Diamond double-side brush-washing machine

A scrubbing machine and double-sided technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of easily scratched sapphire substrates and complicated procedures, and reduce the risk of being scratched Probability, simple process, ensure the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

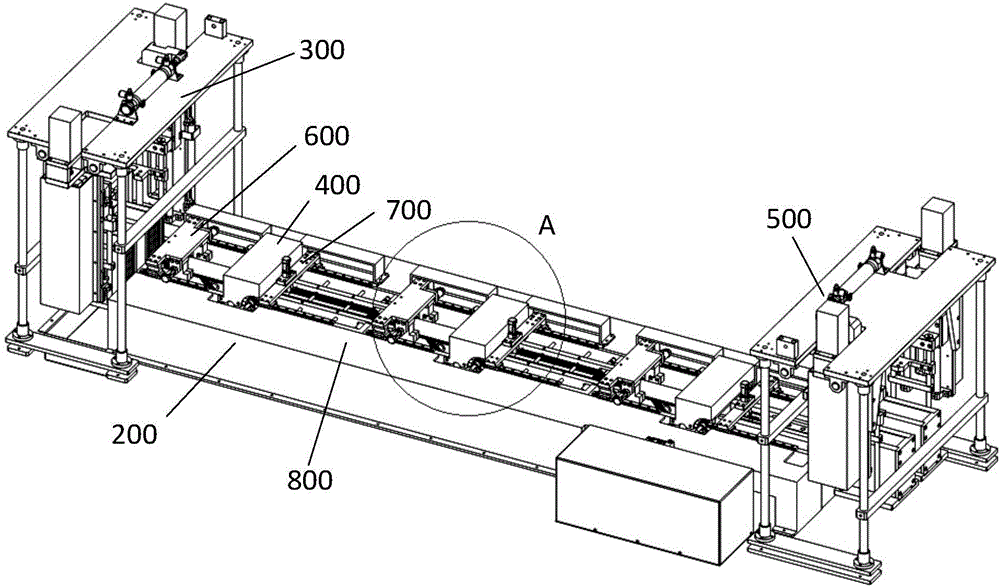

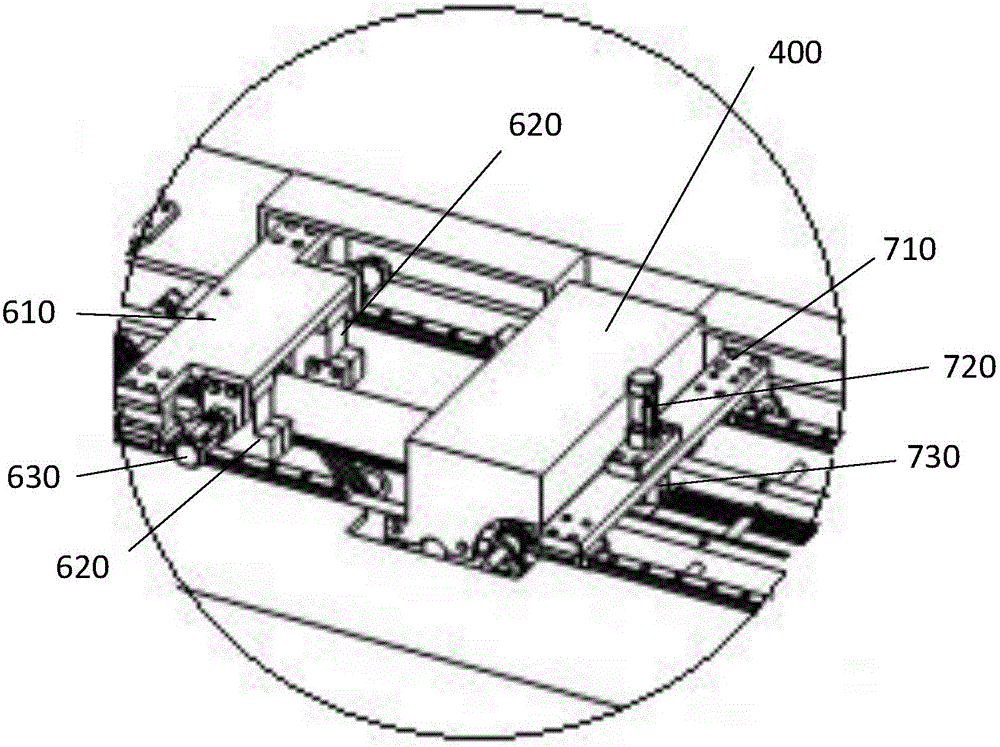

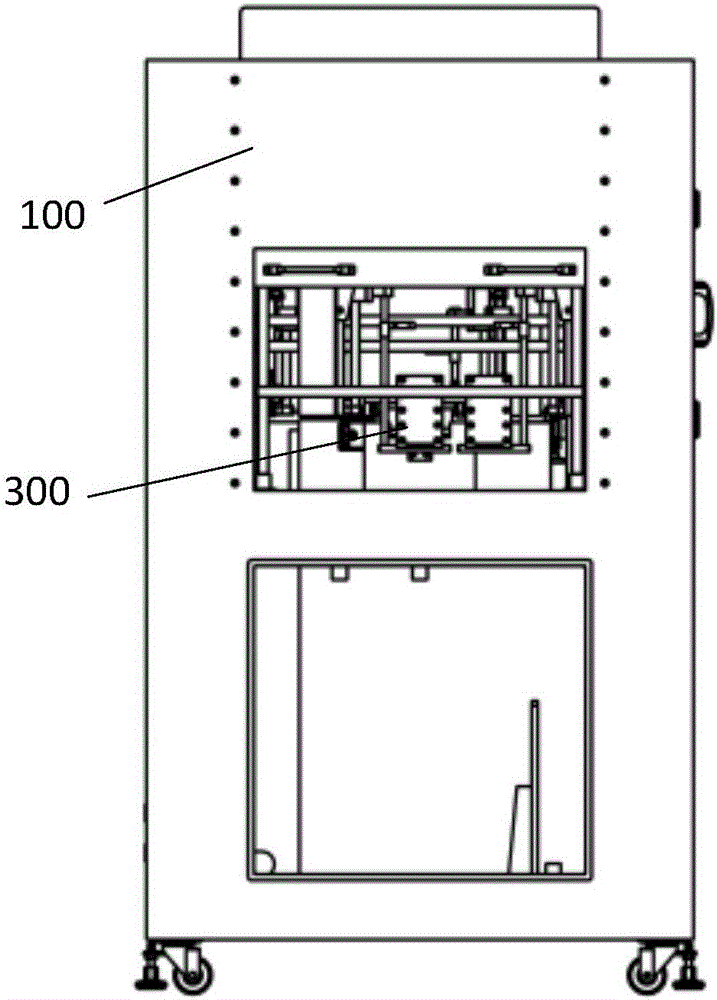

[0026] like Figure 1 to Figure 4 As shown, the square sheet double-sided scrubbing machine of the present invention includes: a protective cover 100, a workbench 200 installed in the protective cover 100, a feeding device 300 arranged successively from one end of the workbench 100 to the other end, and a plurality of groups A double-sided brush device 400 and a discharge device 500; wherein, between the feeding device 300 and the double-sided brush device 400, between two adjacent groups of double-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com