Automatic-feeding pipe fitting flaw detection device

A flaw detection, automatic feeding technology, applied in the direction of analyzing materials, instruments, etc., can solve problems such as hidden dangers of personnel and peripheral equipment safety, processing efficiency and safety discounts, and increased probability of safety accidents, so as to improve the safety of use and the Reliability, the effect of reducing human involvement, and reducing the frequency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

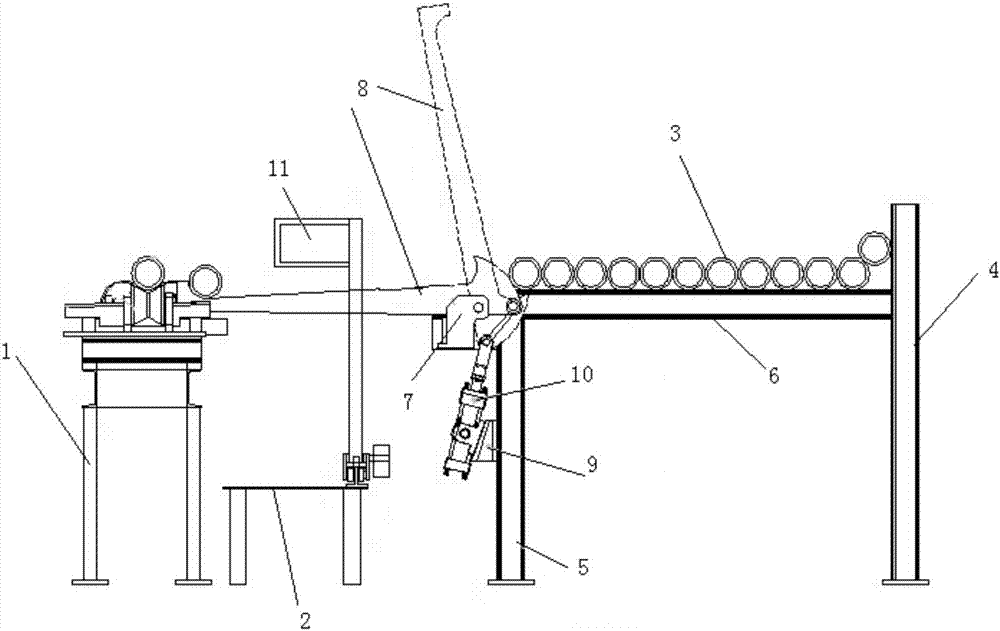

[0023] like figure 1 As shown, a pipe fitting flaw detection device with automatic feeding, the device includes a detection installation frame 1, a detection work frame 2, a detector, a storage rack and an automatic feeding unit, and the detection work frame 2 is arranged on the detection installation frame 1 and Between the storage racks, the storage rack is used to place the pipe fittings 3 to be tested. The detector is set on the detection work frame 2. The automatic feeding unit is movably connected to the storage rack. When feeding, the automatic feeding unit is connected to the detection installation frame 1, and transport the pipe fitting 3 to the detection installation frame 1. After the feeding is completed, the automatic feeding unit will automatically separate from the detection installation frame 1, and the detector on the detection work frame 2 will automatically run for flaw detection.

[0024] Wherein, the stocker includes a first pillar 4, a second pillar 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com