Steam heavy oil thermal recovery equipment and method thereof

An equipment and technology for heavy oil, which is applied in the field of equipment for steam thermal recovery of heavy oil, can solve the problems of depth limitation, high power consumption, and steam channeling in non-oil layers of ground steam injection thermal recovery technology, and achieves improved viscosity reduction and thermal recovery. Displacement effect, the effect of reducing the consumption of electric energy and improving the degree of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

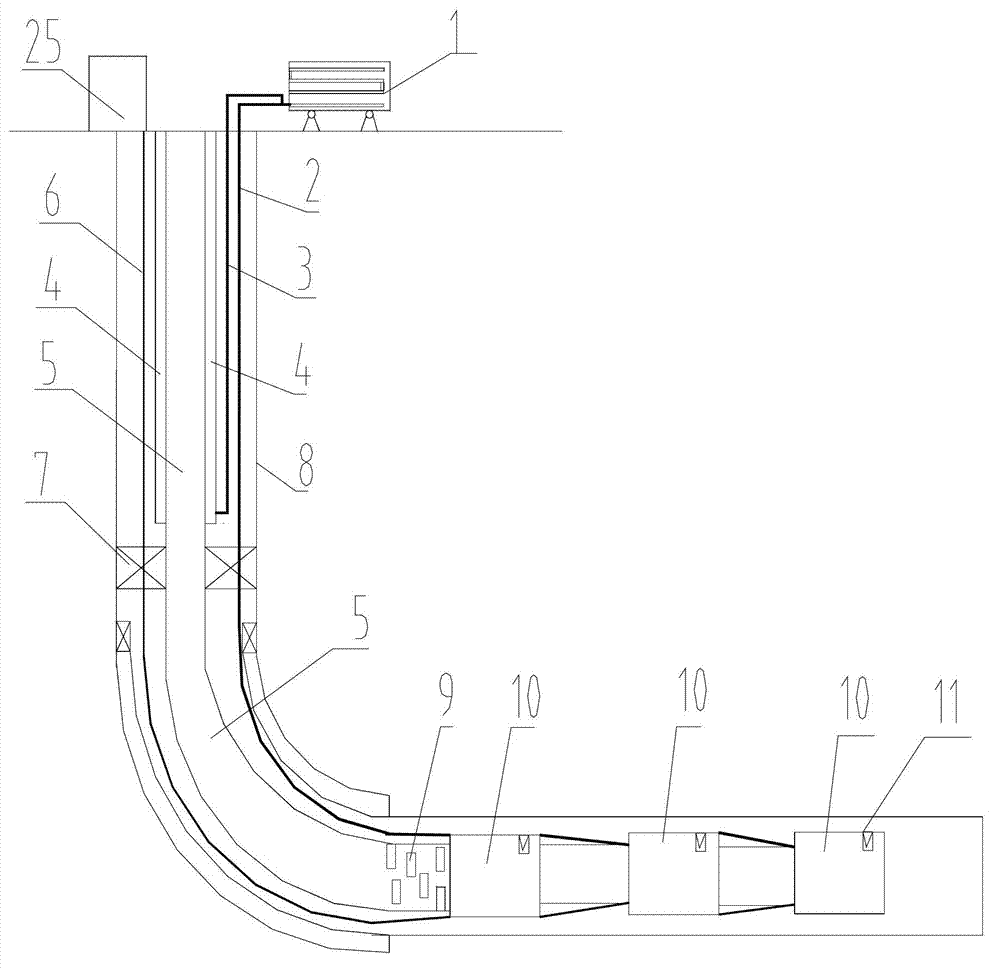

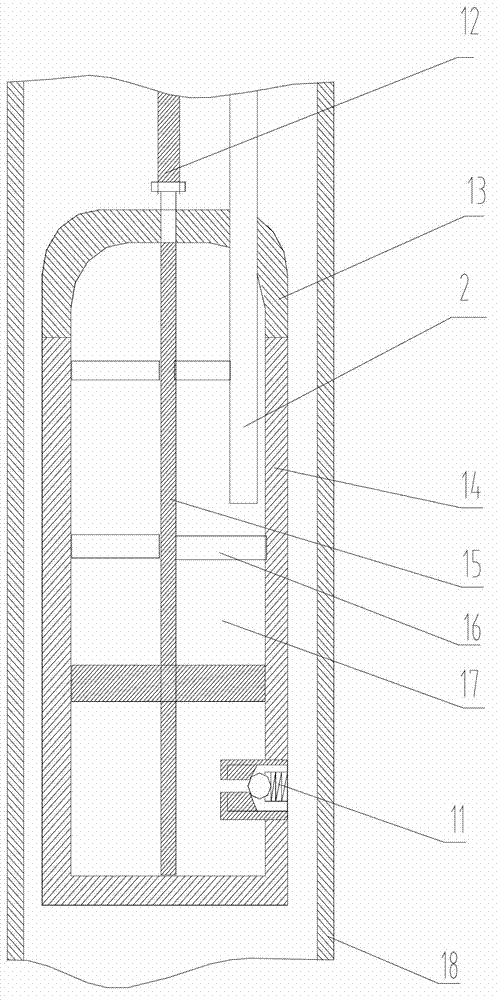

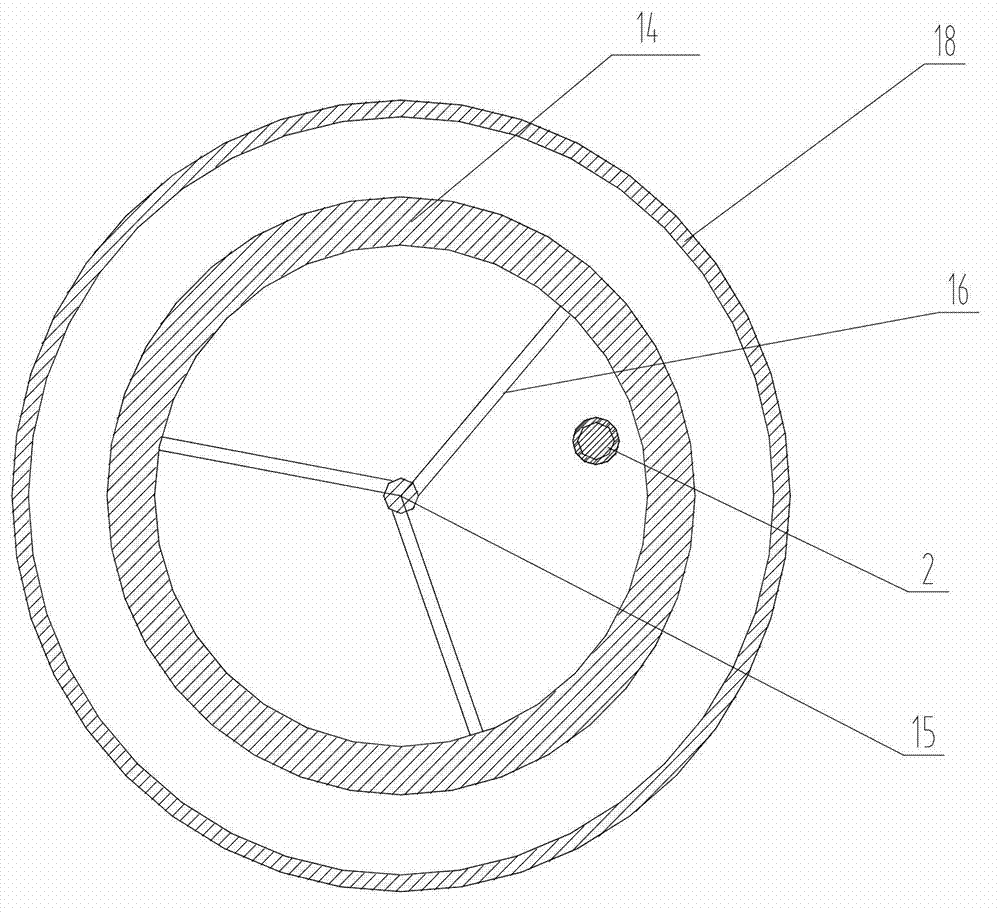

[0043] The steam heat recovery equipment of heavy oil in the embodiment of the present invention is realized in this way, see figure 1 Shown, this equipment comprises ground device and downhole device, and surface device comprises solar water heater 1 and transformer 25, and downhole device comprises three steam generators 10, and the upper end of water pipe 2 is connected with solar water heater 1, and the upper end of cable 6 is connected with transformer 25, the wellbore 8 includes a vertical well section, a deflected well section and a horizontal section, the oil pipe 5, the water delivery pipe 2 and the cable 6 enter the wellbore 8 together, and extend to the horizontal wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com