Plugging control method for treating steam channeling during steam huff and puff

A technology of steam and steam channeling, which is used in the field of oil recovery of oil reservoirs to achieve the effect of reducing oil-water interfacial tension, high viscosity and large flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

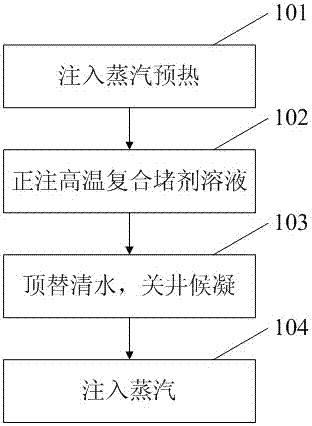

[0042] Since the mining of Jin 6 Block of Jinjia Oilfield, the phenomenon of steam channeling has been serious in the first cycle of steam huffing and puffing. This method is used to control the steam channeling of Jin 6-6 well. The specific implementation steps are as follows:

[0043] Step 1: Inject 200t of steam into the steam injection well, the steam injection rate is 9t / h, and the dryness of steam injection is ≥75%. During the steam injection process, pay attention to record the steam injection pressure change, so as to adjust the steam injection parameters according to the pressure in time.

[0044] Step 2: inject plugging agent. Positive injection of high temperature composite plugging agent solution 70m 3 (composite plugging agent formula: 5.6 tons of modified tannin extract, concentration 8%, cross-linking agent 2.8 tons, concentration 4%), top extrusion water 20m 3 ; Close the well and wait for 24h.

[0045] Step 3: Inject 1600t of steam into the steam injection ...

Embodiment 2

[0048] In the second cycle of steam injection in Jin17-Ping24 well of Jin17 Block in Jinjia Oilfield, steam channeling occurred with adjacent wells. For Jin17-Ping24 well, this method is used to control steam channeling. The specific implementation steps are as follows:

[0049] This implementation provides a blockage adjustment method applied to control steam huff and puff channeling, including the following steps:

[0050] Step 1: Inject 200t of steam into the steam injection well, the steam injection rate is 9t / h, and the dryness of steam injection is ≥75%. During the steam injection process, pay attention to record the steam injection pressure change, so as to adjust the steam injection parameters according to the pressure in time.

[0051] Step 2: inject plugging agent. Positive injection of high temperature composite plugging agent solution 100m 3 (composite plugging agent formula: 8 tons of modified tannin extract, concentration 8%, 4 tons of cross-linking agent, conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com