Testing platform for combined machine tool hydraulic cylinder

A technology of a test platform and a compound machine tool, which is applied in fluid pressure actuation system testing, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of poor reliability, low efficiency, time-consuming and laborious, etc., and achieve complete test functions, The effect of reducing labor costs and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

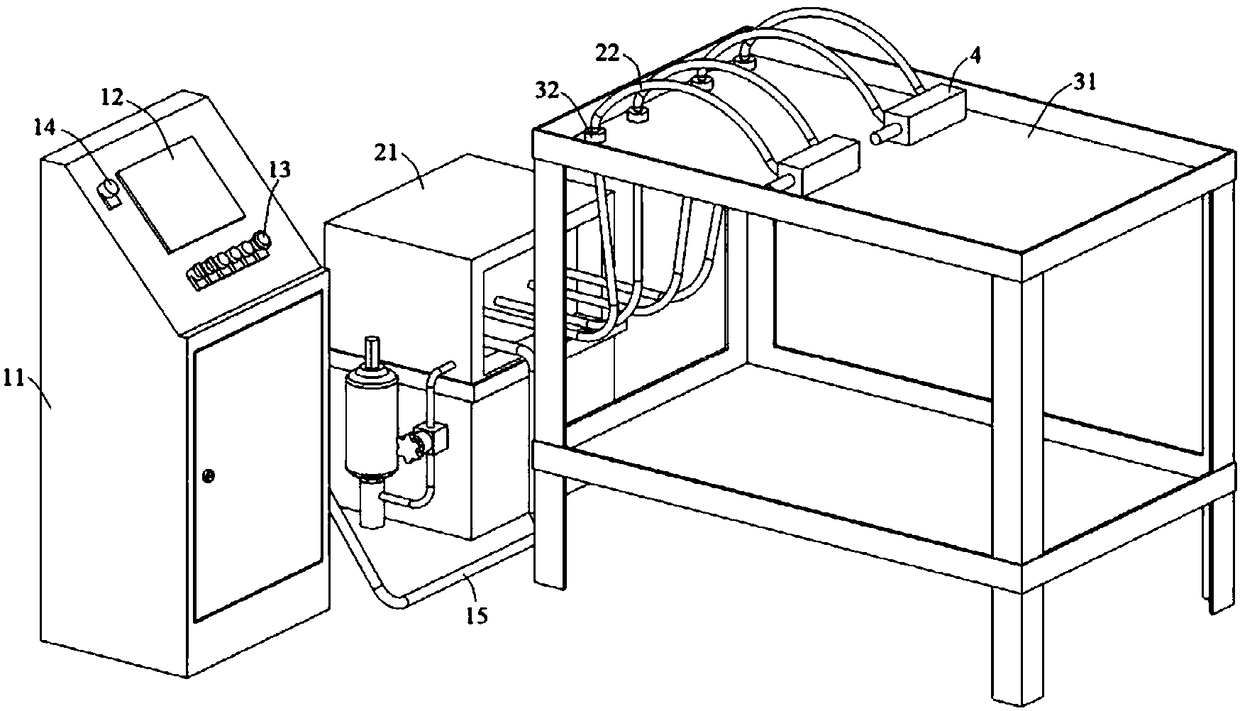

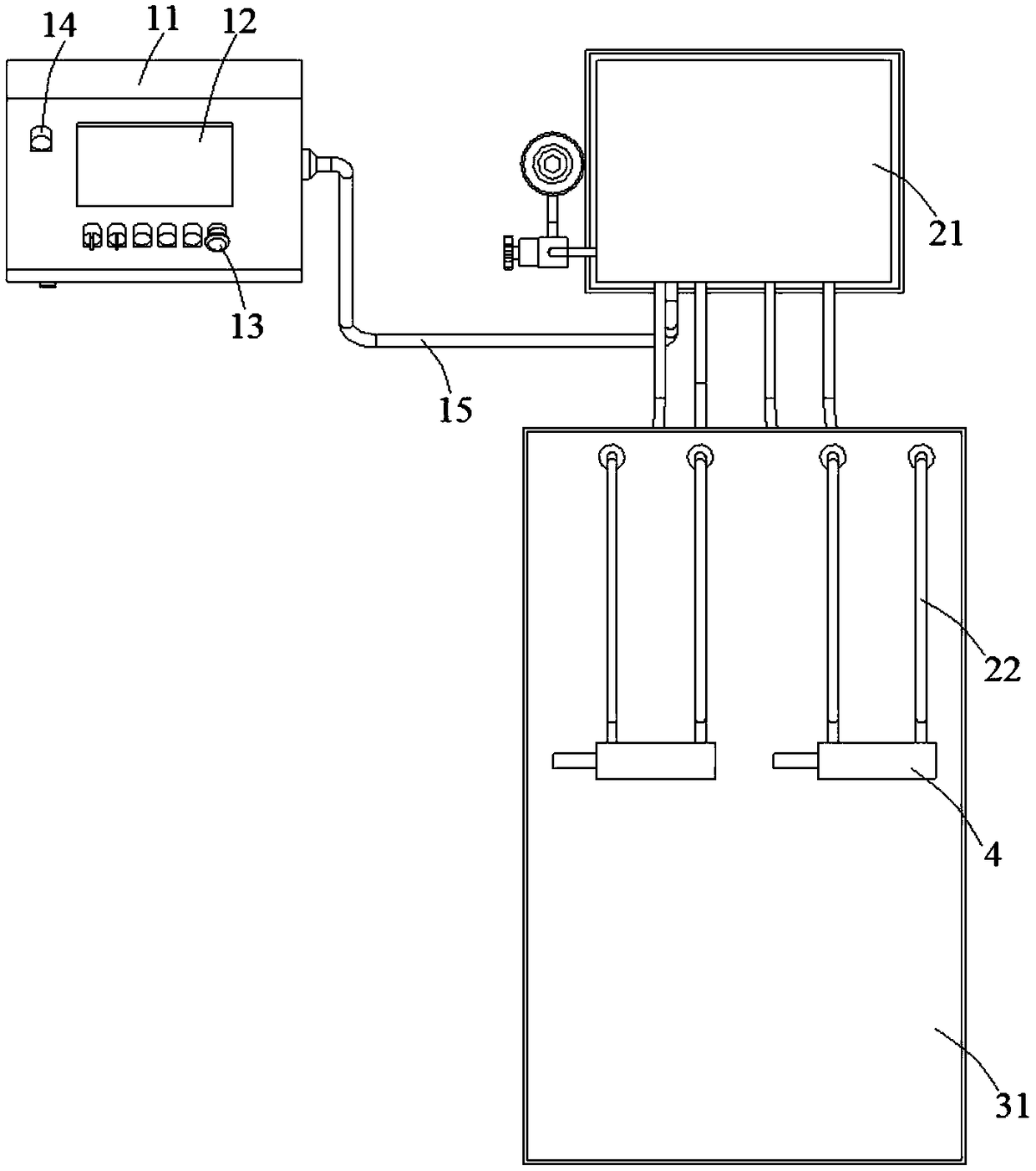

[0033] to combine figure 1 and figure 2 , a composite machine tool hydraulic cylinder test platform in this embodiment includes a cabinet 11, a control panel 13, a hydraulic station 21, an oil pipeline 22 and a PLC control system. The PLC control system is arranged inside the cabinet 11 (not shown in the figure), and the PLC control system is the brain center of the whole test device, controlling the whole test process. The output end of the PLC control system is connected to the hydraulic station 21 through the control line 15 , the control panel 13 controls the hydraulic station 21 , and the hydraulic station 21 is connected to the hydraulic cylinder 4 through the oil pipeline 22 .

[0034] In this embodiment, a control program is programmed in the PLC control system to control the cycle start or stop of the hydraulic station 21. The hydraulic station 21 is connected to the hydraulic cylinder 4 through the oil pipeline 22, and the action of the hydraulic cylinder 4 can be ...

Embodiment 2

[0040] A kind of compound machine tool hydraulic cylinder test platform of this embodiment is basically the same as embodiment 1, and its difference is: this embodiment is to fully tap the function of the test platform, and a cabinet door is set on one side of the cabinet body 11, and the inside of the cabinet door The upper and lower areas are separated by a transverse partition, and the two areas can be used as storage areas. The PLC control system is provided with a chuck controller, and the two interfaces of the chuck controller are connected with the two joints of the coil. Correspondingly, the magnetization / demagnetization button is set on the control panel 13 . Press the magnetization / demagnetization button and continuously energize the coil for about 5 hours. If the coil is intact, it means that the coil is qualified and can be applied to the machine tool. The coil is placed on the diaphragm inside the cabinet and will not occupy outside space.

Embodiment 3

[0042] A hydraulic cylinder test platform for a composite machine tool in this embodiment is basically the same as in Embodiment 1, except that a hydraulic station 21 is provided in this embodiment to connect six oil pipelines 22 at the same time, and three hydraulic cylinders 4 are tested simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com