Automatic wire feeding device for micro electrical discharge machining

A wire feeding device and EDM technology, which is applied in the field of automatic wire feeding devices for micro-EDM, can solve the problems of difficulty, long electrode wire preparation cycle, and electrode wire troubles for researchers, etc., and achieve novel structure, improved economy and The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

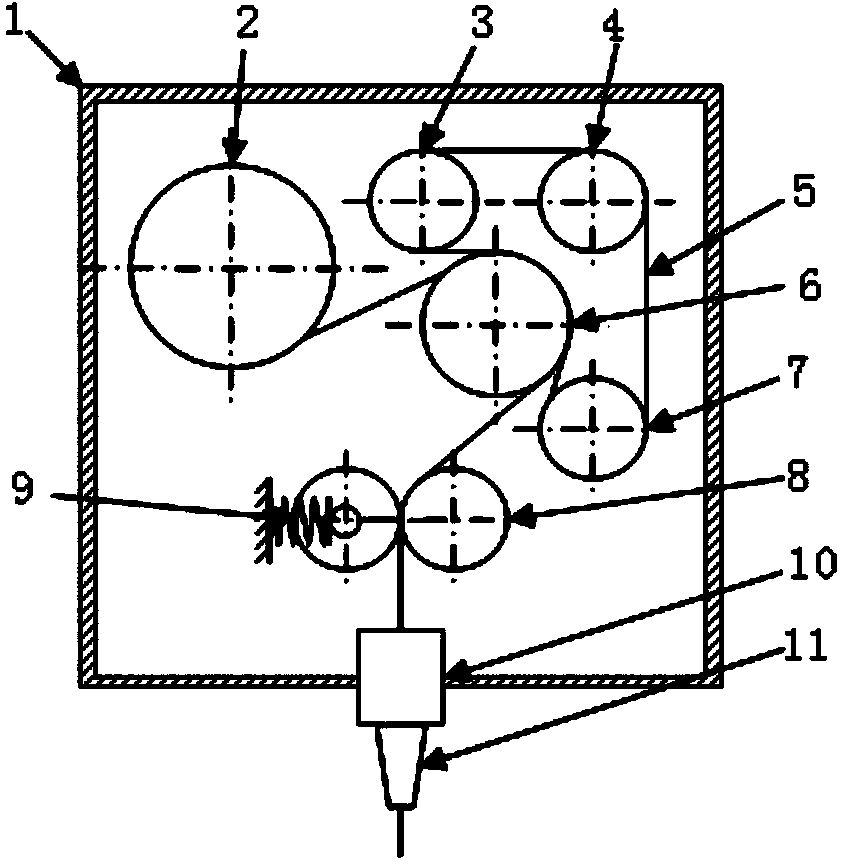

[0016] like figure 1 shown. An automatic wire feeding device for micro electric discharge machining, including a box body 1, a wire storage wheel 2 is installed in the rear of the box body 1, and a wire cutting wire as an electrode wire is wound on the wire storage wheel 2, inside the box body 1 The rear part and the right side of the wire storage wheel 2 are rotated and installed with three positive wire auxiliary wheels 3, 4, 7 distributed in a character shape, and the positive wire elastic belts that are closed and wrapped around the three normal wire auxiliary wheels 3, 4, 7 5. The rear part of the box body 1 and the right side of the wire storage wheel 2 are also rotatably equipped with a normal wire wheel 6, wherein the normal wire elastic belt between the two normal wire auxiliary wheels 3 and 7 is pressed on the normal wire wheel 6, and the normal wire The silk elastic belt is elastically tensioned, and the front part of the box body 1 is rotated with elastic wheels 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com