Accumulation-type gas supply device

一种气体供给、气体供给单元的技术,应用在流体压力致动装置、阀装置、运输和包装等方向,能够解决不能应对气体供给线路数设置空间、削减、小型化困难等问题,达到置换性提高、实现占地面积、时间缩短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ]

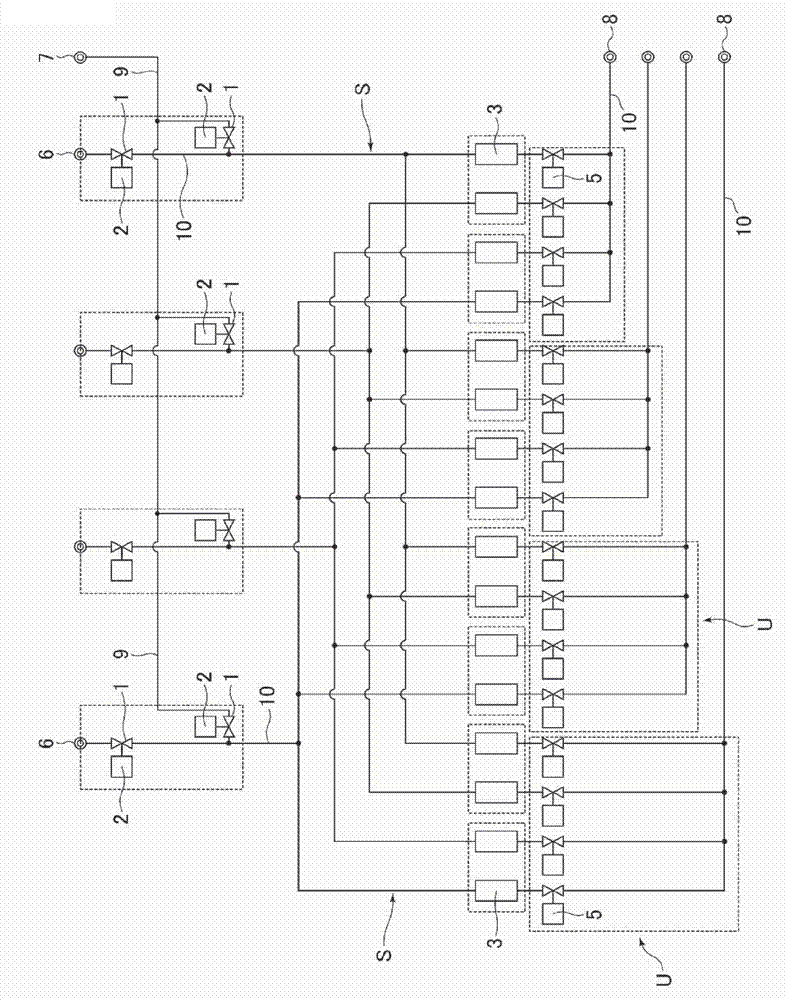

[0050] Figure 1 to Figure 7 is a diagram showing an integrated gas supply device for a semiconductor manufacturing apparatus according to a first embodiment of the present invention. In this first embodiment, as figure 1 As shown in the diagram of the gas supply system, the four gas types supplied to the processing gas inlet joint 6 pass through 16 gas supply lines S and one of the four processing gas passages 10, and then flow from the processing gas outlet joint 8 to the processing device ( omitting the illustration) supply.

[0051] That is, in the present embodiment, a total of 16 gas supply lines S are divided into four groups, the gas flowing in from each processing gas inlet joint 6 is introduced into the four groups, and the four groups are led out from each of the four groups. The gas supply lines S of the four systems are merged into one, and are supplied from the processing gas passage 10 to processing devices (not shown in the figure).

[0052] In addition, in ...

no. 1 example )

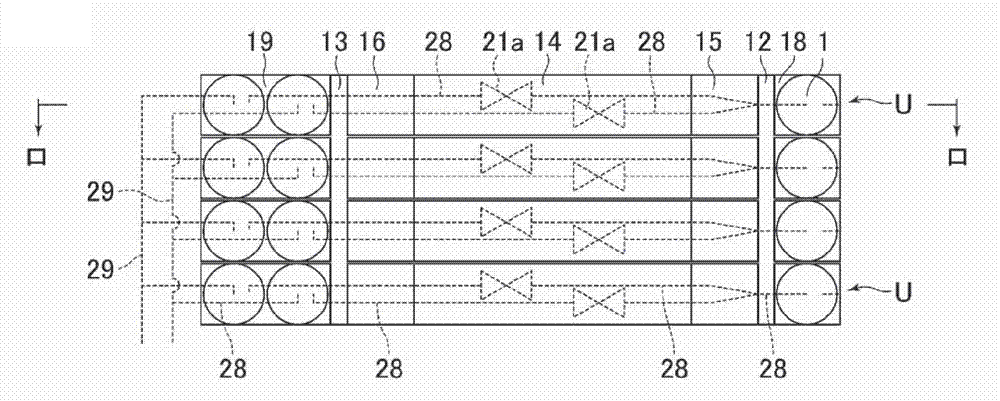

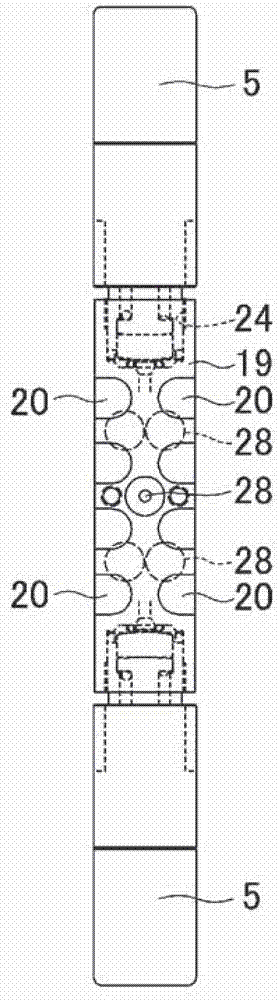

[0060] Figure 4 It is a diagram showing the structure of the gas supply unit U used in the first example. The gas supply unit U of the first example is formed by making the first unit body U of the same structure 1 and the second unit U 2 The gas inlet side block 12 and the gas outlet side block 13 arranged vertically parallel to each other and assembled to the front side and the back side of the gas inlet side block 12 and the gas outlet side block 13 are horizontally opposed.

[0061] That is, the first unit body U 1 It consists of a square main body block 18 for the inlet on-off valve, a square main body block 19 for the outlet on-off valve, a flow controller 3, an inlet on-off valve 1 and two outlet on-off valves 5, etc., and the inlet on-off valve The main body block 18 is airtightly fixed on the right side of the gas inlet side block 12, and the outlet opening and closing valve is airtightly fixed on the left side of the gas outlet side block 13 with the main body blo...

no. 2 example )

[0080] Image 6 It is a diagram showing a second example of the pressure type flow controller 3 used in the first embodiment of the present invention, and differs from the first example only in that a pressure detector 4 a is provided in addition to the pressure detector 4 .

[0081] By providing the pressure detector 4a to detect the pressure on the upstream side and the downstream side of the orifice 27, the flow rate can be controlled with high precision even in a non-critical state gas flow.

[0082] In addition, since the pressure detector 4a itself of the second example is well known, its description is omitted here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com