Exploitation method of vaporizing formation water and displacing heavy oil by microwaves in situ

A production method and technology for formation water, which are applied in the fields of production of fluids, earthwork drilling, wellbore/well components, etc., can solve problems such as losses, reduce heat energy loss, improve development effect, and solve the effect of steam dryness loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The production method of the present invention is explained by taking a certain heavy oil reservoir as an example, but it should be noted that the present invention is by no means limited to the heavy oil reservoir. The reservoir depth is 1600m, the viscosity of crude oil at the reservoir temperature is 100000 centipoise, the average formation pressure at the end of huff and puff is 1.5MPa, the effective average thickness of oil layer 9 is 16m, and the distance between adjacent steam huff and puff wells is 70m, calculated at the end of huff and puff The recovery rate of injected water is 54%, that is, the underground water storage rate is 46%.

[0041] A. Deploy injection-production well pattern:

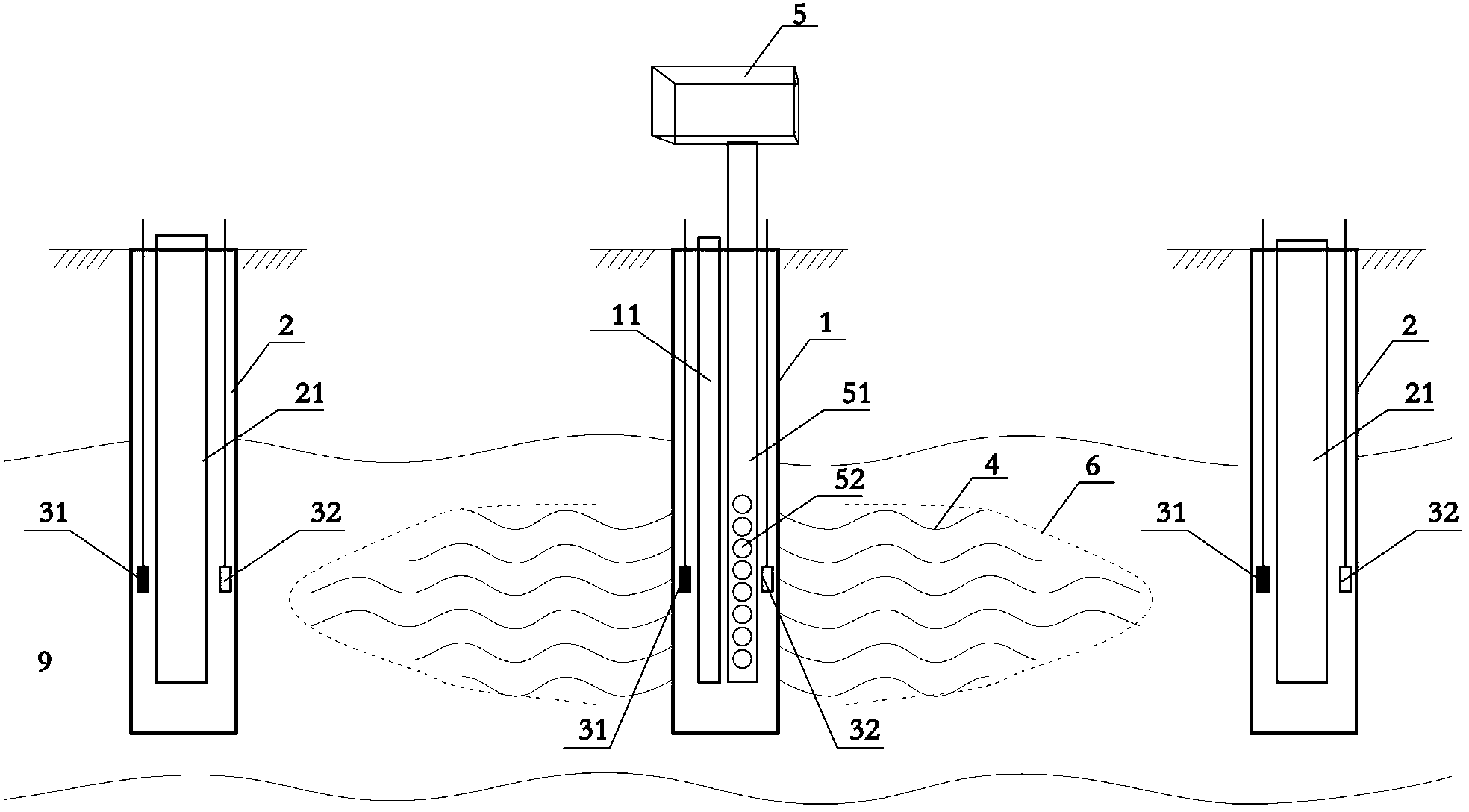

[0042] Such as figure 1 As shown, the injection-production well pattern is set in the steam huff and puff old well area of the heavy oil reservoir; the injection-production well pattern includes at least one injection-production well group; figure 1 Shown in is an injecti...

Embodiment 2

[0055] The reservoir depth is 1900m, the crude oil viscosity at the reservoir temperature is 200000 centipoise, the average formation pressure at the end of huff and puff is 1.9MPa, the effective average thickness of oil layer 9 is 20m, and the distance between adjacent steam huff and puff wells is 100m, calculated at the end of huff and puff The recovery rate of injected water is 47%, that is, the underground water storage rate is 53%.

[0056] A. Deploy injection-production well pattern:

[0057] Such as figure 1 As shown, the injection-production well pattern is set in the steam huff and puff old well area of the heavy oil reservoir; the injection-production well pattern includes at least one injection-production well group; figure 1 Shown in is an injection-production well group, the injection-production well group includes a displacement well 1 and a plurality of production wells 2 around the displacement well 1; An old steam huff and puff well with good cementing qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com