Method for raising recovery efficiency of heavy oil deposit through chemical steam flooding

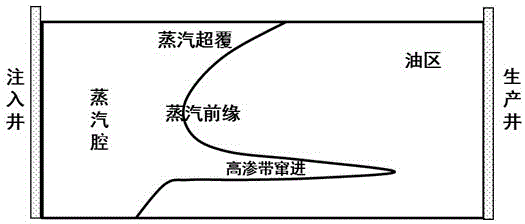

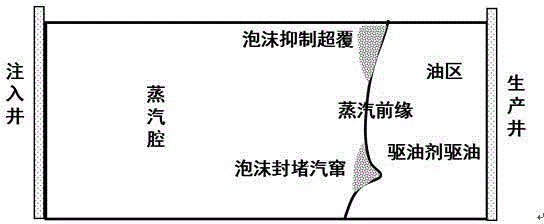

A heavy oil reservoir, chemical steam technology, applied in the field of chemical steam flooding, can solve the problems affecting steam flooding effect and recovery, small steam sweep volume, uneven steam displacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

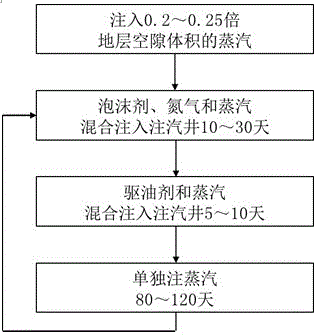

[0023] The method proceeds as follows:

[0024] ①. Select oil reservoirs with burial depth of 900m, effective oil layer thickness ≥ 8m, and crude oil viscosity > 100 mPa.s under oil layer conditions, and inject 0.25 times the formation pore volume of steam first, and the steam injection rate is 1.6 tons per day. per hectare. thickness per meter;

[0025] ②. Mix sulfonate containing benzene ring with straight chain structure on benzene ring, nitrogen with purity ≥ 95% and steam into the steam injection well for 30 days. The mass concentration of the structural sulfonate is 200000mg / L, the injection amount of the sulfonate containing benzene ring and the linear structure on the benzene ring: steam injection amount = 1.2: 100 parts by mass ratio, nitrogen injection amount: steam injection Volume = 0.5:100 underground volume ratio, steam injection rate is 2.0 tons / day. per hectare. per meter of thickness;

[0026] ③. Mix and inject the sulfonate containing aromatic groups and st...

Embodiment 2

[0030] The method proceeds as follows:

[0031] ①. Select oil reservoirs with burial depth of 1600m, effective oil layer thickness ≥ 8m, and crude oil viscosity > 100 mPa.s under oil layer conditions, and inject 0.2 times the formation pore volume of steam first, and the steam injection rate is 2.0 tons per day. per hectare. thickness per meter;

[0032] ②. Mix sulfonate containing benzene ring with straight chain structure on benzene ring, nitrogen with purity ≥ 95% and steam into the steam injection well for 10 days. The mass concentration of the structural sulfonate is 300000mg / L, the injection amount of the sulfonate containing benzene ring and the linear structure on the benzene ring: steam injection amount = 0.4: 100 parts by mass ratio, nitrogen injection amount: steam injection Volume = 1.5:100 underground volume ratio, steam injection rate is 1.6 tons / day. per hectare. per meter of thickness;

[0033] ③. Inject the aromatic group-containing sulfonate and steam into ...

Embodiment 3

[0037] The method proceeds as follows:

[0038] ①. Select oil reservoirs with burial depth of 1250m, effective oil layer thickness ≥ 8m, and crude oil viscosity > 100 mPa.s under oil layer conditions, and inject 0.22 times the formation pore volume of steam first, and the steam injection rate is 1.8 tons per day. per hectare. thickness per meter;

[0039] ②. Mix sulfonate containing benzene ring with straight chain structure on benzene ring, nitrogen with purity ≥ 95% and steam into the steam injection well for 20 days. The mass concentration of the sulfonate of the structure is 250000mg / L, the injection amount of the sulfonate containing benzene ring and the linear structure on the benzene ring: steam injection amount = 0.8: 100 parts by mass ratio, nitrogen injection amount: steam injection Quantity=1.0:100 volume ratio, steam injection rate is 1.8 tons / day. per hectare. per meter of thickness;

[0040] ③. Inject the aromatic group-containing sulfonate and steam into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com