery production

InactiveCN108772016AImprove mixing efficiencyImprove the mixing effectRotating receptacle mixersTransportation and packagingLaser transmitterEngineering

The invention discloses a graphite raw material mixing device for lithium battery production, the graphite raw material mixing device comprises a mixing tank, the top of the mixing tank is provided with a feeding port, a mixing drum is arranged below the feeding port, driven gears are disposed at both ends of the outer sidewall of the mixing drum, a feeding zone is disposed between the driven gears at the both ends, one side of the feeding zone is provided with a circular through hole, one side of the circular through hole is provided with a cover plate, the other side of the circular throughhole is embedded with a laser emitter, the bottom end of the cover plate is provided with a rotating rod, one end of the rotating rod is connected to an output shaft of a rotating electrical machine,and the rotating electrical machine is disposed inside the side wall of the mixing drum, the upper ends of the driven gears at the two ends of the mixing drum are provided with driving gears, and oneside of each driving gear is connected with a first rotating shaft, and one end of the first rotating shaft passes through one side of the mixing tank, and is connected with a first drive motor.

Owner:熊冠

Waste rubber desulfurization and plasticization processing device and process

InactiveCN111763348AAvoid depositionImprove processing efficiencyPlastic recyclingStationary filtering element filtersImpellerCoupling

The invention discloses a waste rubber desulfurization and plasticization processing device and process, and relates to the technical field of waste rubber processing. The desulfurization effect is improved. The processing device specifically comprises an inner cylinder and an outer cylinder, the inner wall of the top of the outer cylinder is welded to the side wall of the top of the inner cylinder, the outer wall of one side of the outer cylinder is connected into a steam system through a steam conveying pipe, and the inner cylinder is filled with water. A stirring motor is fixed to the outerwall of the top of the inner cylinder through screws, and the output end of the stirring motor is rotationally connected with a rotating main shaft through a shaft coupling. The processing process comprises the following steps: taking out defiberized rubber powder, and mixing the defiberized rubber powder with a regenerant in proportion; and adding water into the inner cylinder, and introducing steam into the outer cylinder. By arranging the inner cylinder, the outer cylinder and other structures, rubber powder can be subjected to desulfurization treatment through a water-oil method, the stirring motor works to drive an impeller to rotate, water in the inner cylinder is lifted and stirred, and the rubber powder is effectively prevented from being deposited at the bottom of the inner cylinder.

Owner:安徽中宏橡塑有限公司

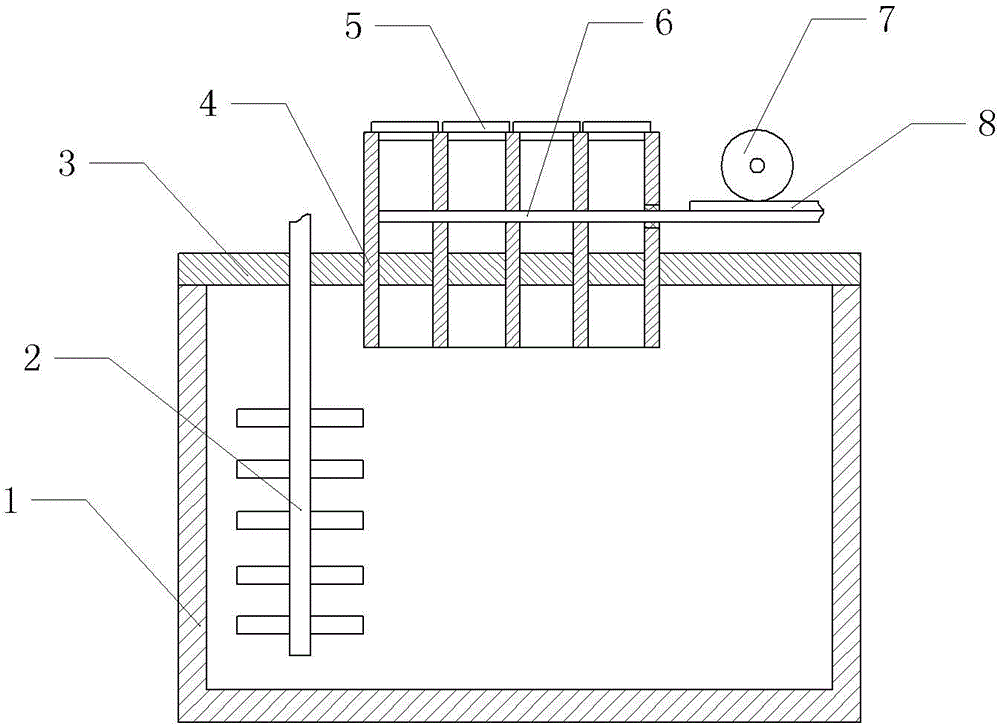

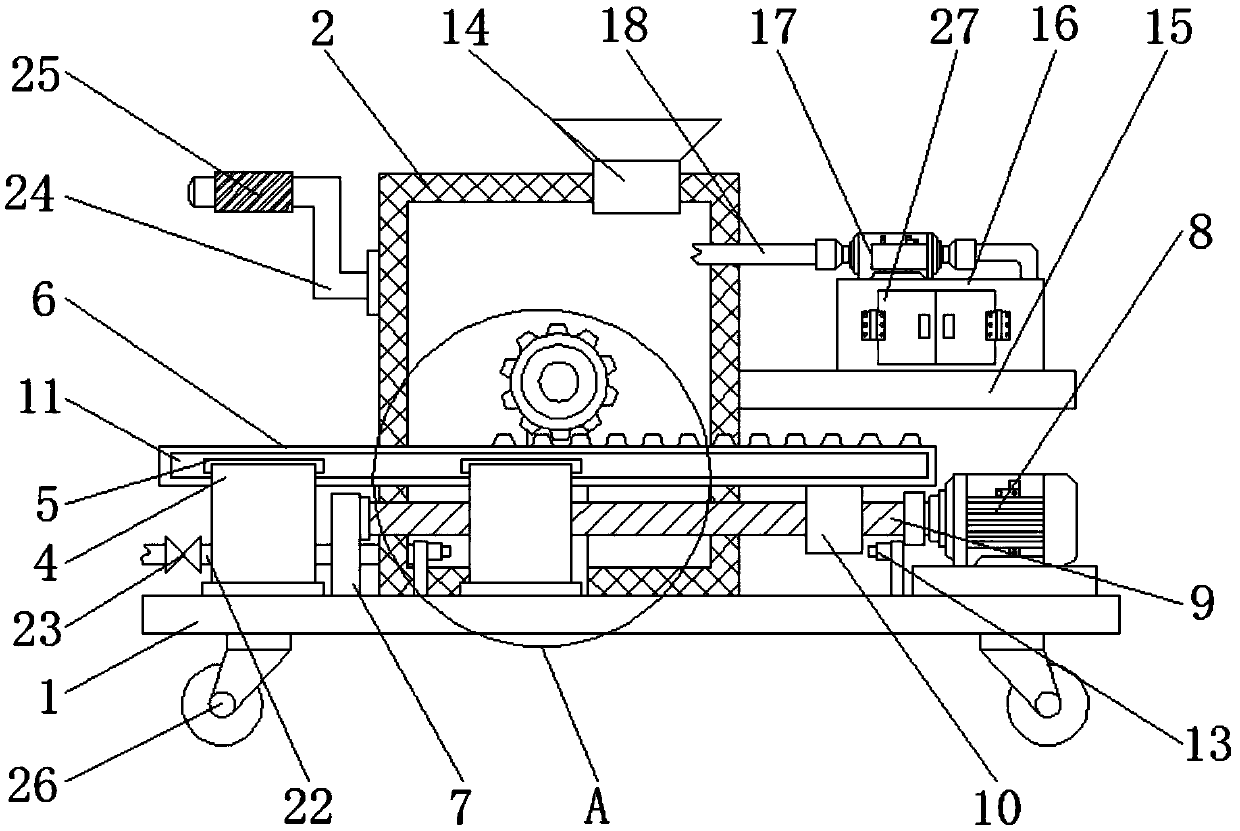

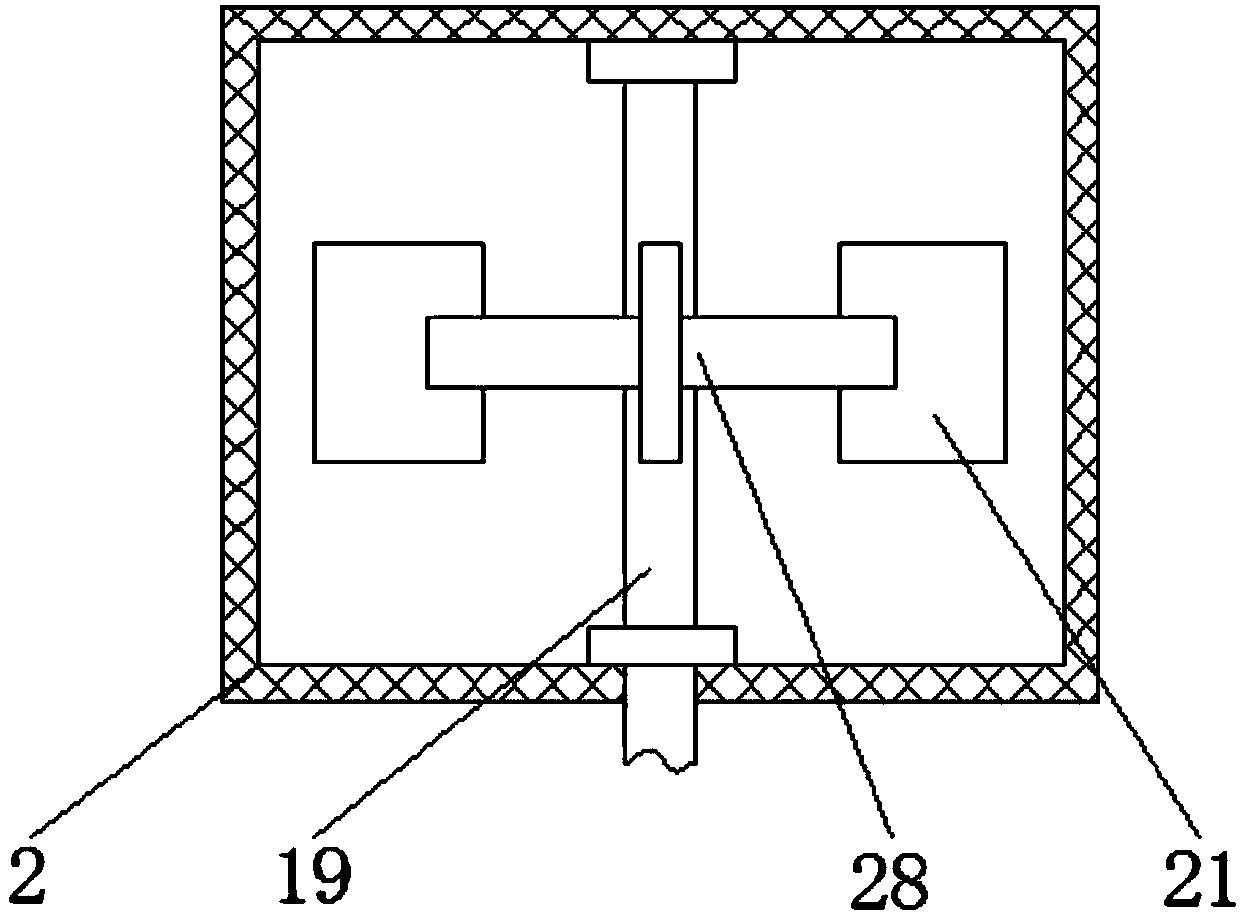

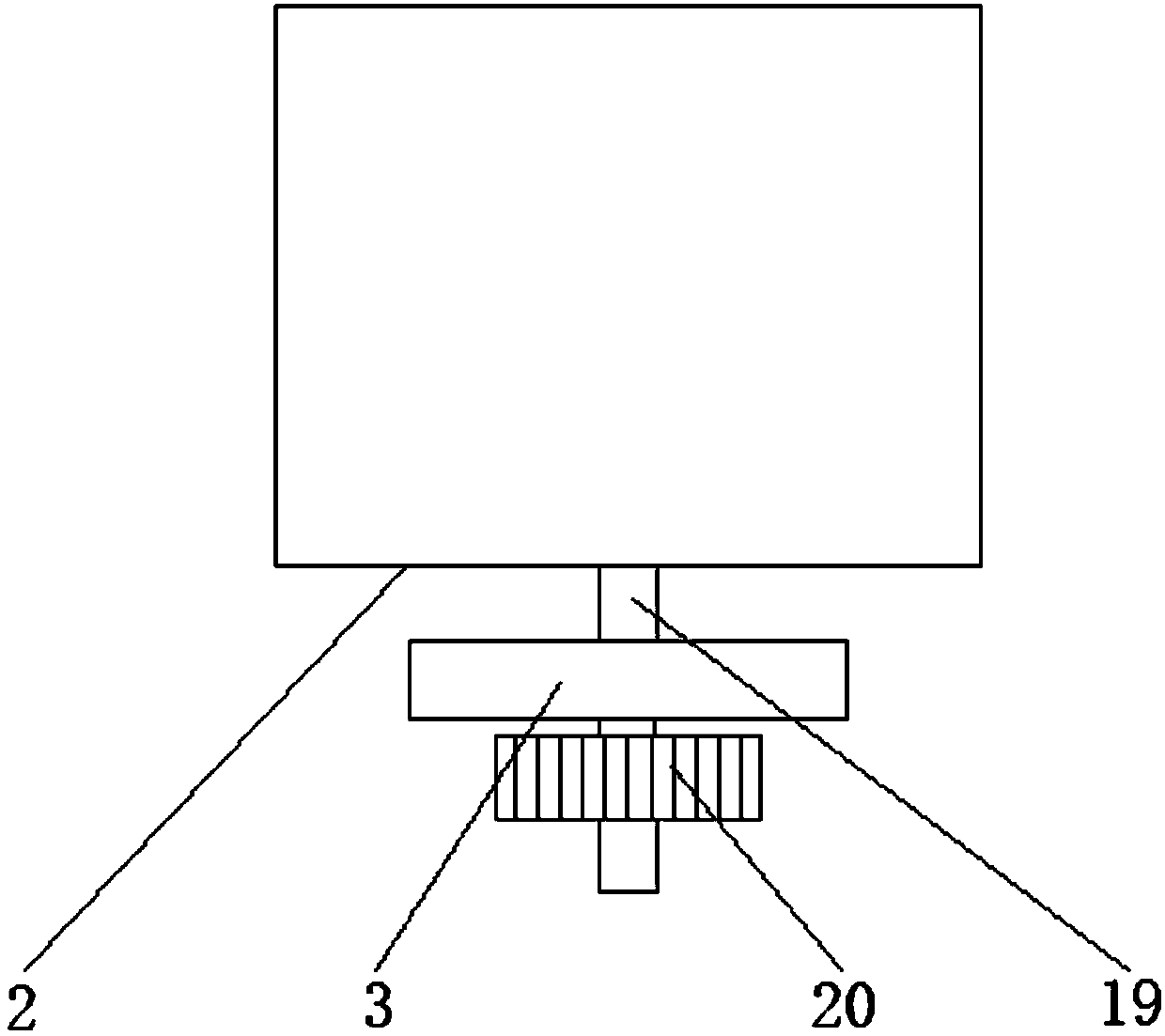

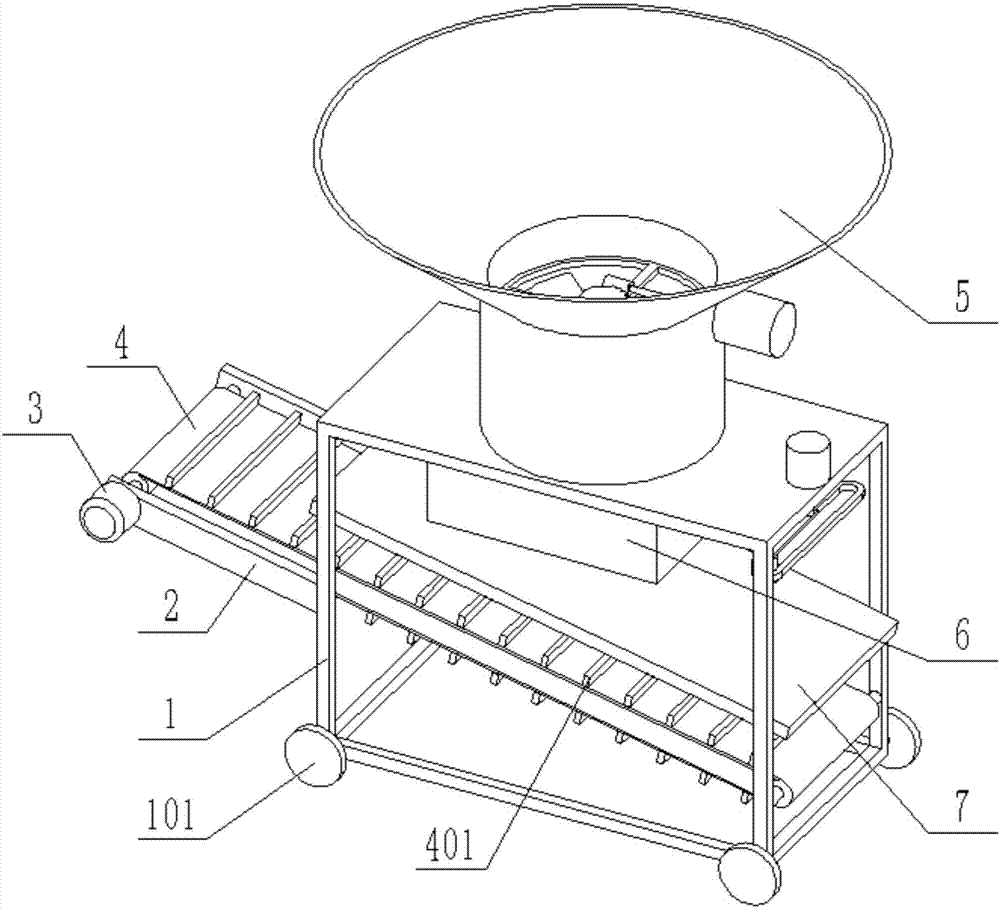

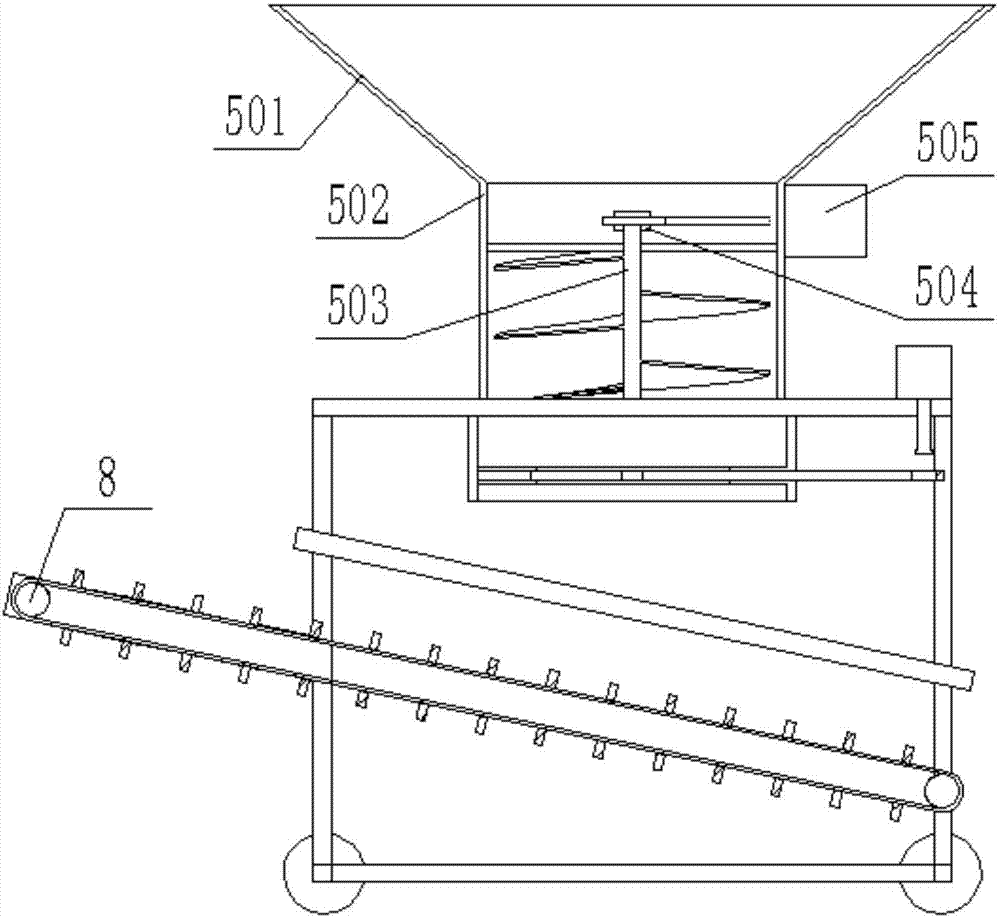

Agricultural waste utilization feed processing equipment

InactiveCN107812463APromote stirringShorten the timeFeeding-stuffRotary stirring mixersFeed processingAgricultural engineering

The invention discloses agricultural waste utilization feed processing equipment, which comprises a base plate. A box is fixedly connected at the top of the base plate. A support plate is fixedly connected at the right side of the box and at the top of the base plate, and support blocks are fixedly connected at the right side of the support plate and at the top of the base plate. A slide block isfixedly connected at the back side of the support block. The external surface of the slide block is slidingly connected to a movable rack. A vertical plate is fixedly connected between the two supportblocks and at the top of the base plate. The invention relates to the technical field of feed processing equipment. By the agricultural waste utilization feed processing equipment, stirring during the agricultural waste utilization feed processing can be realized, and stirring is very fast and complete. Thus, time is saved, and processing efficiency of processing workers is raised. In addition, stirring is very complete and feeds are processed better. Agricultural wastes can be greatly utilized, thus saving resources.

Owner:赖泽江

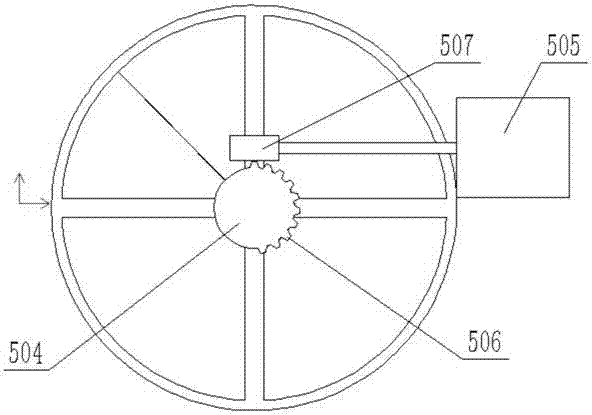

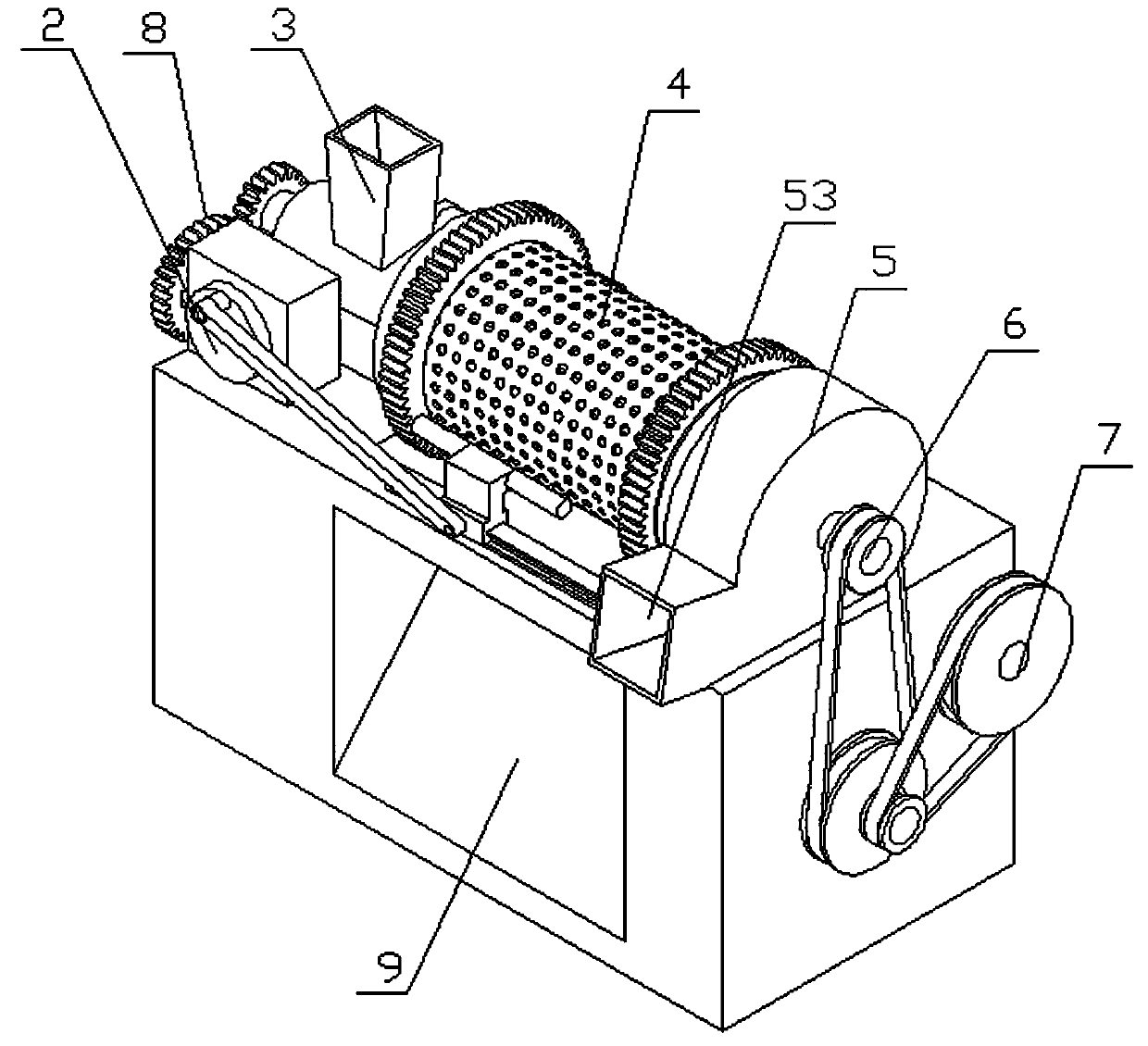

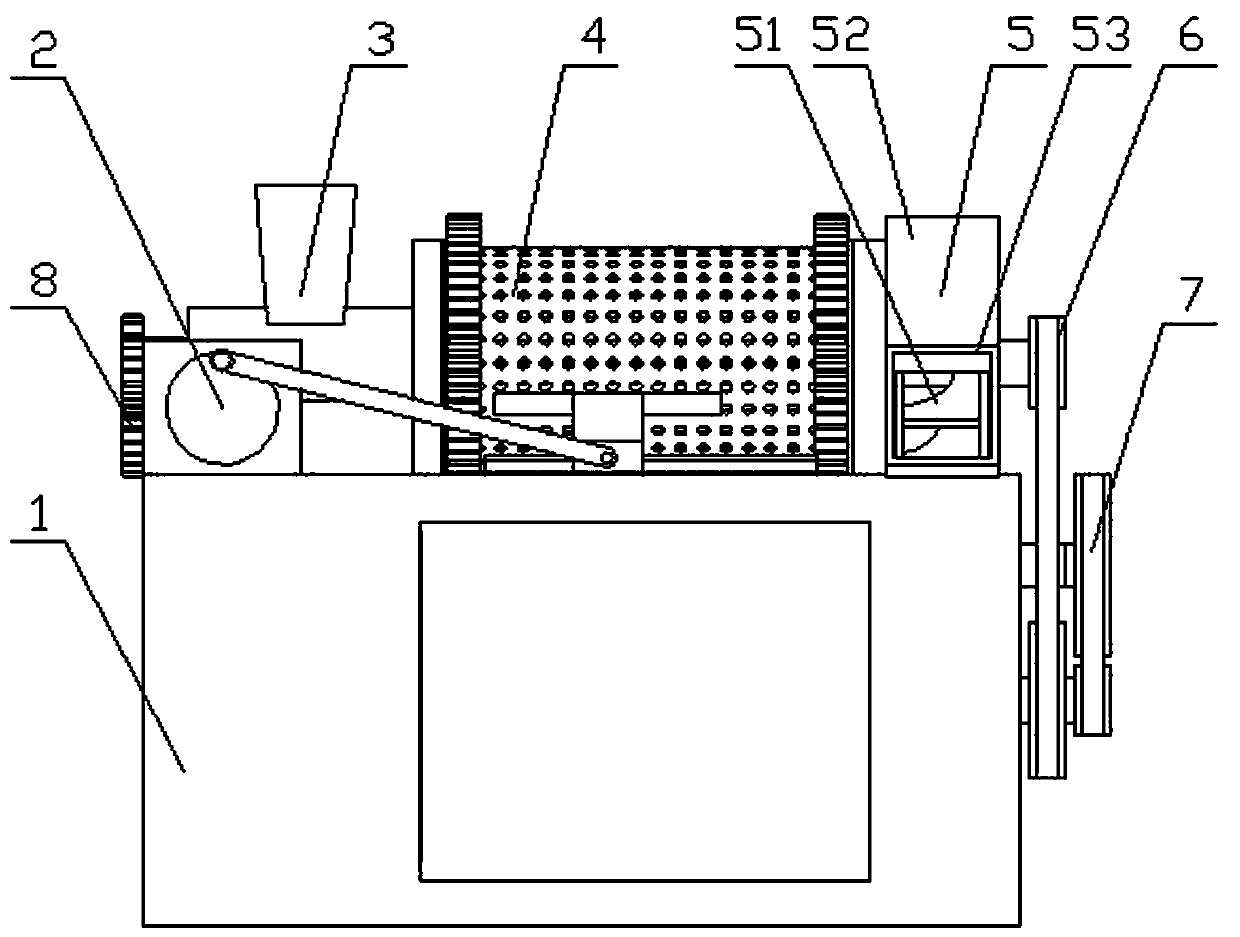

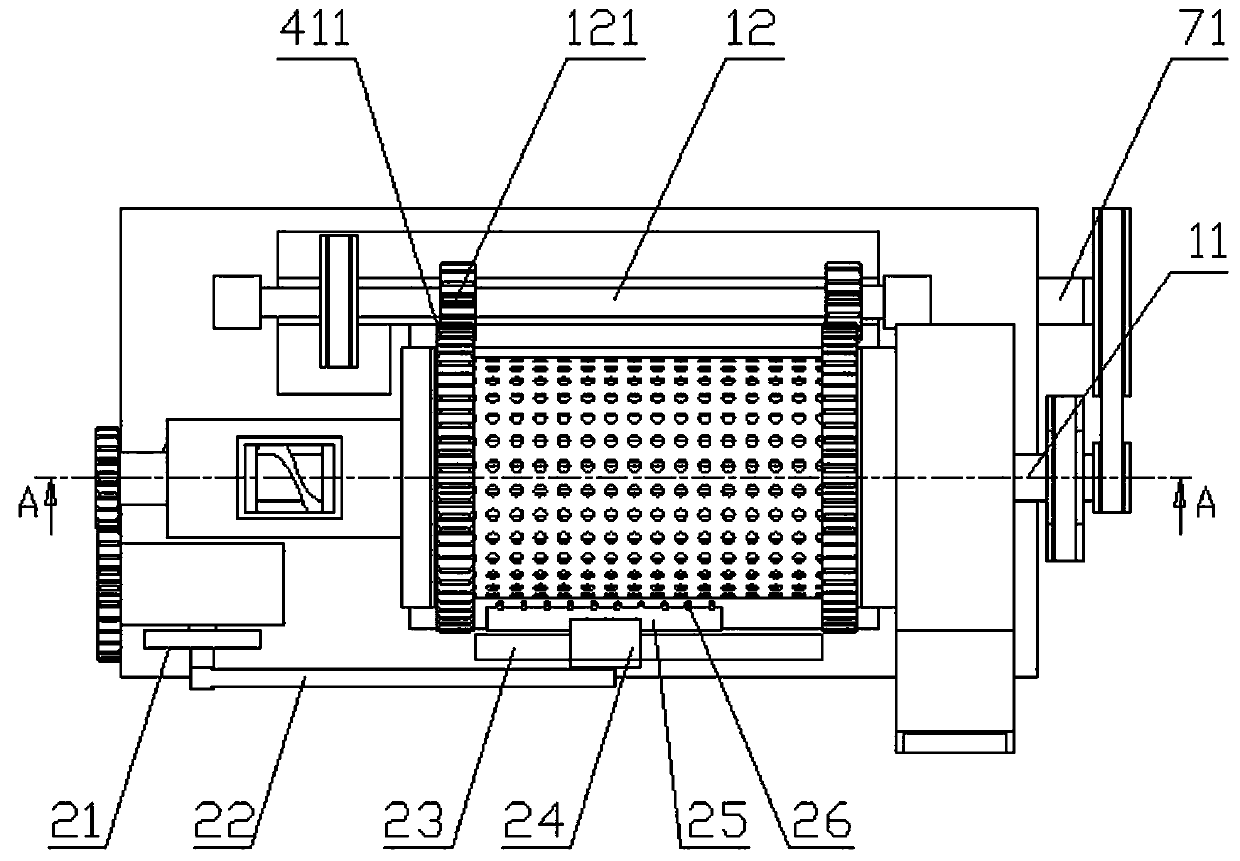

Sand screening machine used for construction

PendingCN107470135AAvoid affecting the sand screening effectFeed realizationSievingScreeningMotor driveScreening effect

The invention discloses a sand screening machine used for construction. The sand screening machine used for construction comprises a machine frame. A feeding device is mounted at the upper end of the machine frame, and a uniformizing device is arranged below the feeding device. A vibrating screen is mounted in the machine frame. A supporting frame is mounted on one side of the machine frame. A conveying motor is mounted on one side of the supporting frame. Conveying shafts are mounted in the machine frame and the supporting frame correspondingly and wrapped with a conveying belt. The sand screening machine used for construction has the beneficial effects that a feeding motor operates, a worm is matched with transmission teeth on the outer side of a driven wheel so as to transmit power, a feeding screw is driven to rotate, then intermittent and quantitative feeding is achieved, and the situation that the sand screening effect is affected due to the fact that the feeding quantity is too large is prevented; a uniformizing motor drives a sliding column to rotate through a rotating rod, the sliding column is made to slide in a sliding groove rod, then the sliding groove rod drives a feeding plate to slide in a feeding partition plate through a uniformizing sliding rod, the relative positions of a uniformizing through hole and a feeding through hole are changed accordingly, sand can evenly distributed on the surface of the vibrating screen, and the sand screening efficiency can be improved easily.

Owner:绍兴意诺贸易有限公司

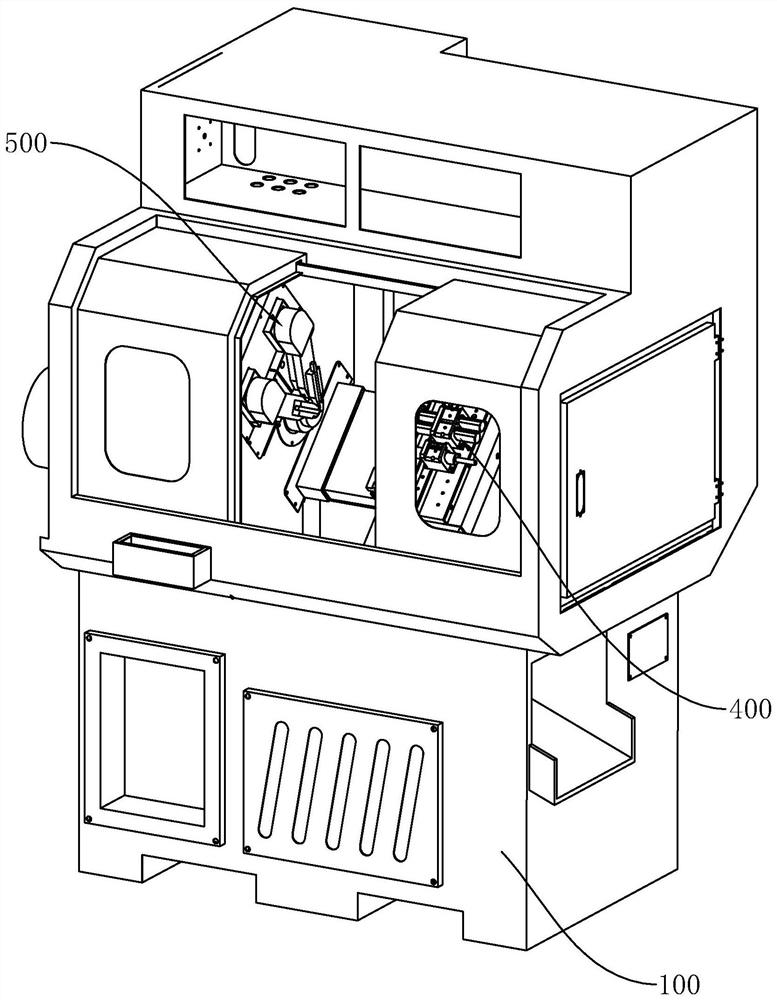

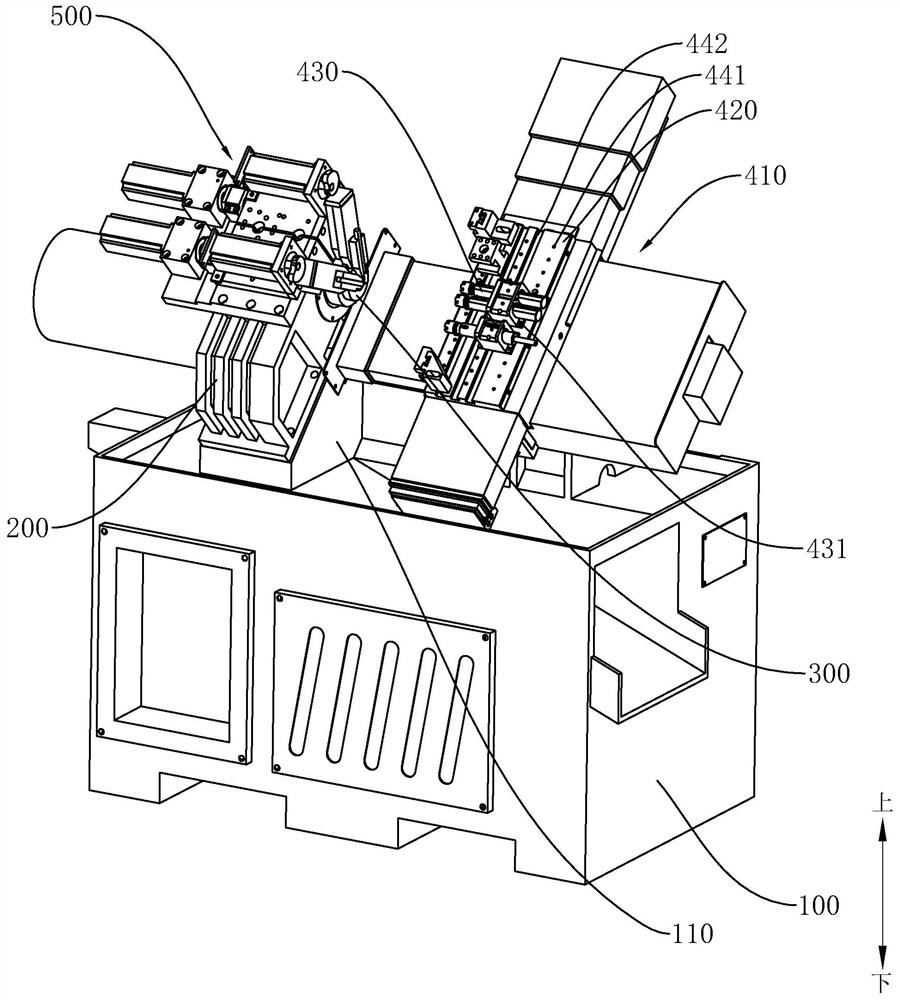

Multi-axis lathe

PendingCN111957988AFeed realizationImprove work efficiencyLarge fixed membersTurning machinesControl engineeringMachine

The invention discloses a multi-axis lathe. The multi-axis lathe comprises a machine seat, a spindle mechanism, a main feed tool mechanism and at least one auxiliary feed tool mechanism. Each auxiliary feed tool mechanism comprises an X-axis drive mechanism, a Z-axis drive mechanism, a tool apron and a sliding table, wherein the sliding table comprises a bottom plate slidingly arranged on the sideface of a spindle seat and a feed plate, an included angle is formed between the bottom plate and the feed plate, the feed plate stretches towards a clamping jaw assembly along the end face of the spindle seat from the side face of the spindle seat, the tool apron is slidingly arranged on the feed plate, the X-axis drive mechanism is arranged on the sliding table and can drive the tool apron to move in the radial direction of the clamping jaw assembly, and the Z-axis drive mechanism is arranged on the spindle seat and can drive the sliding table to move in the axial direction of the clampingjaw assembly. Through the arrangement of the auxiliary feed tool mechanisms, the lathe can carry out multi-axis machining, the production efficiency is improved, through the reasonable arrangement ofthe sliding tables, the auxiliary feed tool mechanisms can achieve X-axis and Z-axis feed, the use flexibility is high, and the application range is wide.

Owner:中山市中台精密数控车床有限公司

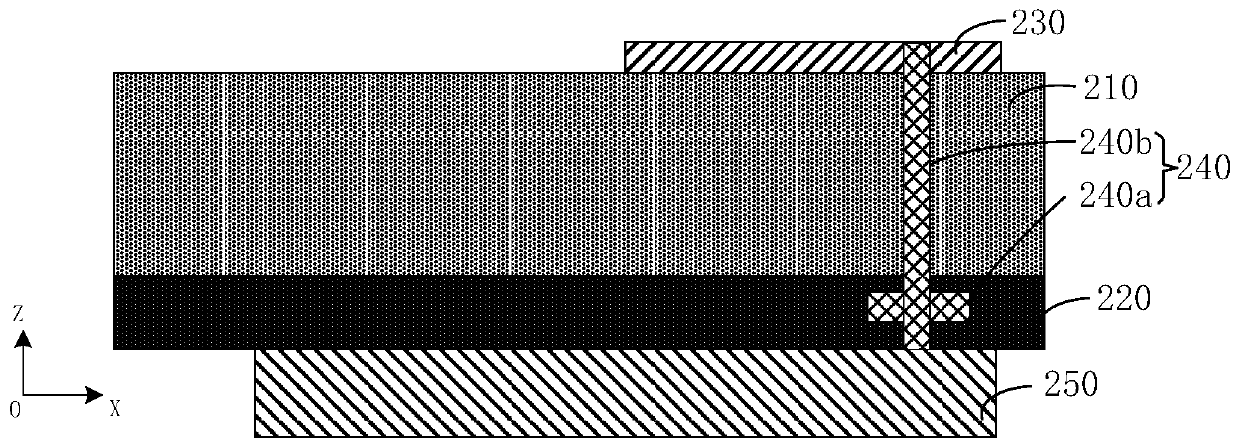

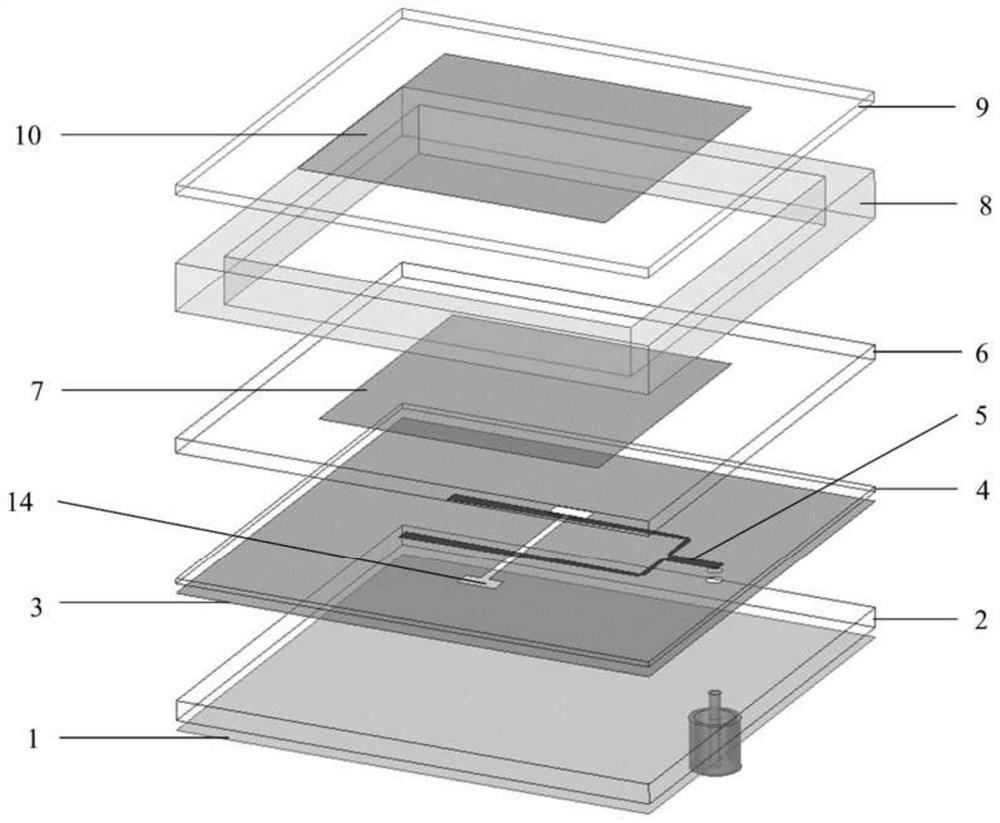

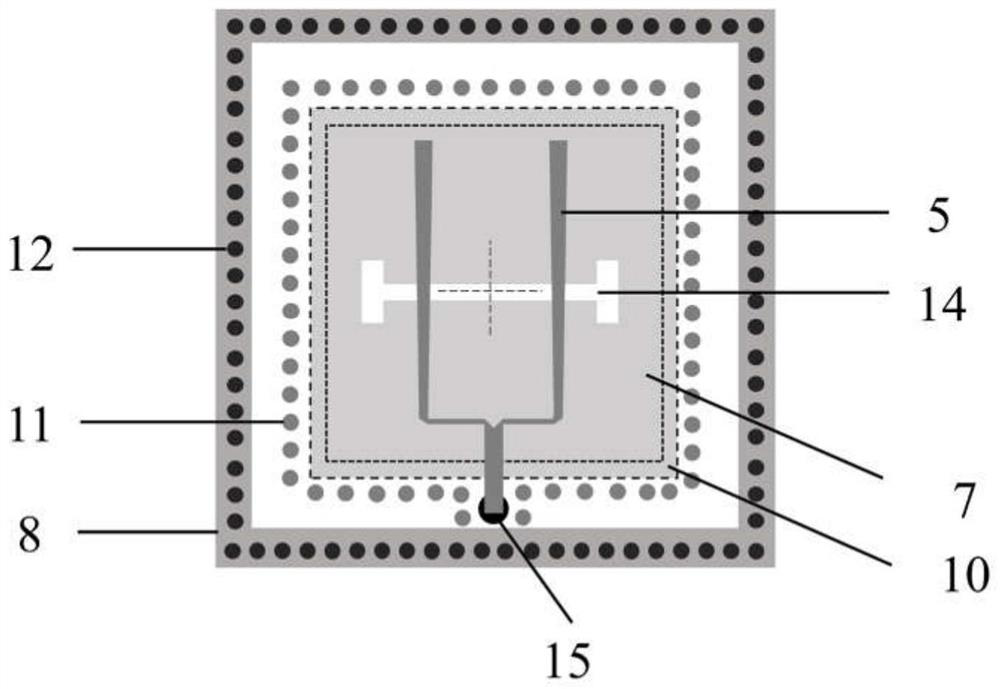

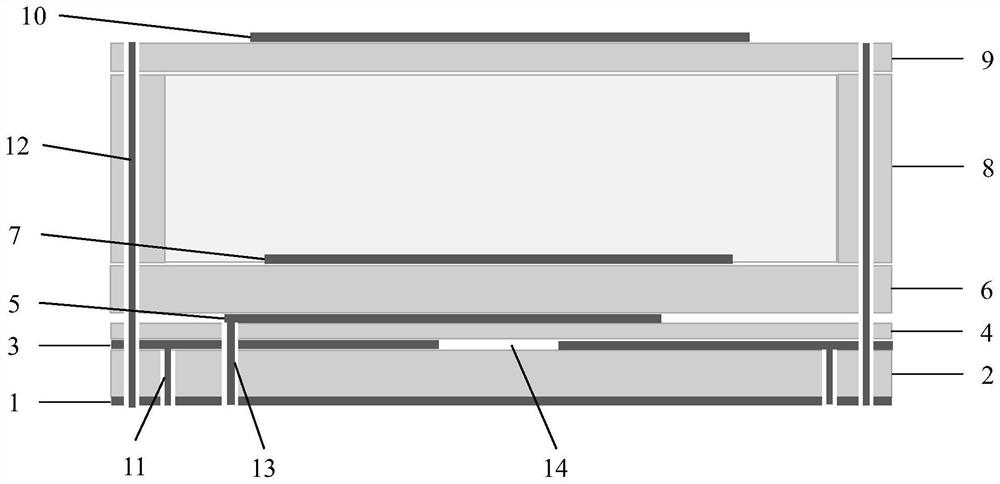

Broadband low cross polarization microstrip patch phased-array antenna unit

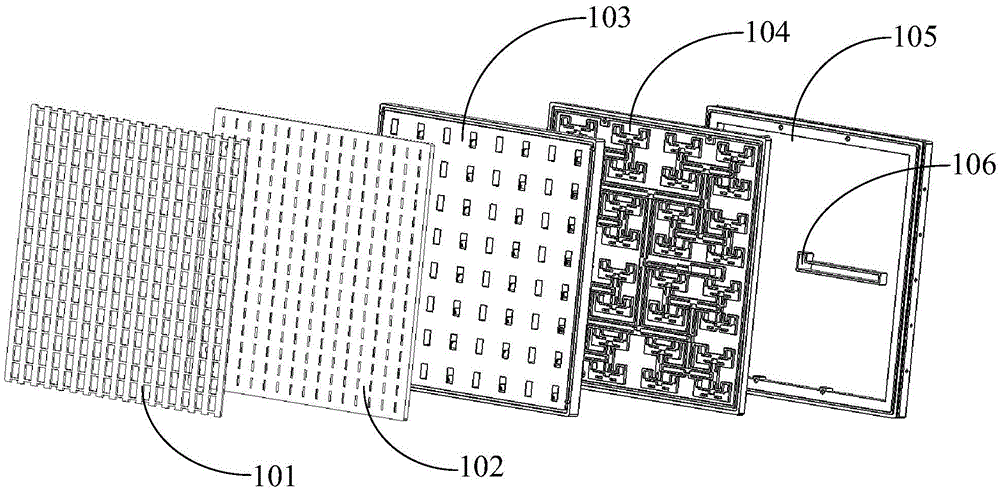

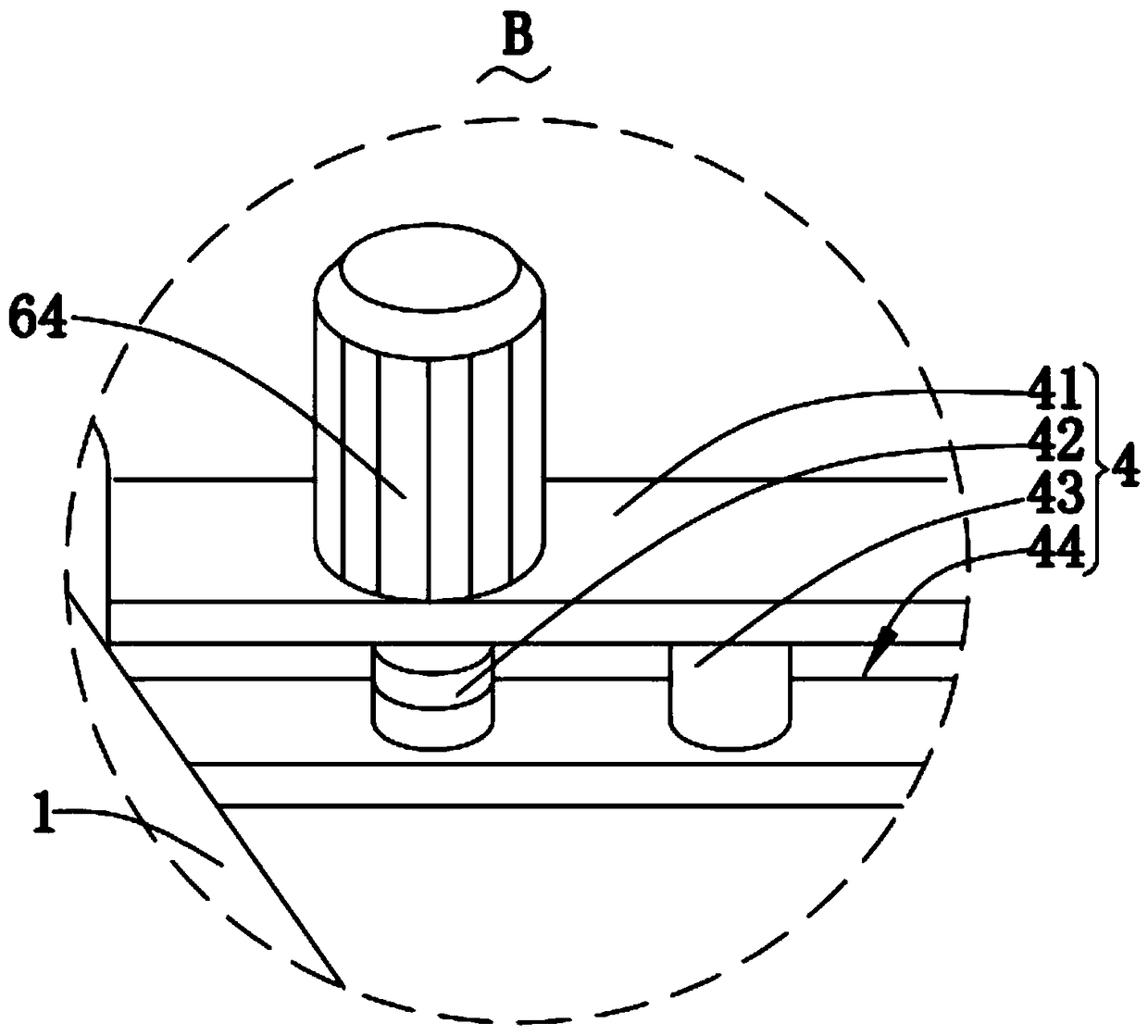

PendingCN114784512ALow cross polarizationFeed realizationDisturbance protectionIndividually energised antenna arraysMicrowaveDielectric substrate

The invention discloses a broadband low cross polarization microstrip patch phased-array antenna unit, and belongs to the technical field of microwave antennas. The antenna unit is composed of five layers of dielectric substrates, and the reflection floor is laid on the lower surface of the first dielectric substrate. The slot floor is laid on the lower surface of the second dielectric substrate, the feed microstrip line conduction band is laid on the upper surface of the second dielectric substrate, the square driving patch is laid on the upper surface of the third dielectric substrate, the square parasitic patch is laid on the upper surface of the fifth dielectric substrate, and the central area of the fourth dielectric substrate is hollowed out. The first support is used for supporting the fifth dielectric substrate; metal blind holes are formed in the periphery of the first dielectric substrate and used for connecting the reflection floor and the slot floor to form a closed metal cavity, metal through holes are designed in the periphery of the antenna unit to penetrate through all the dielectric substrates, and equivalent metal walls are formed around patches to block propagation of surface waves. According to the invention, the broadband, low-cross-polarization and wide-scanning-angle microstrip patch phased-array antenna unit with a multilayer structure can be obtained.

Owner:中国人民解放军63660部队

A device for slicing astragalus

ActiveCN111873006BAchieve automatic feedingUniform thicknessMetal working apparatusAnimal scienceMedicine

The invention relates to a slicing device, in particular to an astragalus slicing device. The technical problem to be solved is to provide an automatic feeding device for astragalus slicing with uniform slice thickness. The technical solution is: an astragalus slicing device, comprising: a base, a first support column is arranged on one side of the base; a workbench, a workbench is arranged on the first support column; Sieve; spacer, a spacer is provided on the side of the workbench away from the collection sieve; a slicing mechanism, a slicing mechanism is provided on the side of the workbench close to the collection sieve; a feeding mechanism, a feeding mechanism is provided on the workbench, and the feeding mechanism is located in the slicing mechanism between the pads. The invention achieves the effect of automatic feeding and uniform slice thickness.

Owner:岷县归芪堂药业有限公司

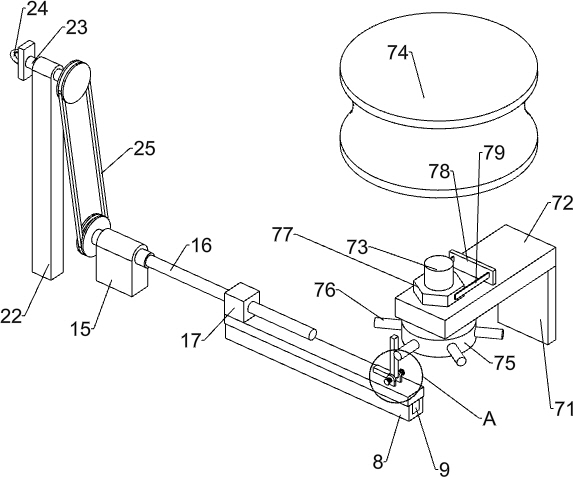

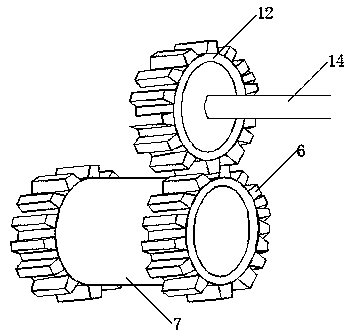

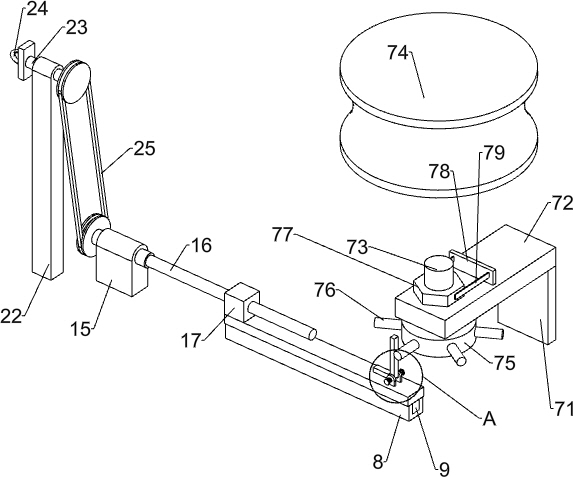

Automatic wire feeding device for micro electrical discharge machining

InactiveCN103785908AImprove economyImprove processing efficiencyElectrical-based machining electrodesMachine controlControl system

The invention discloses an automatic wire feeding device for micro electrical discharge machining. The automatic wire feeding device for micro electrical discharge machining is used for machining an electrode wire for micro electrical discharge machining. According to the automatic wire feeding device for micro electrical discharge machining, a wire-electrode cutting wire can be used as a tool electrode for micro electrical discharge machining, cost of micro electrical discharge machining is lowered, and machining efficiency is improved. Firstly, a user winds the electrode wire with a certain diameter around a wire reel, and the electrode wire reaches a conductive wheel through wire rectifying wheels, penetrates through a feeding system and a wire guide nozzle, and extends by a certain distance. The conductive wheel is connected with a micro electrical discharge machining power source to achieve conduction from the power source to the electrode wire. Switching-on and switching-off of the power source and feeding and retracting of the electrode wire are controlled a micro electrical discharge machining control system so as to achieve micro electrical discharge machining.

Owner:HEFEI UNIV OF TECH

Stripping machine for gleditsia sinensis seed husks

ActiveCN110313621AImprove stripping efficiencyAvoid strandedHuskingHullingMechanical engineeringGleditsia sinensis

The invention discloses a stripping machine for gleditsia sinensis seed husks. The stripping machine comprises a mounting table, a main rotation shaft is arranged on a horizontal rack of the upper endof the mounting table, and a feeding mechanism, a stripping mechanism and a discharging mechanism are axially installed on the main rotation shaft in sequence and communicated with one another; the stripping mechanism comprises a rotation brush installed on the main rotation shaft, a rotation cylinder sleeves the exterior of the rotation brush, and multiple residue discharging holes are formed inthe rotation cylinder; a gleditsia sinensis seed husk stripping area is formed between the rotation cylinder and the rotation brush, and a reverse driving mechanism is connected to the rotation cylinder and drives the rotation cylinder, so that the rotation direction of the rotation cylinder is opposite to that of the rotation brush. According to the stripping machine, by arranging the feeding mechanism, the stripping mechanism and the discharging mechanism, feeding, stripping and outputting of gleditsia sinensis grains are achieved, the stripping machine is driven by a motor, the gleditsia sinensis seed husks are mechanically stripped from the gleditsia sinensis grains, and compared with existing manual stripping, the efficiency of stripping the gleditsia sinensis seed husks from the gleditsia sinensis grains is greatly improved.

Owner:河南省林业科学研究院

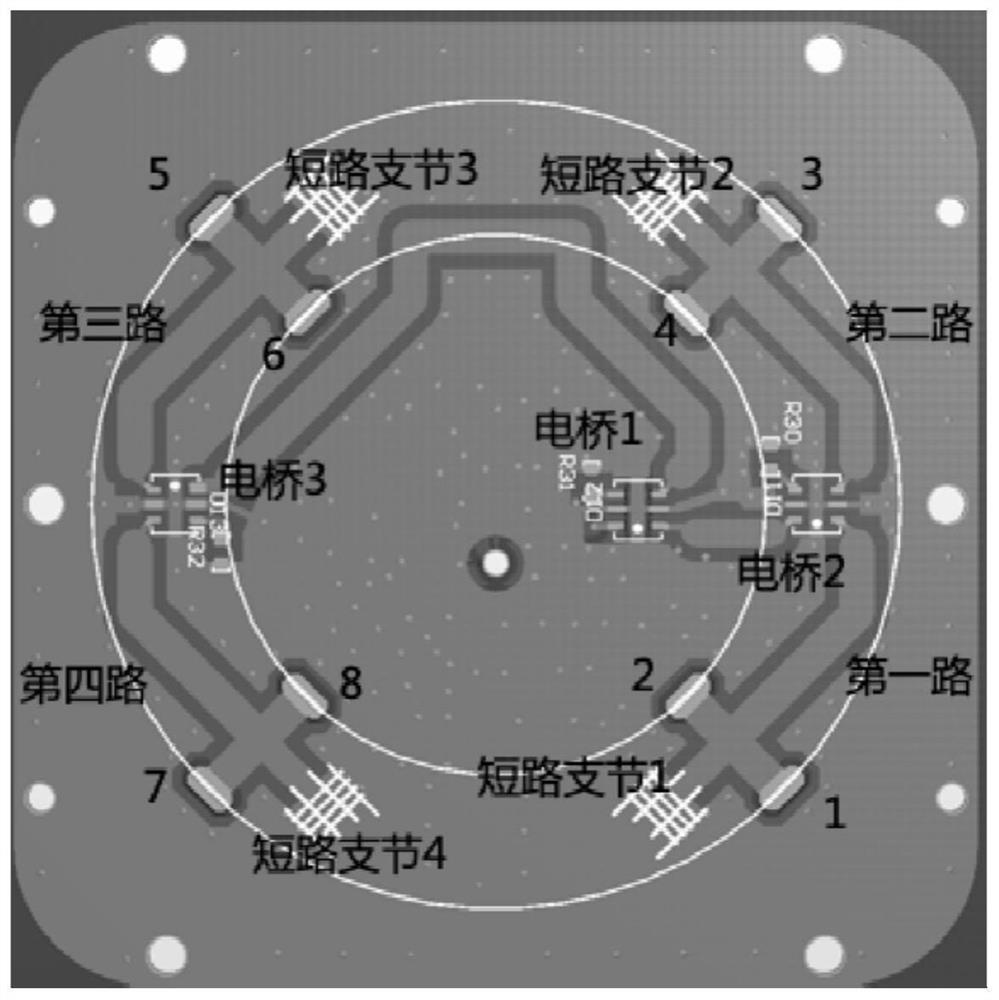

Eight-arm spiral double-frequency circularly polarized antenna

PendingCN114094315AHigh gainExcellent dual frequency circular polarization performanceRadiating elements structural formsCircularly polarized antennaControl engineering

The invention relates to the field of antennas, and discloses an eight-arm spiral double-frequency circularly polarized antenna. The eight-arm spiral double-frequency circularly polarized antenna comprises four low-frequency antenna arms and four high-frequency antenna arms which are mutually independent, and a feed network on a PCB (Printed Circuit Board); the feed network realizes a one-to-four feed network through three bridges and microstrip lines, and four paths of feed output meet the requirements that the amplitude is equal, and the phase is anticlockwise and sequentially lagged by 90 degrees; the tail end of each feed microstrip line comprises a low-frequency feed point, a high-frequency feed point and a short-circuit branch; the four low-frequency antenna arms are respectively connected with the four low-frequency feeding points, and the four high-frequency antenna arms are respectively connected with the four high-frequency feeding points. Through the two groups of independent four-arm spiral antennas and only one feed network, the PCB not only provides a feed function, but also serves as the ground of the antenna, so that the antenna gain is improved while the excellent dual-frequency circular polarization performance is obtained, and meanwhile, the implementation cost is lower.

Owner:QIANXUN SPATIAL INTELLIGENCE INC

Diamond double-side brush-washing machine

The invention discloses a diamond double-side brush-washing machine. The diamond double-side brush-washing machine comprises a protective cover and a worktable mounted in the protective cover, as well as a feeding device, a plurality of sets of double-side brushing devices and a discharging device which are sequentially arranged from one end of the worktable to the other end, wherein pick-up devices are arranged between the feeding device and the double-side brushing devices, between every two adjacent sets of the double-side brushing devices, and between the double-side brushing devices and the discharging device; and limiting components are further arranged at the positions corresponding to the double-side brushing devices. According to the diamond double-side brush-washing machine, the double-side brushing devices are adopted to clean the upper sides and the lower sides of sapphire substrates, the process is simple and the operation is convenient; the pick-up devices are utilized to reduce the scratch probability of the sapphire substrates, so that the yield of the sapphire substrates is improved; and the limiting components are adopted to control the cleaning time of the sapphire substrates on the double-side brushing devices according to actual demands so as to guarantee the cleaning effect of the sapphire substrates.

Owner:苏州辰轩光电科技有限公司

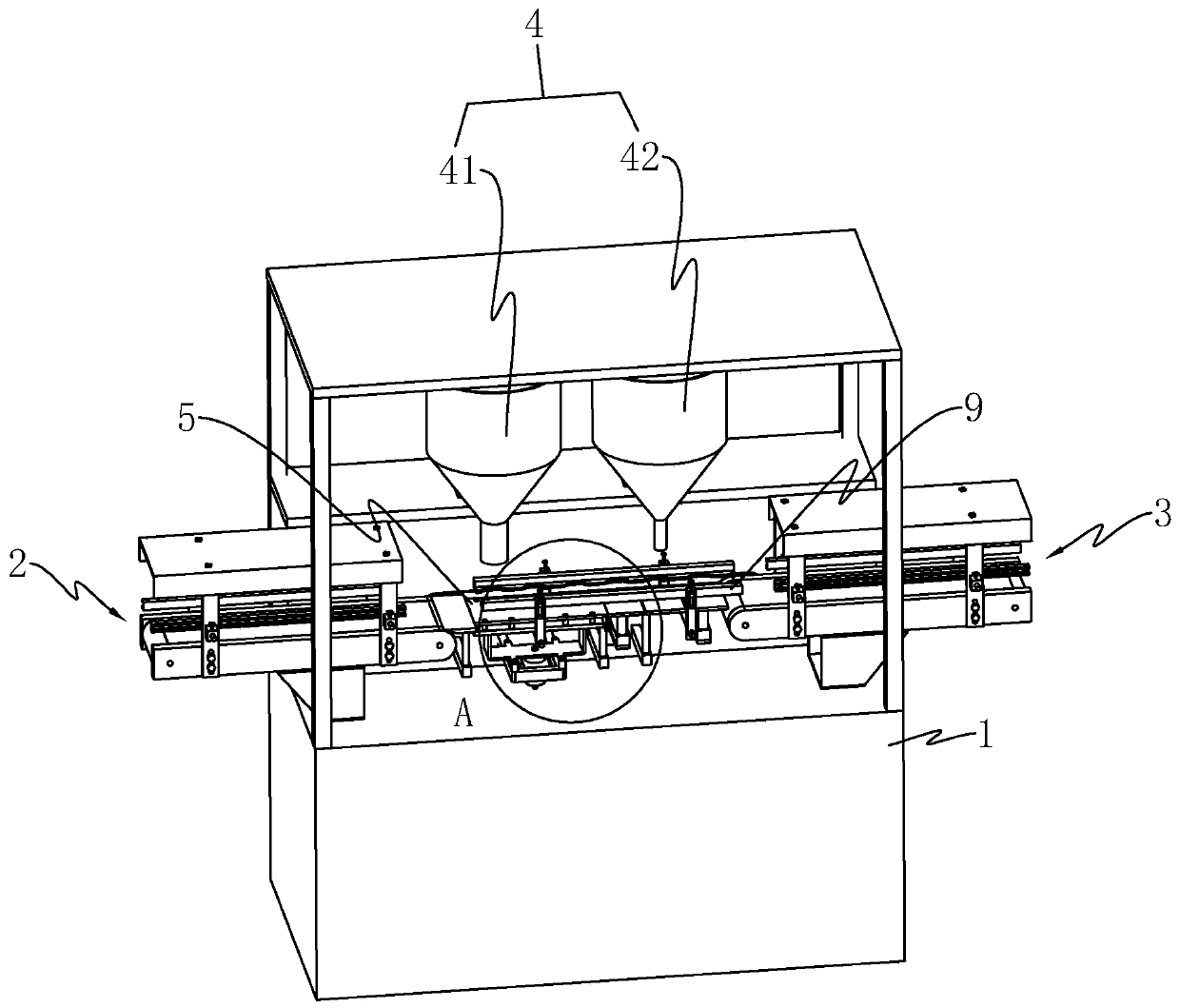

a filling machine

ActiveCN108382657BAvoid interferenceGuaranteed fillingLiquid materialMechanical equipmentEngineering

The invention discloses a filling machine and belongs to the field of packaging mechanical equipment. The filling machine comprises a rack, a hopper, a conveyor belt group and a weighing device; the conveyor belt group comprises a front conveyor belt and a back conveyor belt; a supporting plate is erected between the front conveyor belt and the back conveyor belt; clamping plates are arranged on the two sides of the supporting plate in a width direction respectively; the rack is provided with a clamping power component and a feeding power component; the clamping power component comprises a moving bracket, a rotation bracket, a first transmission rod, a second transmission rod and a clamping cylinder; the feeding power component comprises a linkage frame, a supporting frame and a feeding cylinder; the hopper comprises a first hopper and a second hopper; and the first hopper and the second hopper are arranged in a length direction of the supporting plate at an interval. The invention provides the filling machine which is fully automatic and is stable in work, convenient and rapid to operate and very high in both filling efficiency and filling accuracy of a product.

Owner:上海达和荣艺包装机械有限公司

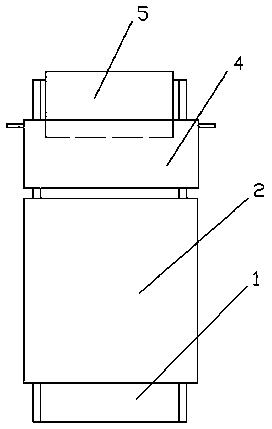

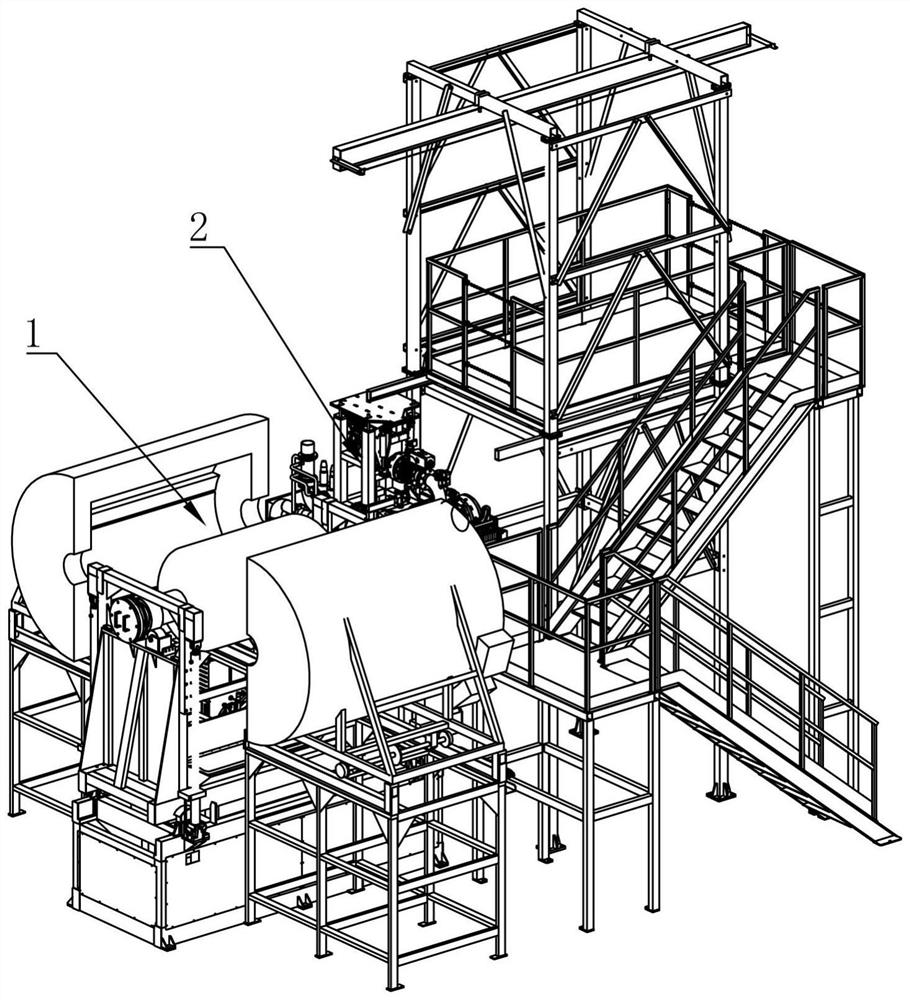

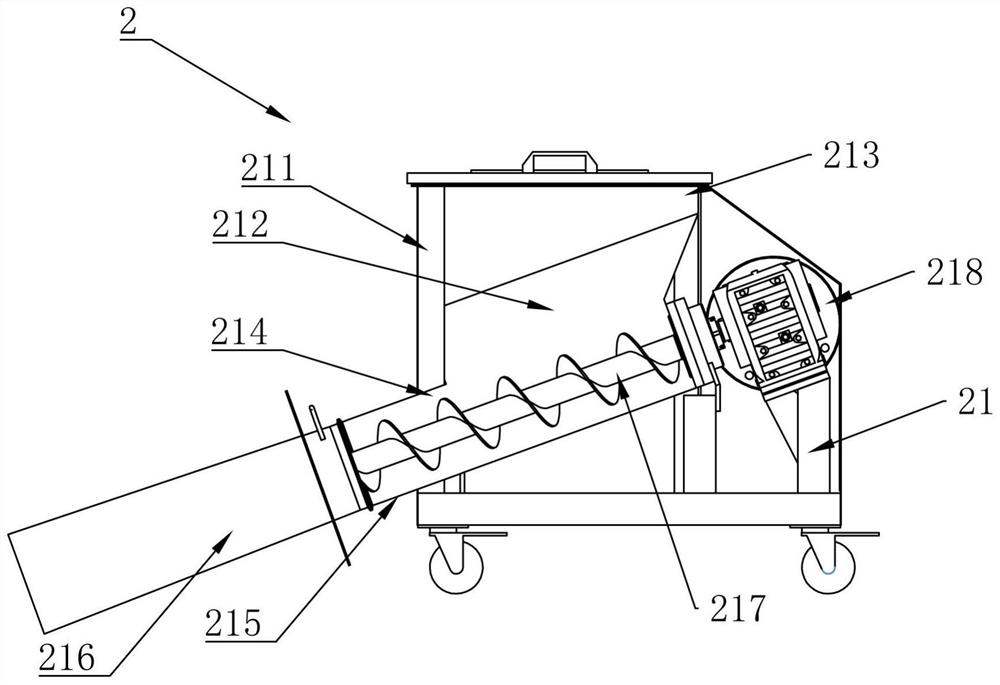

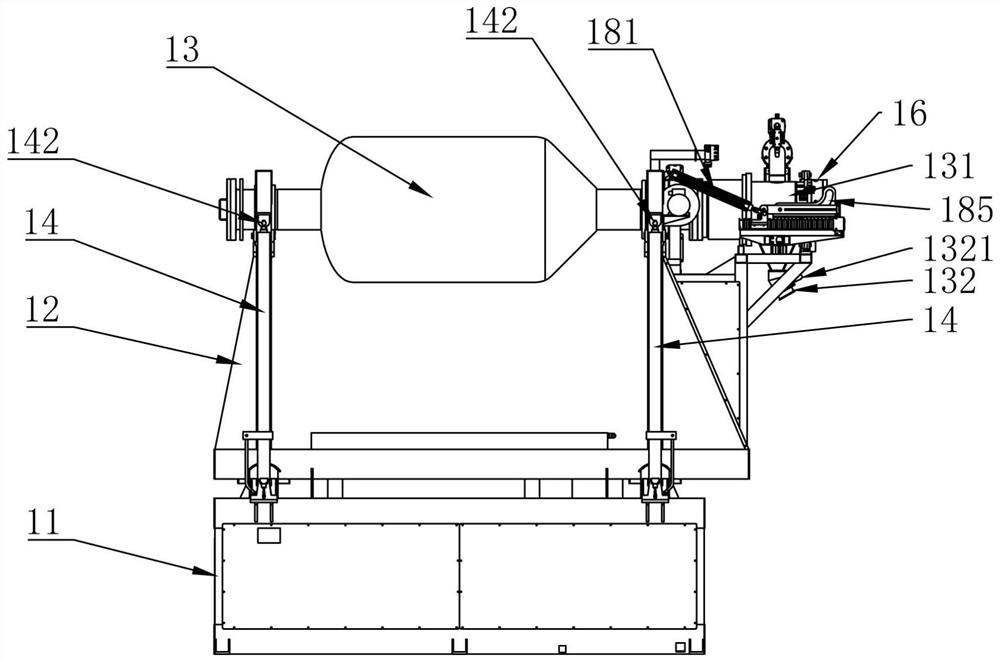

NdFeB hydrogen decrepitation furnace

PendingCN113618070AReduce volumeSave spaceProcess efficiency improvementStructural engineeringManufacturing engineering

The invention discloses an NdFeB hydrogen decrepitation furnace which comprises a main machine, a feeding device and a vacuum system which are arranged in a matched mode, wherein the main machine comprises a base, a first rack and a barrel, the two ends of the first rack are movably connected with the base through jacking oil cylinders, the barrel is provided with a feeding port, a discharging port and a main pipeline connector, and the feeding port and the discharging port are located at the same end of the barrel; a feeding end cover is movably arranged on the first rack, a first locking flange assembly is movably arranged on the feeding port, and the feeding end cover is matched with the first locking flange assembly in an inserted mode; and the vacuum system comprises a second rack and a main pipeline movably arranged on the second rack, a second locking flange assembly is arranged at the end of the main pipeline, a connecting flange is arranged on a connector of the main pipeline, and the connecting flange is matched with the second locking flange assembly in an inserted mode. The NdFeB hydrogen decrepitation furnace is simple and reasonable in structure, convenient to operate, capable of effectively saving the space needed by installation, beneficial to improving the product quality and reducing the labor intensity of workers, and higher in reliability.

Owner:BAIQIDA INTELLIGENT TECH NINGBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com