Ridge waveguide planar array antenna employing mechanical center feeding

A center-fed, array antenna technology, used in antennas, antenna arrays, resonant antennas, etc., can solve the problems of inconvenient system design changes, antenna replacement, narrow bandwidth, and inability to meet high gain. Circularity, effect of expanding standing wave bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

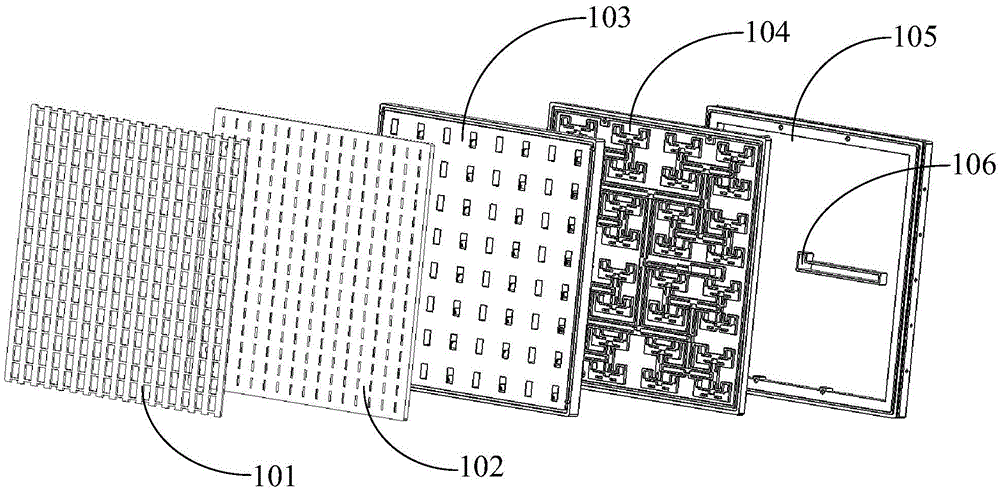

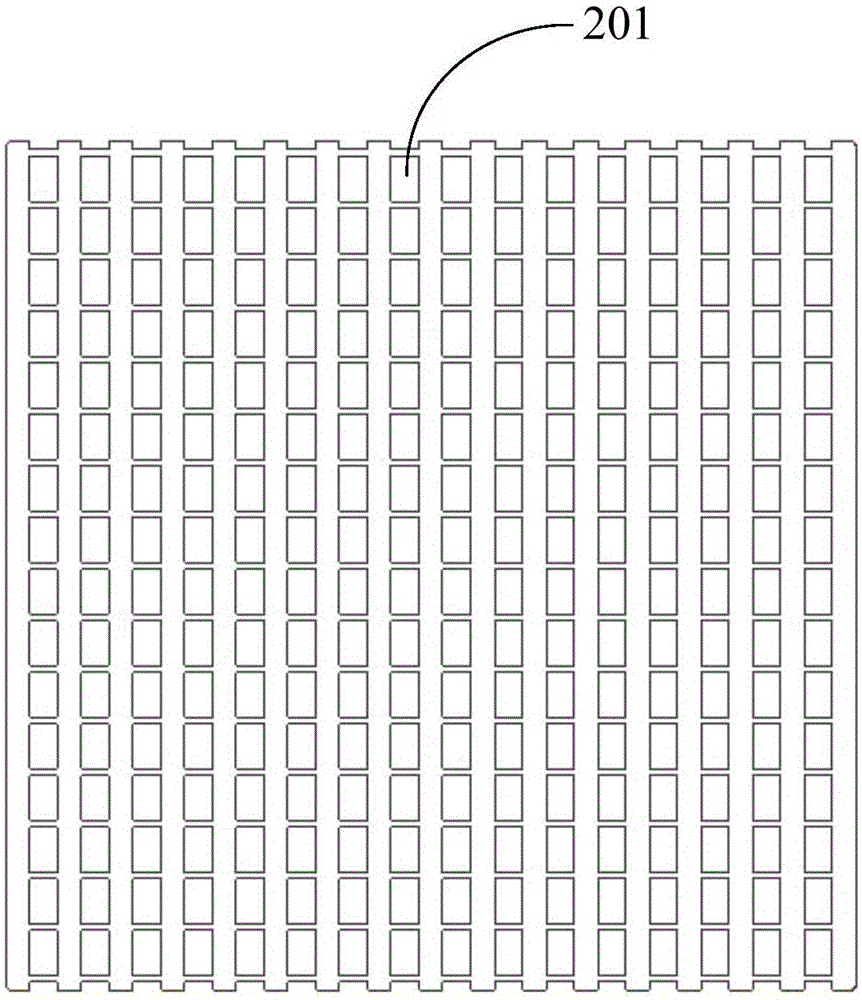

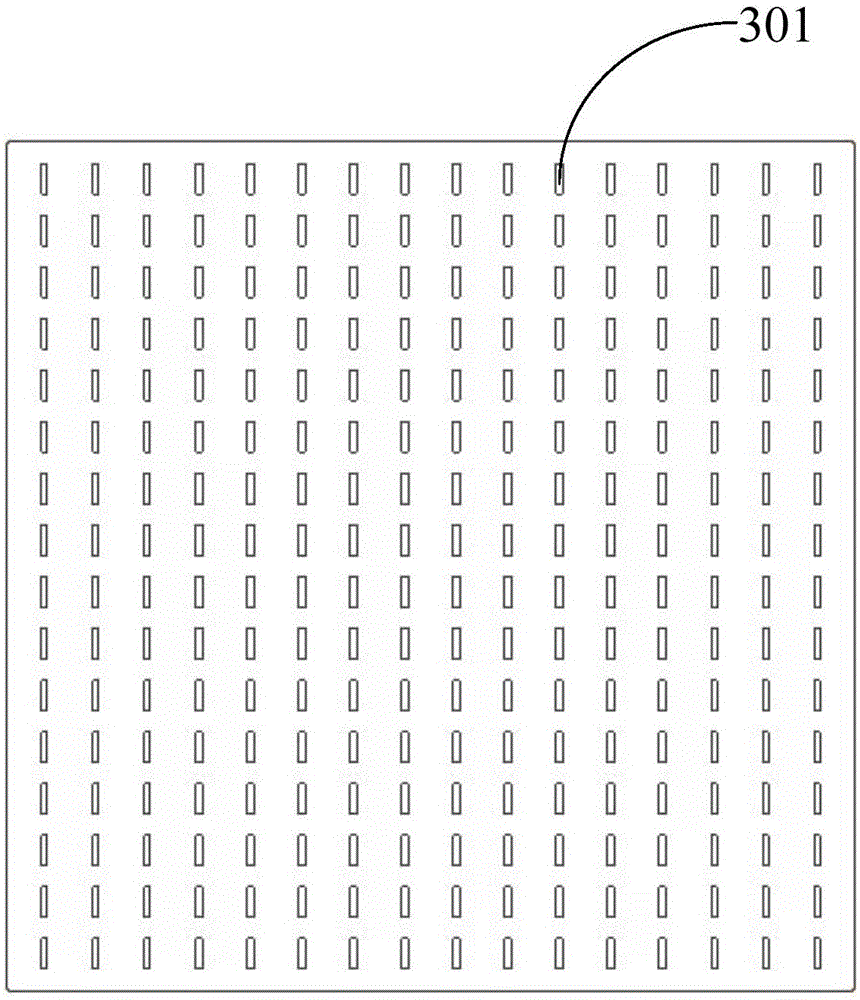

[0030] An embodiment of the present invention provides a mechanical center-fed ridge waveguide planar array antenna, such as Figure 1-7 As shown, the ridge waveguide planar array antenna includes a grid layer 101, a radiation layer 102, a coupling layer 103, a feed network layer 104, and a central feed layer 105 that are sequentially overlapped; the center of the central feed layer 105 is provided with a The waveguide port 106 for signal input and output; the feed network layer 104 is composed of a single ridge waveguide, and the center of the narrow side of each branch of the waveguide power divider 503 on the feed network layer 103 is provided with a ridge 501, and the ridge 501 Used to improve the standing wave bandwidth of the power splitter;

[0031] The substrate material of the ridge waveguide plate array antenna fed by the mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com