Waste rubber desulfurization and plasticization processing device and process

A waste rubber and processing device technology, applied in plastic recycling, chemical instruments and methods, fixed filter element filters, etc., can solve the problems of insufficient rubber powder contact, affecting the desulfurization effect, affecting product quality, etc. Conducive to water circulation and improve the effect of stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

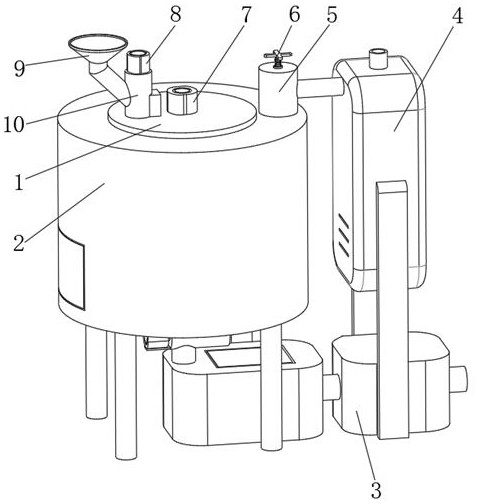

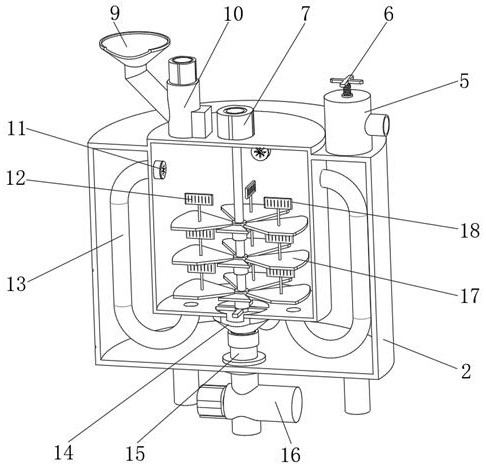

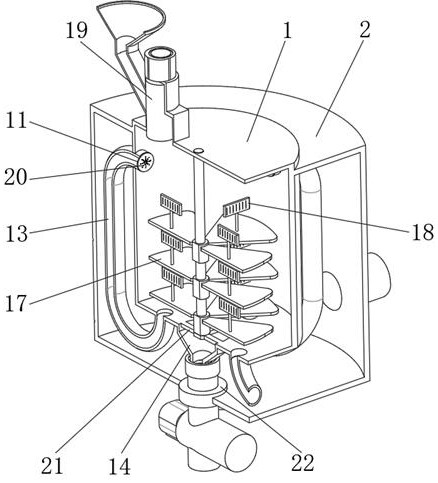

[0039] A waste rubber desulfurization and plasticization processing device, such as Figure 1-5As shown, it includes an inner cylinder 1 and an outer cylinder 2, the top inner wall of the outer cylinder 2 is welded to the top side wall of the inner cylinder 1, and the outer wall of one side of the outer cylinder 2 is connected to the steam system through a steam delivery pipe. The inner cylinder 1 The interior is filled with water; the outer wall of the top of the inner cylinder 1 is fixed with a stirring motor 7 by screws, the output end of the stirring motor 7 is connected to a rotating shaft through a coupling, and the outer wall of the circumference of the rotating shaft is fixed with evenly distributed impellers 17 by screws When the impeller 17 rotates, it generates an upward lifting force on the surrounding water body. One end of the rotating main shaft is installed on the bottom inner wall of the inner cylinder 1 through the bearing seat and the mounting frame 21. The i...

Embodiment 2

[0047] A kind of waste rubber desulfurization and plasticization processing technology, such as Figure 1-5 shown, including the following steps:

[0048] S1: Take out the defibrated rubber powder and mix it with the regeneration agent in proportion;

[0049] S2: Add water into the inner cylinder 1, and pass steam into the outer cylinder 2;

[0050] S3: Add the mixed material into the feed hopper 9, and control the feeding motor 8 to work for feeding;

[0051] S4: The material is transported into the inner cylinder 1 by the material transport seat 19 and the material transport tank 23, and the stirring motor 7 is controlled to drive the impeller 17 and the stirring plate 18 to rotate for stirring; when stirring, the water body is lifted by the impeller 17, and the water body at the bottom rises. The top water flows into the bottom of the impeller 17 through the circulation pipe 13 for replenishment, forming a circulation, and then realizes sufficient stirring with the cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com