Automatic tapping equipment for one end of steel pipe for medical transfer bed

A transfer bed and steel pipe technology, which is applied to metal processing equipment, thread cutting devices, manufacturing tools, etc., can solve the problems of not improving work efficiency, low tapping efficiency, high scrap rate, etc., so as to improve work efficiency and product quality, The effect of saving labor and reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

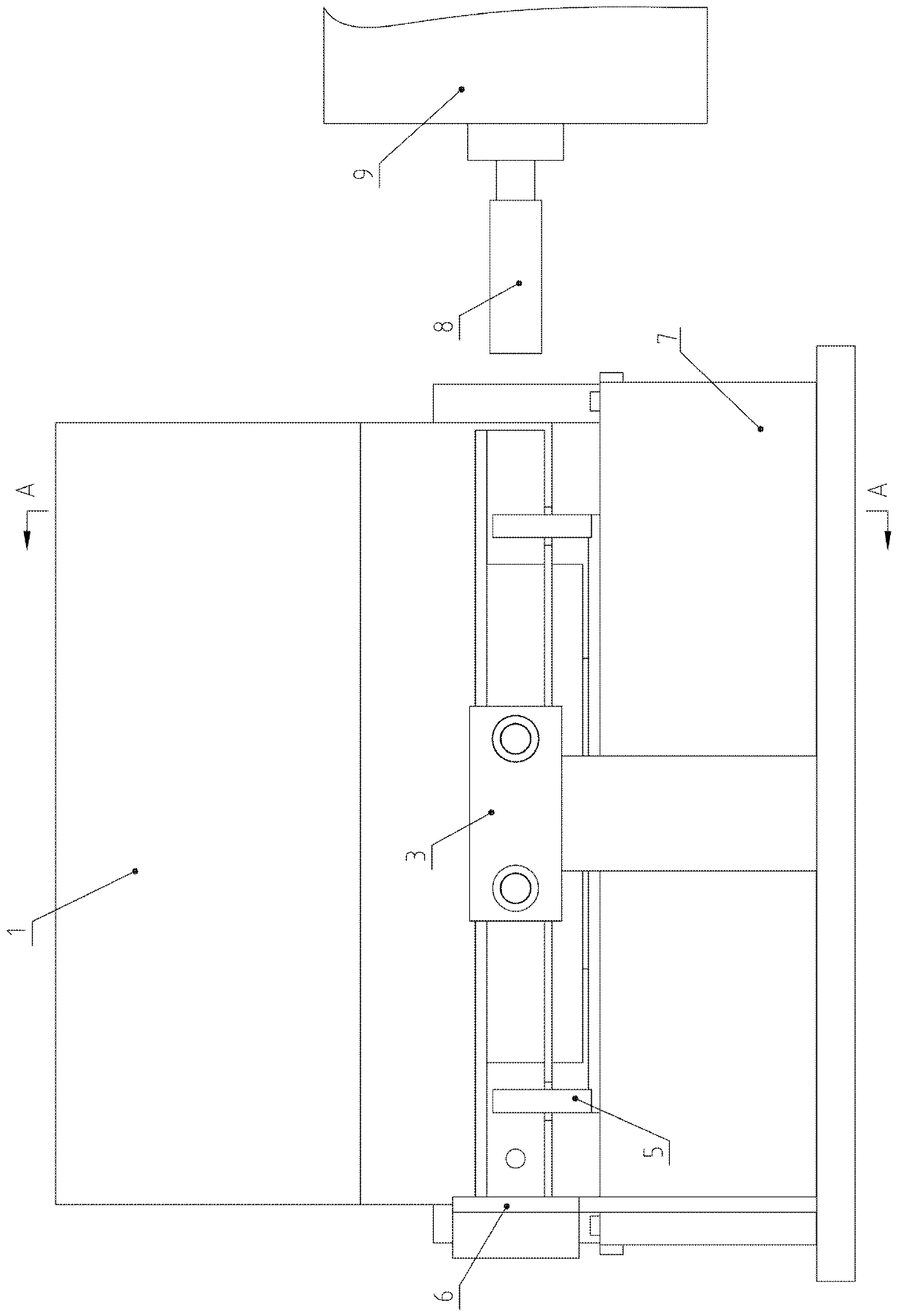

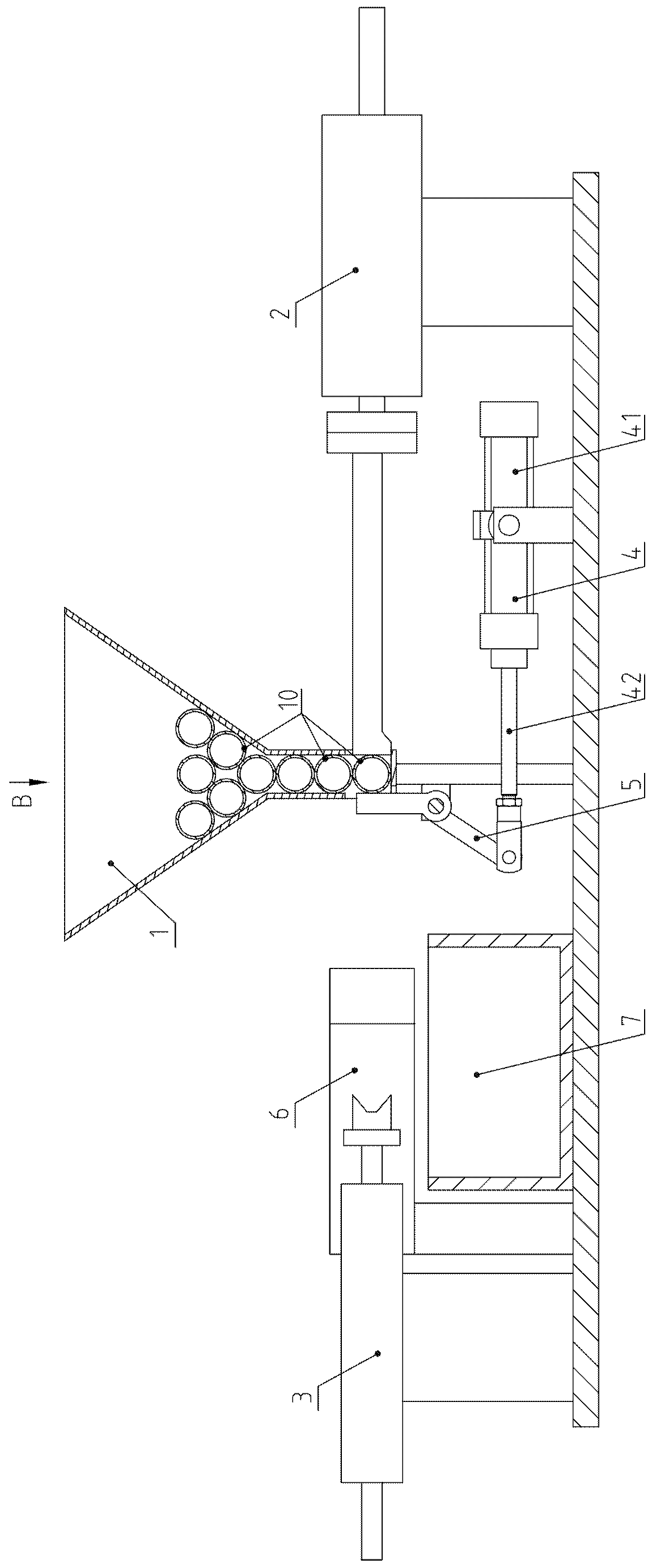

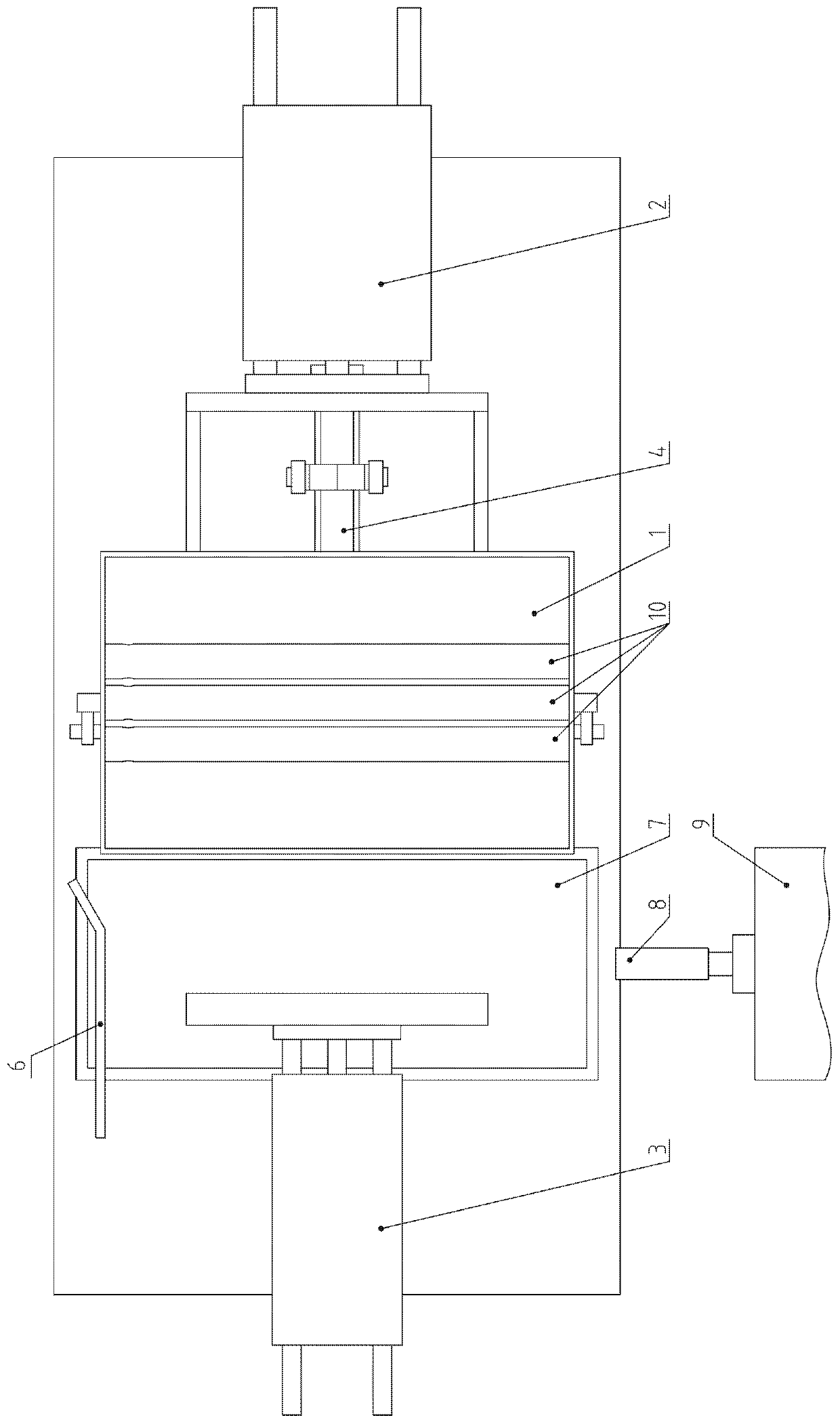

[0056] Example: see Figure 1 to Figure 14 .

[0057] An automatic tapping device at one end of a steel pipe for a medical transfer bed, comprising a horizontal tapping machine 9 and a hopper 1, the horizontal tapping machine 9 is provided with a tap 8; the taps 8 are arranged along the left and right horizontal directions, and the tap 8 faces right; the hopper 1 includes a V-shaped bucket 11 and a narrow channel 12; the bottom opening of the V-shaped bucket 11 communicates with the upper opening of the narrow channel 12; the bottom of the narrow channel 12 has a hopper bottom 13;

[0058] It also includes a hopper 1, a propulsion assembly 2, a retreat assembly 3, a pawl hydraulic cylinder 4, a pawl assembly 5, a top plate 6, an overflow valve 100, an N-type mid-position function electromagnetic reversing valve 200 and a Y-type mid-position function electromagnetic reversing valve. To the valve 300;

[0059] The lower end of the long and narrow channel 12 of the hopper 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com