A kind of cross-linked polymer microsphere-polymer composite deep control and drive agent and its application method

A cross-linked polymer and flood control agent technology, which can be used in drilling compositions, chemical instruments and methods, earthwork drilling and production, etc., and can solve problems affecting polymer flooding efficiency and weak liquid flow redirection ability , to achieve the effects of improving the application range, increasing the sweep coefficient, and improving the displacement ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

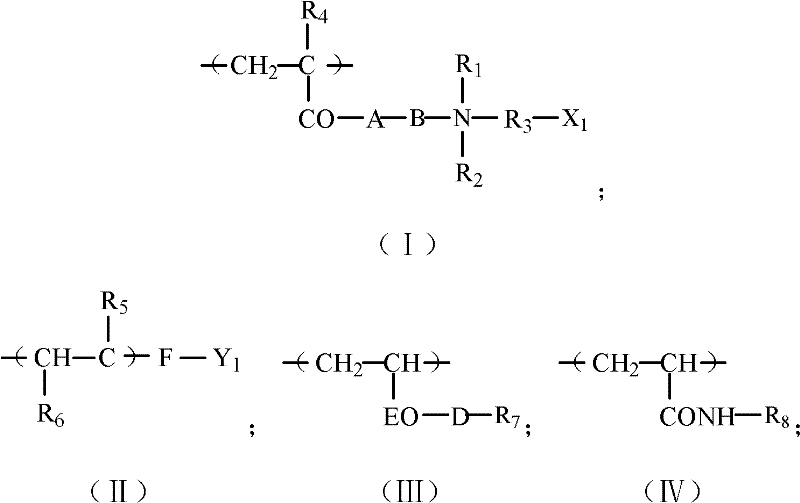

Method used

Image

Examples

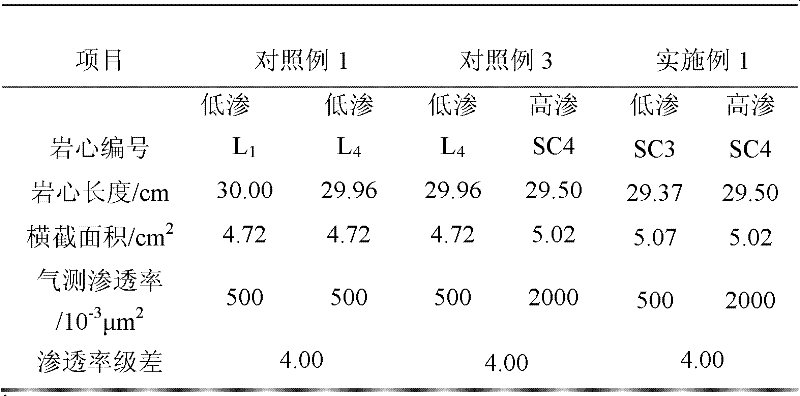

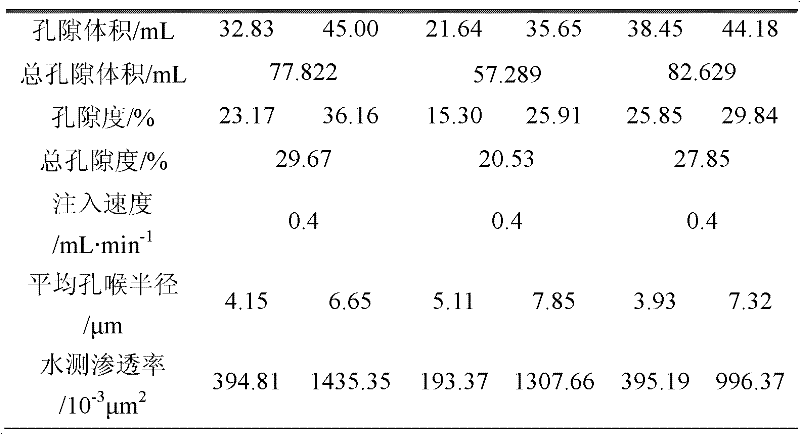

Embodiment 1

[0030] Embodiment 1, cross-linked polymer microspheres-AP-P4 polymer composite deep control and flooding agent

[0031] First, add 0.5% of the calculated amount to the configured SZ36-1 oilfield simulation water according to the cross-linked polymer microsphere powder mother liquor prepared in Example 1 of the patent ZL200710063645.X, so that the mass fraction of the cross-linked polymer microspheres in the system is 300mg / L, shake well; then add the calculated amount of 0.5% viscosity-average relative molecular weight of 12.5 million hydrophobic association type partially hydrolyzed polyacrylamide (AP-P4) mother liquor, so that the mass fraction of HPAM in the system is 1450mg / L, After stirring and mixing evenly, place the cross-linked polymer microspheres-AP-P4 polymer composite deep-seated control and displacement agent at 65°C for 48 hours. In the control and displacement agent, the mass percentage of cross-linked polymer microspheres is 0.03%, the mass percentage of AP-P4...

Embodiment 2

[0032] Embodiment 2, cross-linked polymer microspheres-AP-P4 polymer composite deep control and flooding agent

[0033] First, add 0.5% of the calculated amount to the configured SZ36-1 oilfield simulation water according to the cross-linked polymer microsphere powder mother liquor prepared in Example 1 of the patent ZL200710063645.X, so that the mass fraction of the cross-linked polymer microspheres in the system is 300mg / L, shake well; then add the calculated amount of 0.5% viscosity-average relative molecular weight of 12.5 million hydrophobic association type partially hydrolyzed polyacrylamide (AP-P4) mother liquor, so that the mass fraction of HPAM in the system is 1450mg / L, After stirring and mixing evenly, place the cross-linked polymer microspheres-AP-P4 polymer composite deep-seated control and displacement agent at 65°C for 48 hours. In the control and displacement agent, the mass percentage of cross-linked polymer microspheres is 0.03%, the mass percentage of AP-P4...

Embodiment 3

[0034] Embodiment 3, cross-linked polymer microspheres-AP-P4 polymer composite deep control and flooding agent

[0035] First, add 0.5% of the calculated amount of the cross-linked polymer microsphere emulsion mother liquor prepared according to Example 1 in the patent ZL200710063645.X to the configured SZ36-1 oilfield simulated water, so that the mass fraction of the cross-linked polymer microspheres in the system is 300mg / L, shake well; then add the calculated amount of 0.5% viscosity-average relative molecular weight of 12.5 million hydrophobic association type partially hydrolyzed polyacrylamide (AP-P4) mother liquor, so that the HPAM mass fraction in the system is 1450mg / L, stir After mixing evenly, place the cross-linked polymer microspheres-AP-P4 polymer composite deep-seated flood control agent at 65°C for 48 hours. In the flood control agent, the mass percentage of cross-linked polymer microspheres is 0.03 %, the mass percentage of AP-P4 is 0.0145%, and the relative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com