Patents

Literature

46results about How to "Layers is relatively thick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

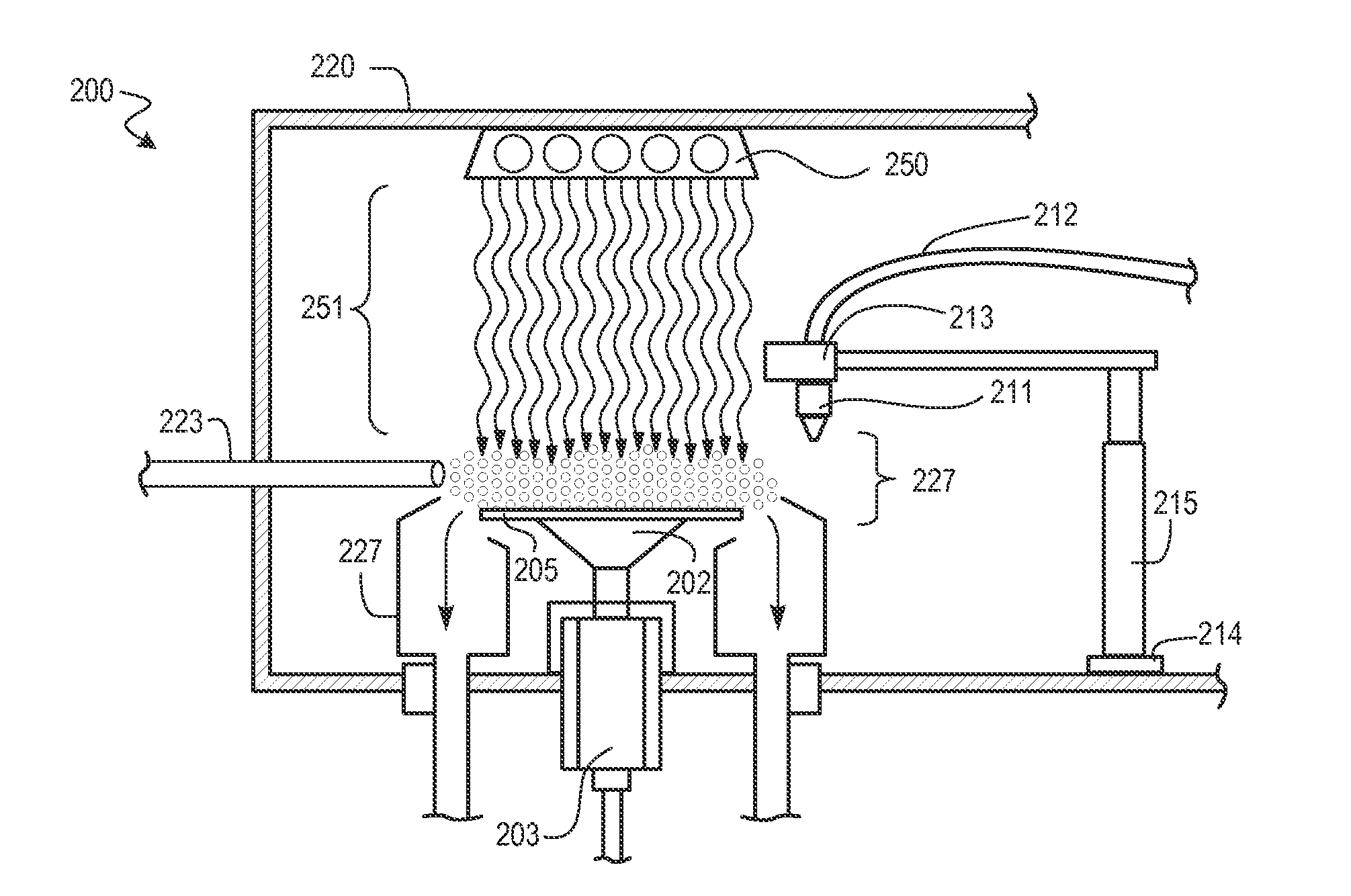

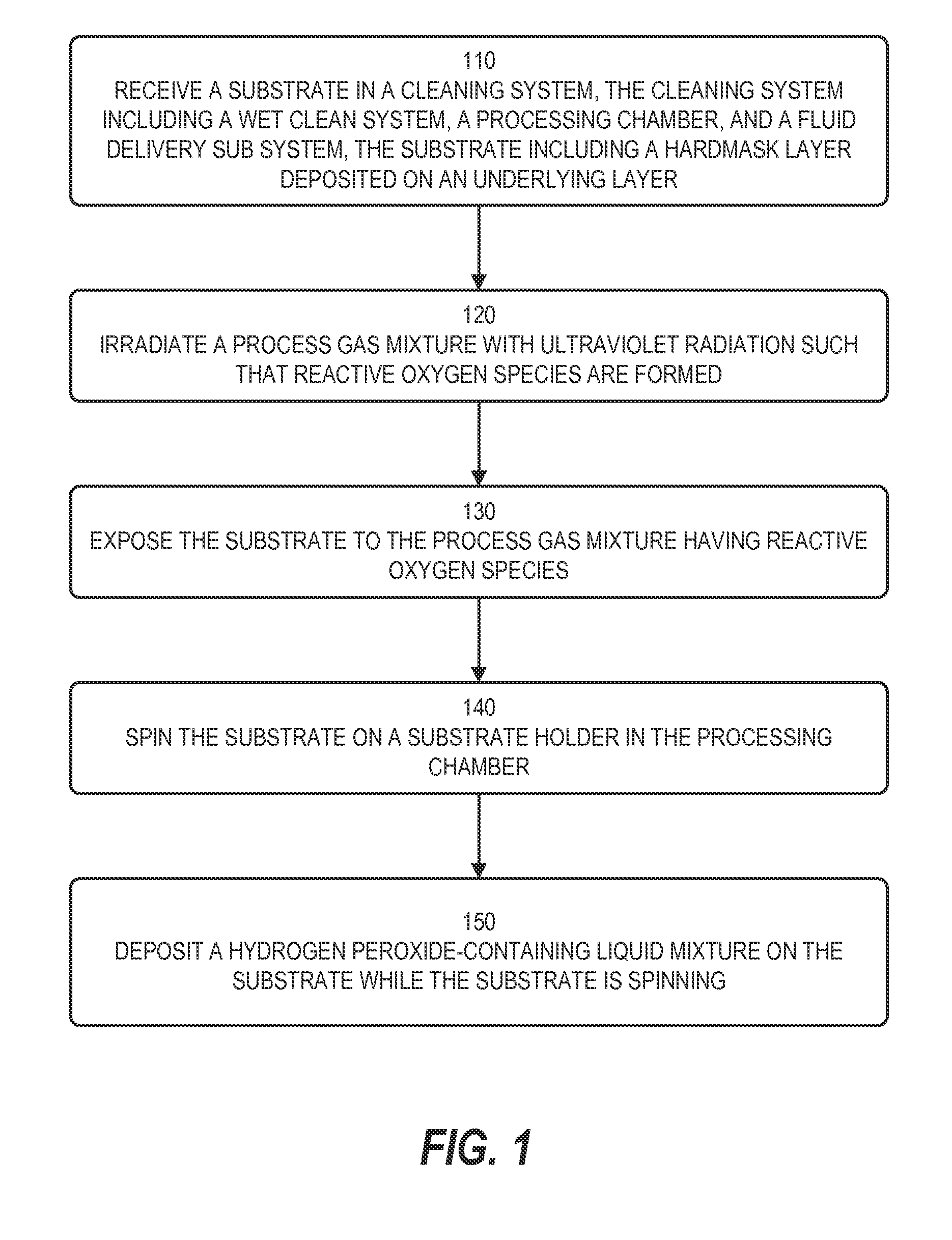

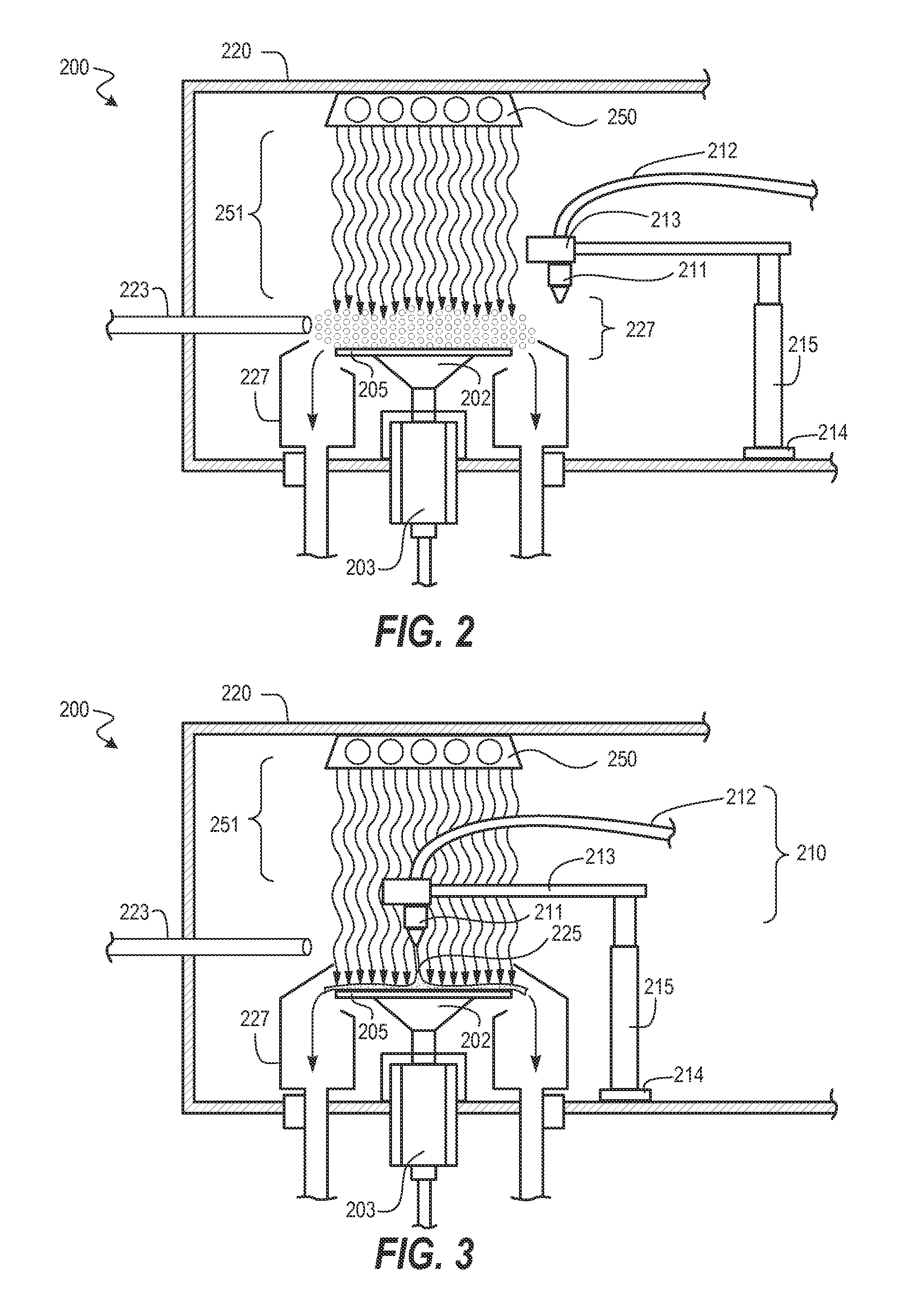

Method and Hardware for Enhanced Removal of Post Etch Polymer and Hardmask Removal

ActiveUS20150128991A1Enhanced sputteringRegulate deliveryElectrostatic cleaningSemiconductor/solid-state device manufacturingHydrogenUltraviolet

Methods for cleaning substrates are described including cleaning substrates having hardmask masks and polymer films, such part of semiconductor fabrication. Cleaning methods include ultraviolet (UV) light exposure of process gas mixtures and liquid cleaning chemistries. A substrate and / or process fluids are exposed to ultraviolet radiation. A process gas mixture being irradiated can include an oxidizing gas mixture (air, clean dry air, oxygen, peroxygen, etc.). Reducing gas mixtures, having hydrogen, can also be irradiated. Reactive species from irradiated gas mixtures are exposed to the substrate to chemically modify film properties, such as by facilitating a subsequent liquid cleaning step. Liquid cleaning chemistries on a substrate surface can also be irradiated. Such cleaning techniques enable shorter cleaning times, lower processing temperatures, and reduced damage to underlying or intermediate layers such as dielectric layers.

Owner:TOKYO ELECTRON LTD

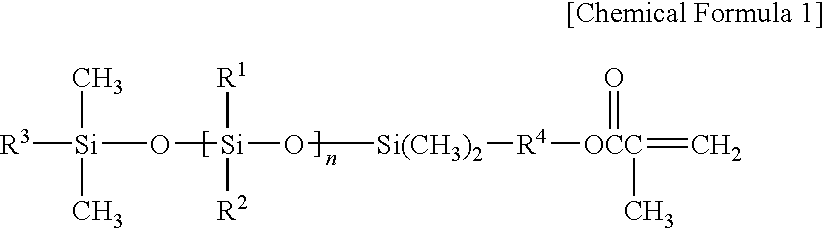

Acrylic pressure-sensitive adhesive composition, acrylic pressure-sensitive adhesive sheet, and methods for bonding the sheet to automotive coating

InactiveUS20100101723A1High bonding strengthMaintain good propertiesImpression capsFilm/foil adhesivesPolymer scienceMeth-

Disclosed is an acrylic pressure-sensitive adhesive composition that gives a pressure-sensitive adhesive layer exhibiting superior adhesiveness even to coatings, which are likely to cause low adhesion due to bleeding typically of a surface conditioner, without requiring, for example, washing process.The acrylic pressure-sensitive adhesive composition contains a vinyl monomer or a partial polymer thereof (a); and a (meth)acrylate co-oligomer (b), in which the vinyl monomer contains, as a main component, an alkyl(meth)acrylate monomer (a1) having an alkyl group with 2 to 14 carbon atoms, and the (meth)acrylate co-oligomer (b) has a weight-average molecular weight of from 1000 to 30000 and contains, as monomer components, 96 to 99.5 percent by weight of an alkyl(meth)acrylate (b1) and 0.1 to 4 percent by weight of a (meth)acryloyl group-containing silicone oil (b2).

Owner:NITTO DENKO CORP

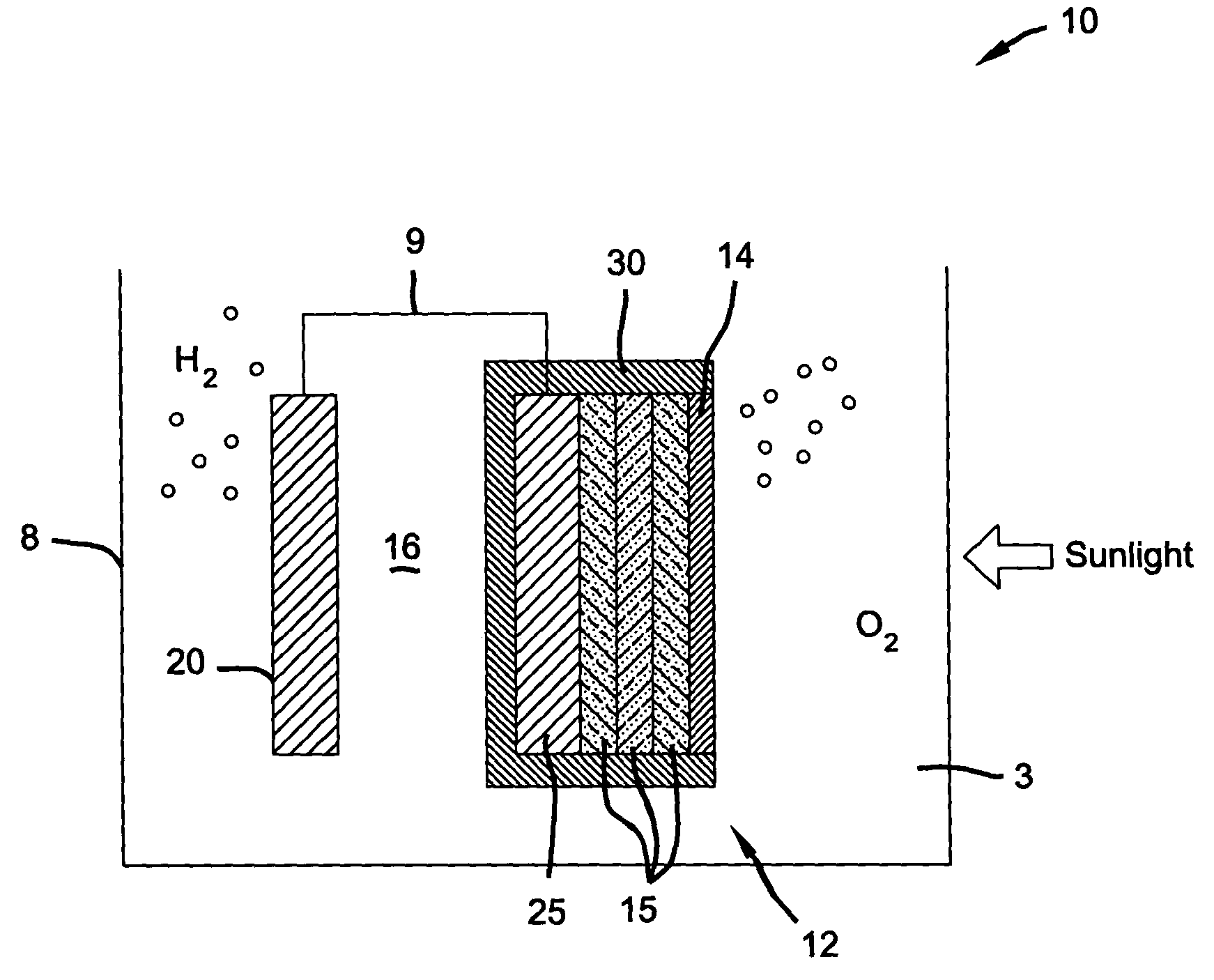

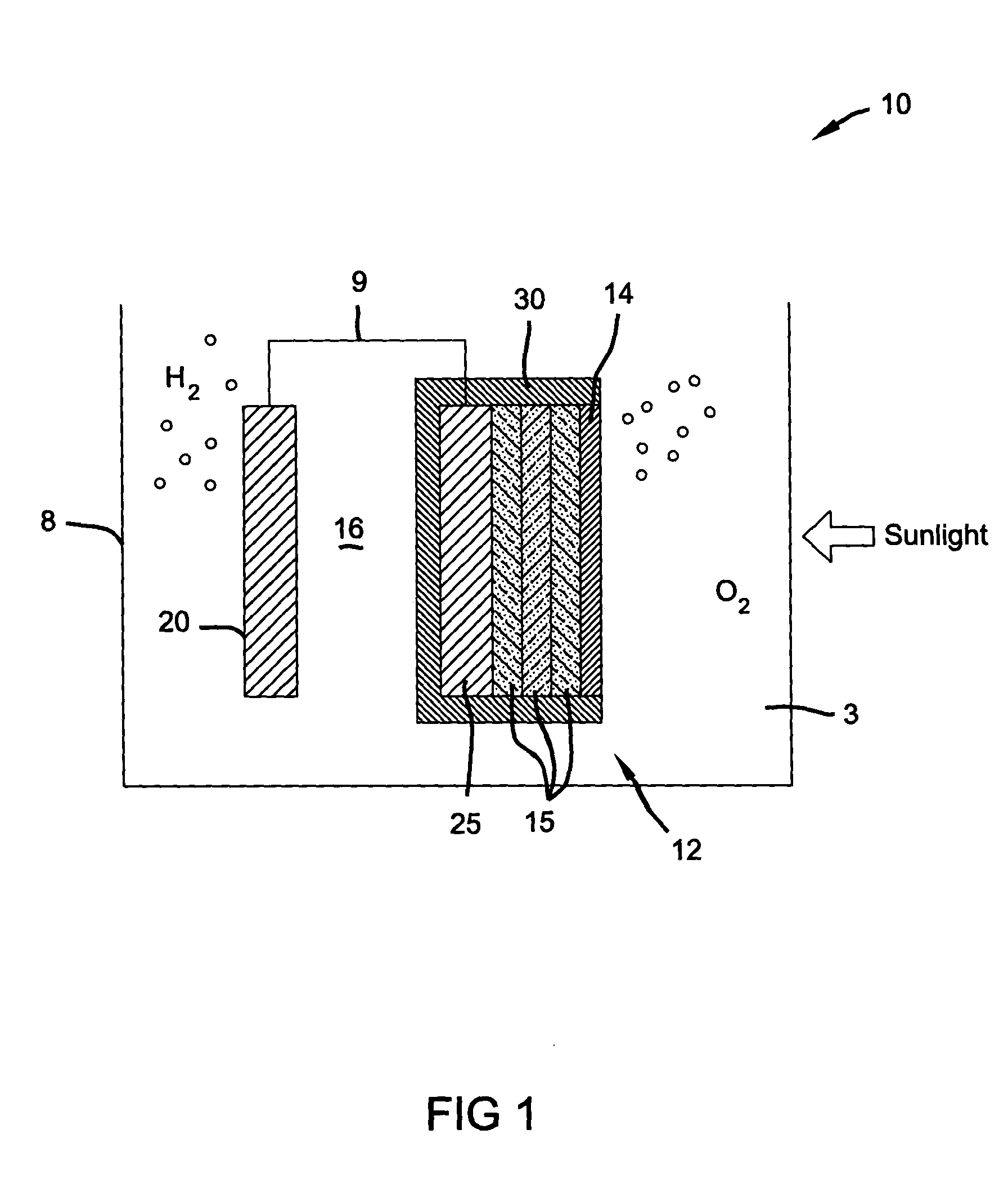

Photoelectrochemical device and method of making

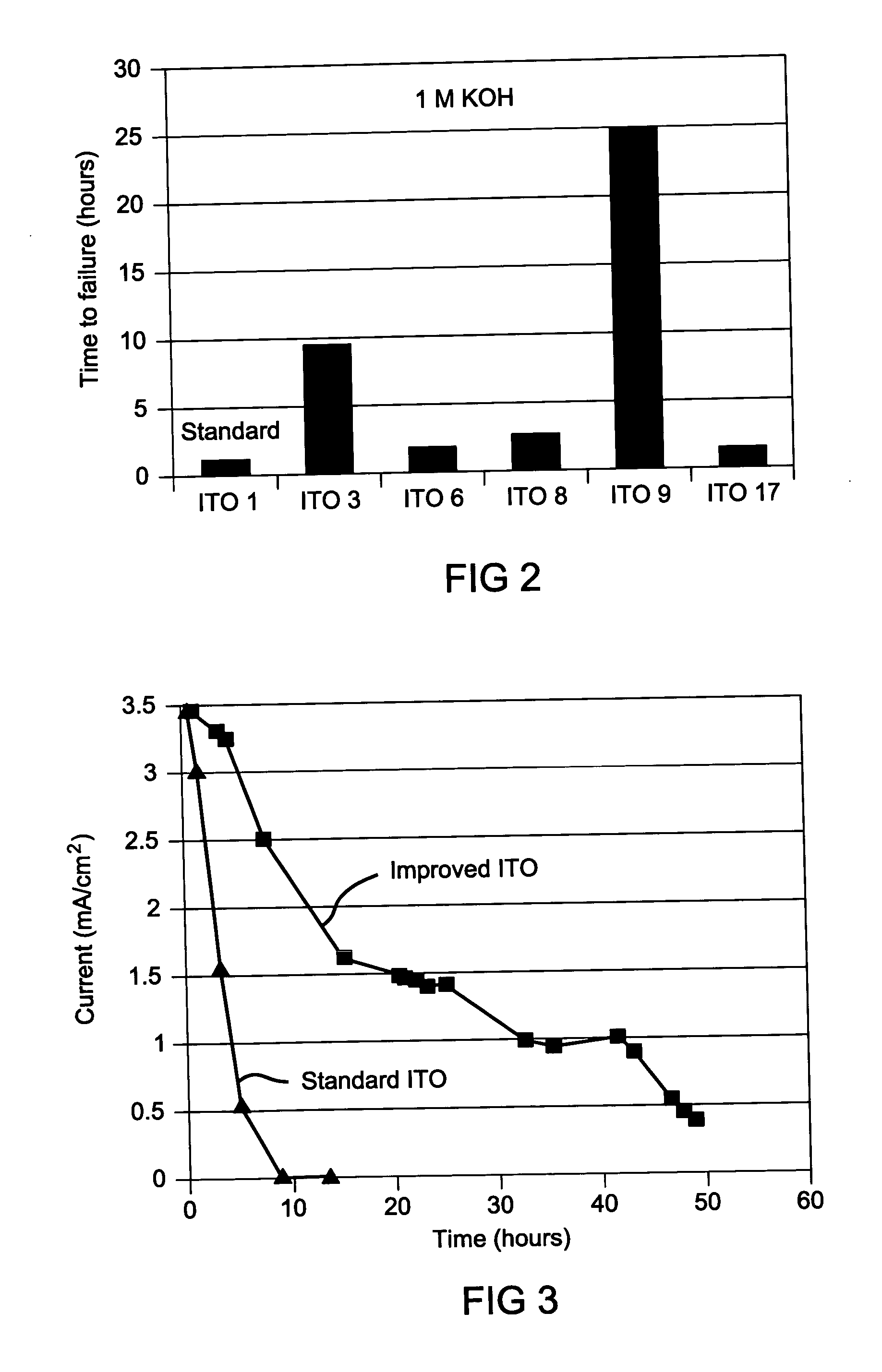

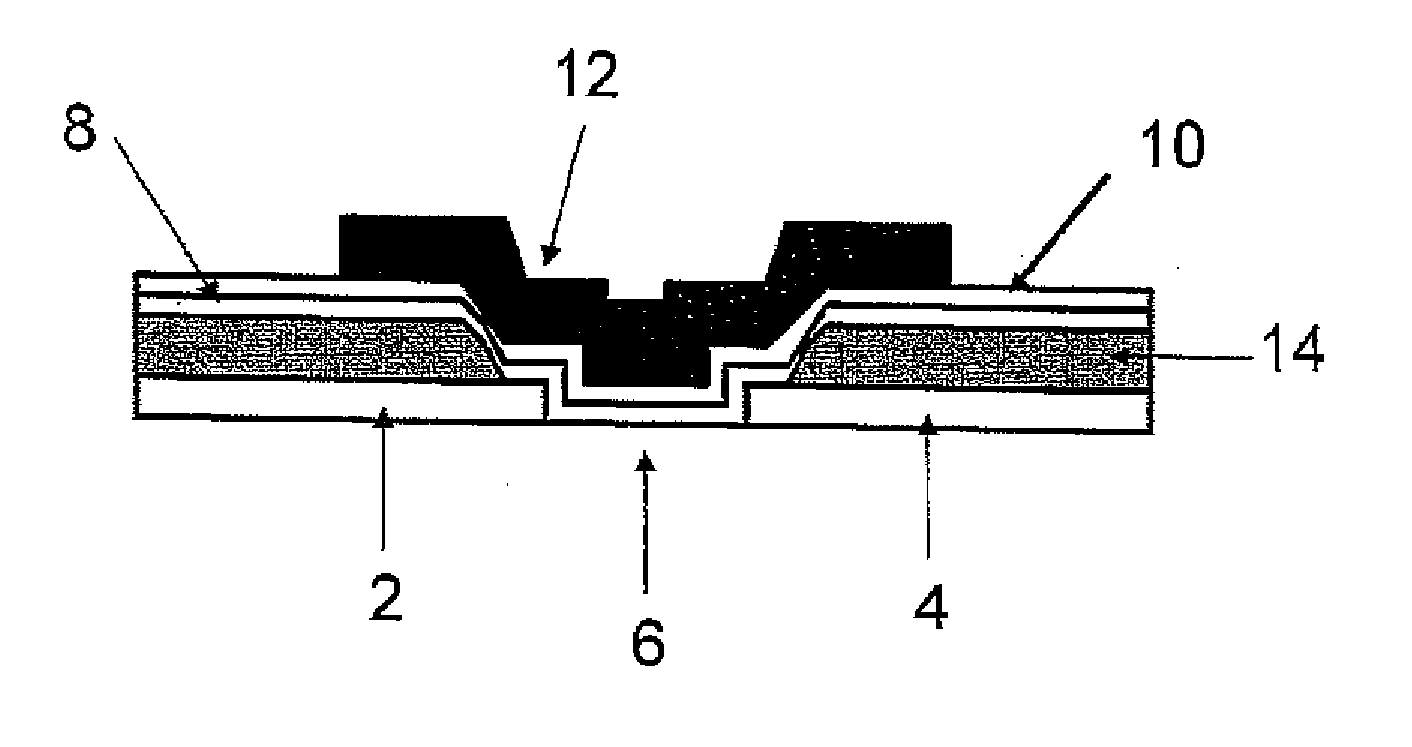

InactiveUS20050059186A1Long deposition timeLayers is relatively thickCellsLight-sensitive devicesCrystal structureIndium tin oxide

The invention provides a method of making a photoelectrode and also provides a photoelectrode comprising a semiconductor layer having a first and second opposite major surfaces, with the first major surface overlaid with a layer of indium tin oxide having a thickness, crystal structure, and composition sufficient for robust operation in an electrochemical cell for electrolysis of water.

Owner:GENERAL MOTORS COMPANY

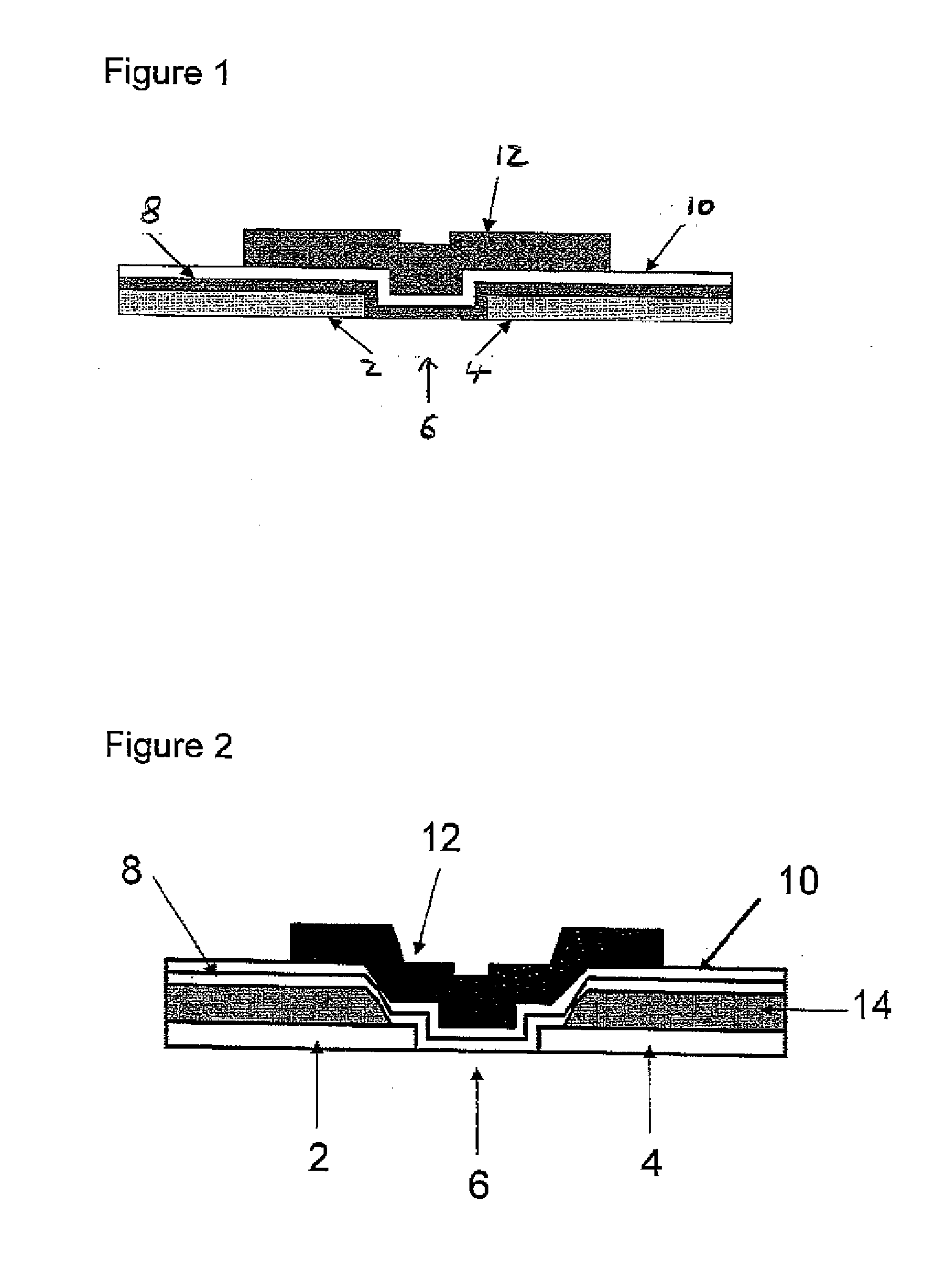

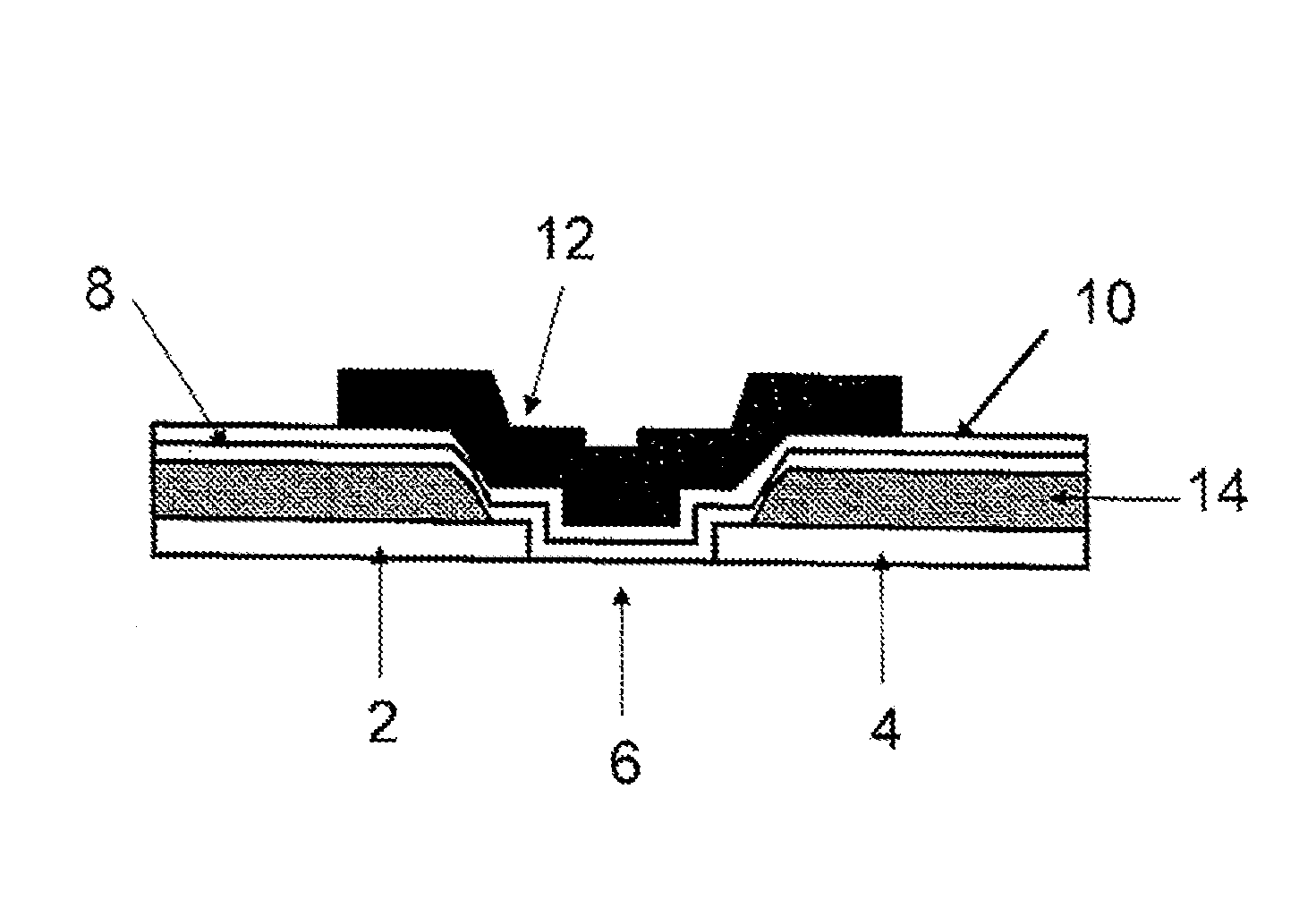

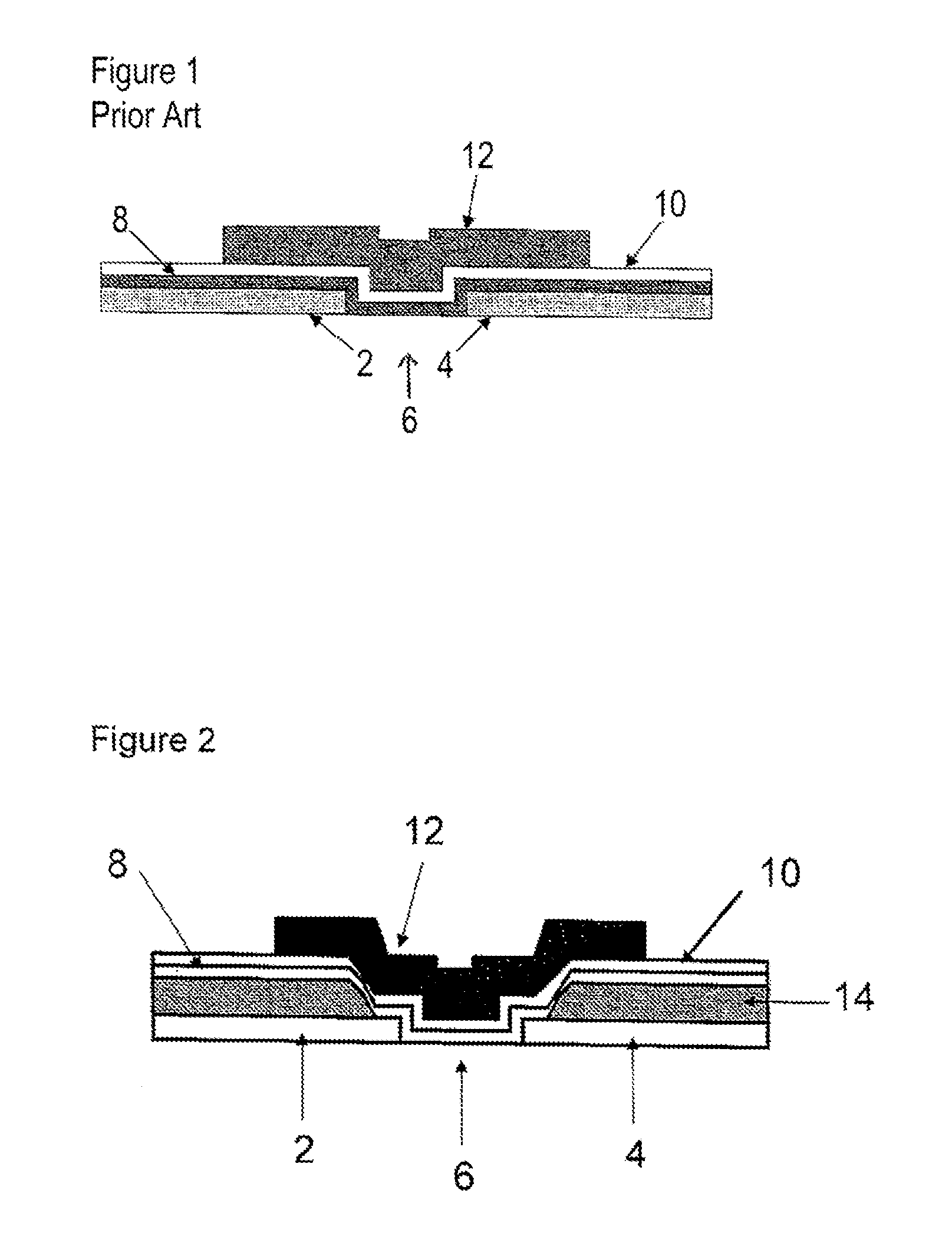

Organic Thin Film Transistors

InactiveUS20100051922A1Minimize parasitic capacitanceMinimise capacitanceTransistorSolid-state devicesConductive materialsOrganic semiconductor

An organic thin film transistor comprising: a substrate; a source electrode and a drain electrode defining a channel; a layer of insulating material disposed over the source and drain electrodes; a layer of organic semi-conductive material extending across the channel; a layer of dielectric material; and a gate electrode disposed over the layer of dielectric material.

Owner:CAMBRIDGE DISPLAY TECH LTD +1

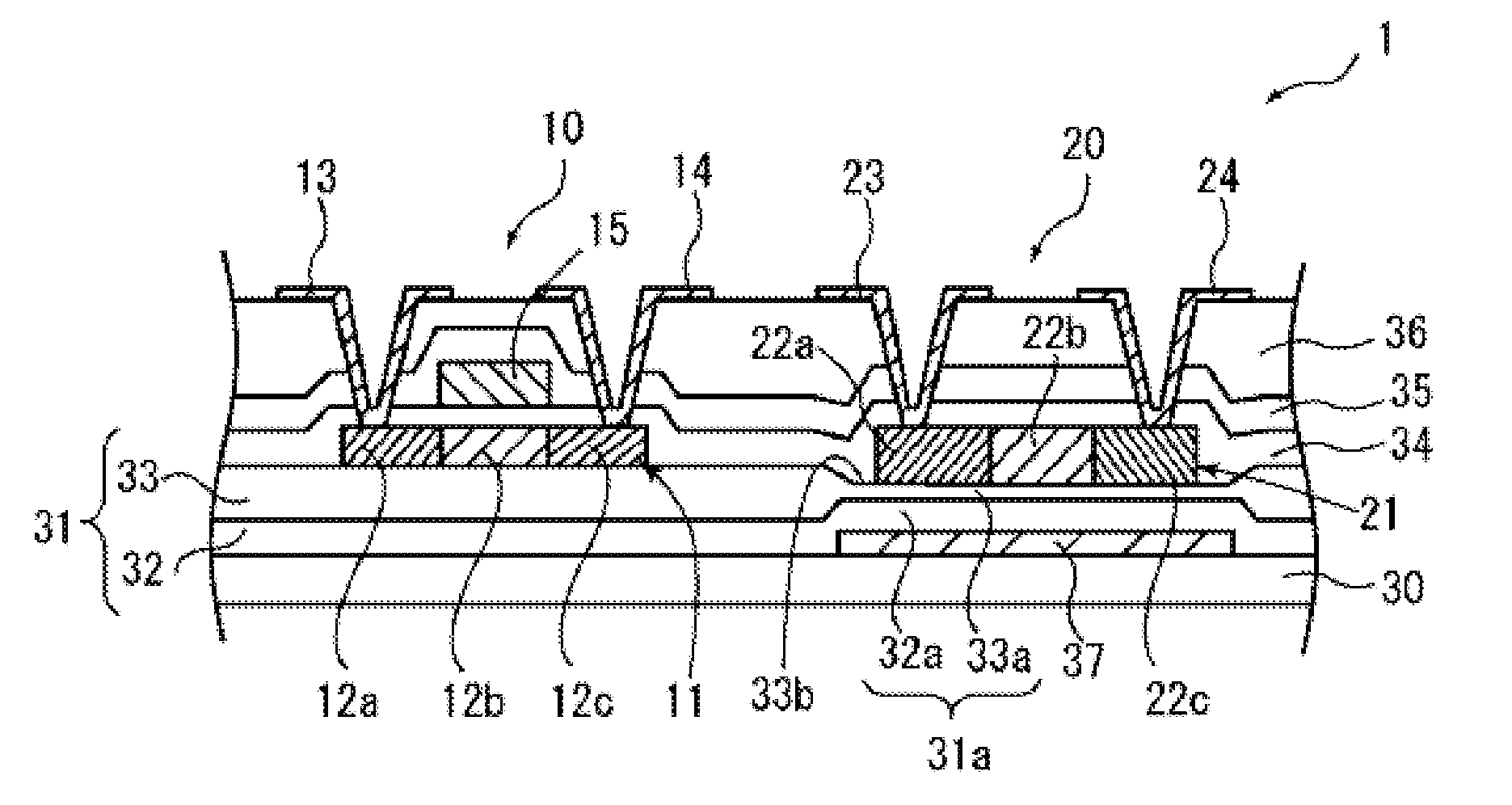

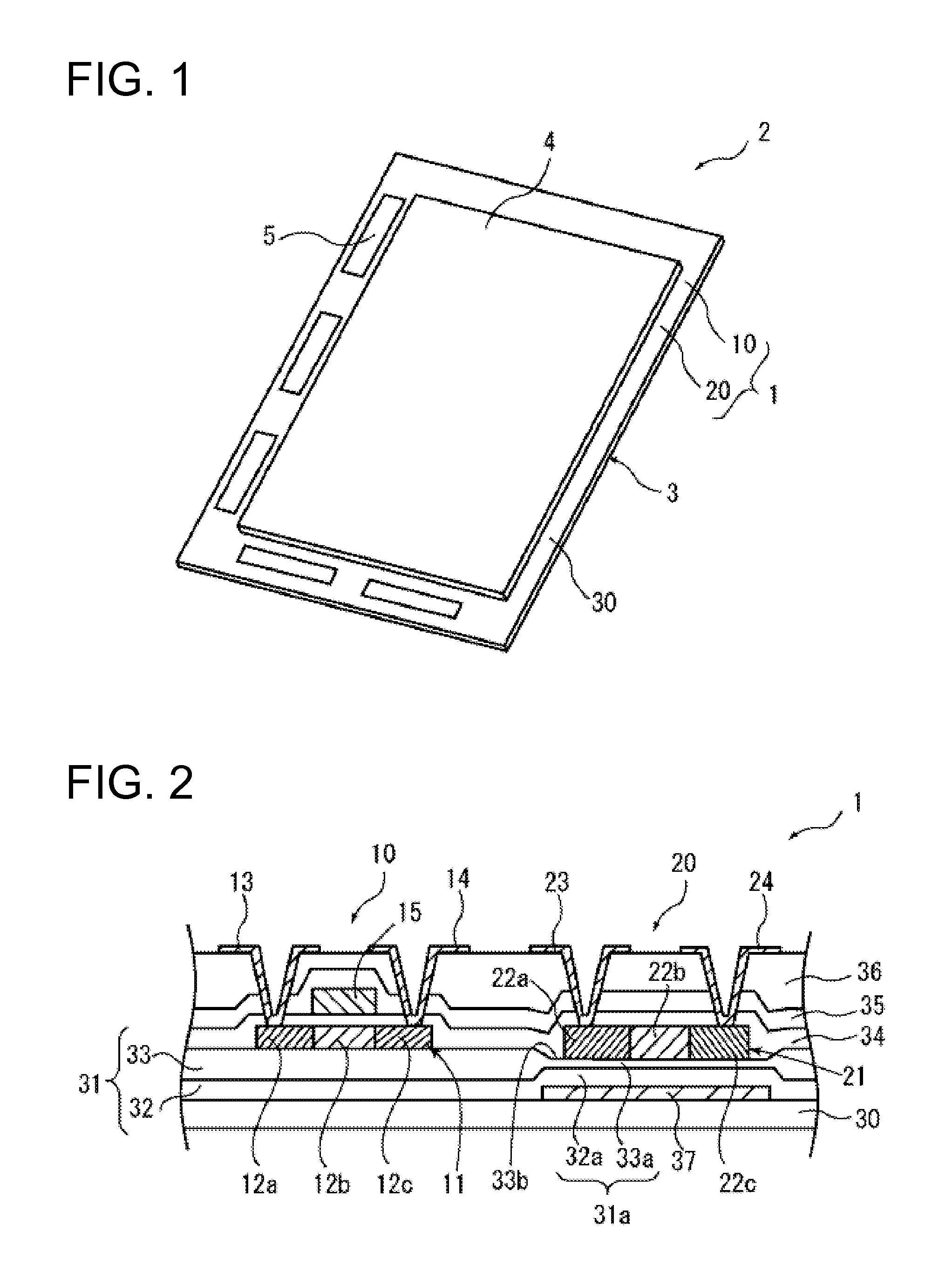

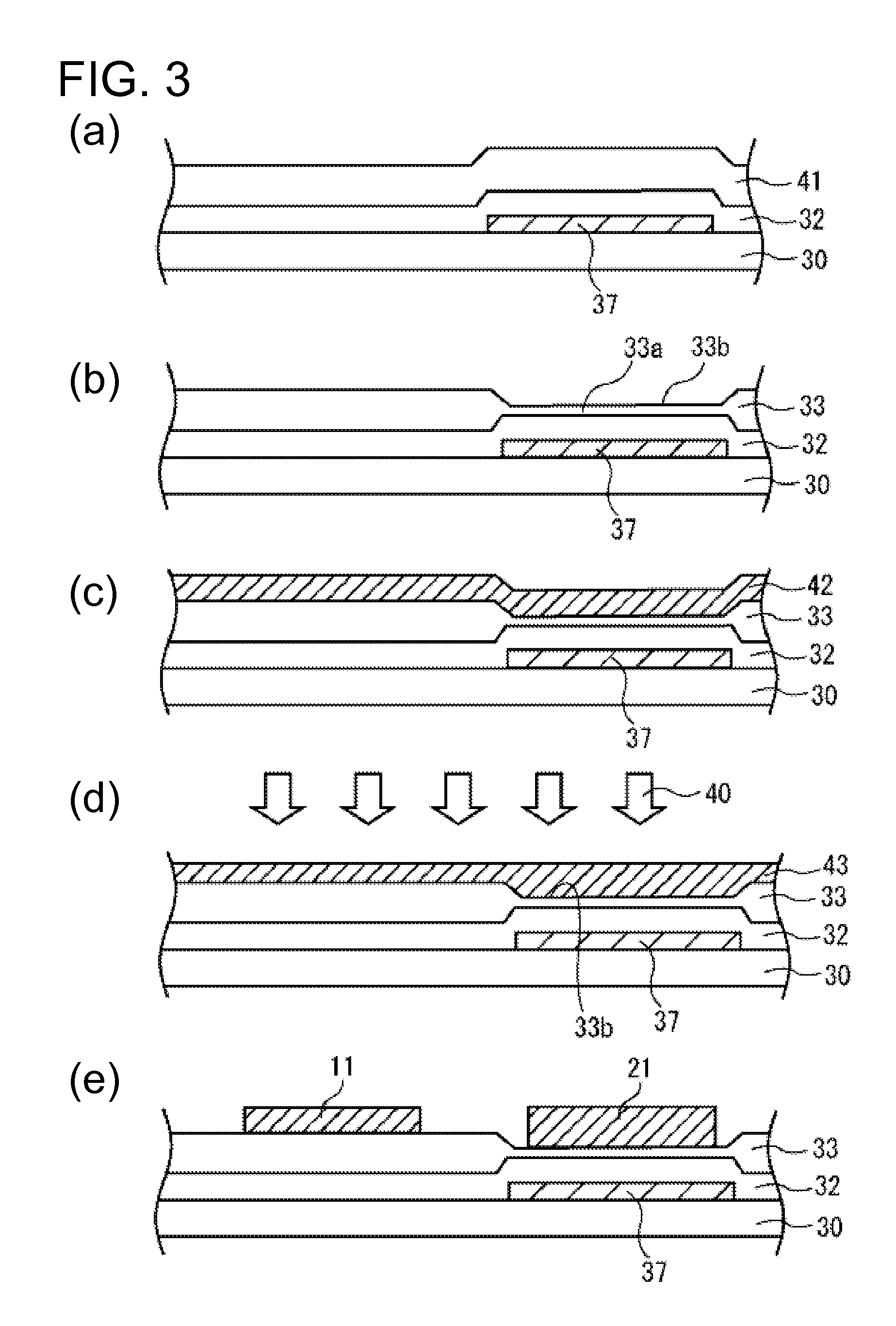

Semiconductor device and method for manufacturing same

InactiveUS20130099290A1Improve performanceLower performance requirementsSolid-state devicesSemiconductor/solid-state device manufacturingMolten siliconCrystalline silicon

Disclosed is a method for manufacturing a semiconductor device that can improve the performance of a photodiode that is formed on a same substrate as a thin film transistor without greatly deteriorating the productivity of the semiconductor device. On a glass substrate 30, a base layer 31 having a recess 33b on the surface is formed, and on the base layer 31, an amorphous silicon thin film 42 is formed. The amorphous silicon thin film 42 is melted to form a crystalline silicon thin film 43, while moving the molten silicon into the recess 33b. Of the silicon thin film 43, a silicon film 11 that constitutes a portion of a thin film transistor 10 is formed of the silicon thin film 43 in a part other than the recess 33b, while a silicon film 21 that constitutes a portion of a photodiode 20 is formed of the silicon thin film 43 in the recess 33b.

Owner:SHARP KK

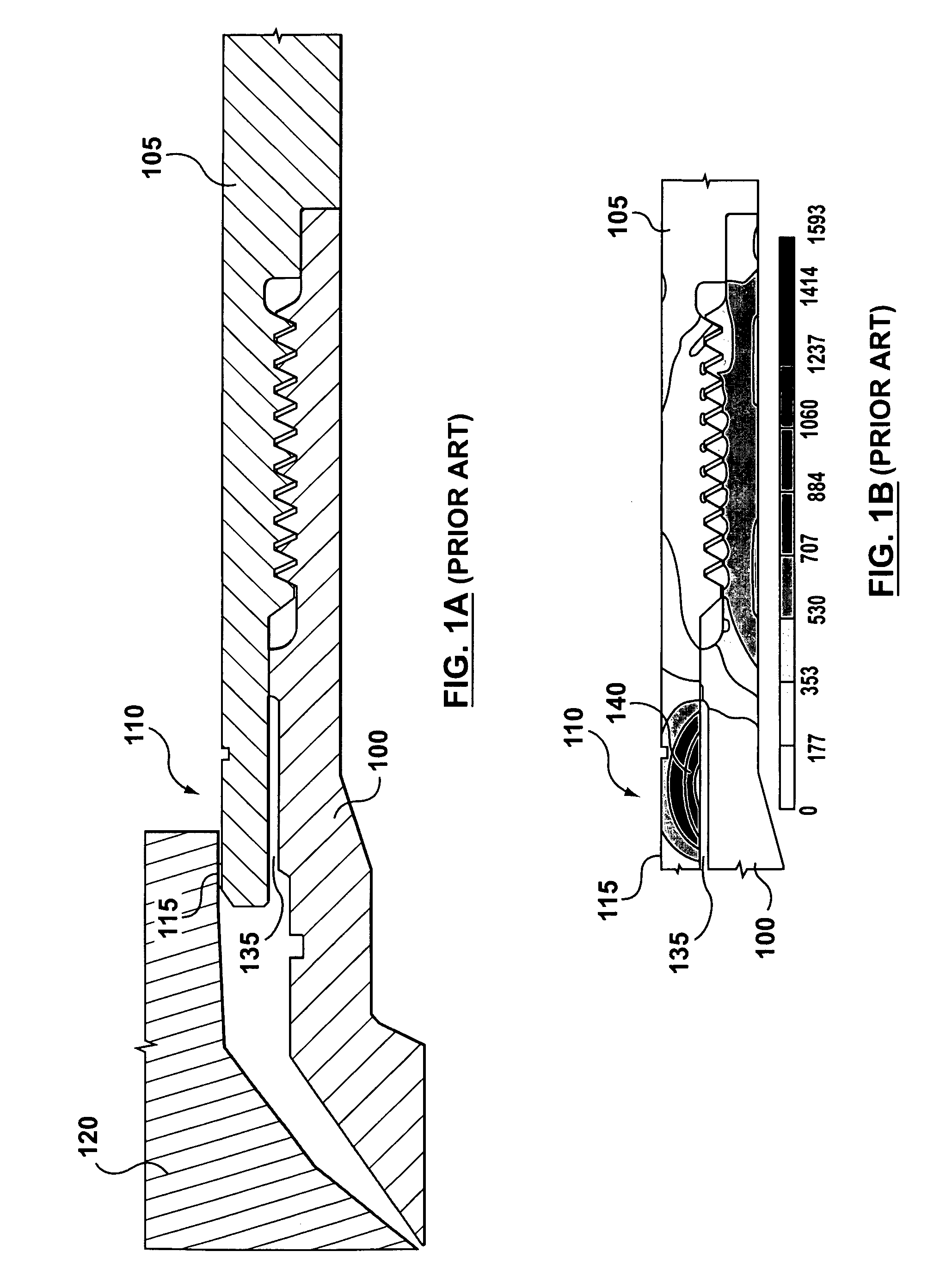

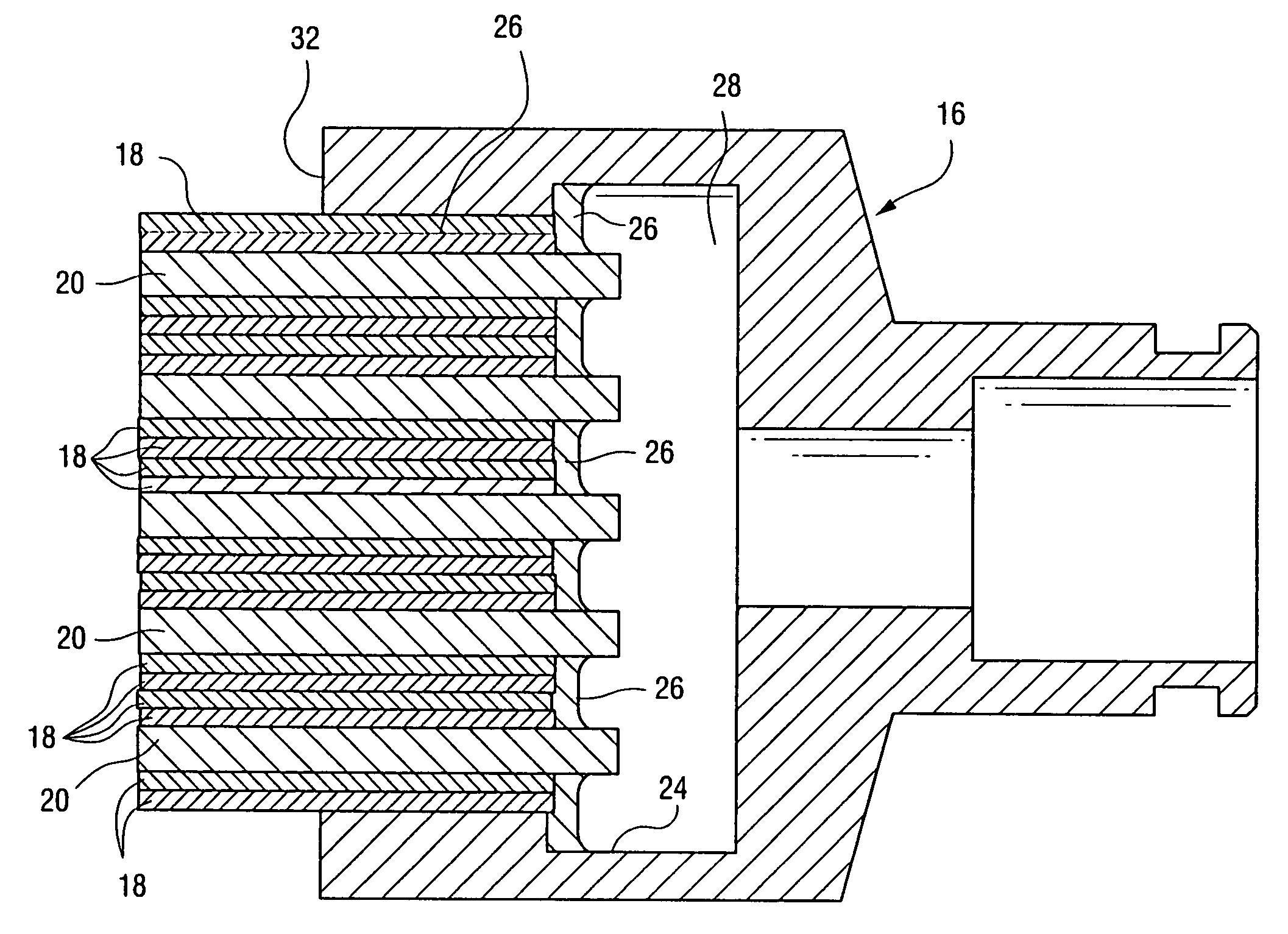

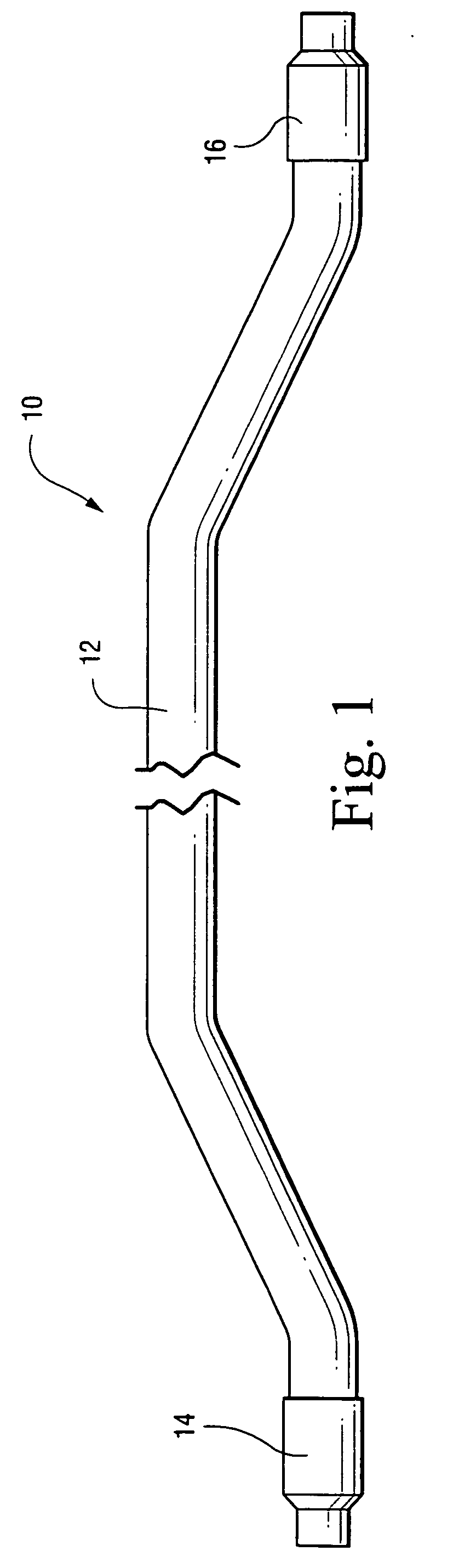

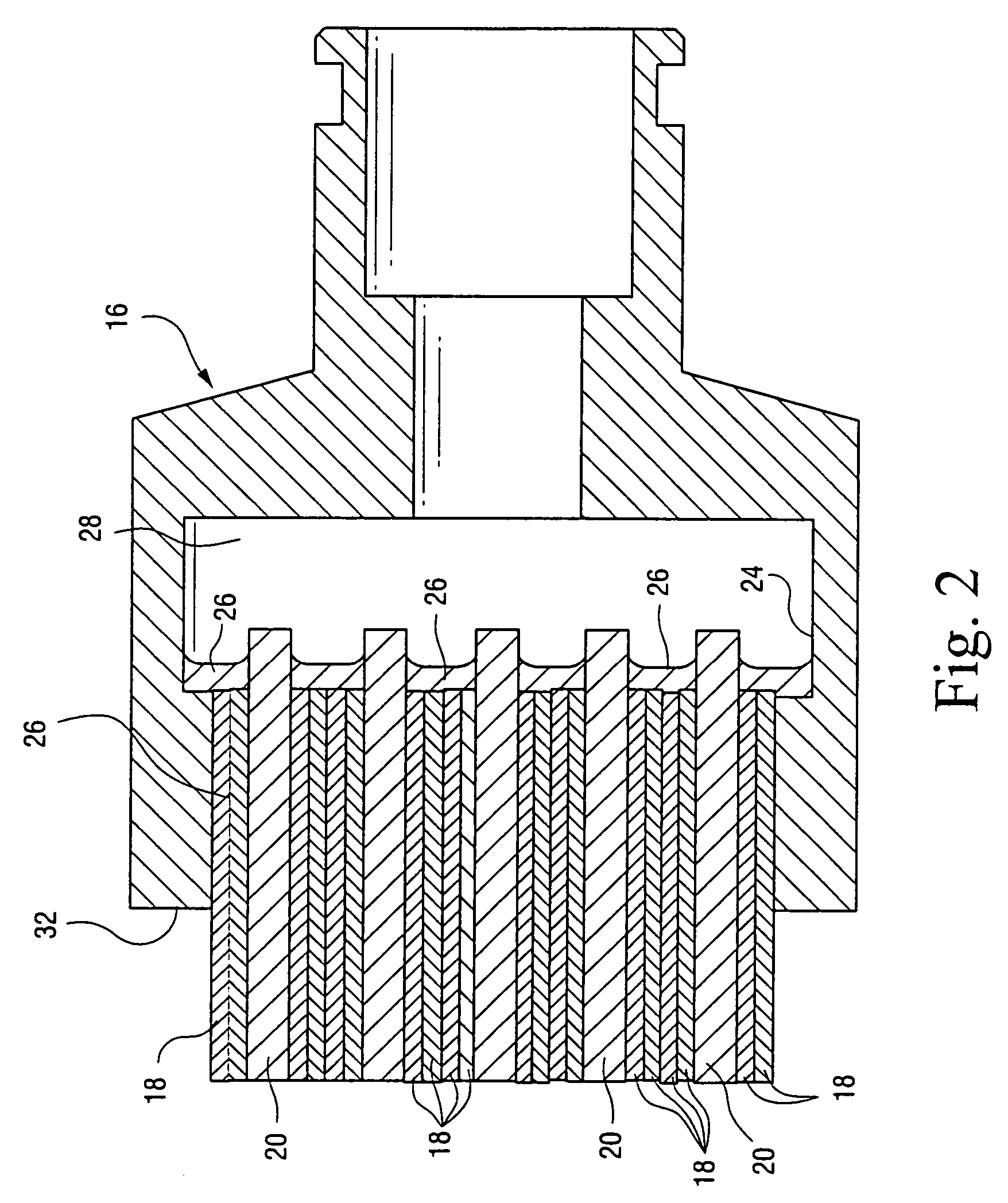

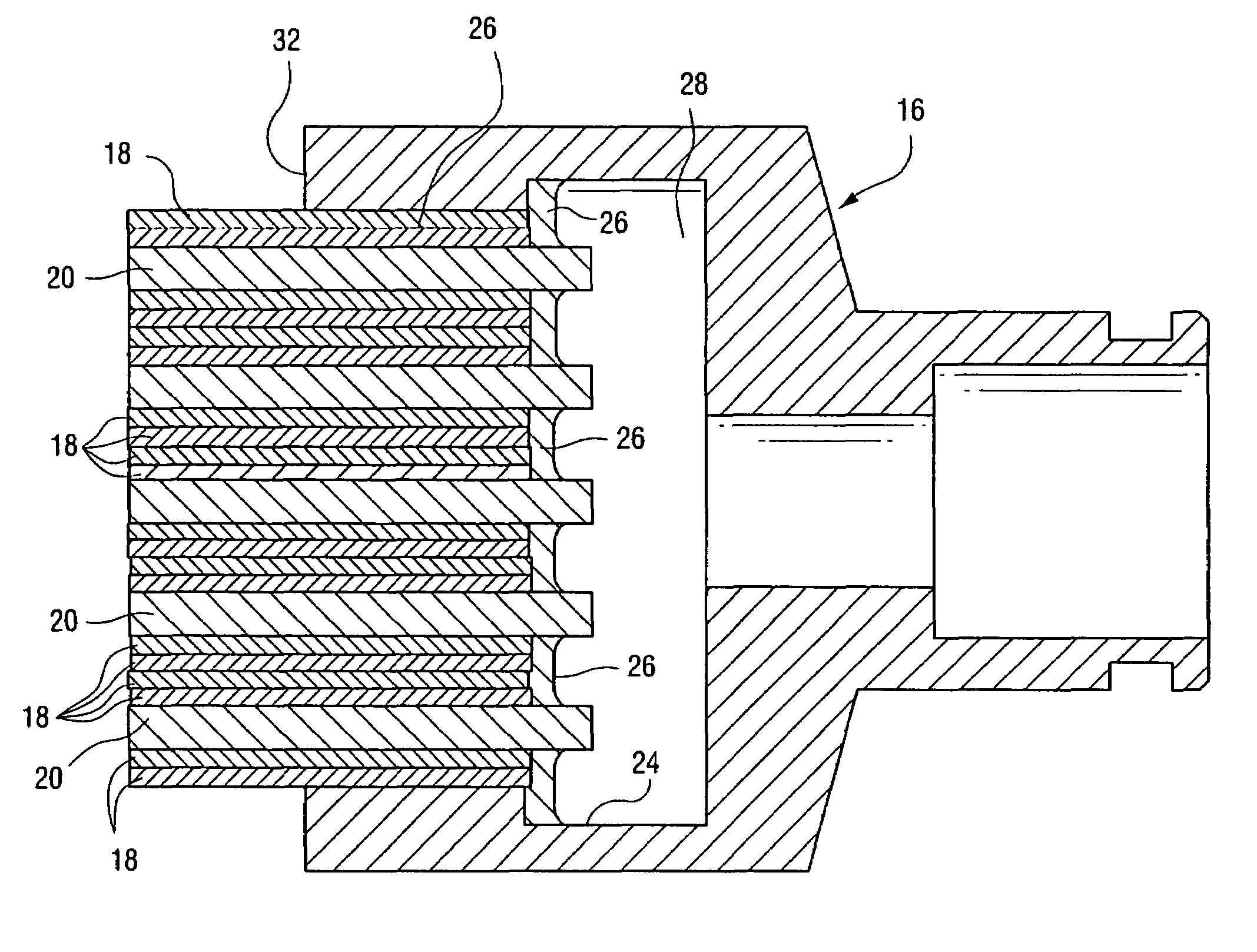

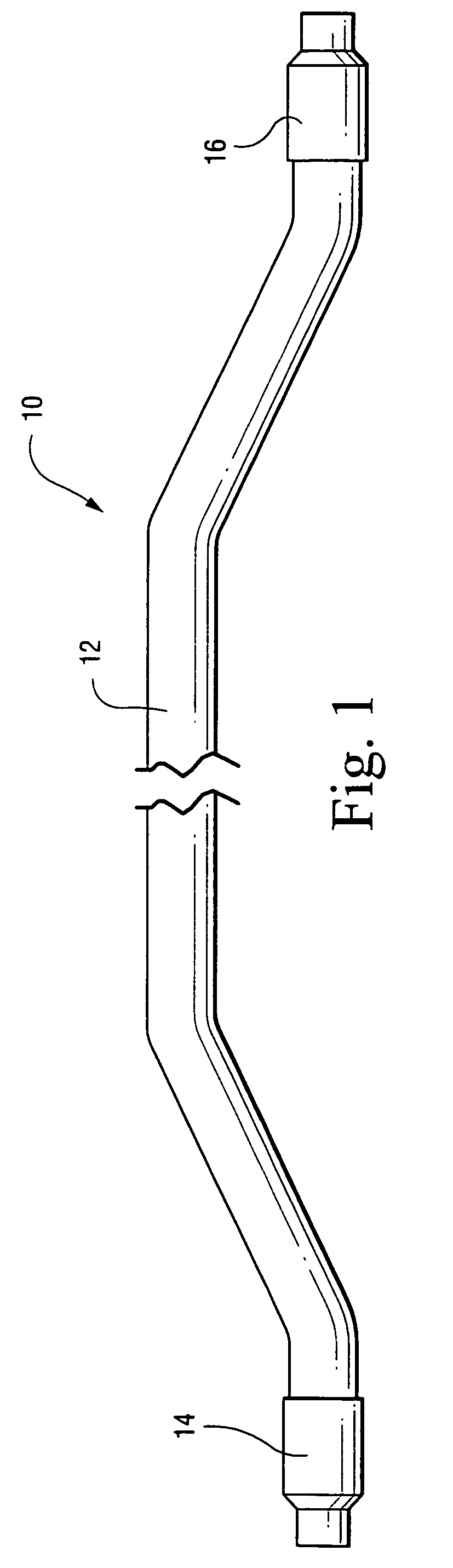

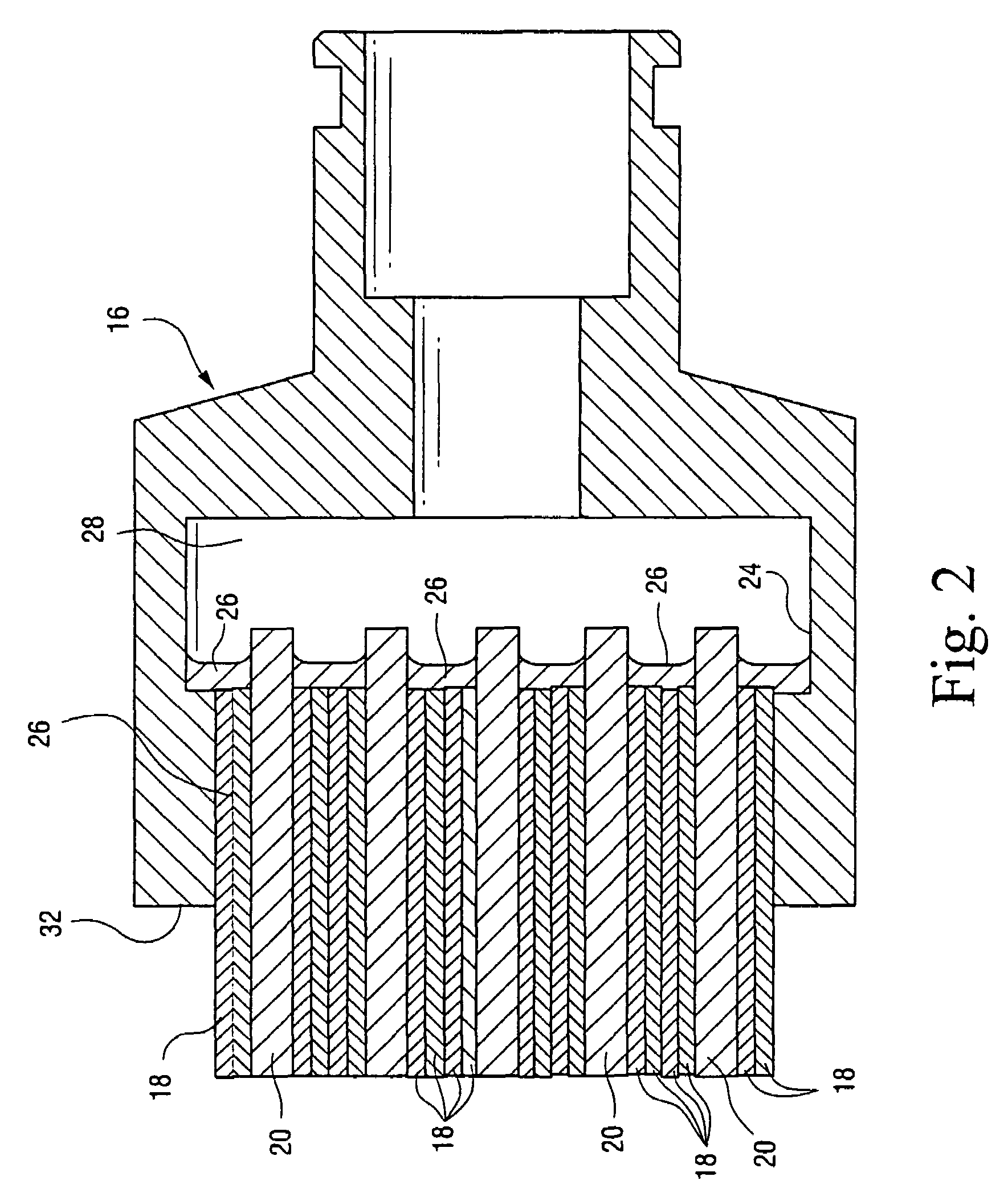

Crevice corrosion-resistant liquid-cooled armature bar clip-to-strand connection and related method

ActiveUS20050247762A1Improved generator availabilityImprove reliabilityTurbinesManufacturing dynamo-electric machinesEngineeringBraze alloy

A brazed joint between an armature bar strand package and an end fitting includes a plurality of strands arranged in a tiered array and forming the strand package; a cavity in the end fitting, free ends of the plurality of strands extending through the opening in the end fitting and received in the cavity; and an essentially phosphorous-free copper-silver braze alloy joining the free ends of the plurality of strands to each other and to interior surfaces of the end fitting.

Owner:GENERAL ELECTRIC CO

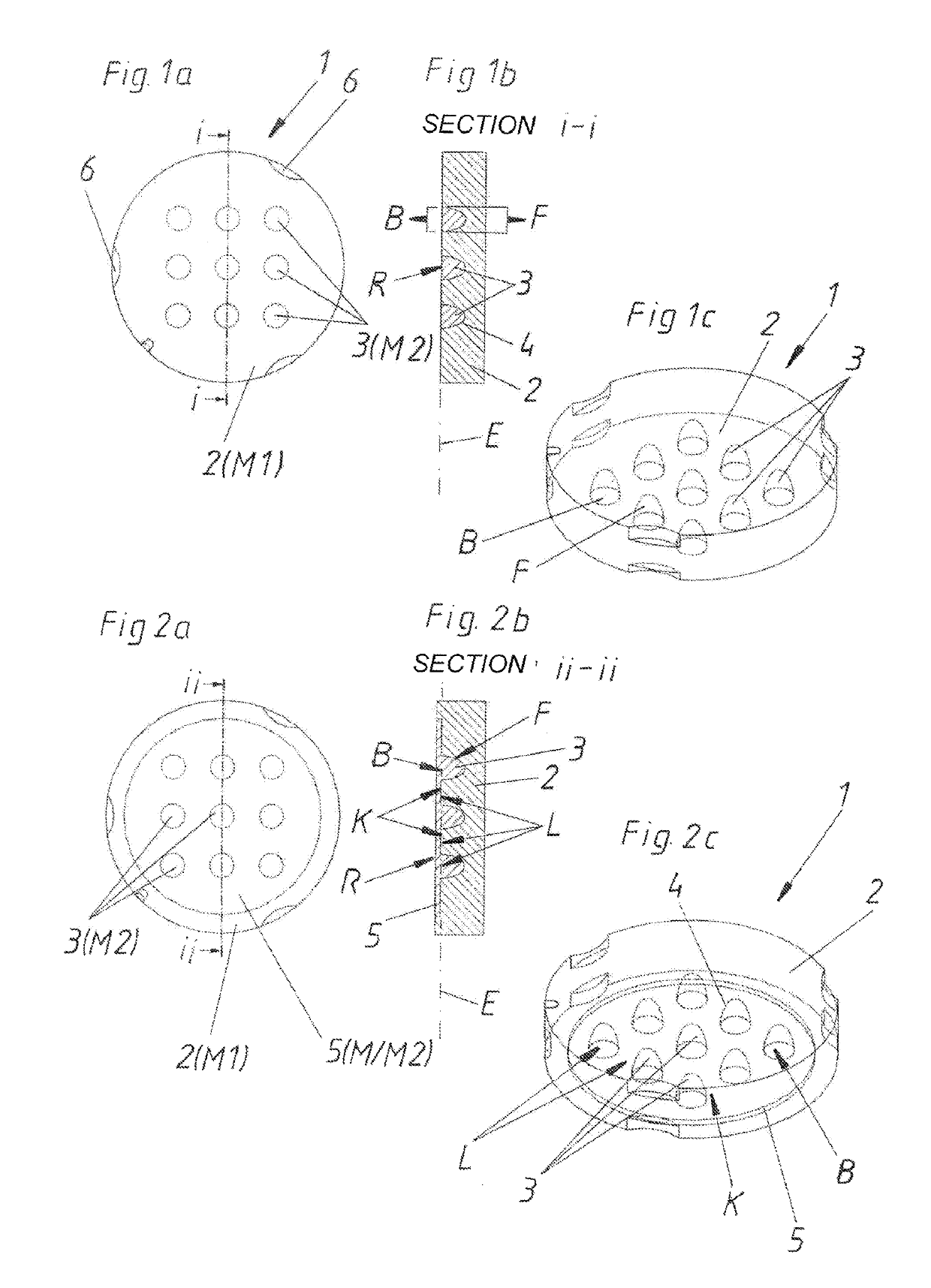

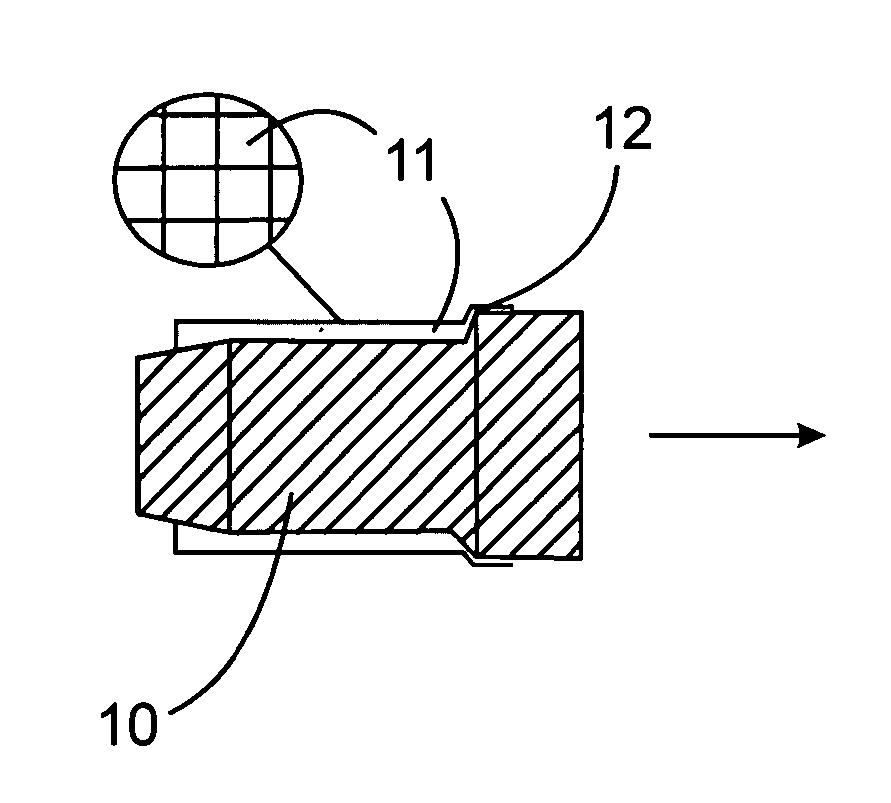

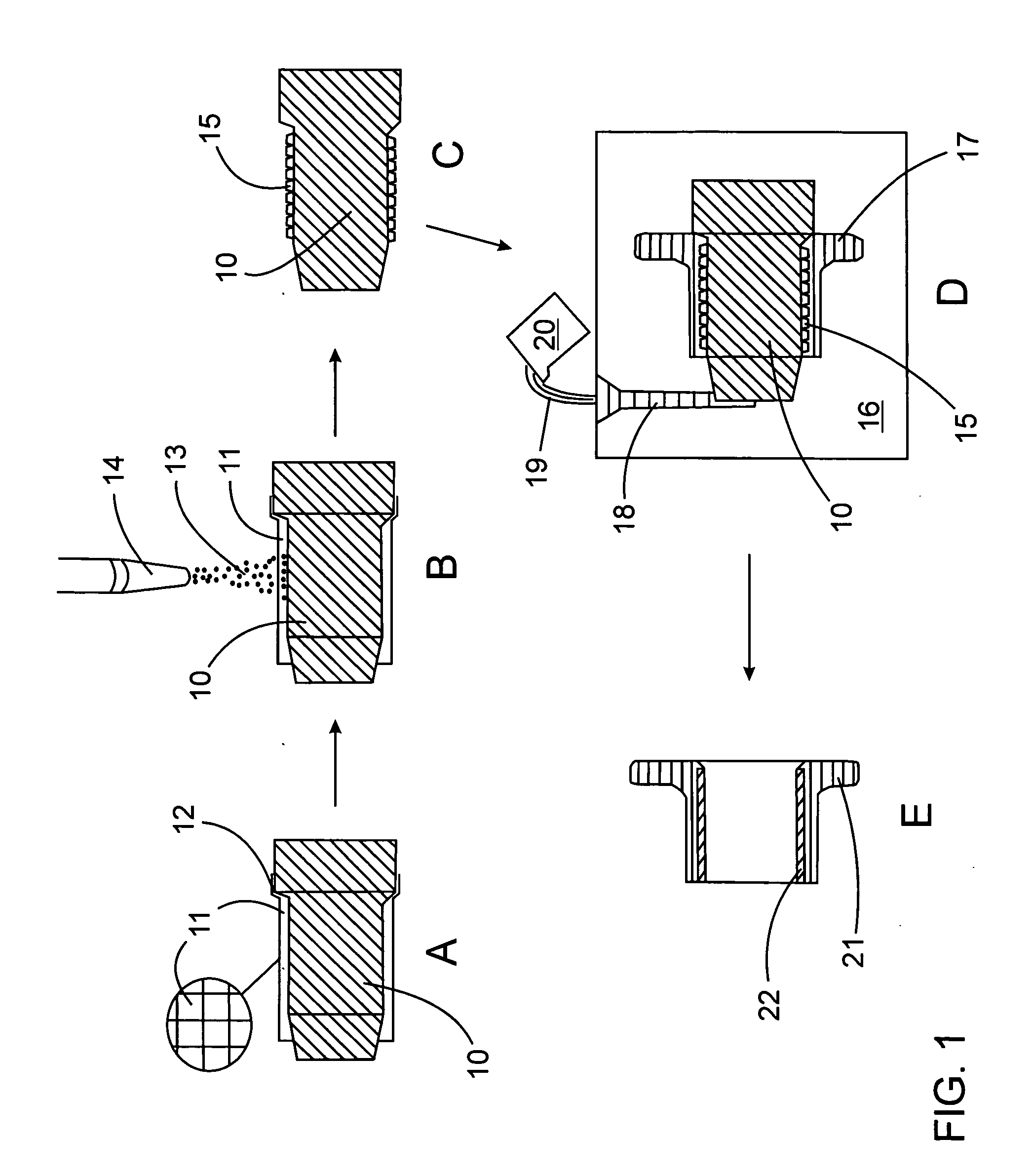

Surface modification of castings

InactiveUS20050205229A1Improve propertiesReduce stress concentrationFoundry mouldsFoundry coresPresent methodSurface layer

A method of modifying a surface of a casting involves providing a casting mould; placing a perforated mask with the mould to define a masked area of the mould; spray-coating the masked area of the mould with a coating material selected for forming a surface layer on the casting; introducing a liquid casting material to the mould; and, solidifying the liquid casting material to form a surface modified casting. The present method reduces the tendency for the coating material to spall from the mould and permits the formation of thicker coating layers on the mould. Thicker and better quality surface layers may be formed on castings.

Owner:NAT RES COUNCIL OF CANADA

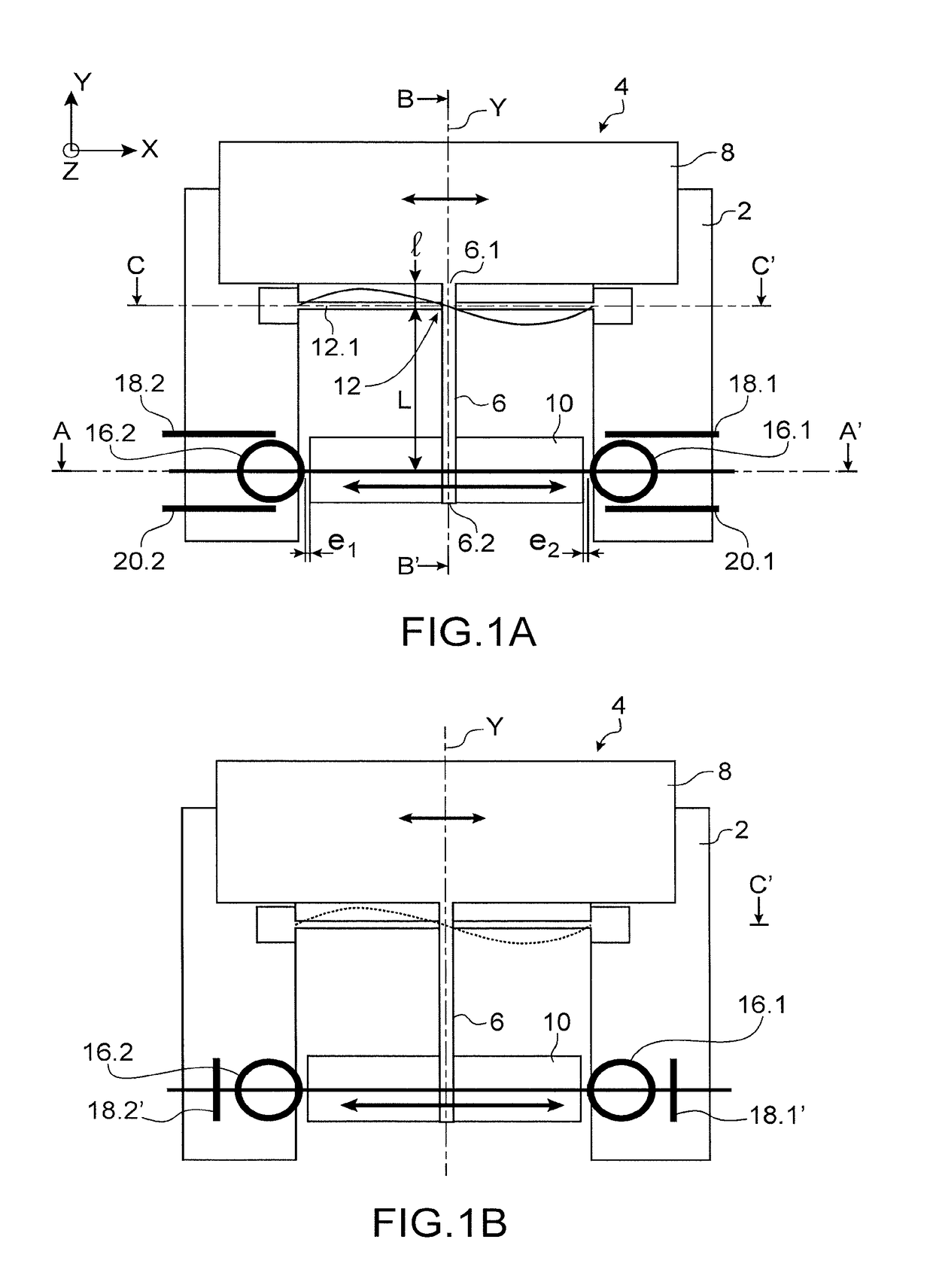

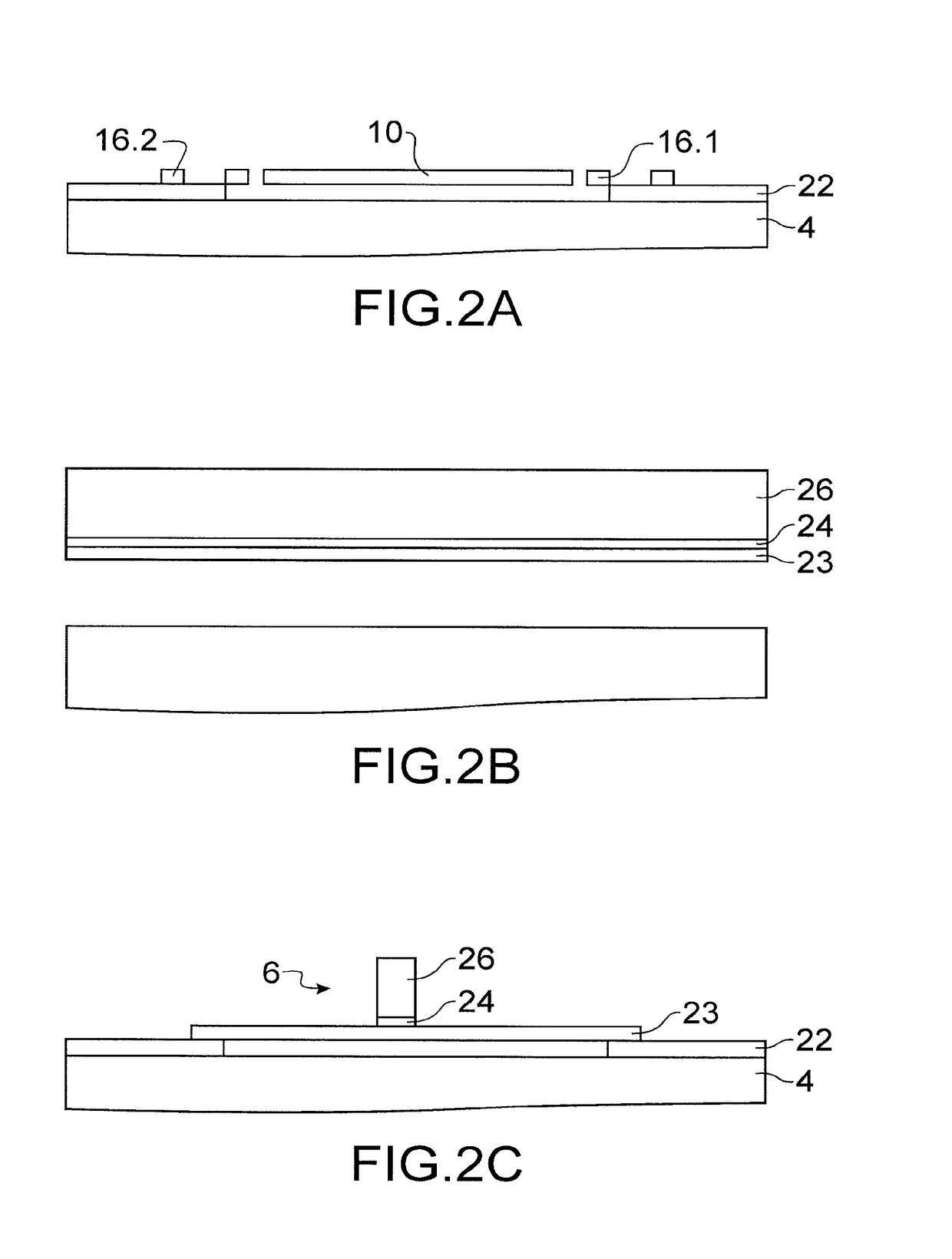

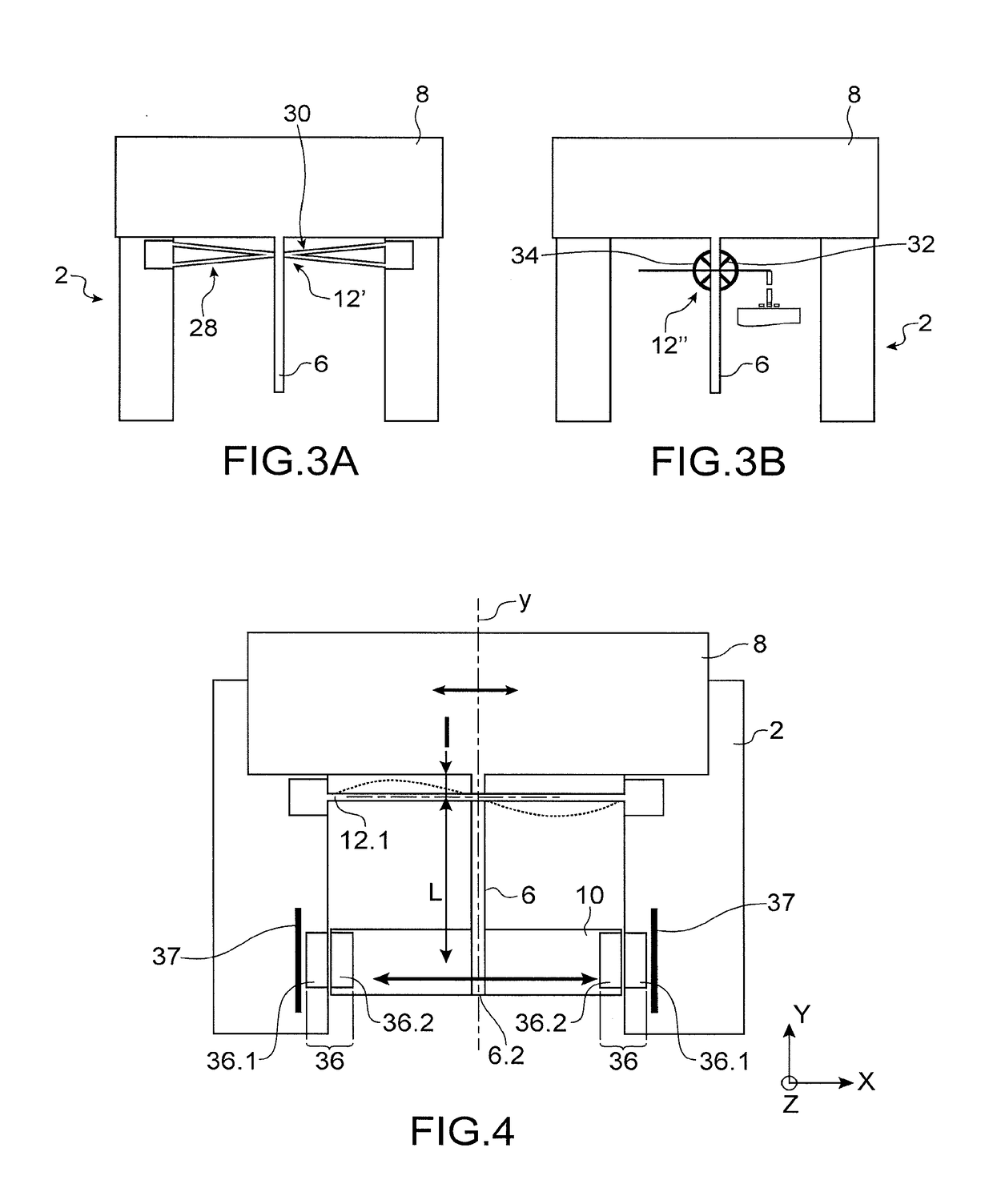

Opto-mechanical physical sensor with an improved sensitivity

ActiveUS20170089944A1High sensitivityHigh detection sensitivityAcceleration measurement using interia forcesResonatorOptical resonance

A physical sensor comprising a substrate (4), a movable mass (8), said mass (8) being able to be moved by an external force, a first optical resonator (16.1), a light wave guide (18.1) for measurement and a light wave guide for detection, a rigid plate (10) which are able to modify the optical resonance frequency of said optical resonator (16.1) by moving closer and away the same, a lever arm (6) rotatably hinged to the substrate (4) by a pivot connection (12) and the mass (8) being movably integral with the transmitting means (6), the rigid plate (10) being disposed relative to the mass (8) and to the pivot connection (12) such that the lever arm (6) transmits to the rigid plate (10), in an amplified manner, the displacement of the mass (8).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

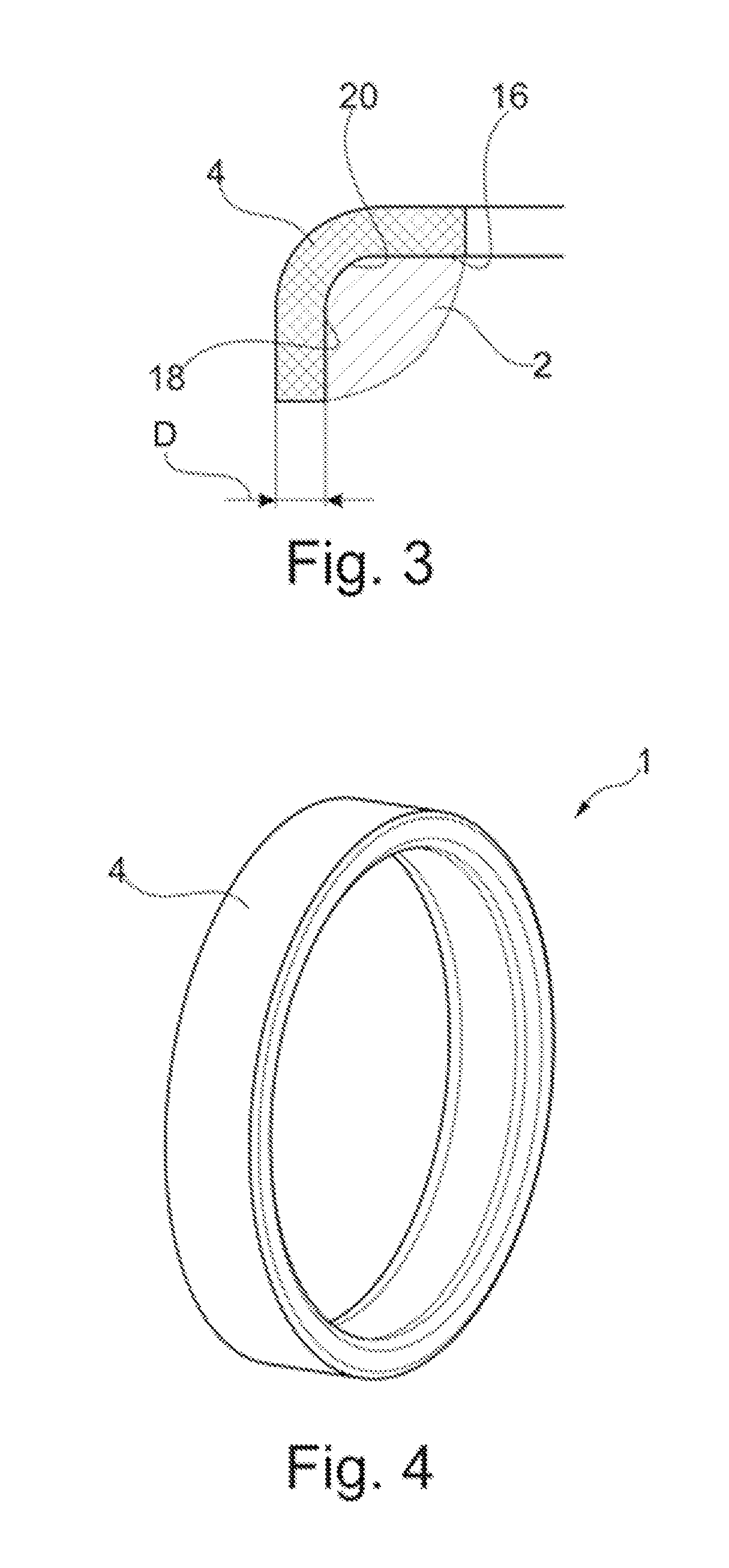

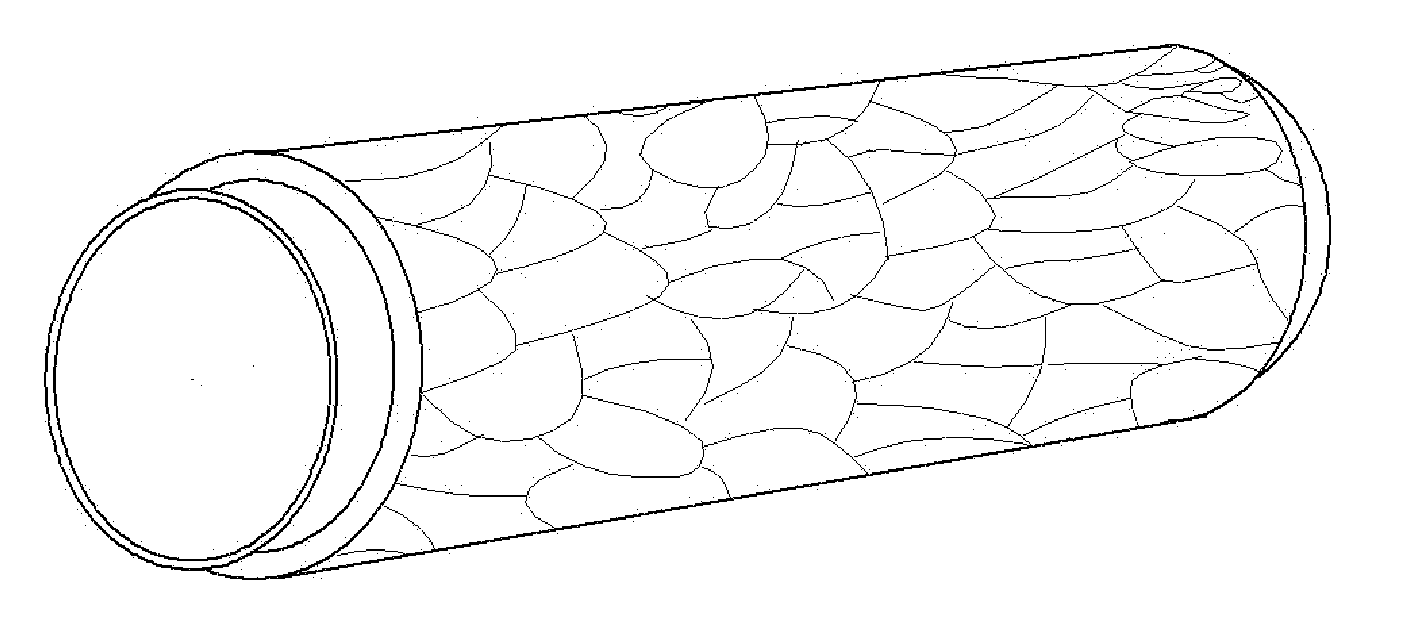

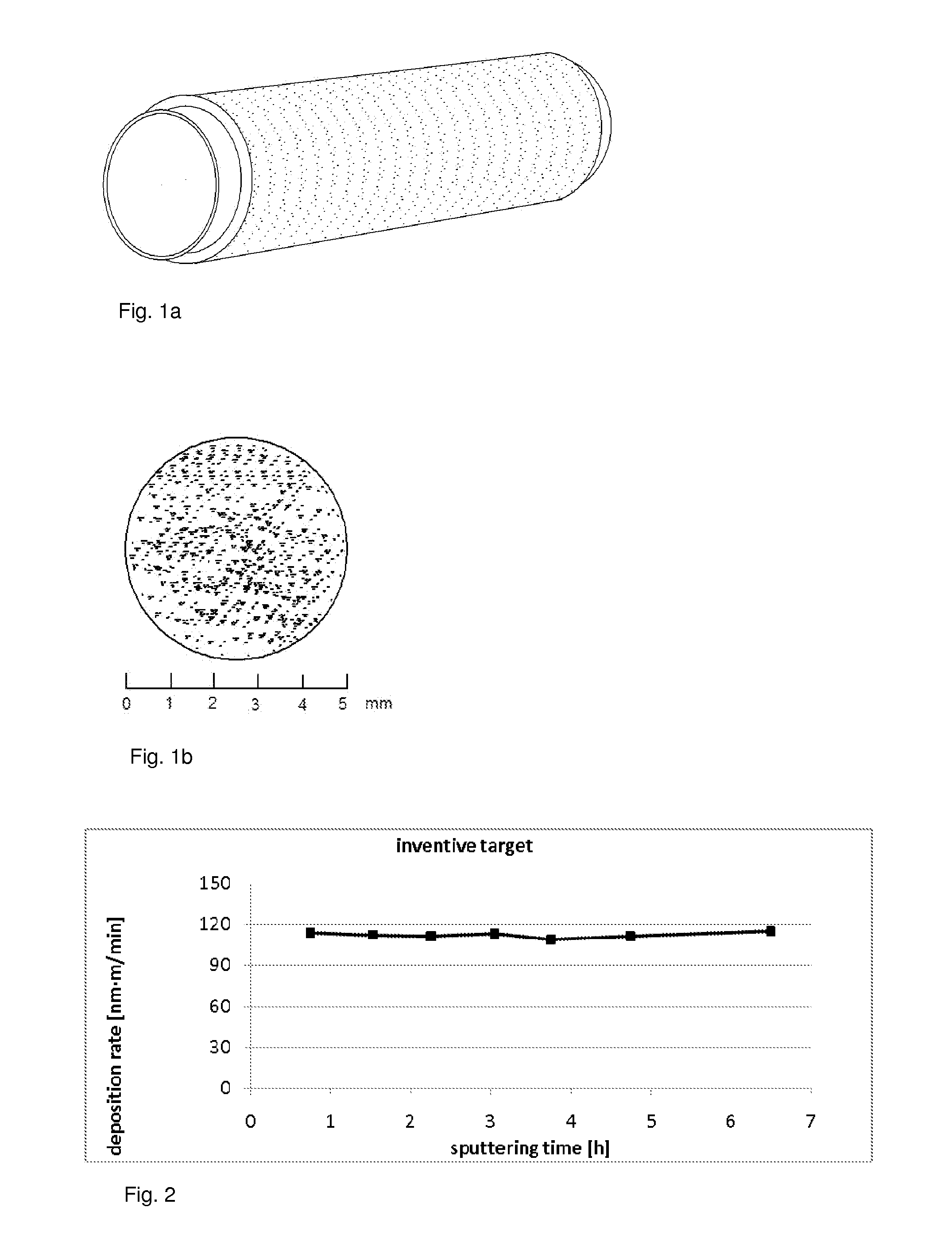

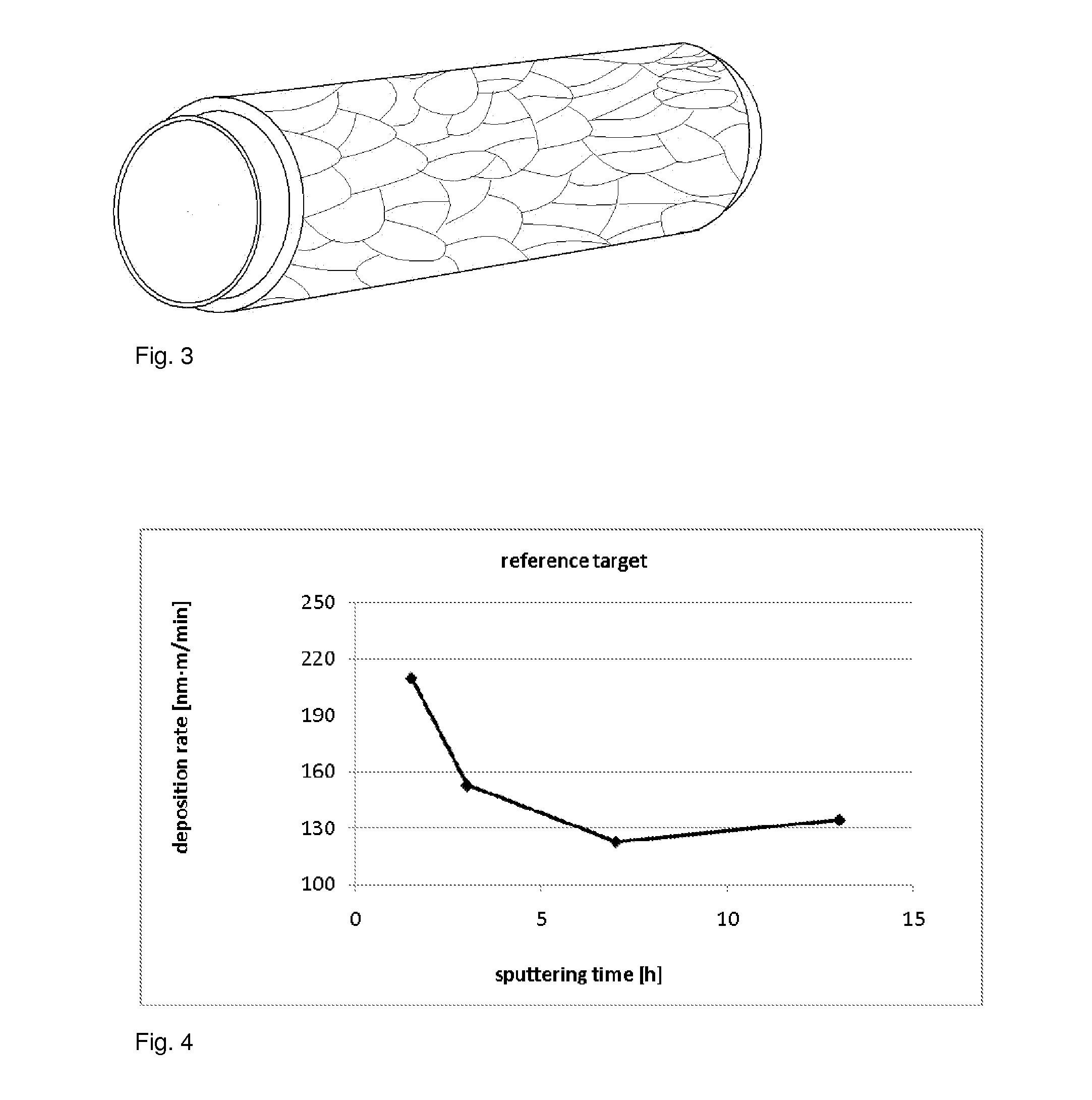

Tube-shaped sputtering target

ActiveUS20120213917A1Improve known sputtering targetLayers is relatively thickMolten spray coatingElectric discharge tubesMean diameterSputtering

A tube-shaped sputtering target is provided having a carrier tube and an indium-based sputtering material arranged on the carrier tube. The sputtering material has a microstructure having a mean grain size of less than 1 mm, measured as the mean diameter of the grains on the sputtering-roughened surface of the sputtering material.

Owner:MATERION ADVANCED MATERIALS GERMANY GMBH

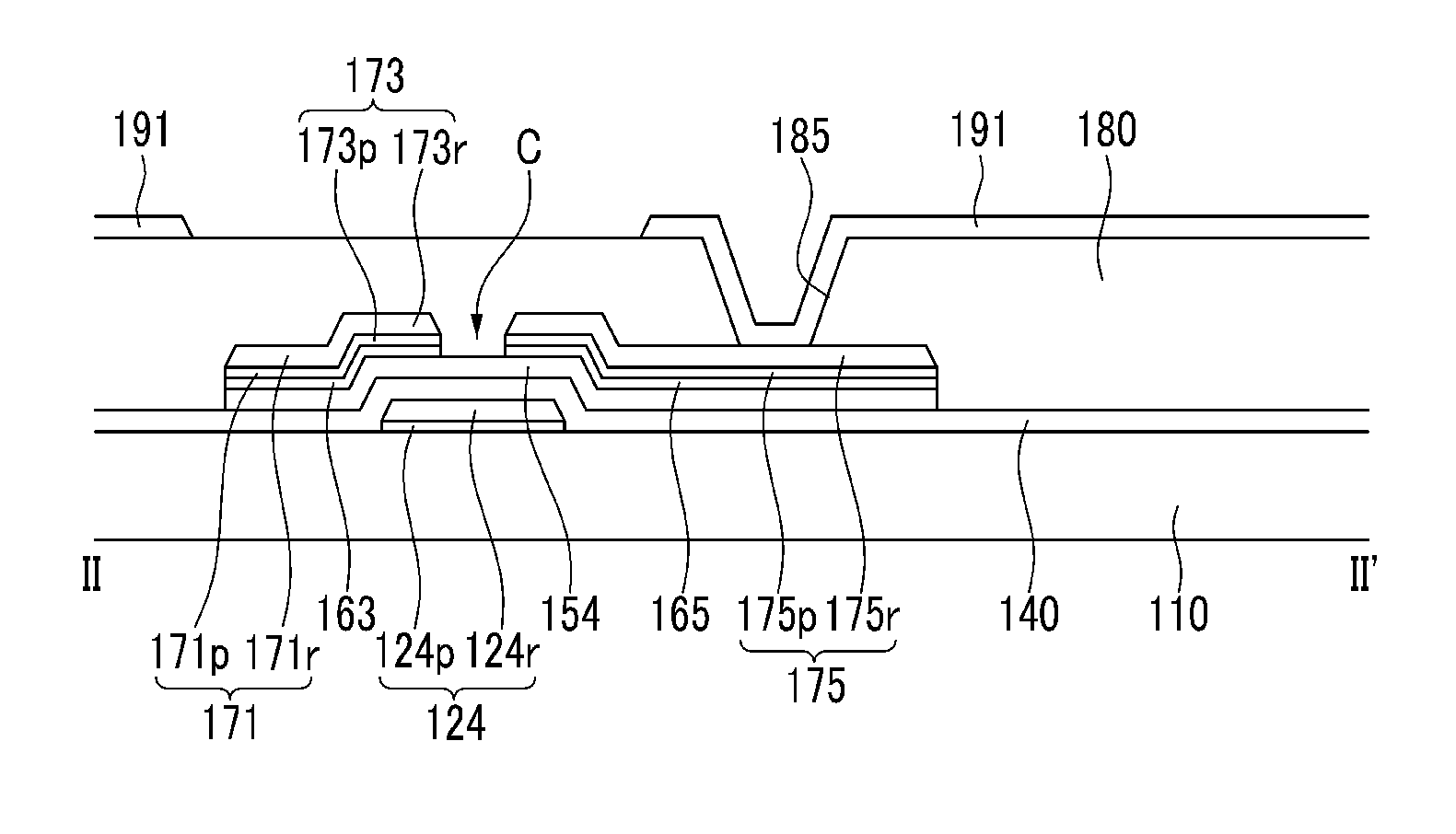

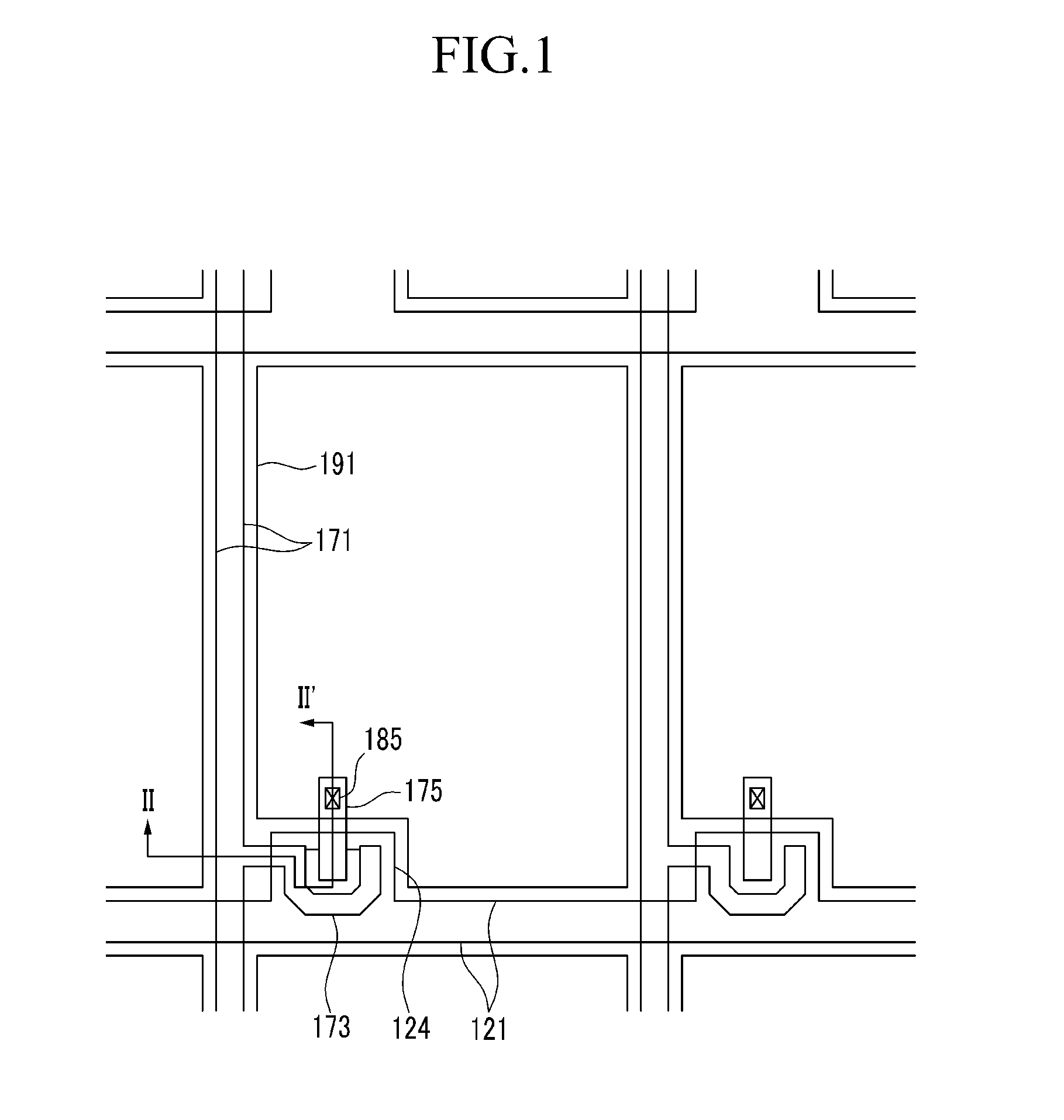

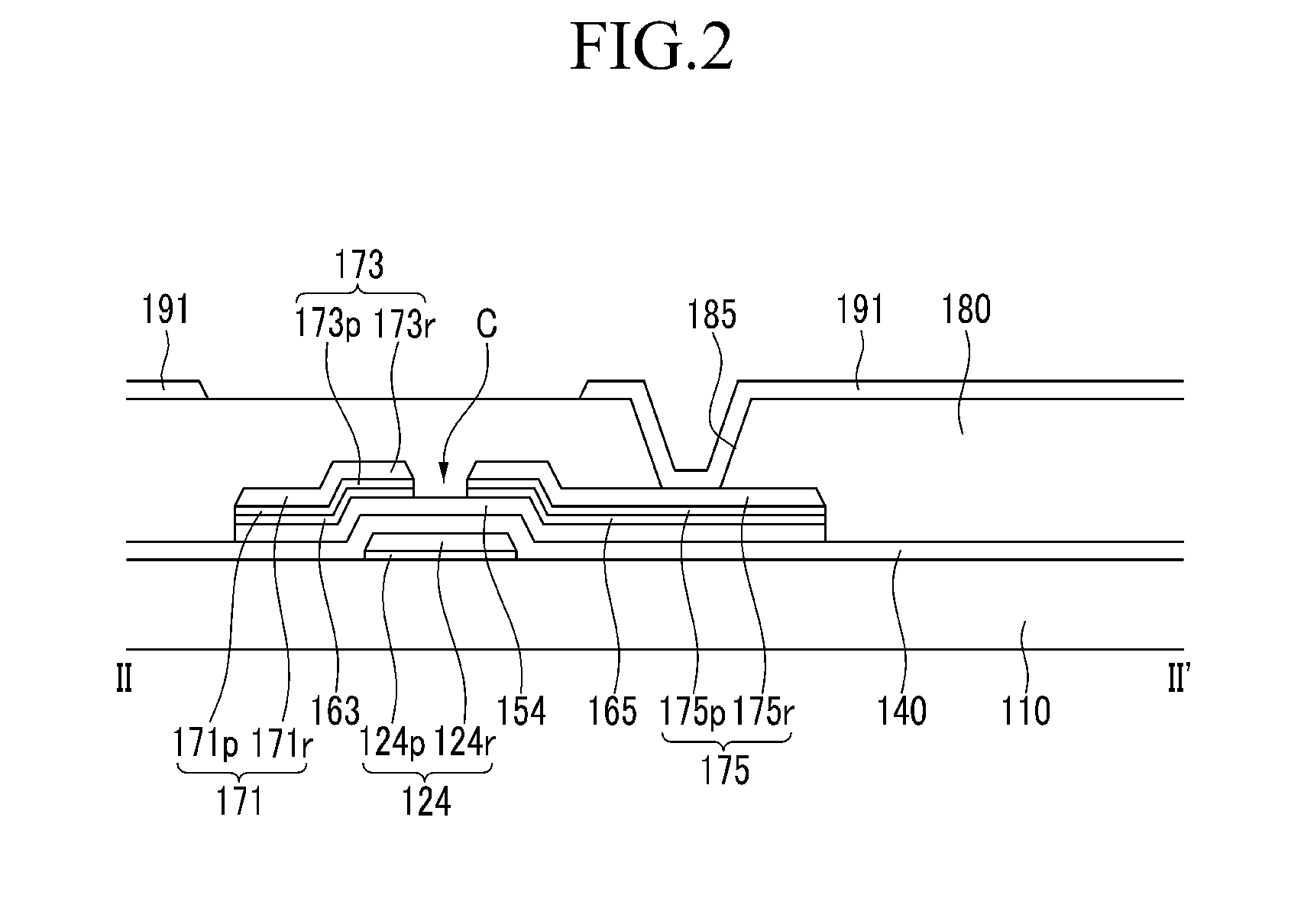

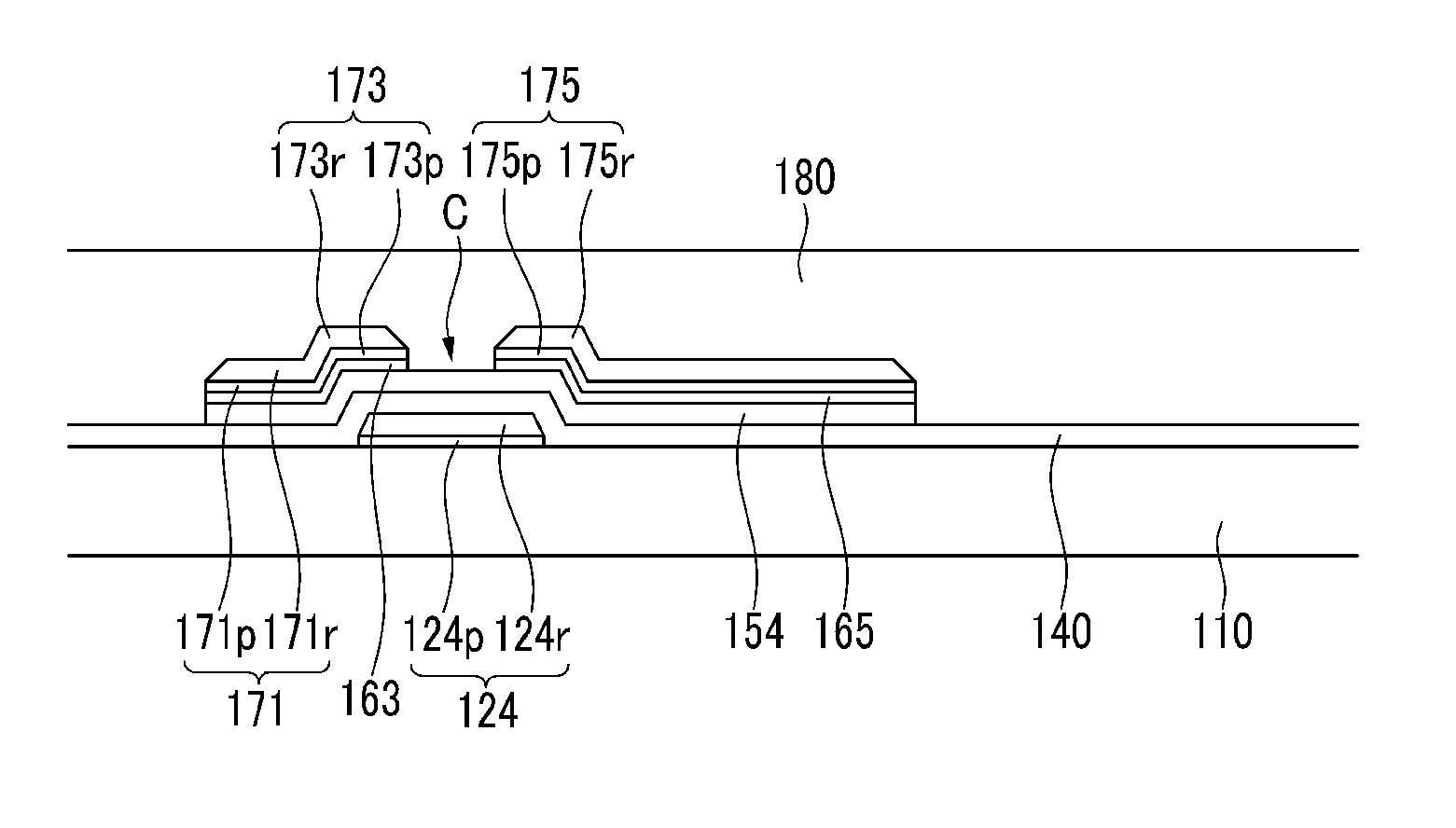

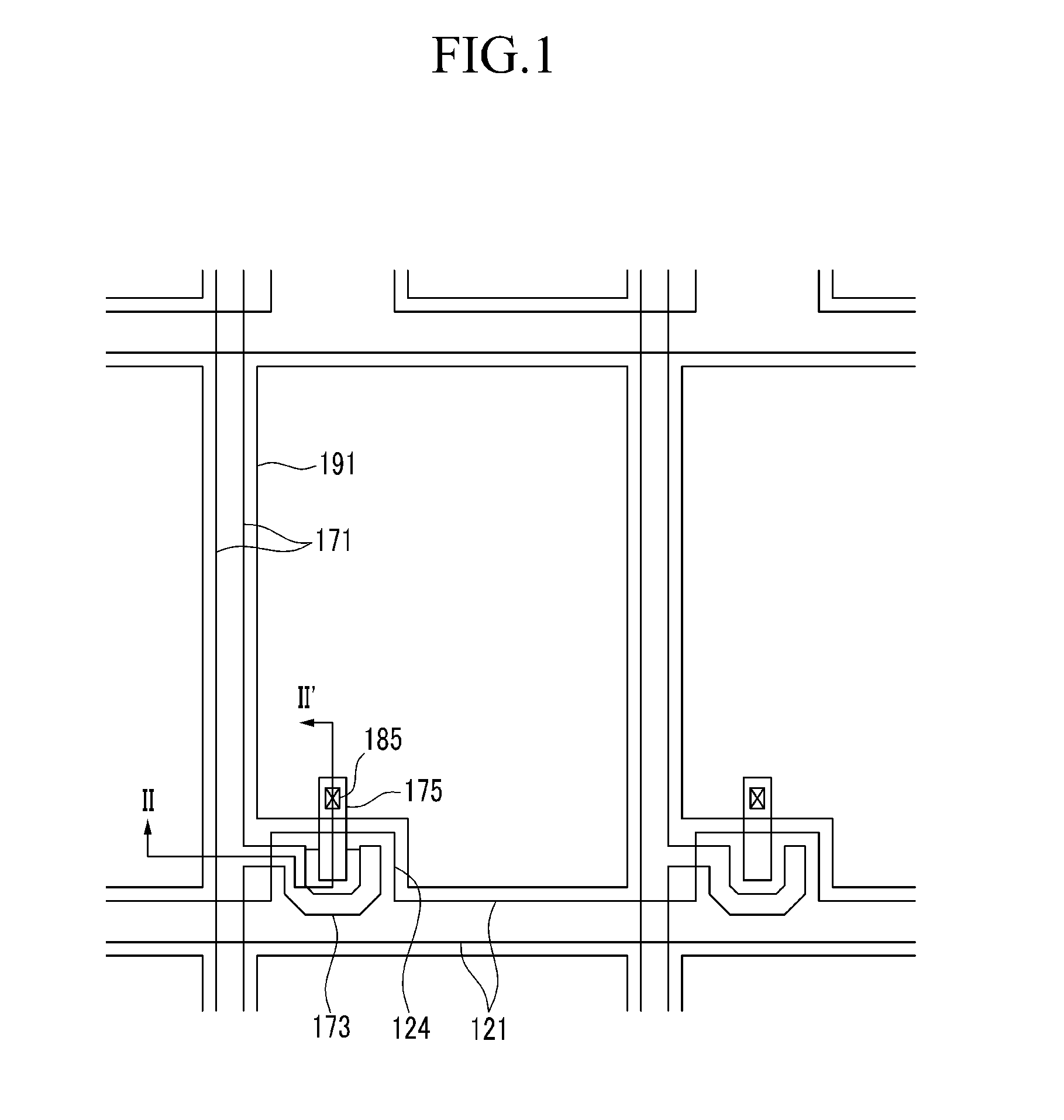

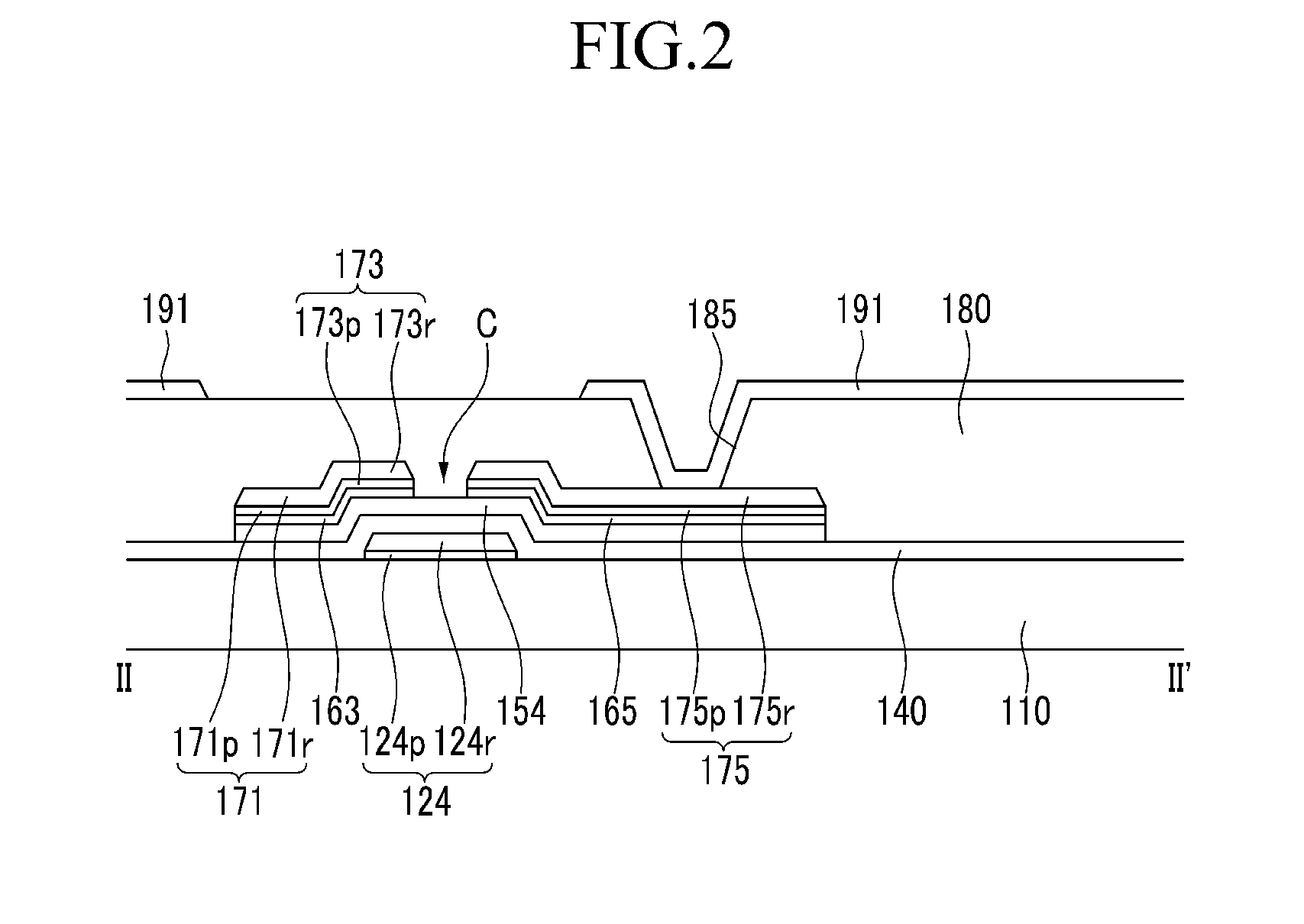

Etchant, display device and method for manufacturing display device using the same

ActiveUS20120153287A1Layers is relatively thickImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingOrganic acidPersulfate

An etchant includes: 5 to 20 wt % of persulfate, 1 to 10 wt % of at least one compound of an inorganic acid, an inorganic acid salt, or a mixture thereof, 0.3 to 5 wt % of a cyclic amine compound, 1 to 10 wt % of at least one compound of an organic acid, an organic acid salt, or a mixture thereof, 0.1 to 5 wt % of p-toluenesulfonic acid, and water, based on the total weight of the etchant. A copper-titanium etchant further includes 0.01 to 2 wt % of a fluoride-containing compound. A method of forming a display device using the etchant, and a display device, are also disclosed.

Owner:SAMSUNG DISPLAY CO LTD +1

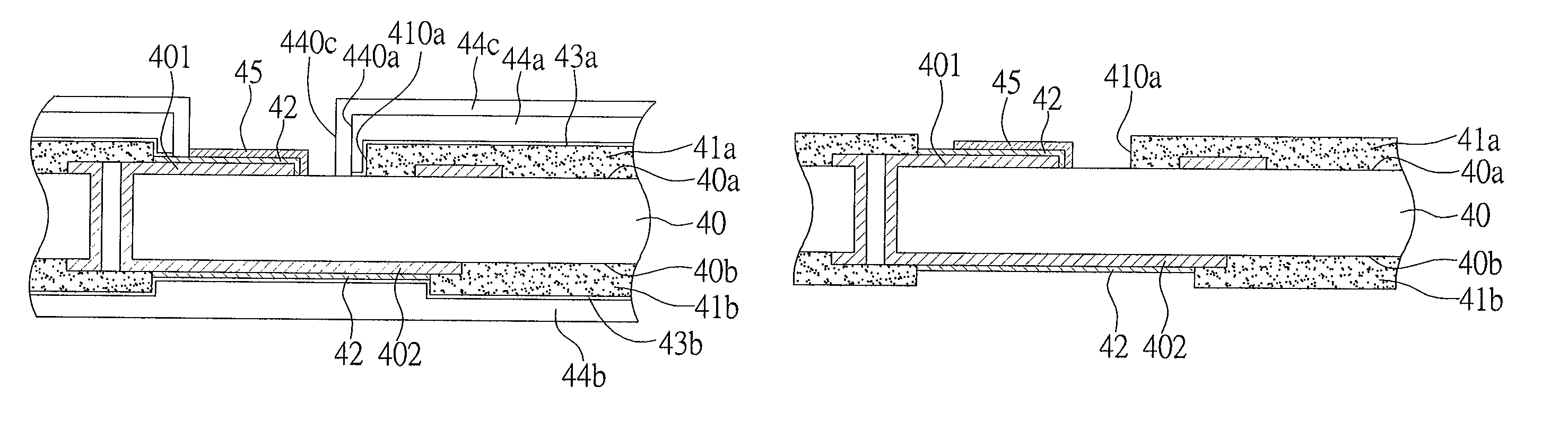

Package substrate and method for fabricating the same

ActiveUS7718470B2High densityLarge spacingSemiconductor/solid-state device detailsStacked resist layersChemical platingLead bonding

A package substrate and a method for fabricating the same are provided according to the present invention. The package substrate includes: a substrate body with a die attaching side and a ball implanting side lying opposite each other, having a plurality of wire bonding pads and a plurality of solder ball pads respectively, and having a first insulating passivation layer and a second insulating passivation layer respectively, wherein a plurality of first apertures and a plurality of second apertures are formed in the first insulating passivation layer and the second insulation passivation layer respectively to corresponding expose the wire bonding pads and the solder ball pads; a chemical plating metal layer formed on the wire bonding pads and solder ball pads respectively; and a wire bonding metal layer formed on a surface of the chemical plating metal layer of the wire bonding metal layer.

Owner:PHOENIX PRECISION TECH CORP

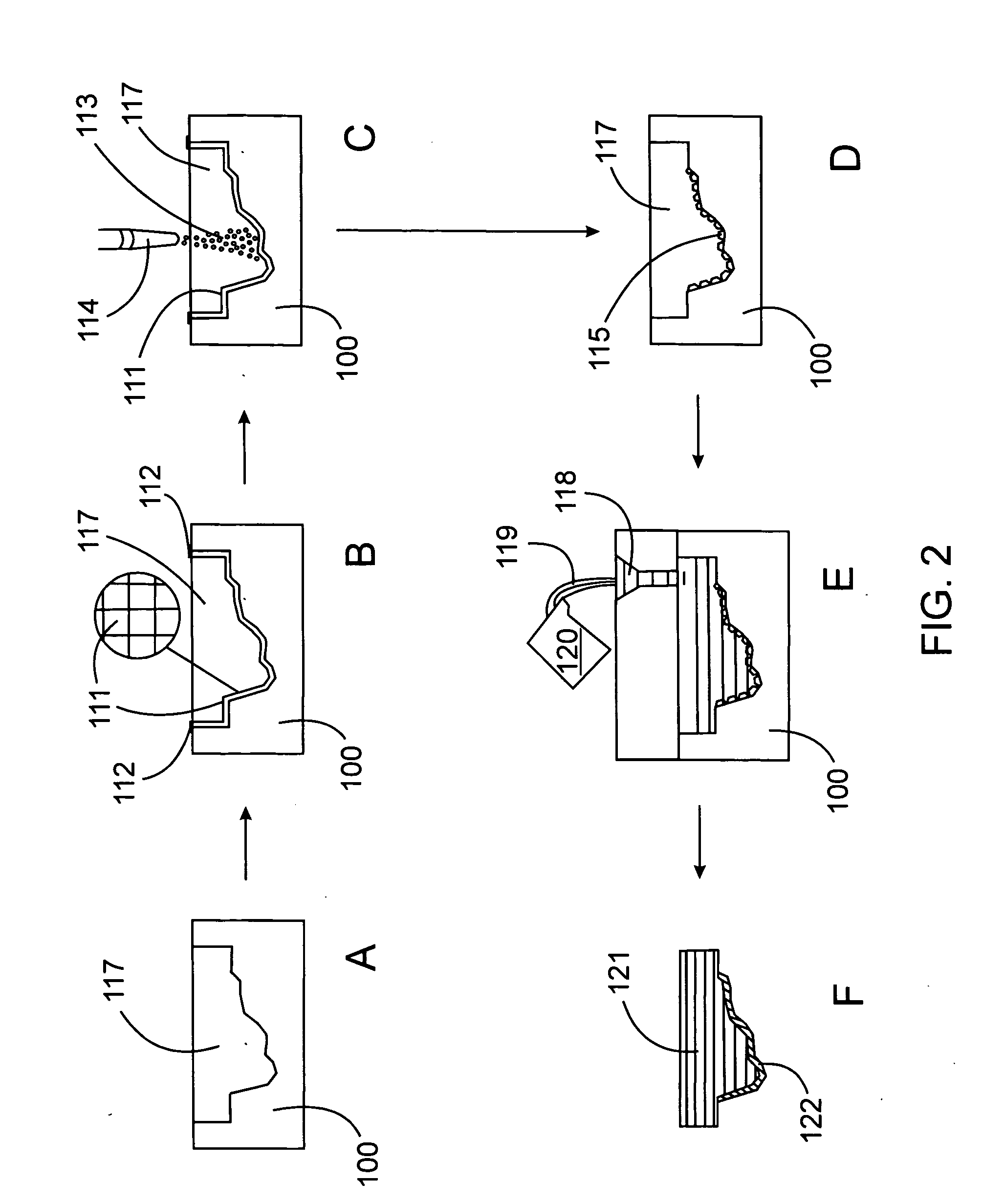

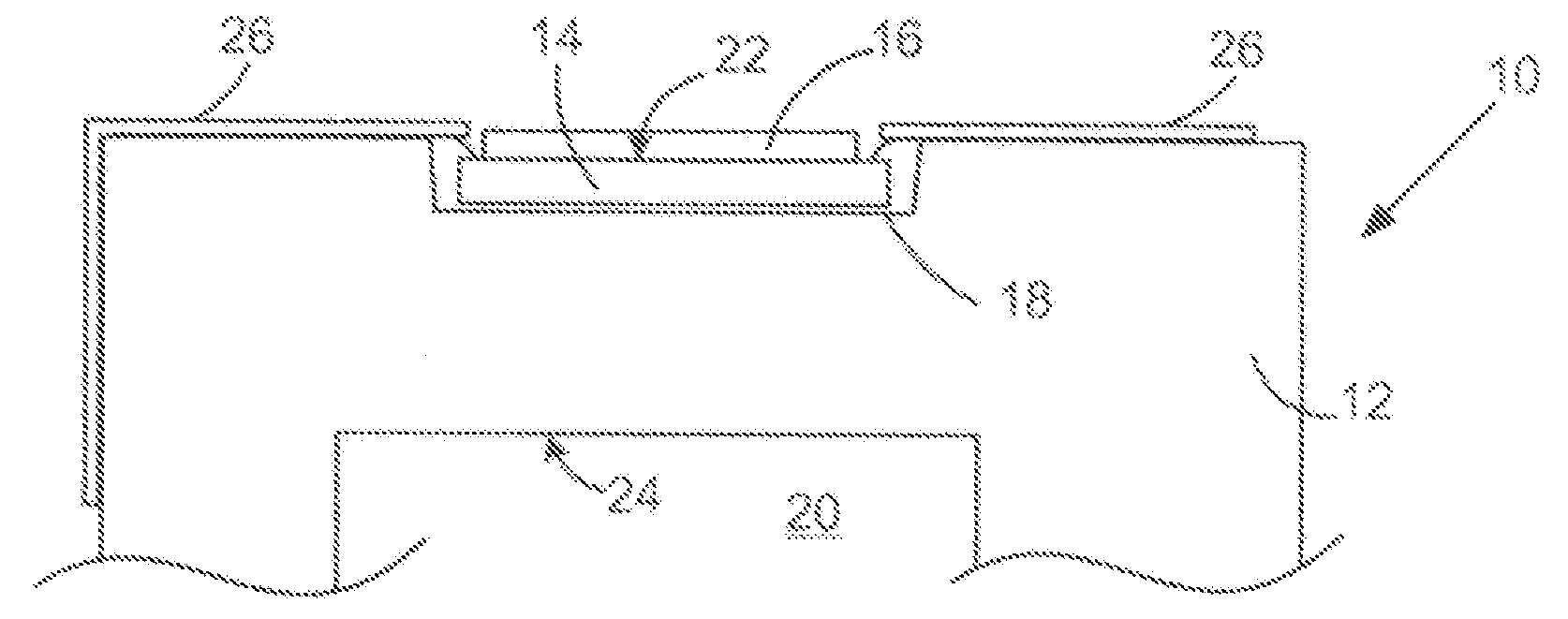

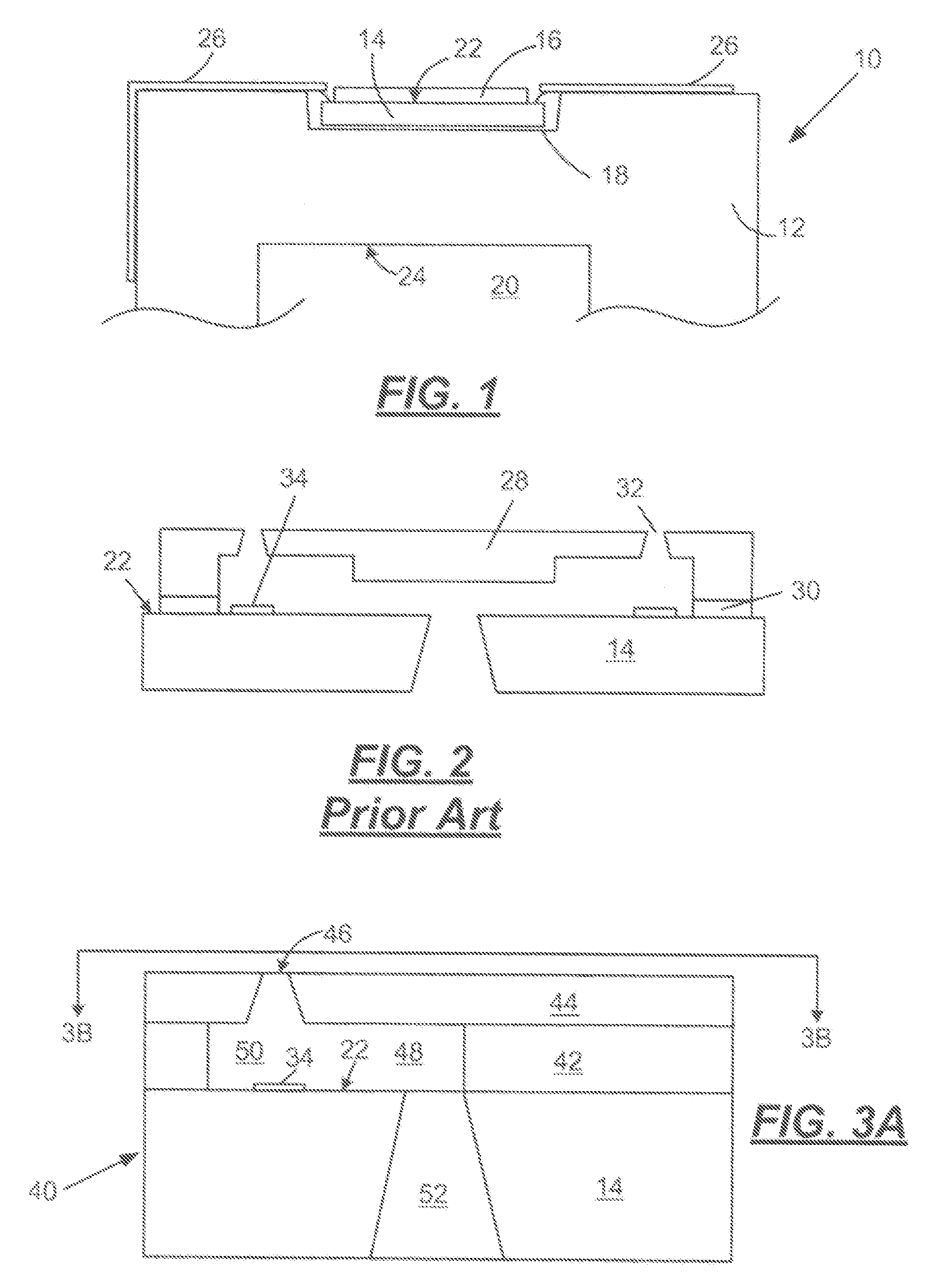

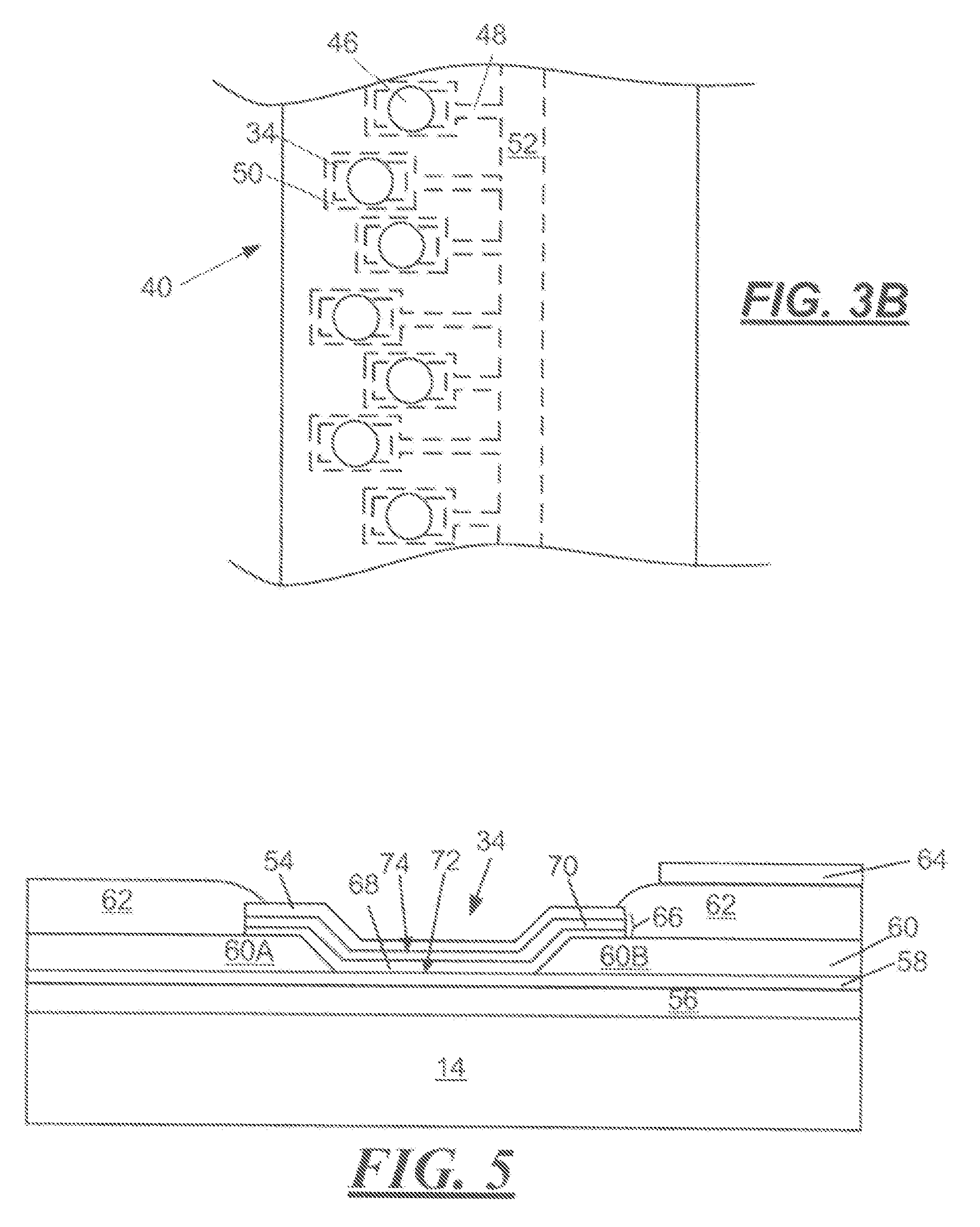

Process for making a micro-fluid ejection head structure

ActiveUS20090091604A1Easy to optimizeAccurate shapeWriting implementsMetal-working apparatusElectrical resistance and conductanceCavitation

A method of making a micro-fluid ejection head structure and micro-fluid ejection heads made by the method. The method includes applying a tantalum oxide layer to a surface of a fluid ejection actuator disposed on a device surface of a substrate so that the tantalum oxide layer is the topmost layer of a plurality of layers including a resistive layer, and a protective layer selected from a passivation layer, a cavitation layer, and a combination of a passivation layer and a cavitation layer. The tantalum oxide layer has a thickness (t) that satisfies an equation t=(¼*W / n), wherein W is a wavelength of radiation from a radiation source, and n is a refractive index of the tantalum oxide layer. A photoimageable layer is also applied to the substrate. The photoimageable layer is imaged with the radiation source and then developed.

Owner:SLINGSHOT PRINTING LLC

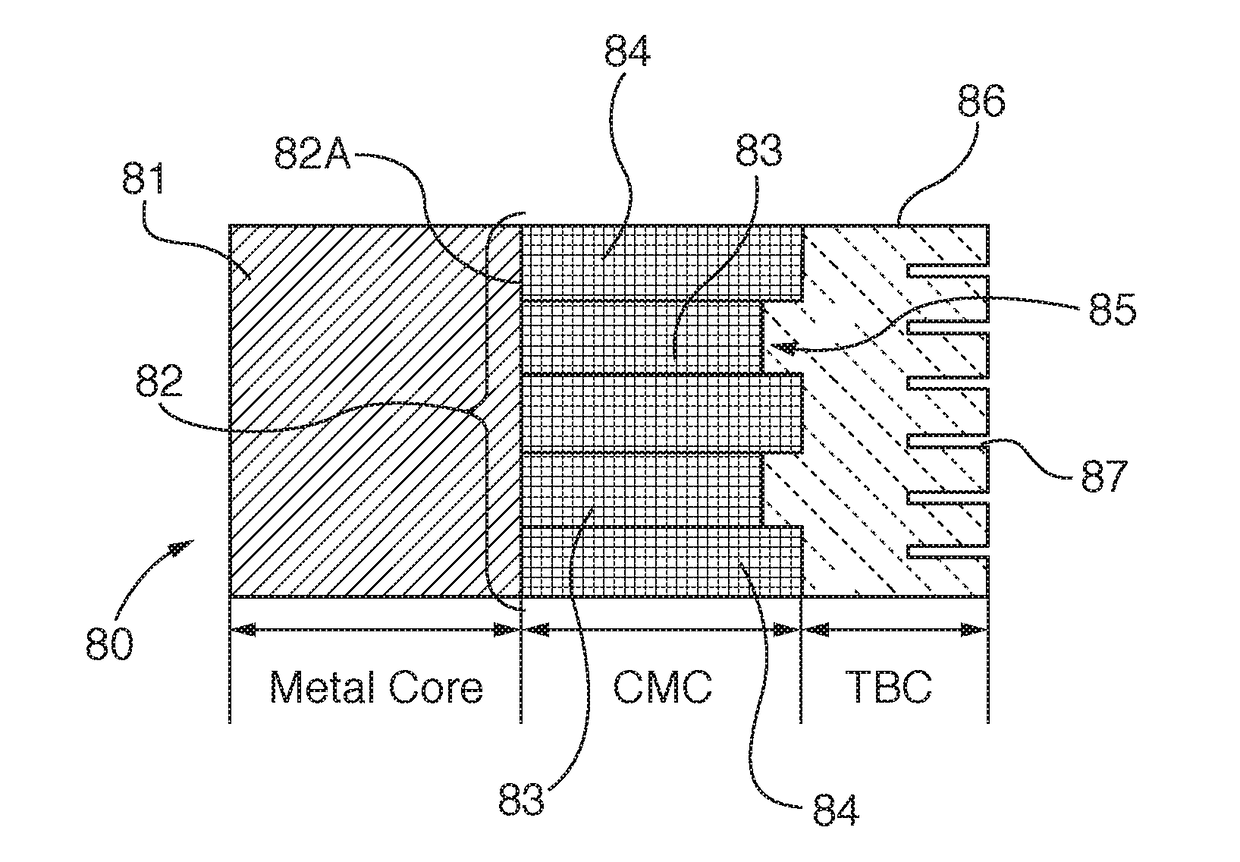

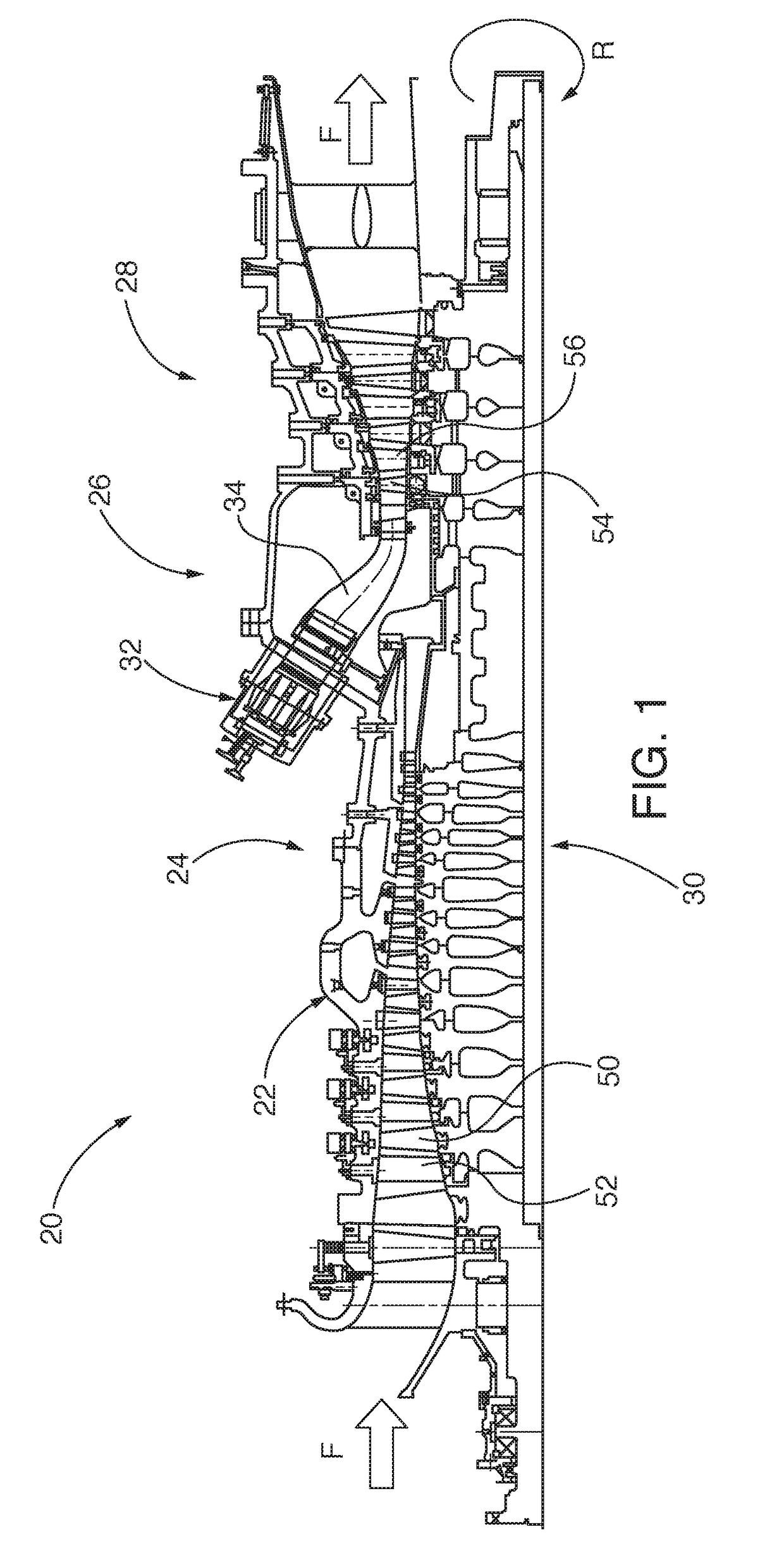

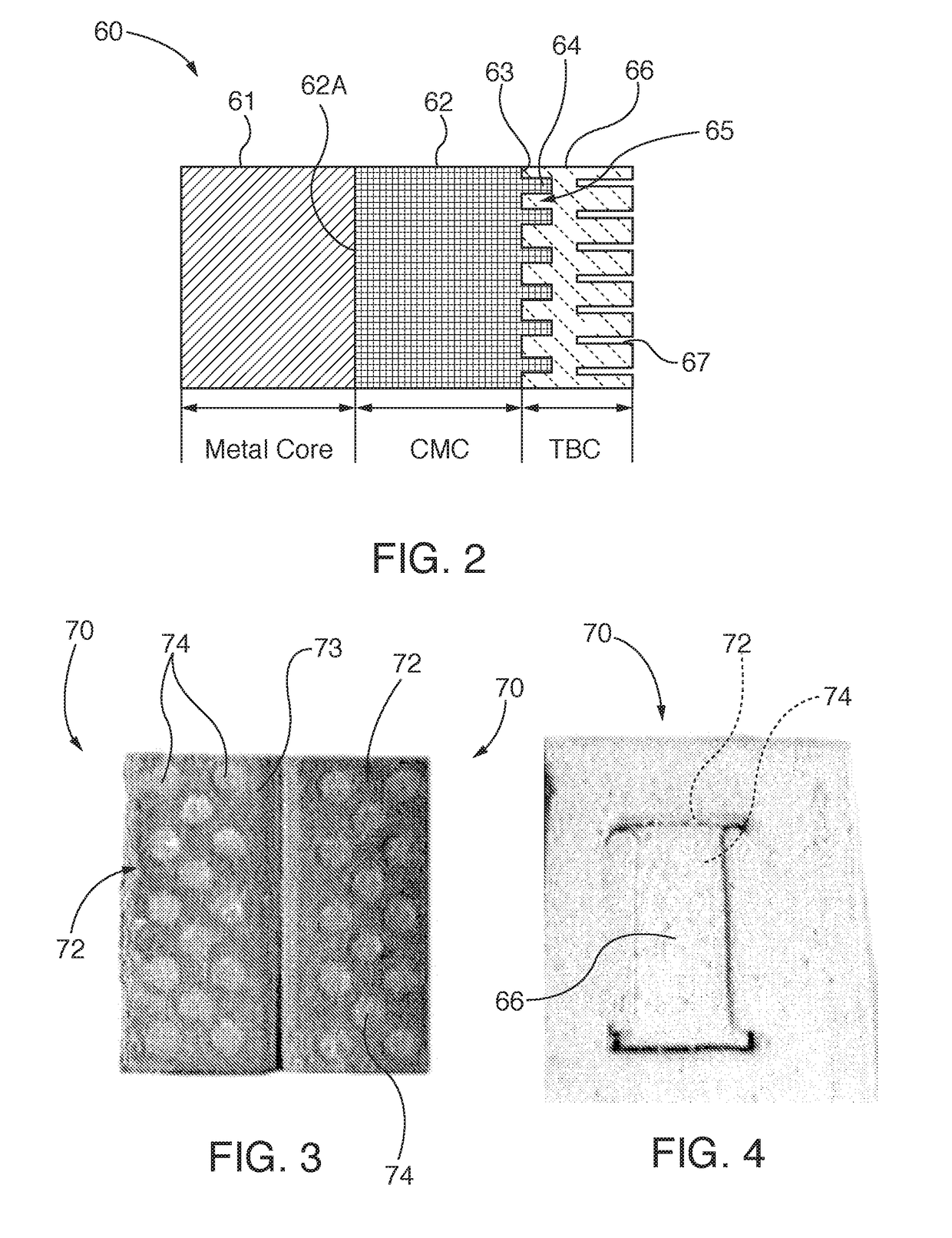

Ceramic matrix composite turbine component with engineered surface features retaining a thermal barrier coat

InactiveUS20180029944A1High retention rateConvenient thermal protectionMolten spray coatingEngine manufactureCombustionThermal barrier coating

Owner:SIEMENS AG

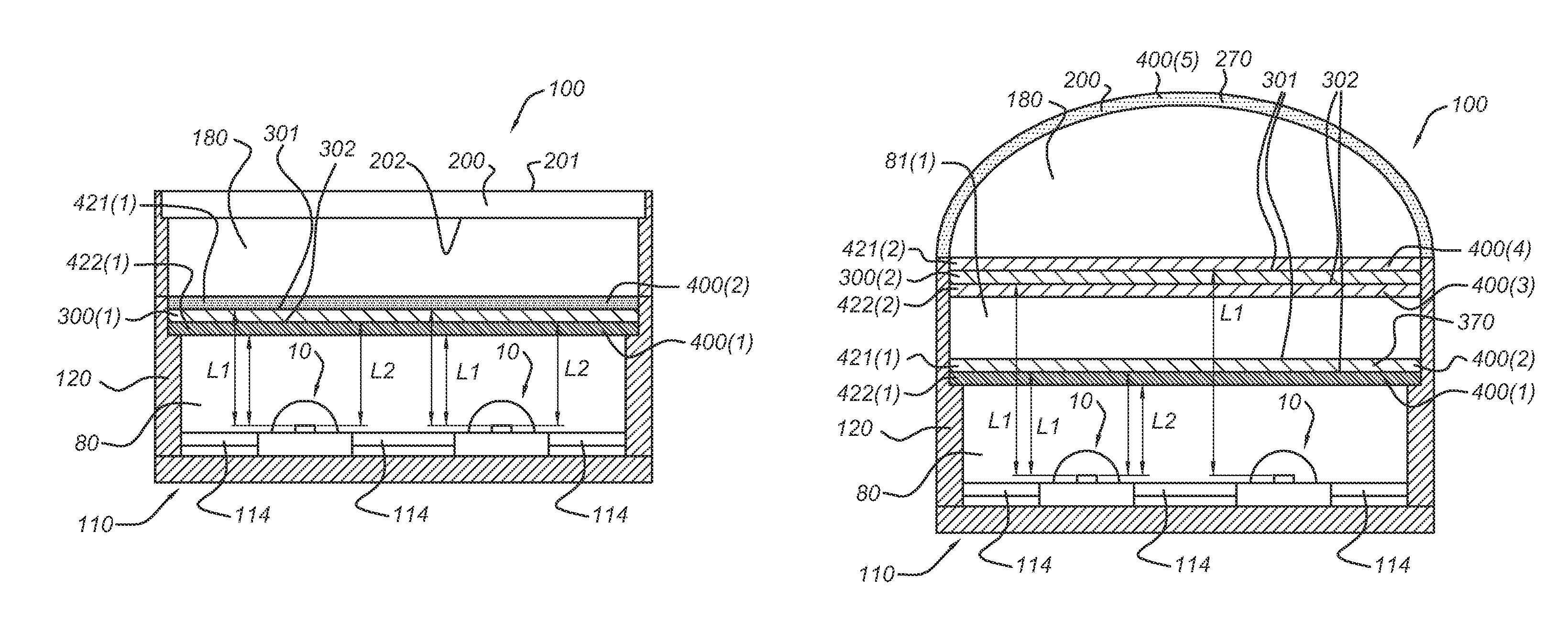

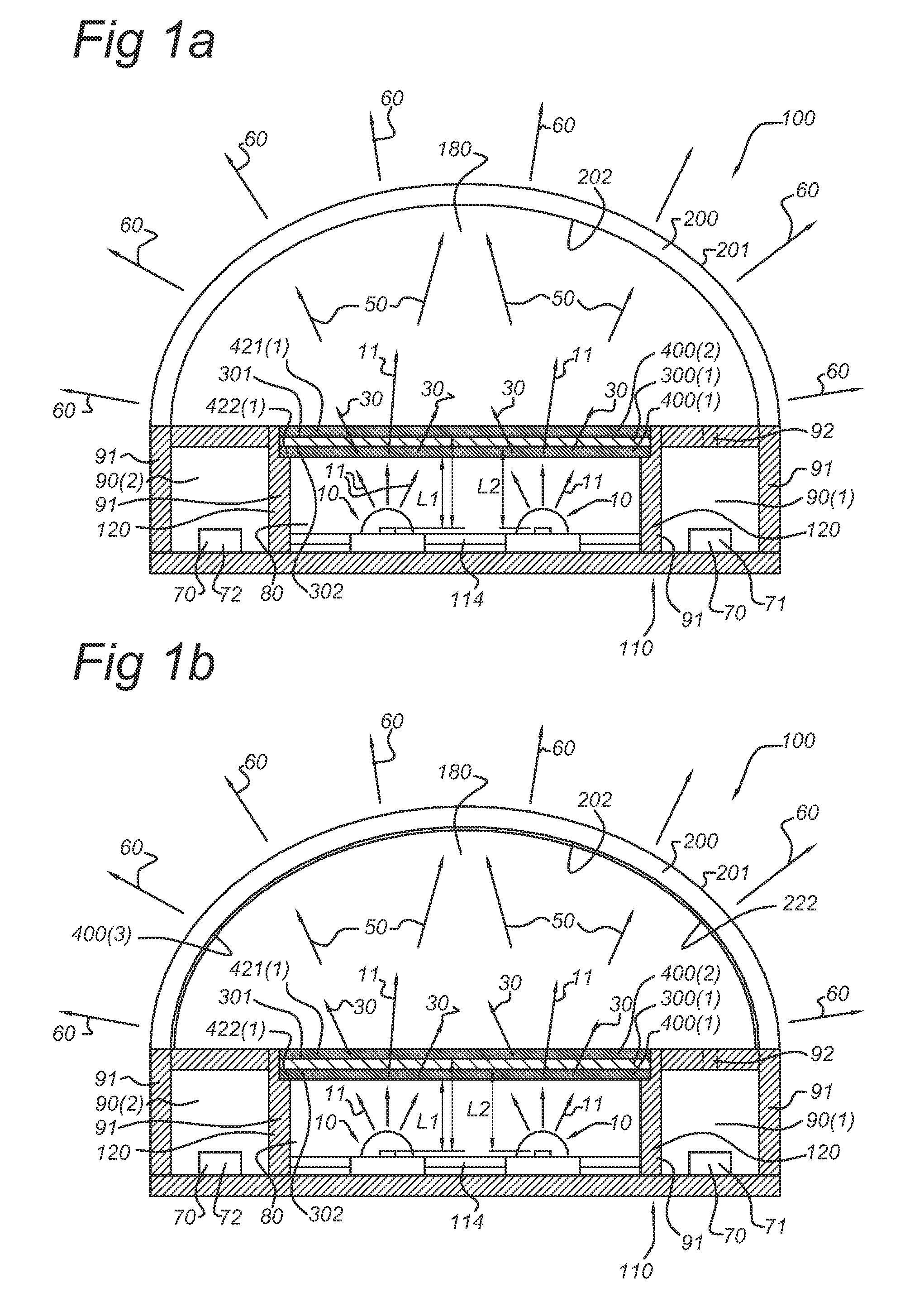

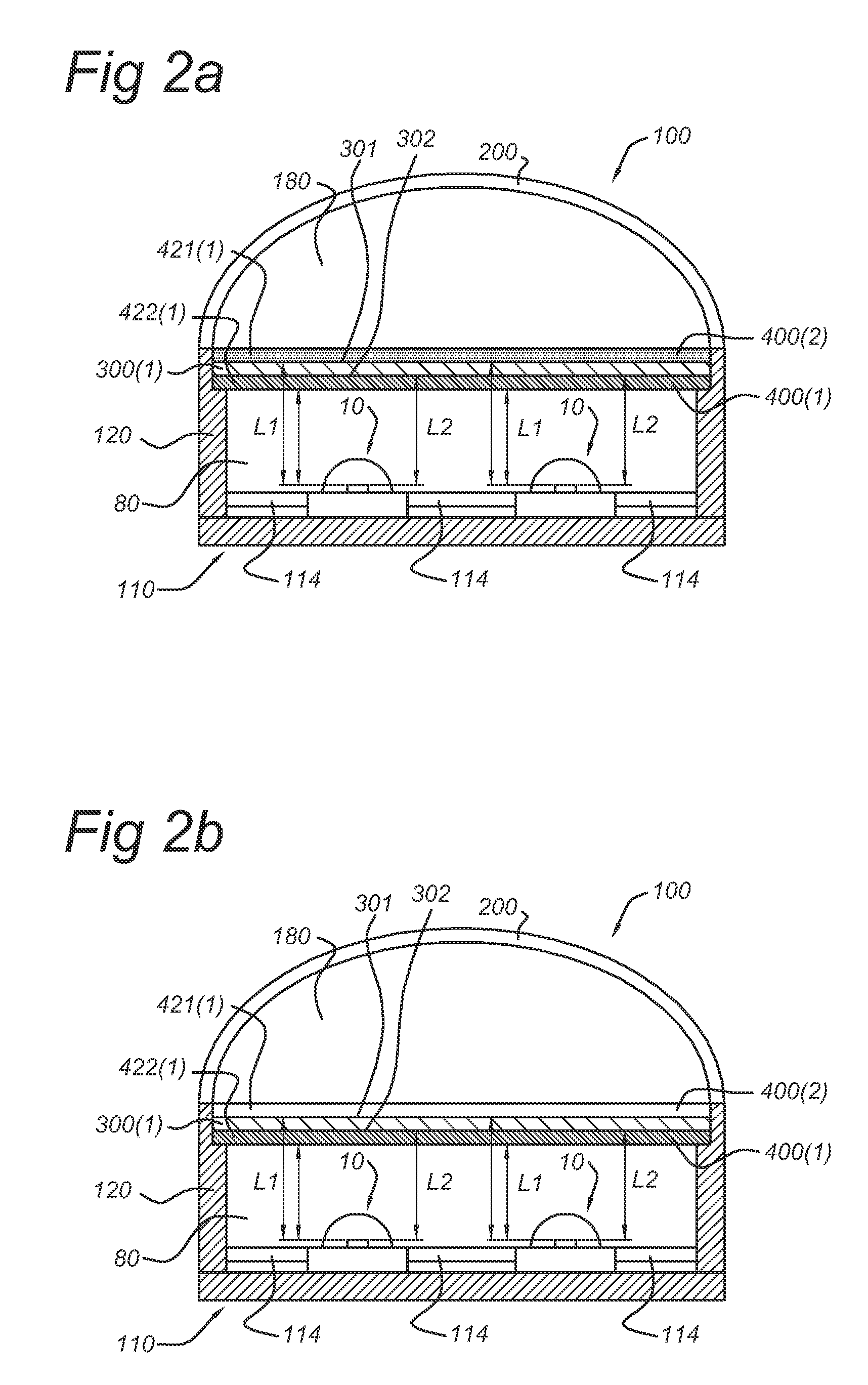

Illumination device with LED and one or more transmissive windows

InactiveUS8567974B2High materialLayers is relatively thickPoint-like light sourcePortable electric lightingLuminescent materialSemi transparent

The invention provides an illumination device (100) comprising a translucent exit window (200), one or more transmissive windows (300), arranged upstream from LED(s) and downstream from the translucent exit window (200), and one or more luminescent material layers (400), which may particularly be coated to the downstream and upstream faces of the transmissive windows (300).

Owner:KONINK PHILIPS ELECTRONICS NV +1

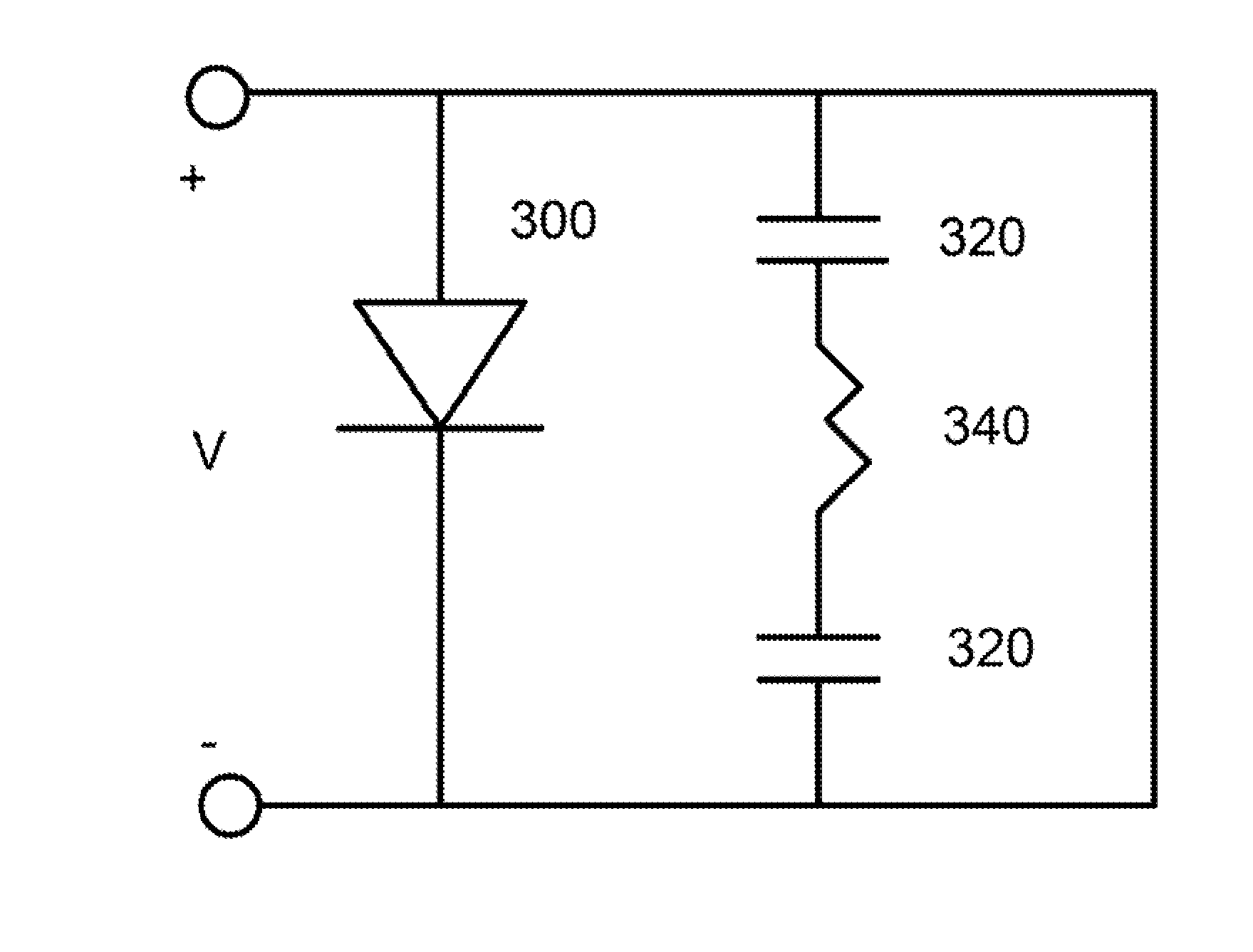

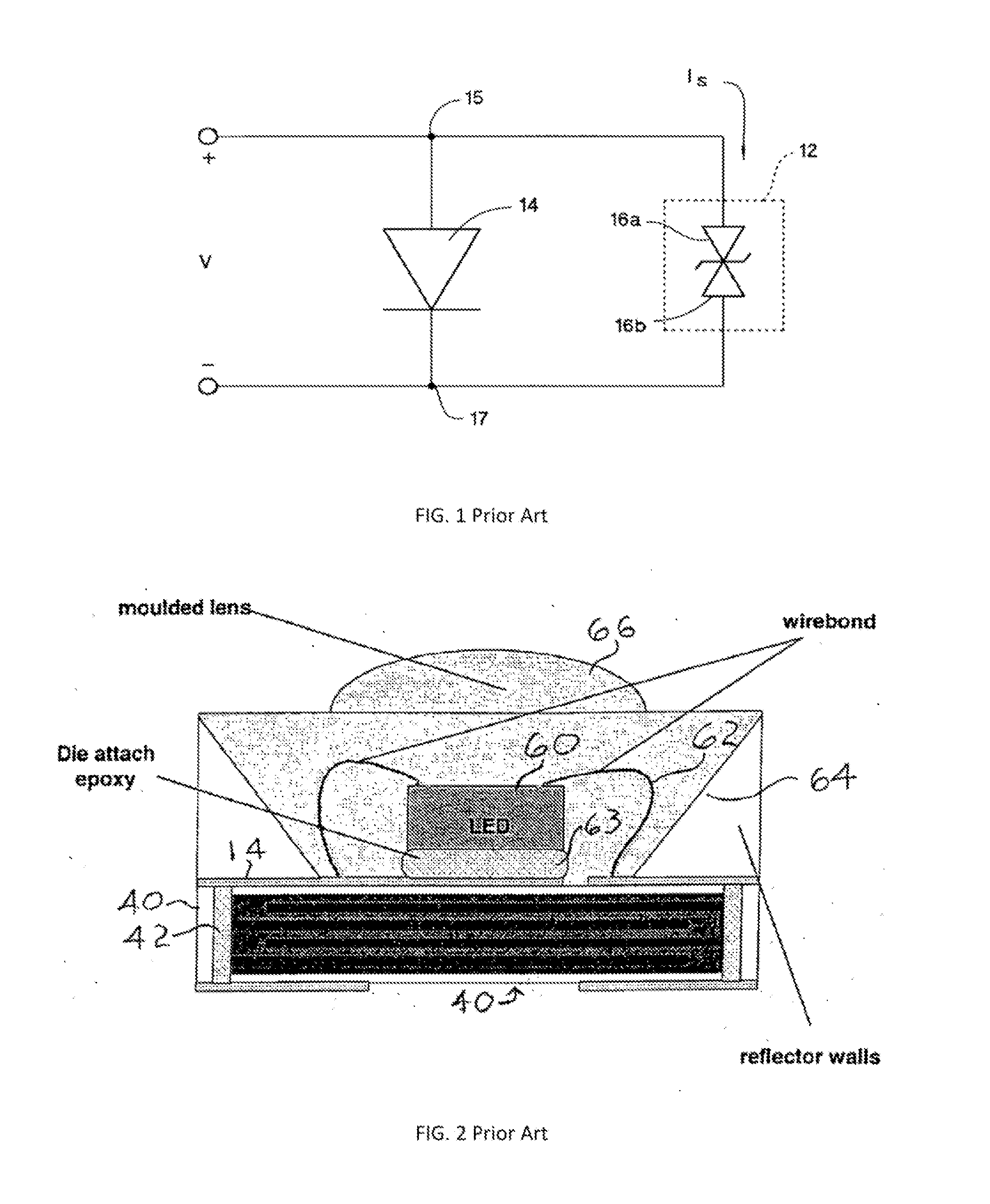

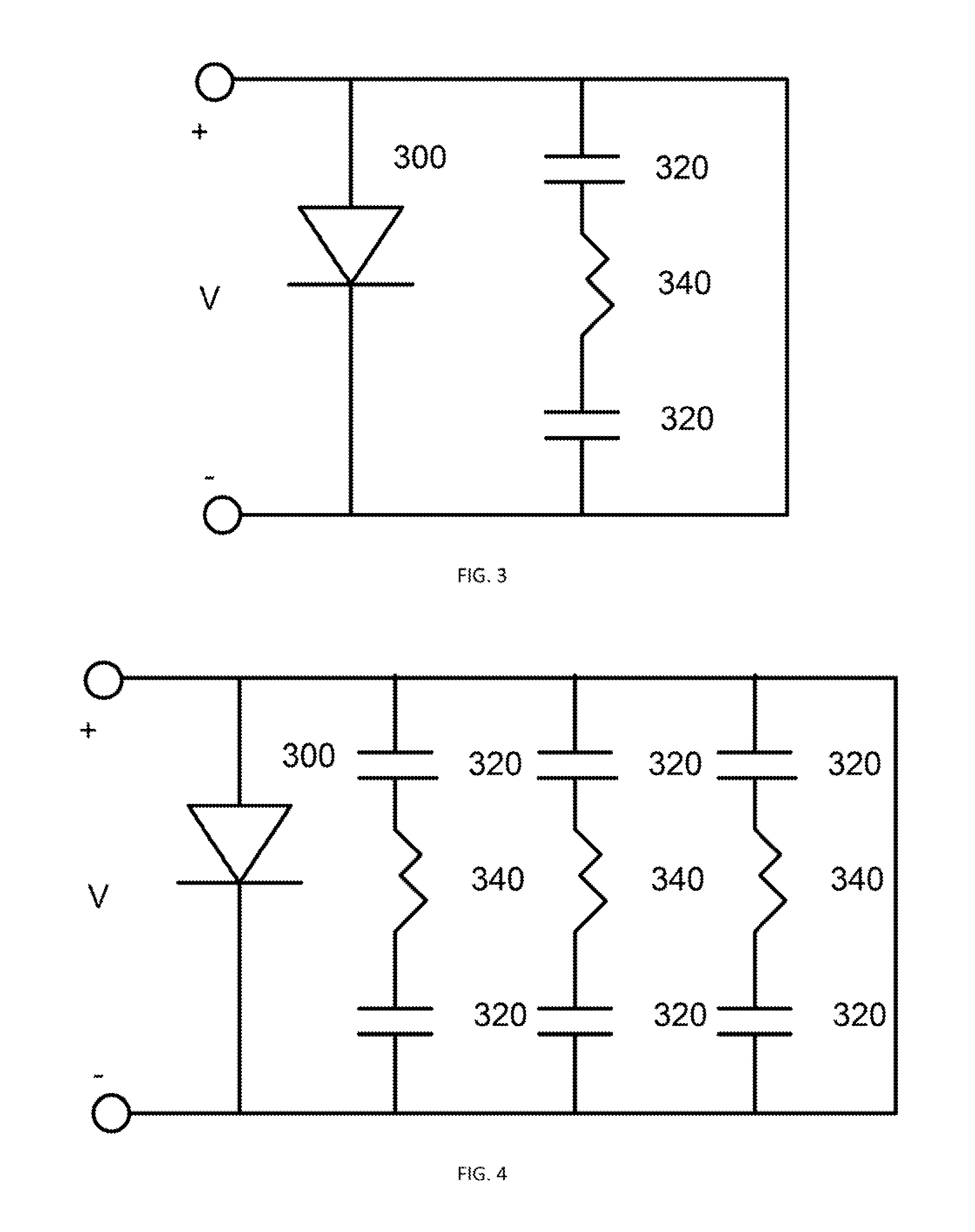

Micromachined High Breakdown Voltage ESD Protection Device for Light Emitting Diode and Method of Making the Same

InactiveUS20140268440A1Extend your lifeImprove breakdown voltageSolid-state devicesEmergency protective arrangements for limiting excess voltage/currentVoltage spikeMicrofabrication

This invention relates to a micromachined ESD protection device and its microfabrication method for light emitting diode (LEDs) chips. The LEDs is coupled to the ESD protection device in a shunt connection to absorb and eliminate the electrostatic charges induced by human contact or other voltage spike sources. The ESD protection circuit can prevent the LED from burning down and extend its lifespan. By using a thick polyimide layer as the dielectric film for capacitors in the micromachined ESD protection device at the current invention has the advantages with high breakdown voltage compared to other ESD protection circuits. And furthermore, the device in the current invention is easy for mass production with low manufacturing cost. Another embodiment of the present invention is that the multiple-array arrangement in current micromachined ESD protection device could greatly enhance the liability due to multiple-protection and thus to provide the possibility of multiple-times usage.

Owner:WISENSTECH

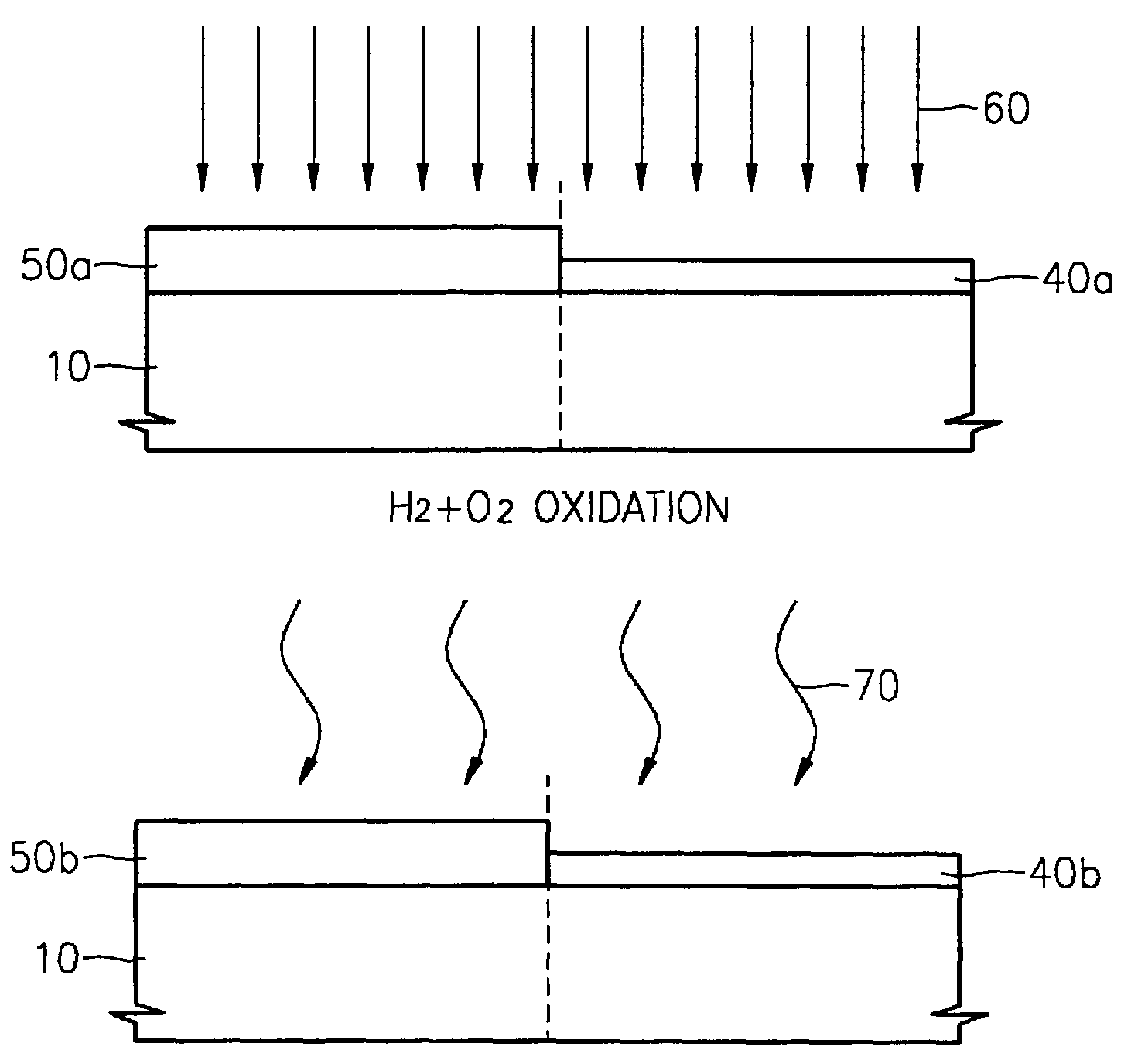

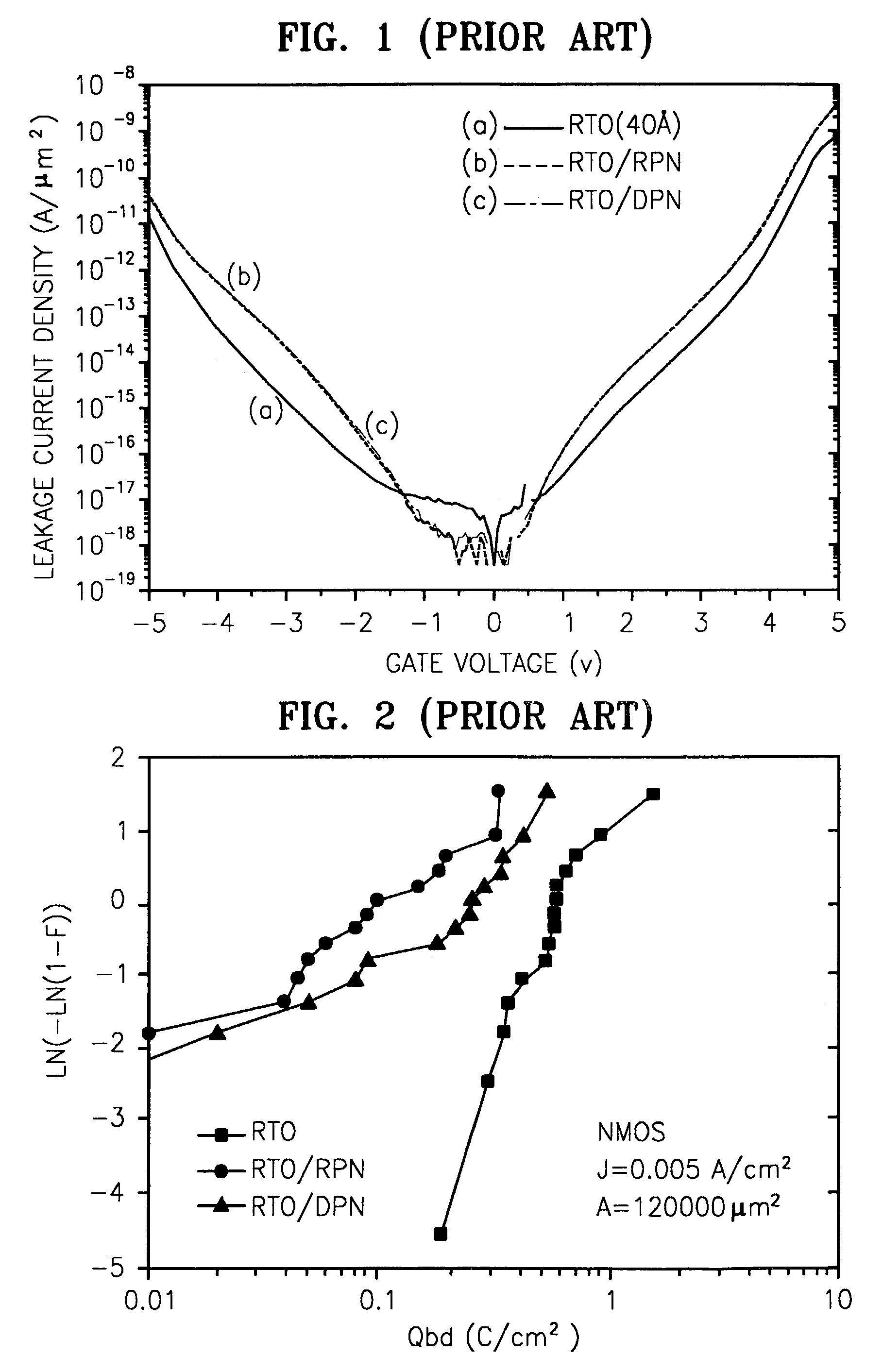

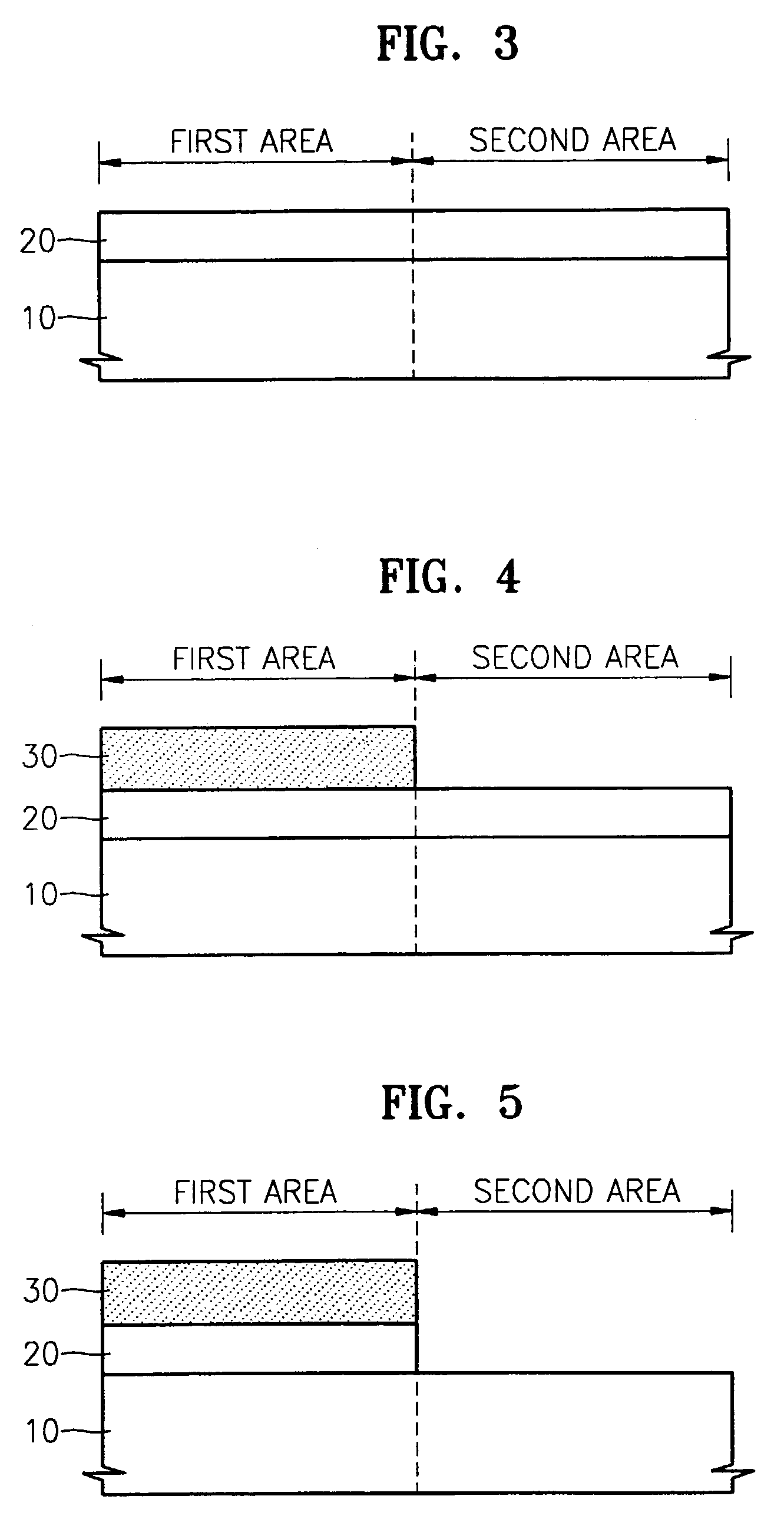

Methods of fabricating oxide layers by plasma nitridation and oxidation

InactiveUS7053006B2Improve featuresLayers is relatively thickSemiconductor/solid-state device manufacturingSemiconductor devicesHydrogenPlasma nitridation

Oxide layers, including gate oxide layers having different thicknesses, are formed, plasma nitridized, and oxidized in an oxygen atmosphere containing hydrogen at a high temperature. Electron trap sites and stress occurring during plasma nitridation may be removed during oxidation.

Owner:SAMSUNG ELECTRONICS CO LTD

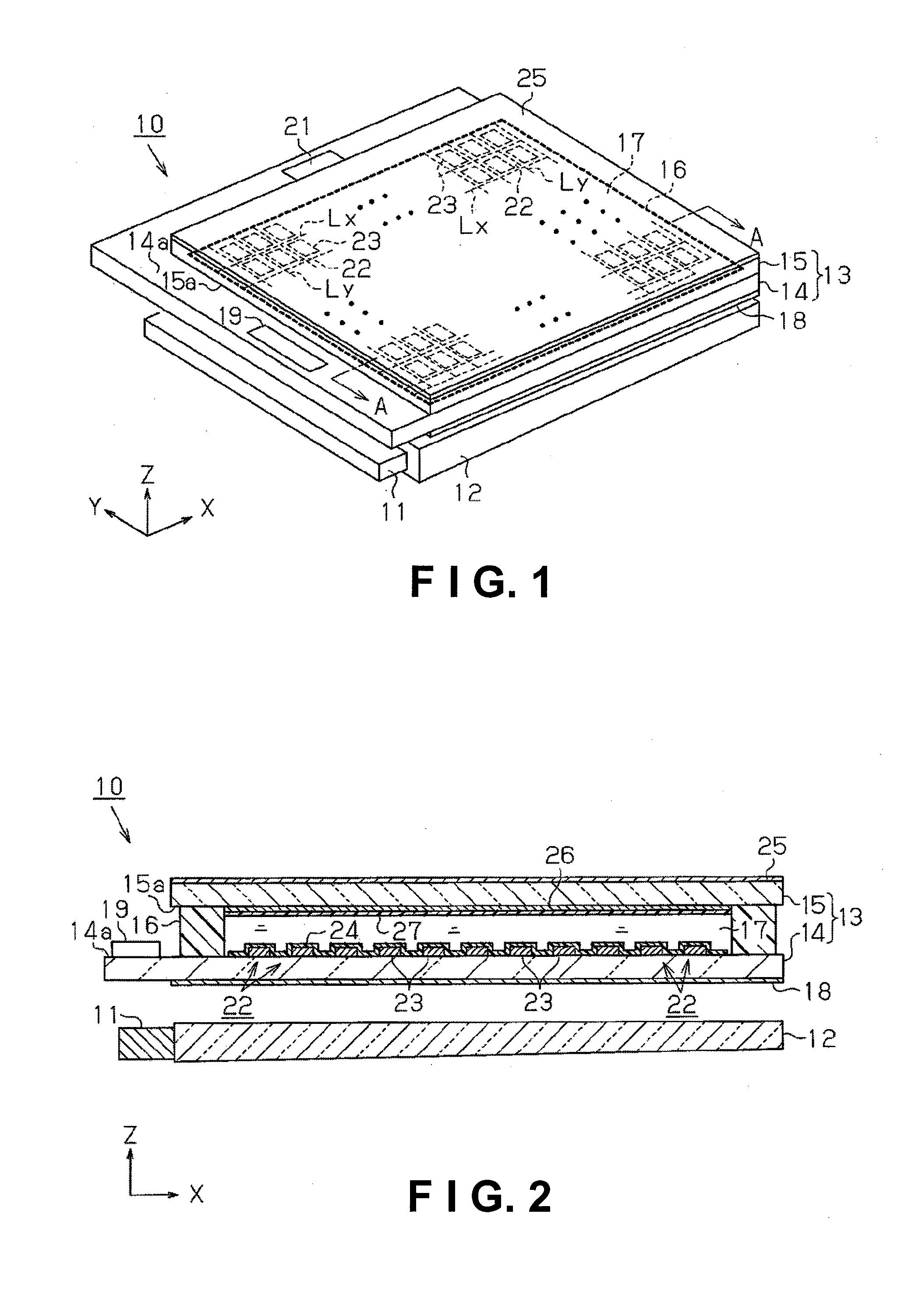

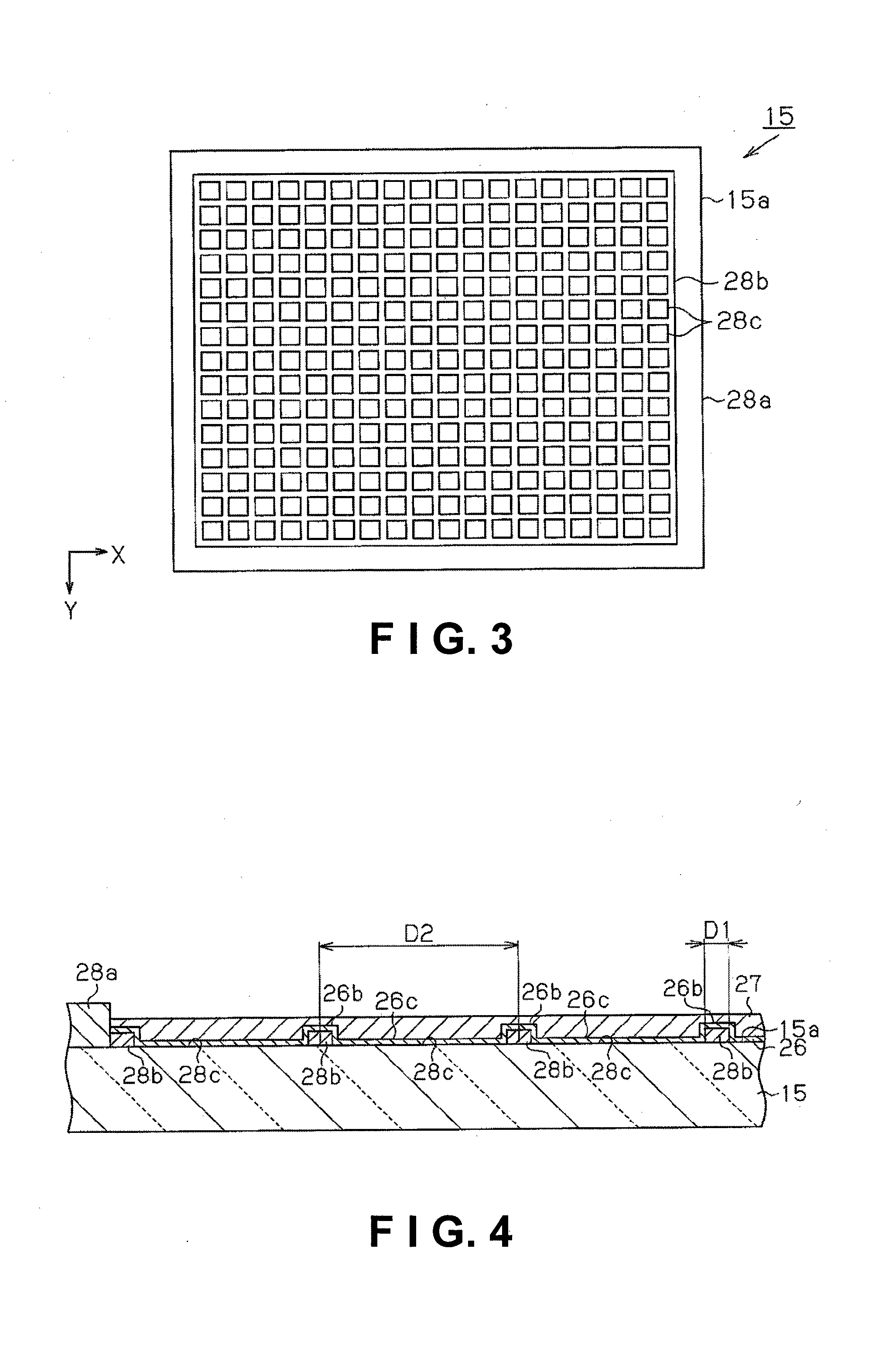

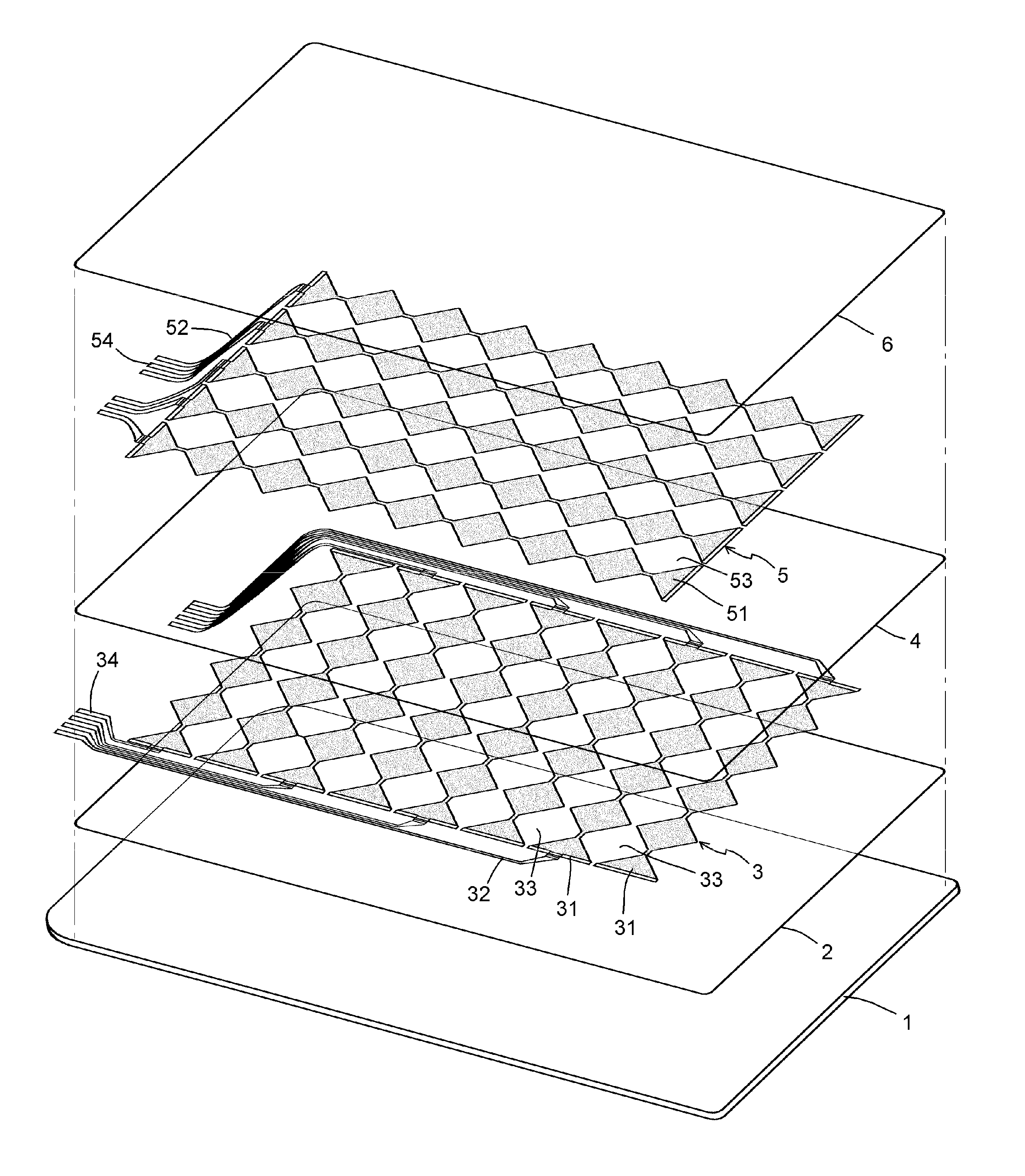

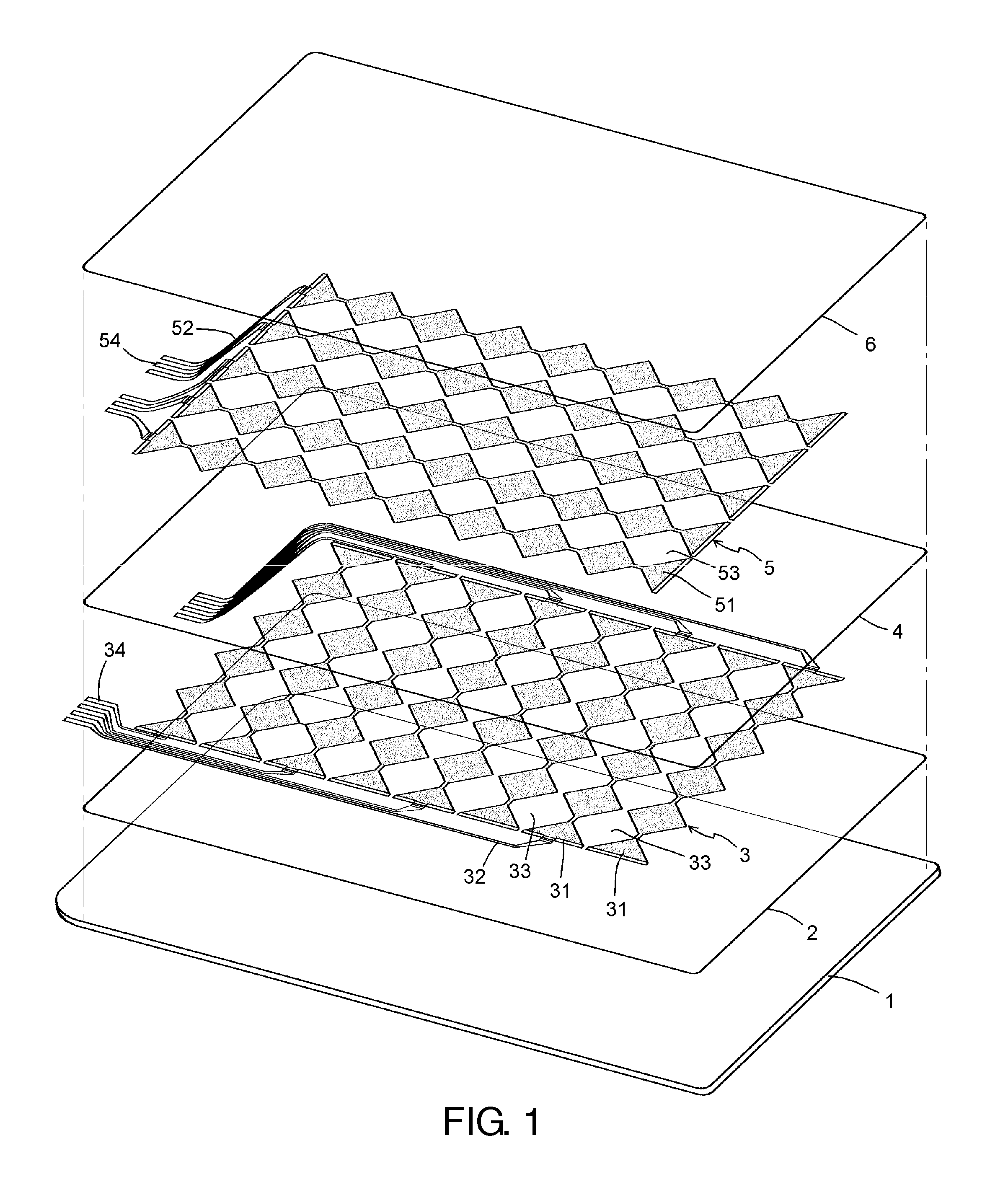

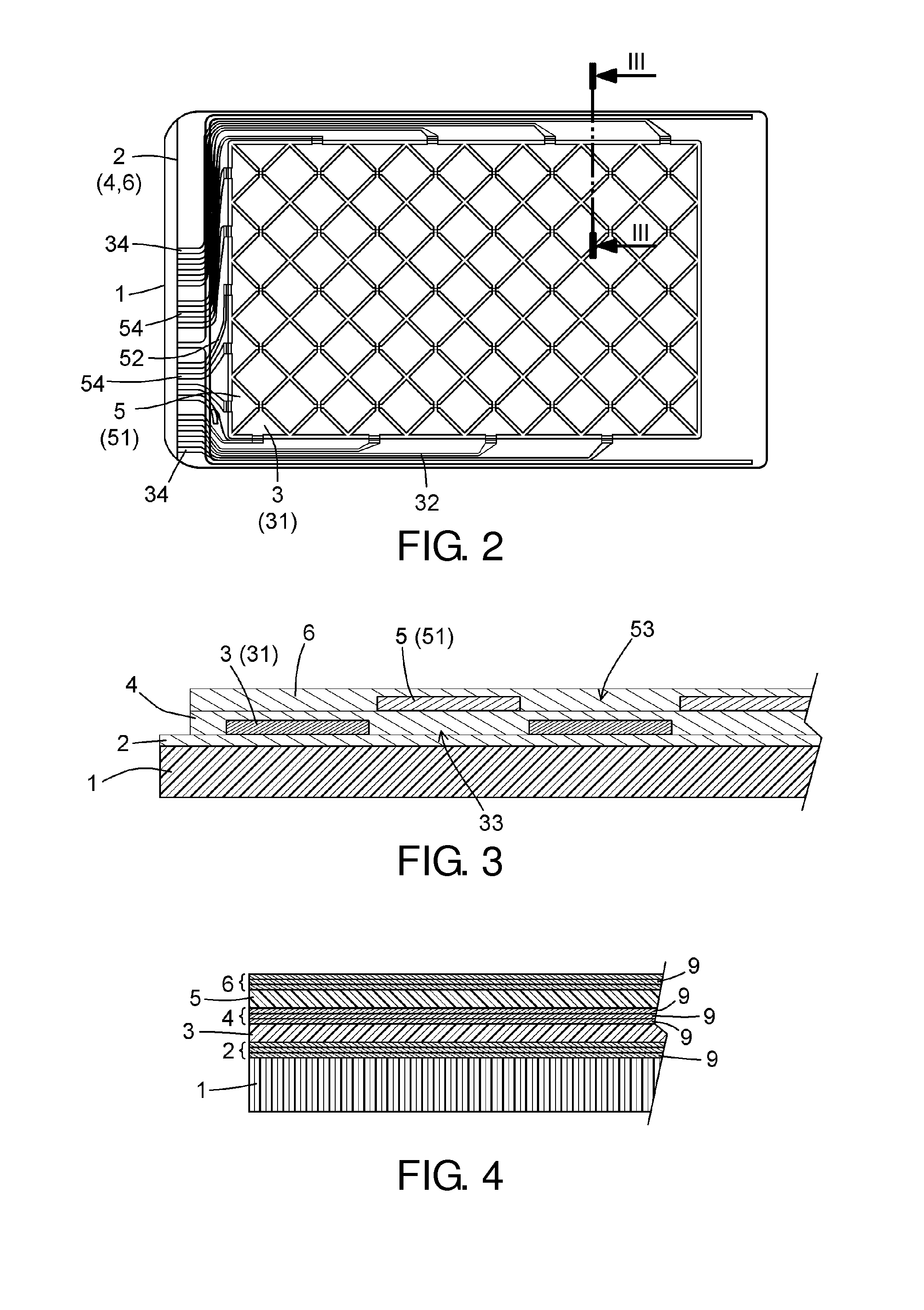

Transparent capacitive touch panel

InactiveUS20140300831A1Good optical performanceLayers is relatively thickDetails for portable computersNon-linear opticsRefractive indexEngineering

The capacitive touch panel includes a transparent substrate, a first transparent conductive layer, a first transparent insulative layer, a second transparent conductive layer, and a second transparent insulative layer. Each transparent conductive layer has a plurality of capacitive sensor rows. Every adjacent two of the capacitive sensor rows are formed with a gap to be insulated. The transparent insulative layers have a refractive index equal to or greater than that of the transparent conductive layers and fill the gaps. Each of the insulative layers is composed of a plurality of insulative coatings, and each coating is less than 100 nm in thickness.

Owner:YOUNG FAST OPTOELECTRONICS

Crevice corrosion-resistant liquid-cooled armature bar clip-to-strand connection and related method

ActiveUS7216796B2Improve availabilityImprove reliabilityTurbinesManufacturing dynamo-electric machinesEngineeringBraze alloy

Owner:GENERAL ELECTRIC CO

Organic thin film transistors

InactiveUS8450142B2Minimise capacitanceMinimise leakageTransistorSolid-state devicesConductive materialsOrganic semiconductor

An organic thin film transistor comprising: a substrate; a source electrode and a drain electrode defining a channel; a layer of insulating material disposed over the source and drain electrodes; a layer of organic semi-conductive material extending across the channel; a layer of dielectric material; and a gate electrode disposed over the layer of dielectric material.

Owner:CAMBRIDGE DISPLAY TECH LTD +1

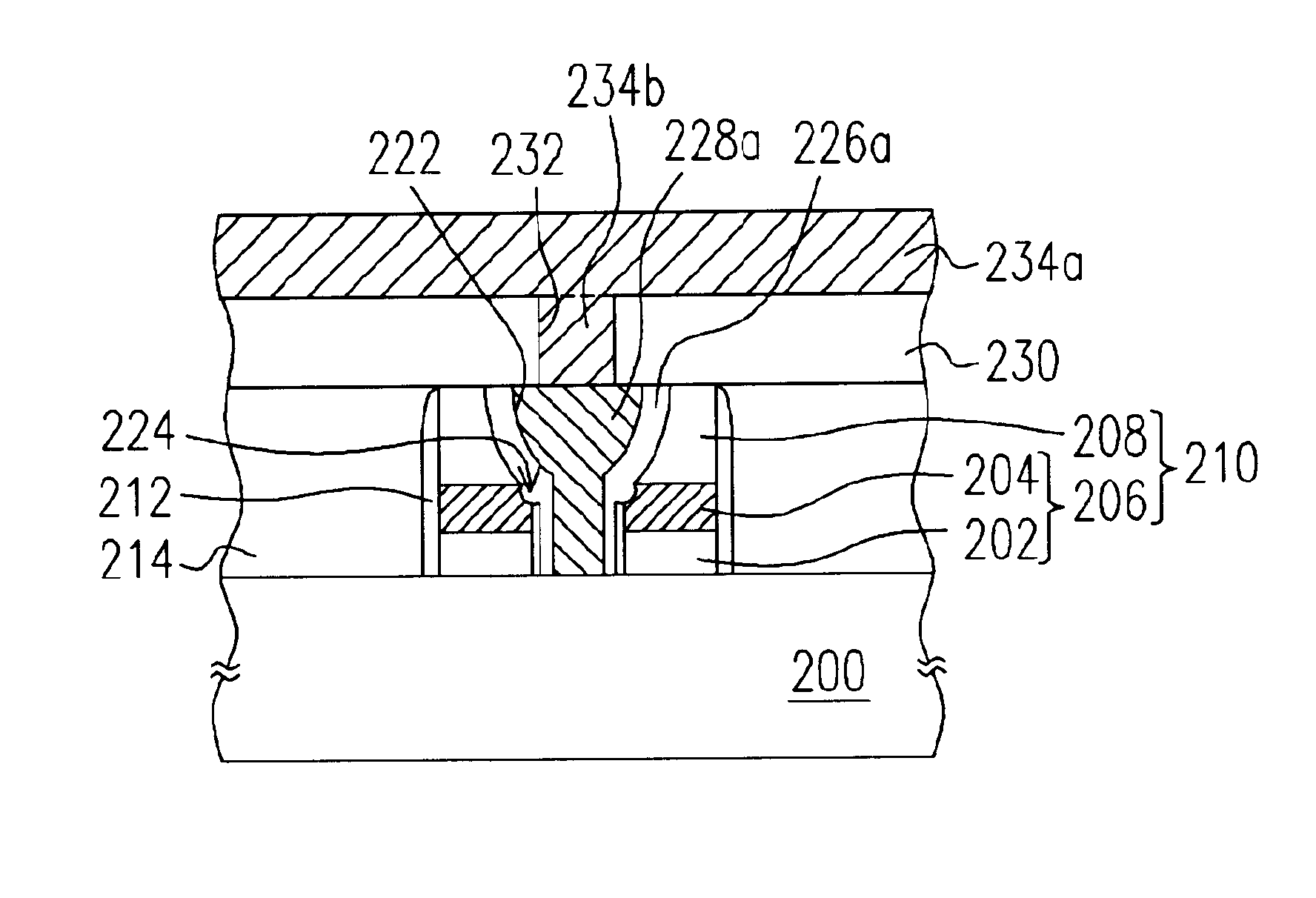

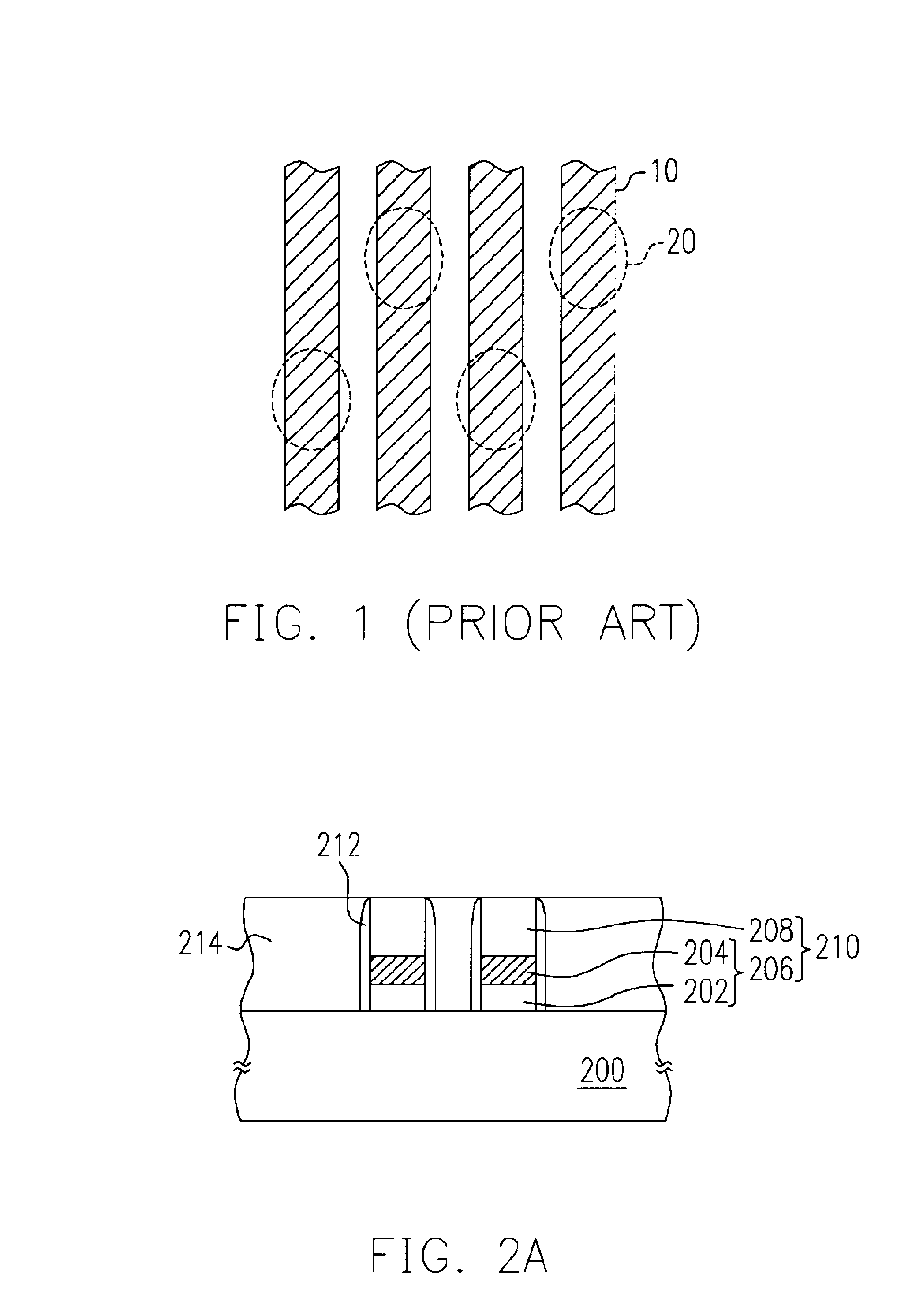

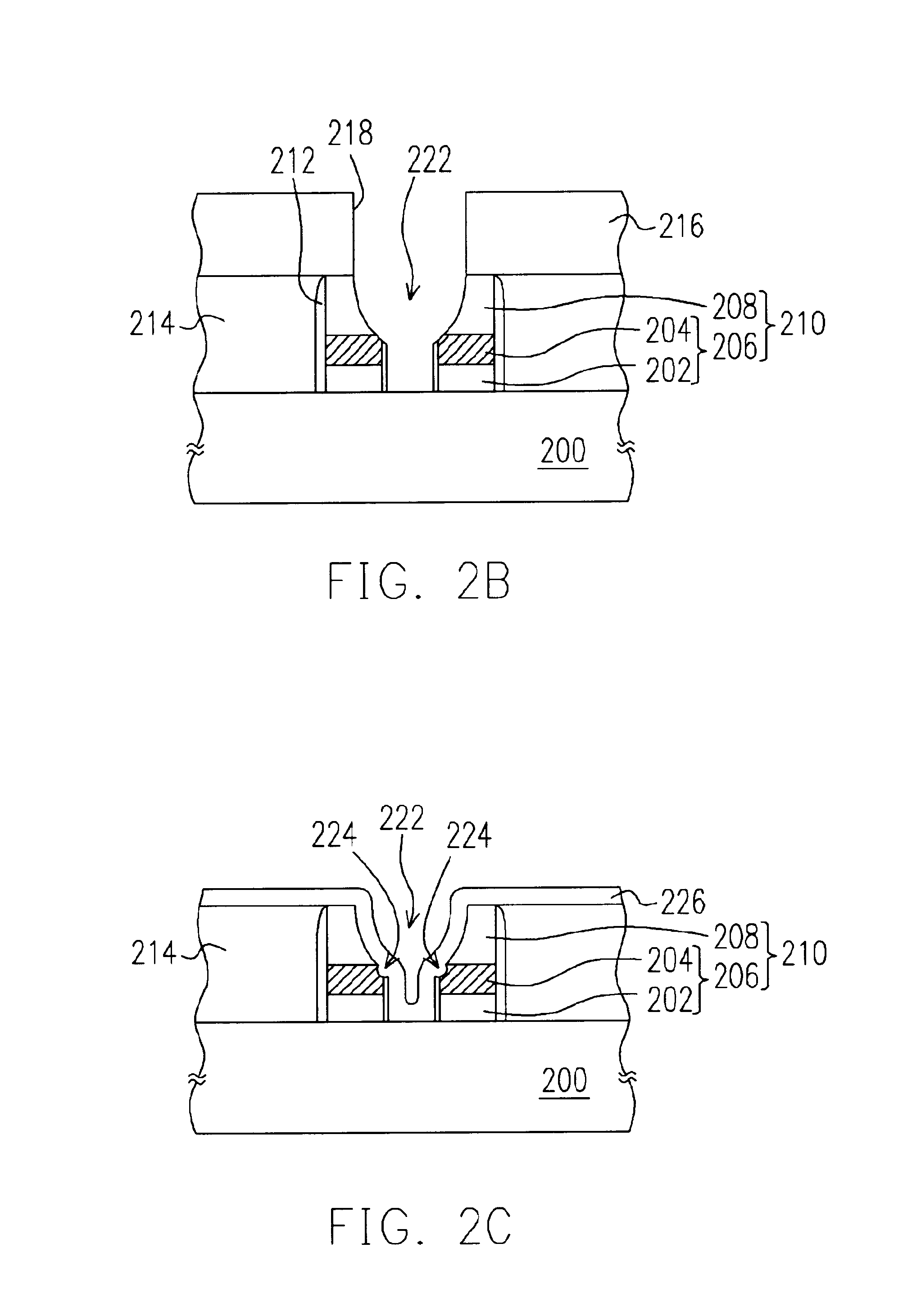

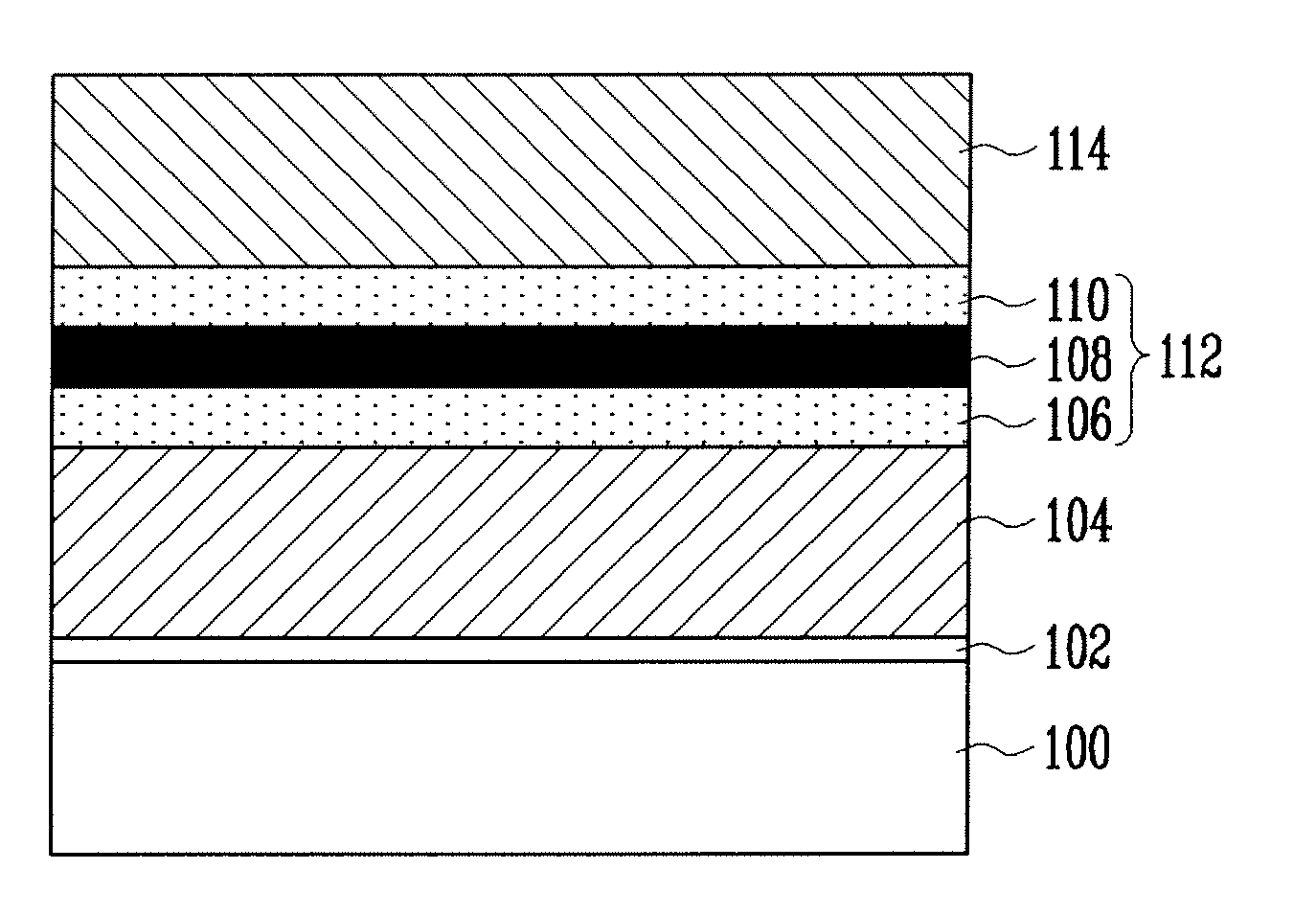

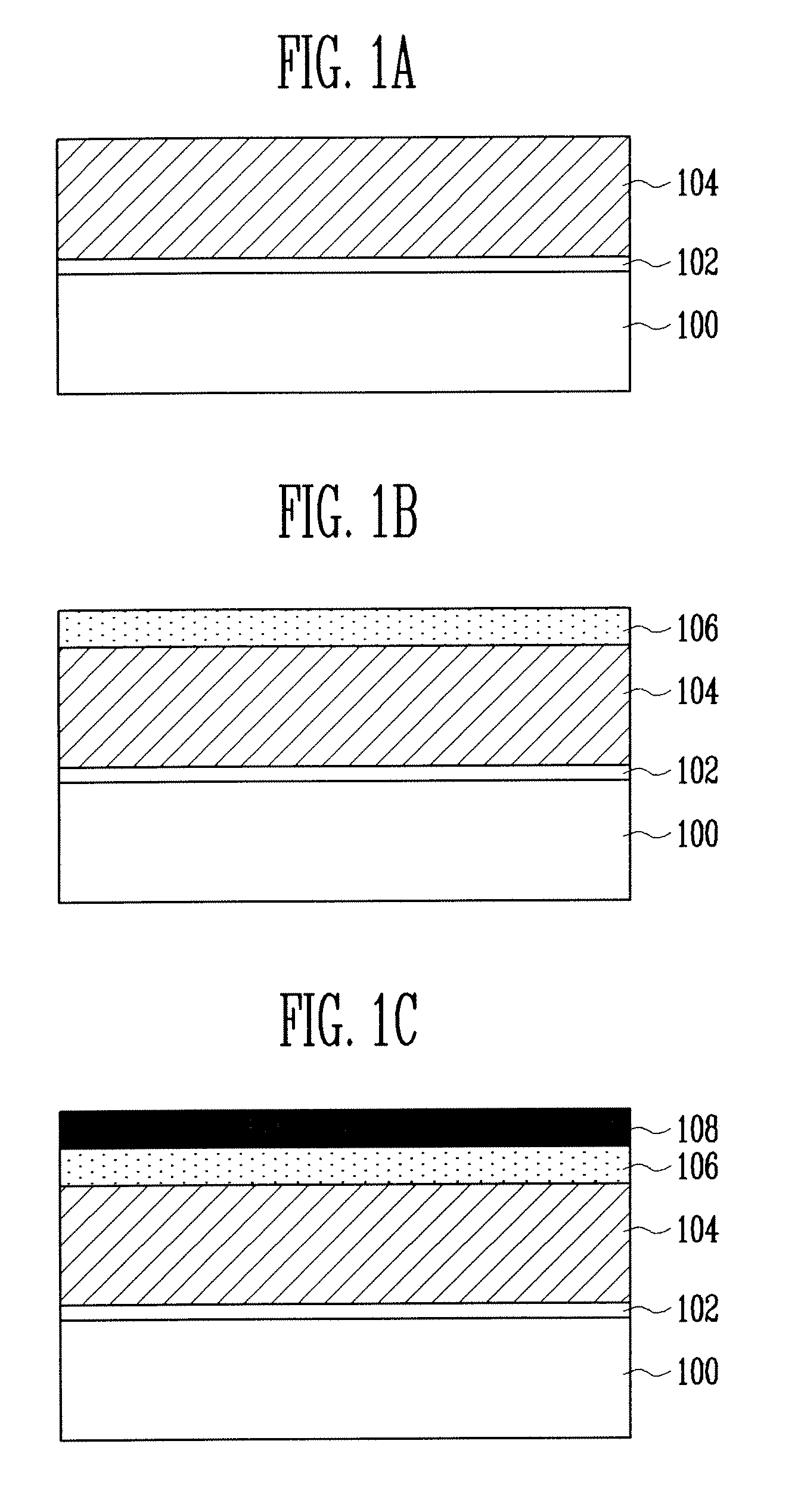

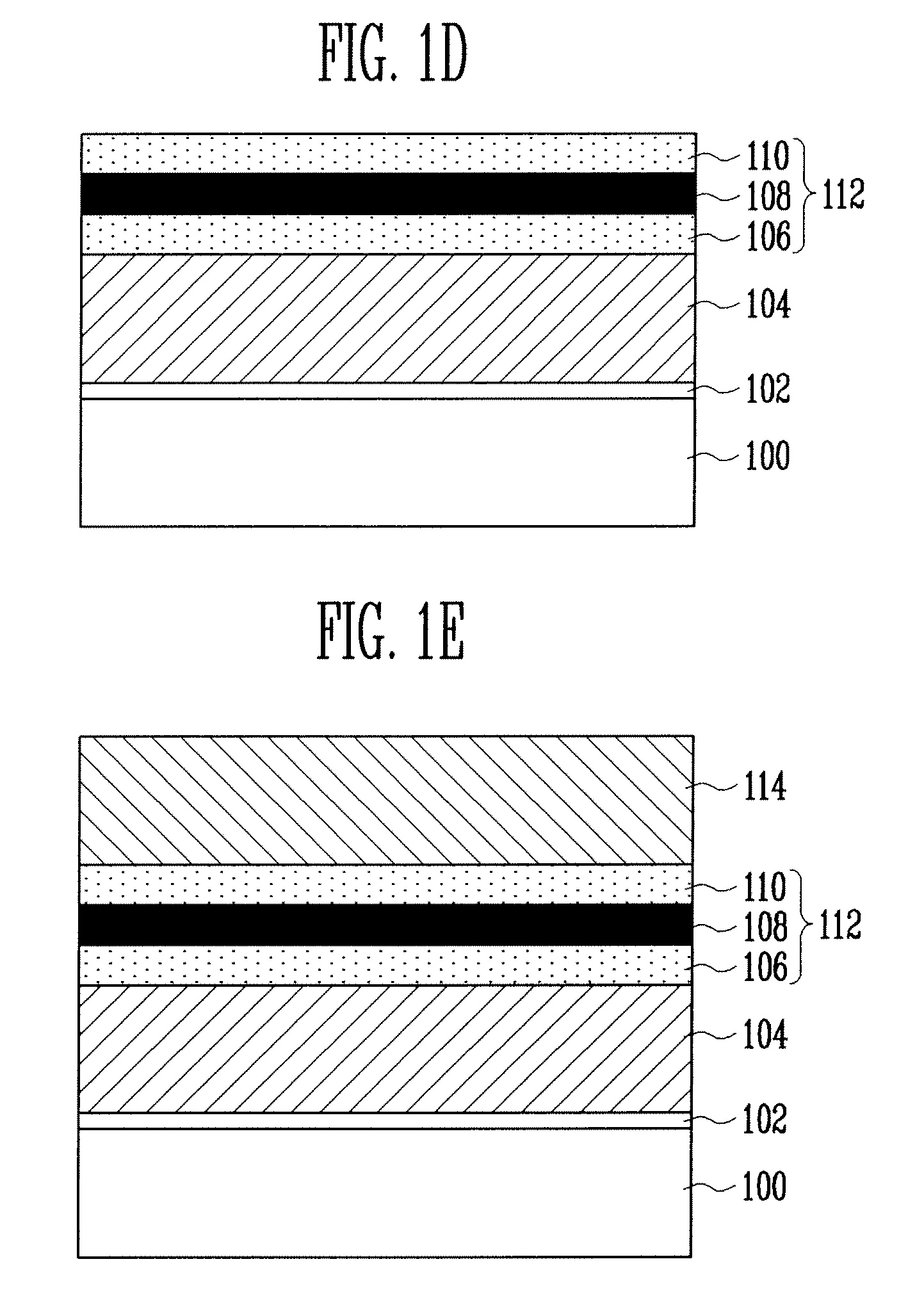

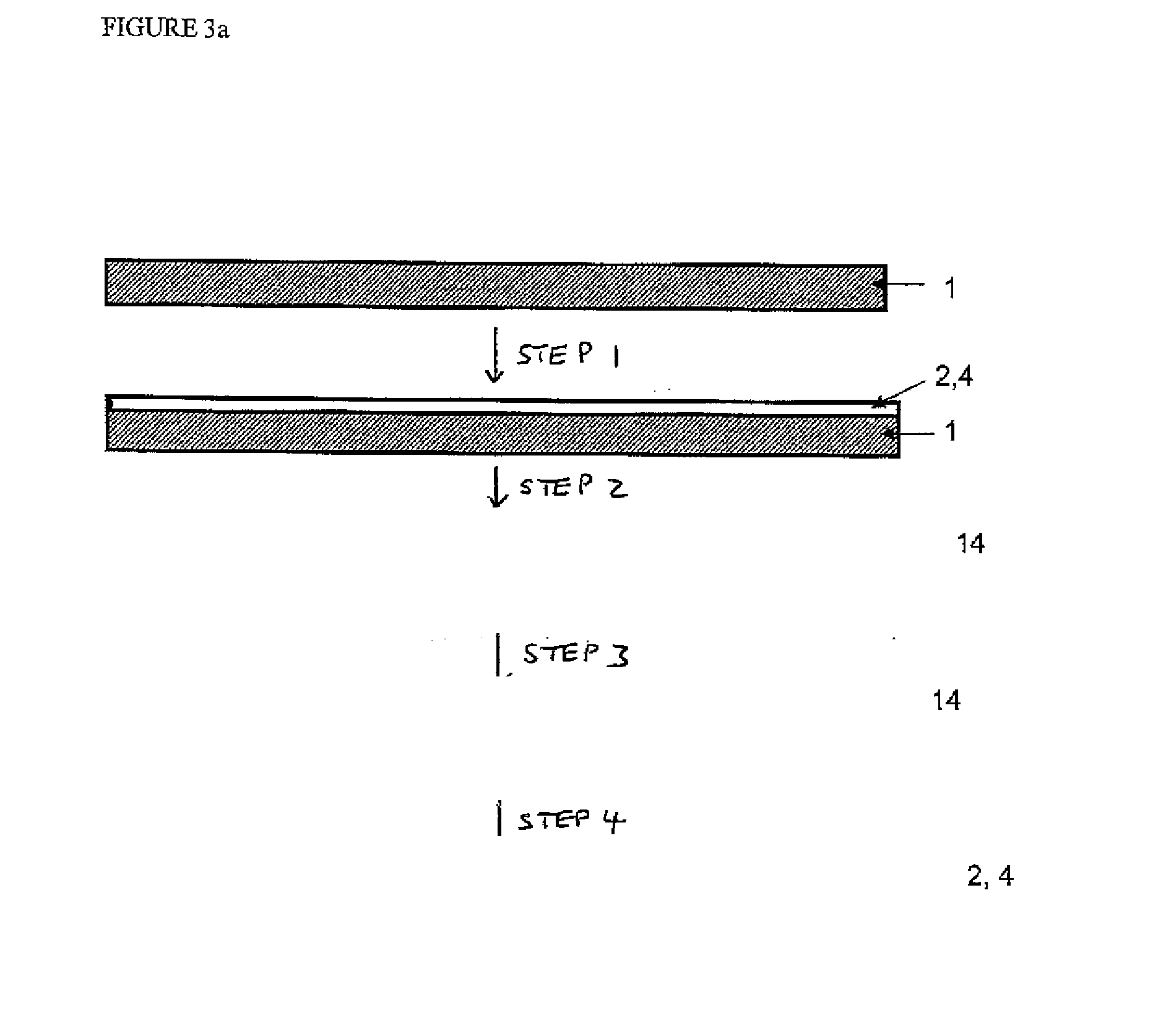

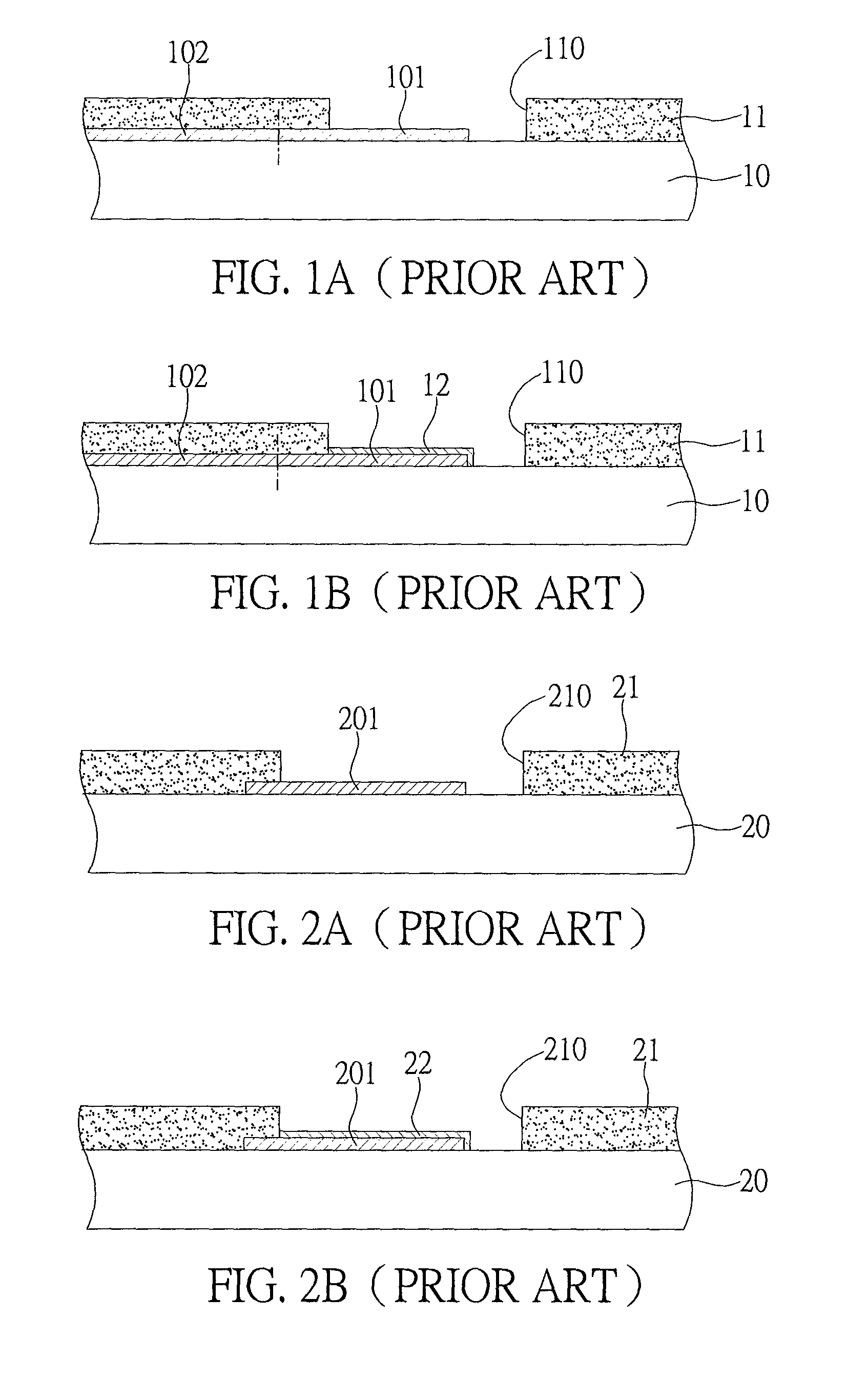

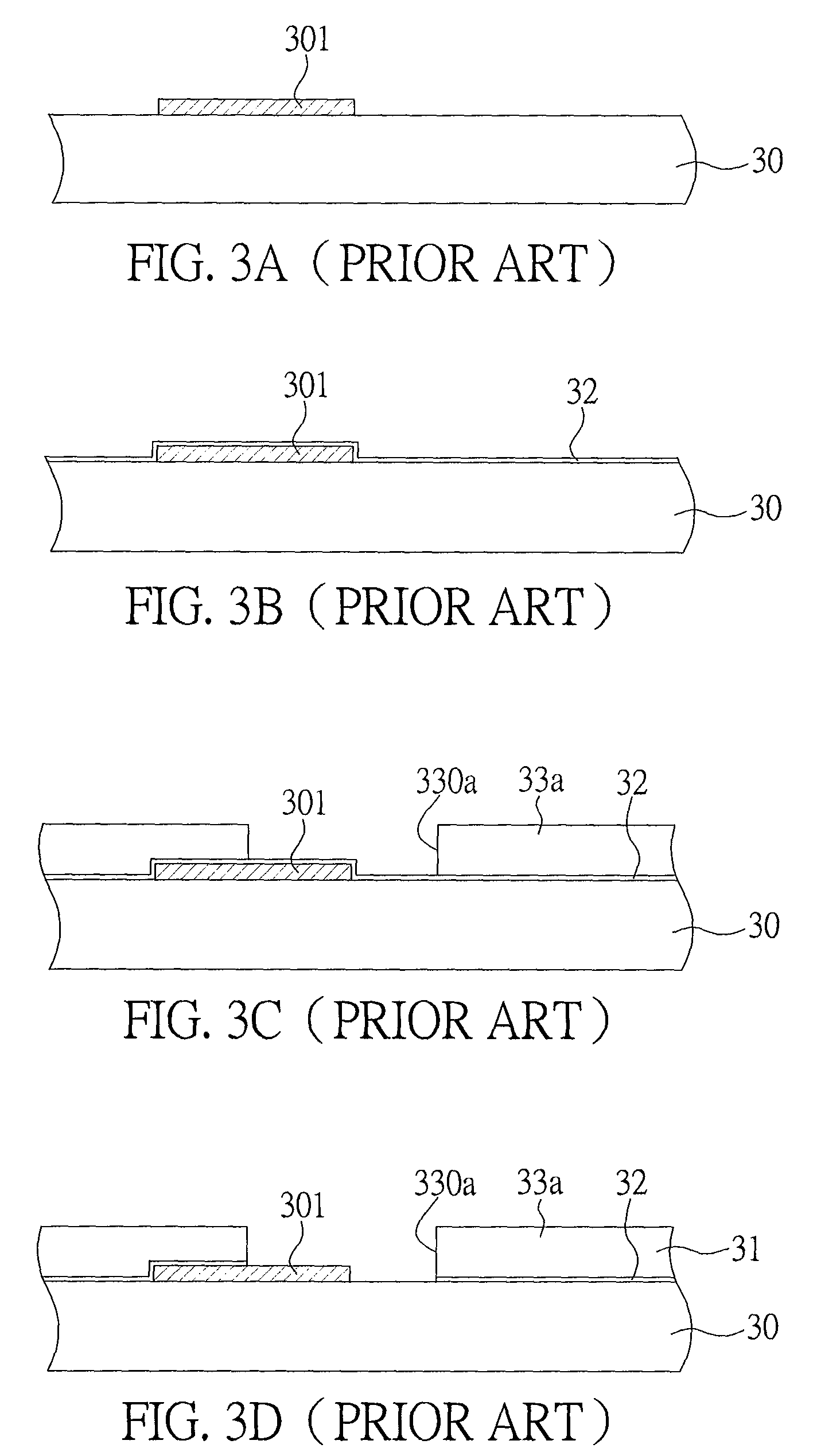

[semiconductor device and fabricating method thereof]

ActiveUS20050012218A1Increase overlay toleranceImprove toleranceSemiconductor/solid-state device detailsSolid-state devicesSemiconductorDevice material

A semiconductor device and method of manufacturing the same are disclosed. A conductive structure, spacers and a dielectric layer are formed on a substrate. Thereafter, a portion of the cap layer, a portion of the spacers and a portion of the dielectric layer of the conductive structure are removed to form a funnel-shaped opening. The shoulder section of the conductive layer exposed by the funnel-shaped opening is removed to form a shoulder recess. A liner layer is formed on the sidewall of the funnel-shaped opening and then a bottom plug is formed inside the funnel-shaped opening. Another dielectric layer is formed over the substrate. A top plug is formed in the dielectric layer such that the top plug and the bottom plug are electrically connected. Finally, a wire line is formed over the substrate.

Owner:NAN YA TECH

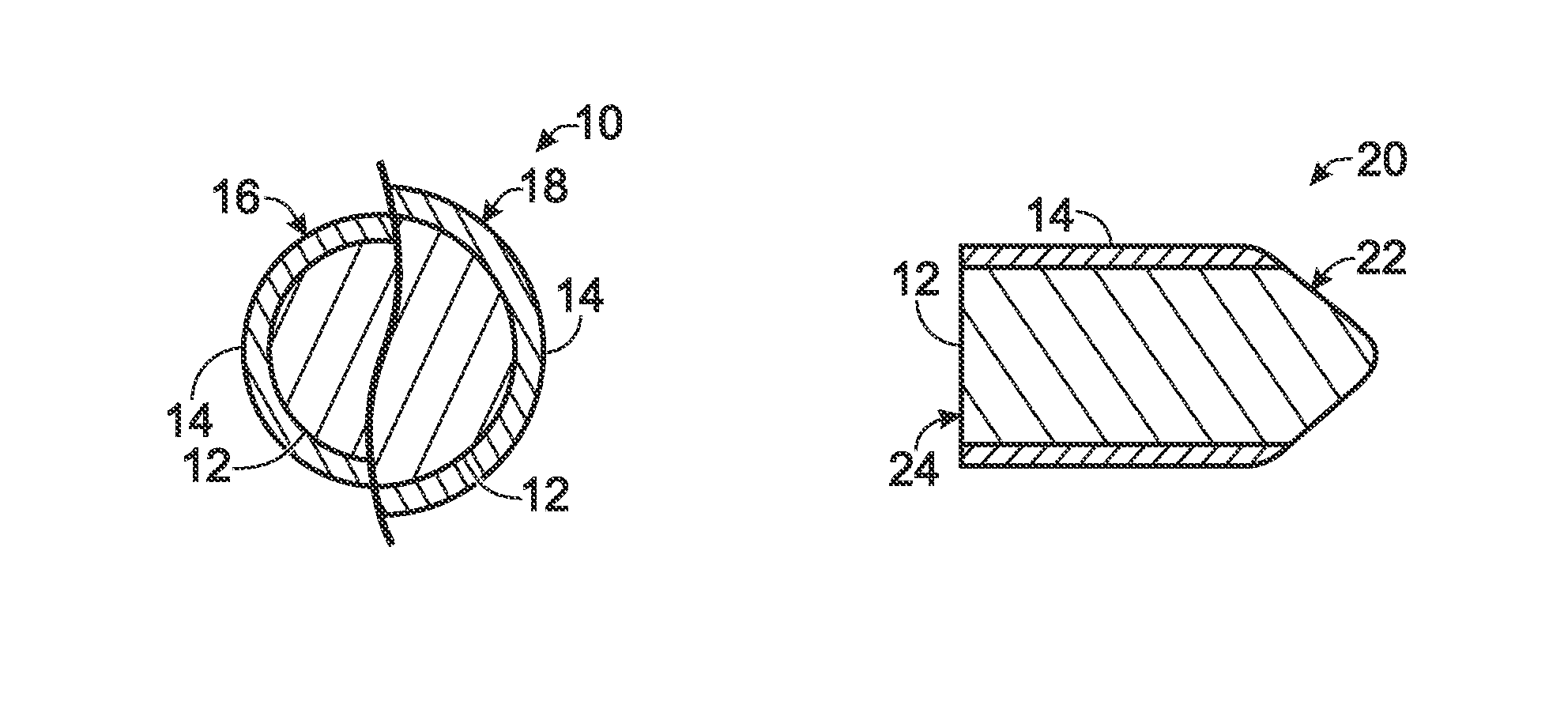

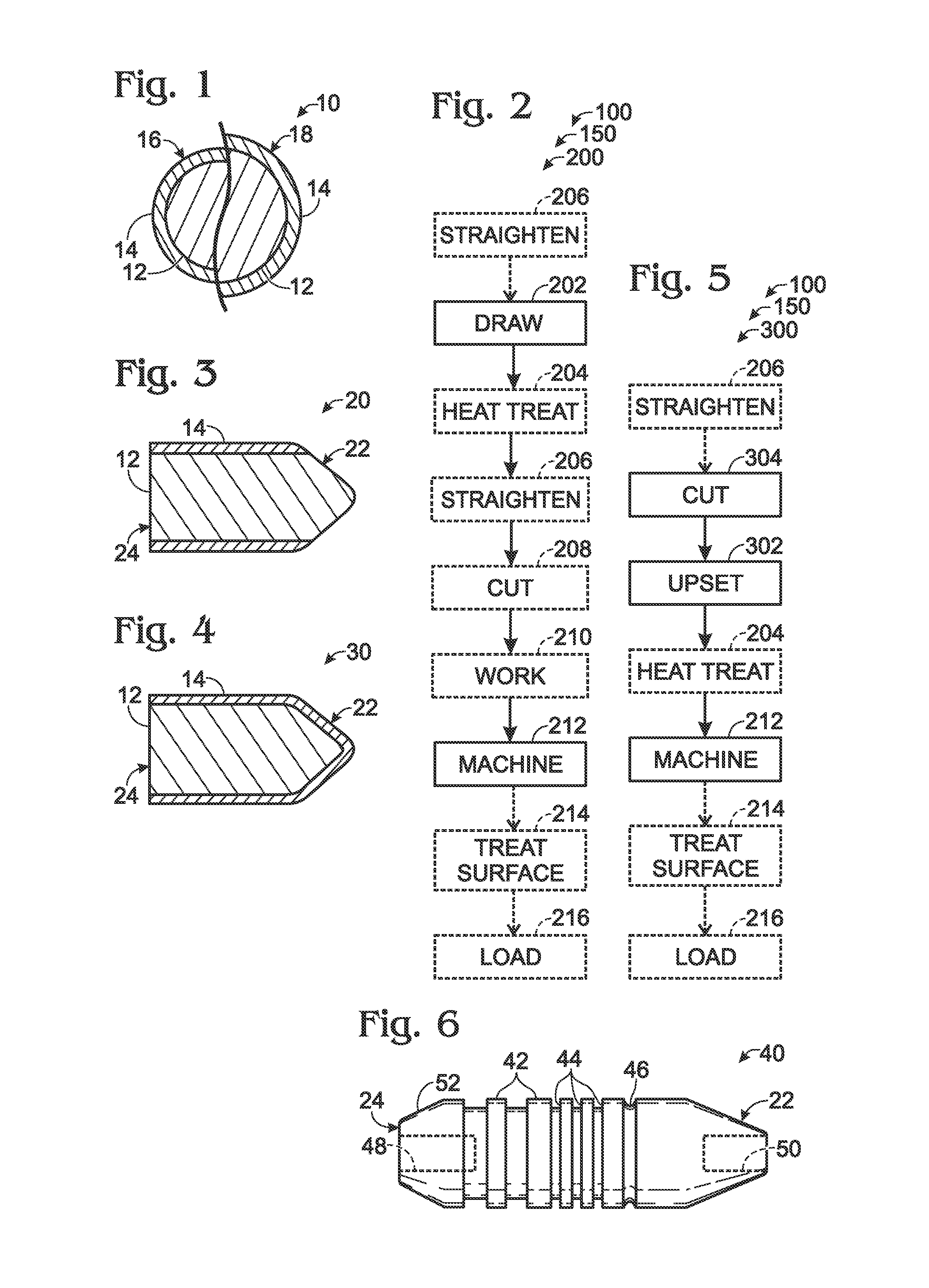

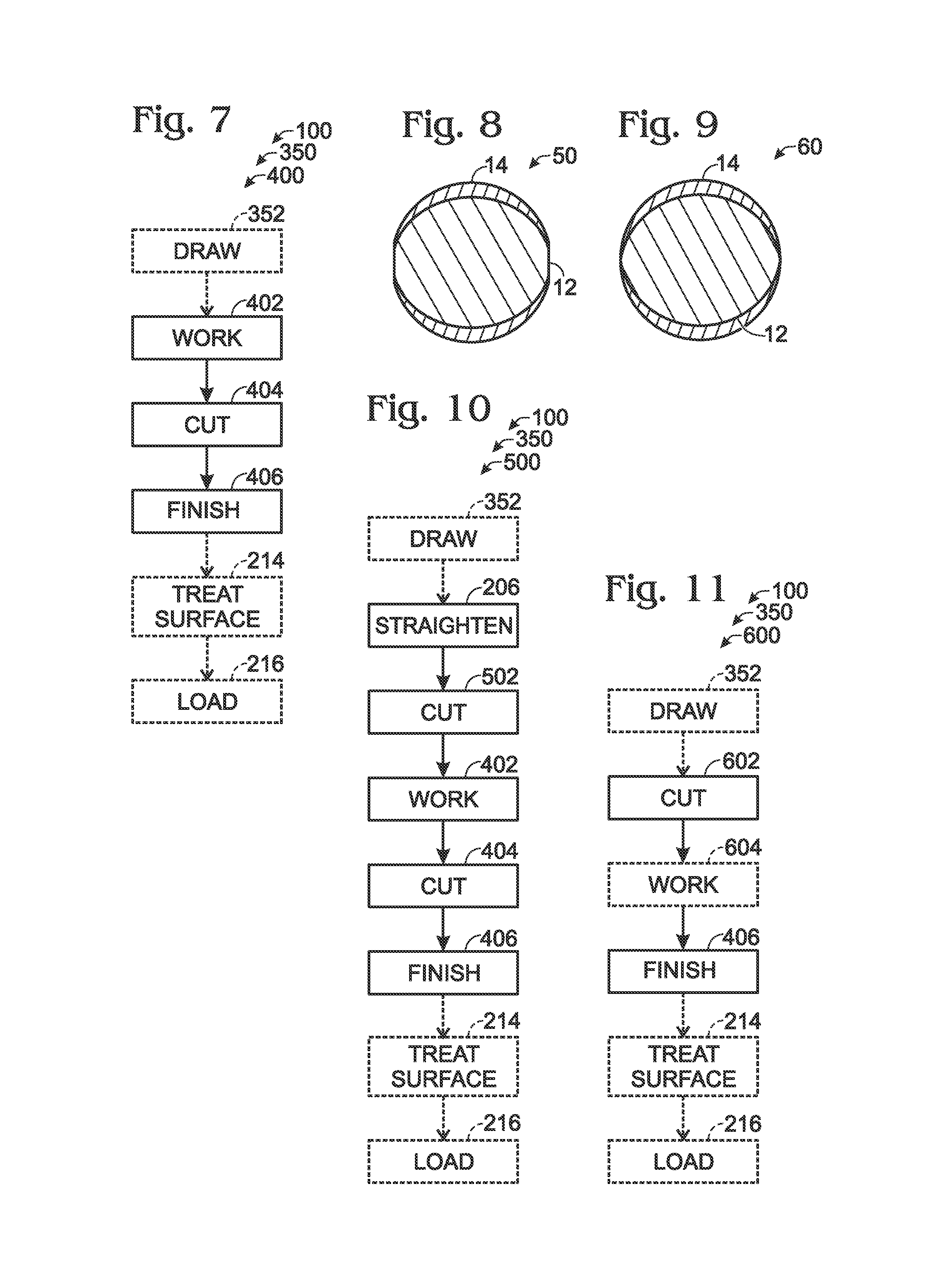

Firearm projectiles and cartridges and methods of manufacturing the same

InactiveUS8783187B2Reduce the overall diameterIncrease the diameterAmmunition projectilesShotgun ammunitionEngineeringCopper-clad steel

Firearm projectiles and methods of manufacturing firearm projectiles from a supply of clad wire. In some embodiments, the clad wire is manufactured as electrical wire, such as copper-clad steel wire. Bullets and shot, as well as methods of forming bullets and shot, from clad wire are disclosed.

Owner:AMICK FAMILY REVOCABLE LIVING TRUST

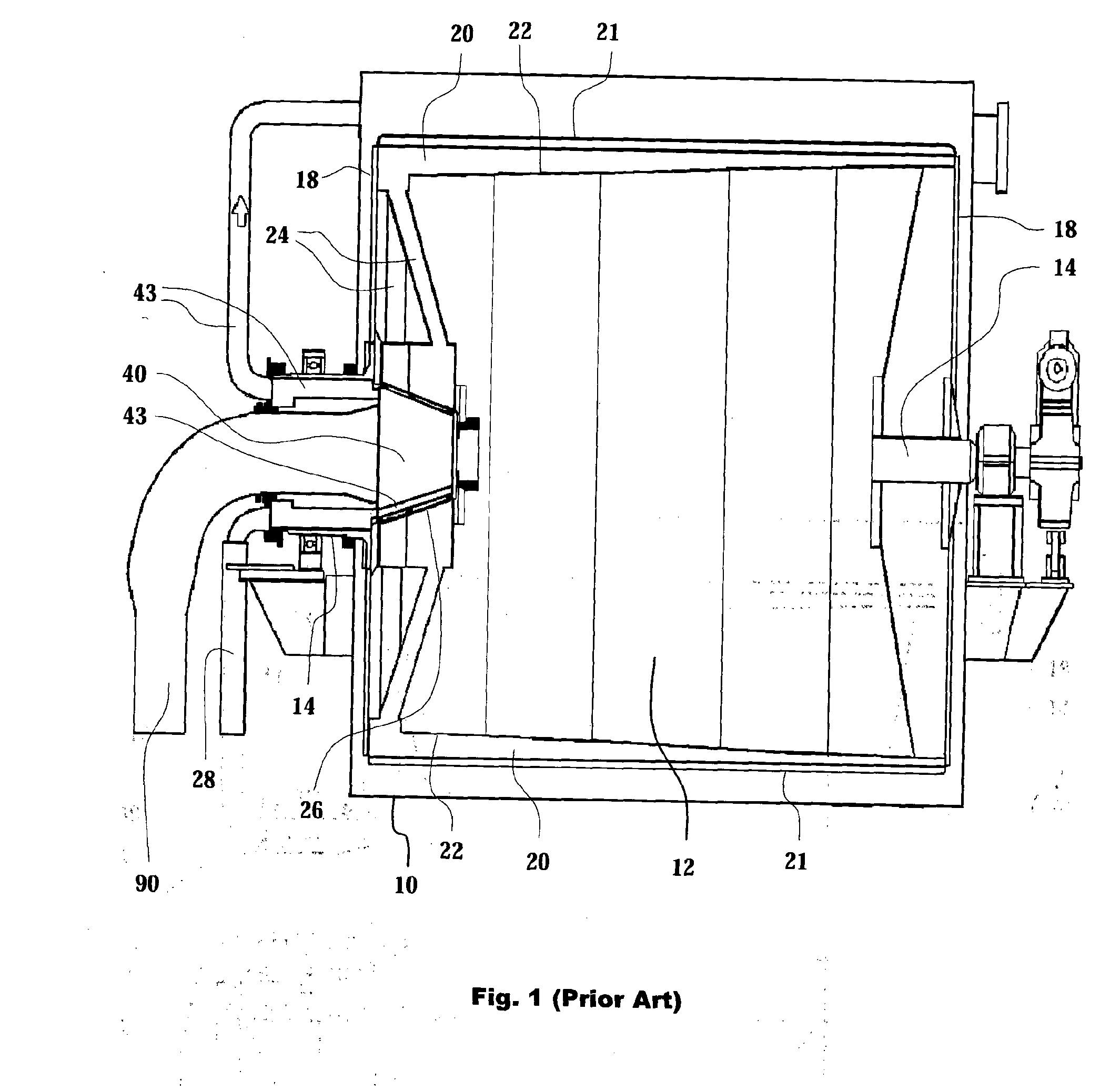

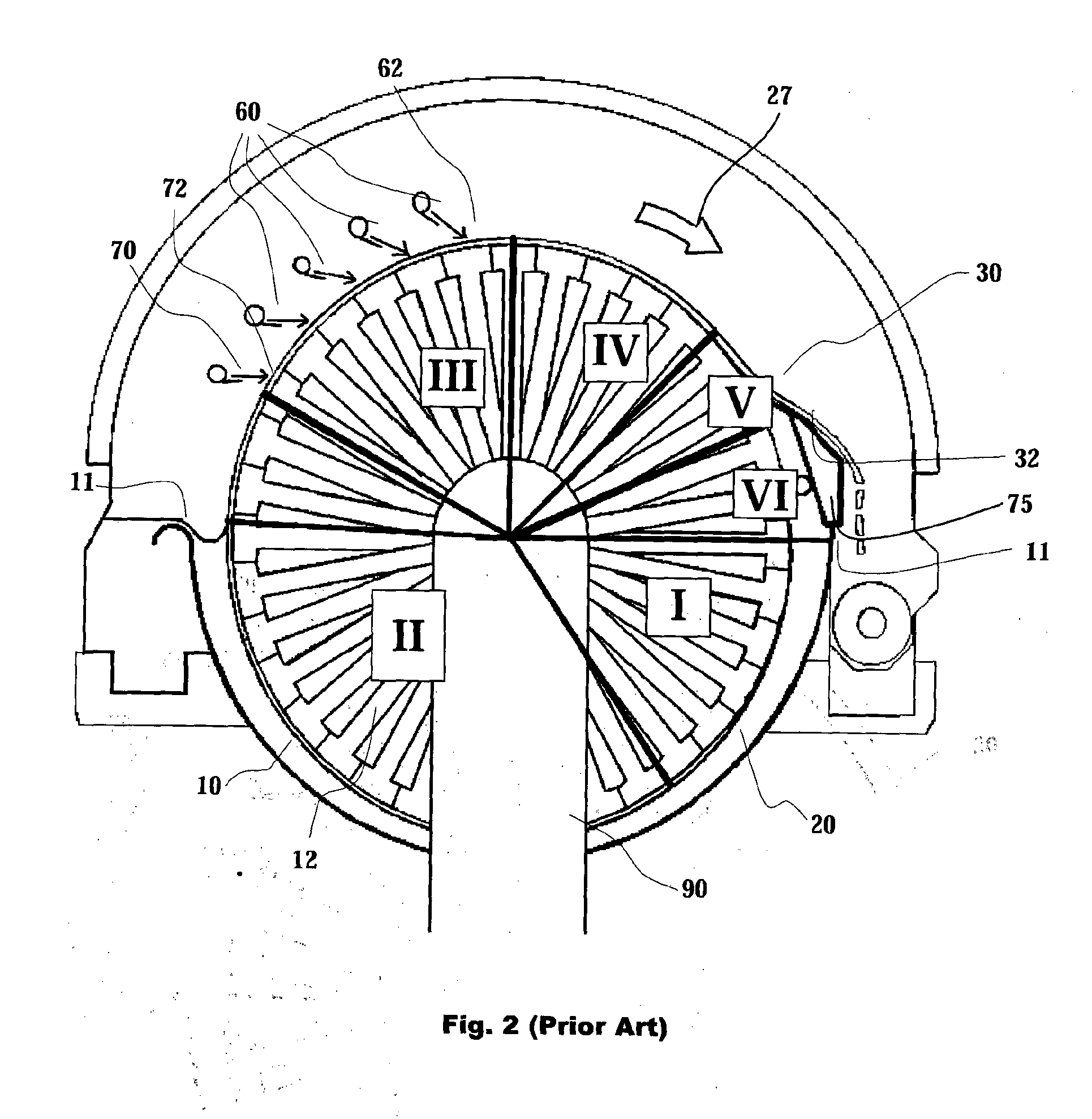

Method and apparatus for washing pulp by means of intensified suction

ActiveUS20140353260A1Improve Emissions ConsistencyReduce impurityWashing/displacing pulp-treating liquorsWater/sewage treatmentFiltrationPulp and paper industry

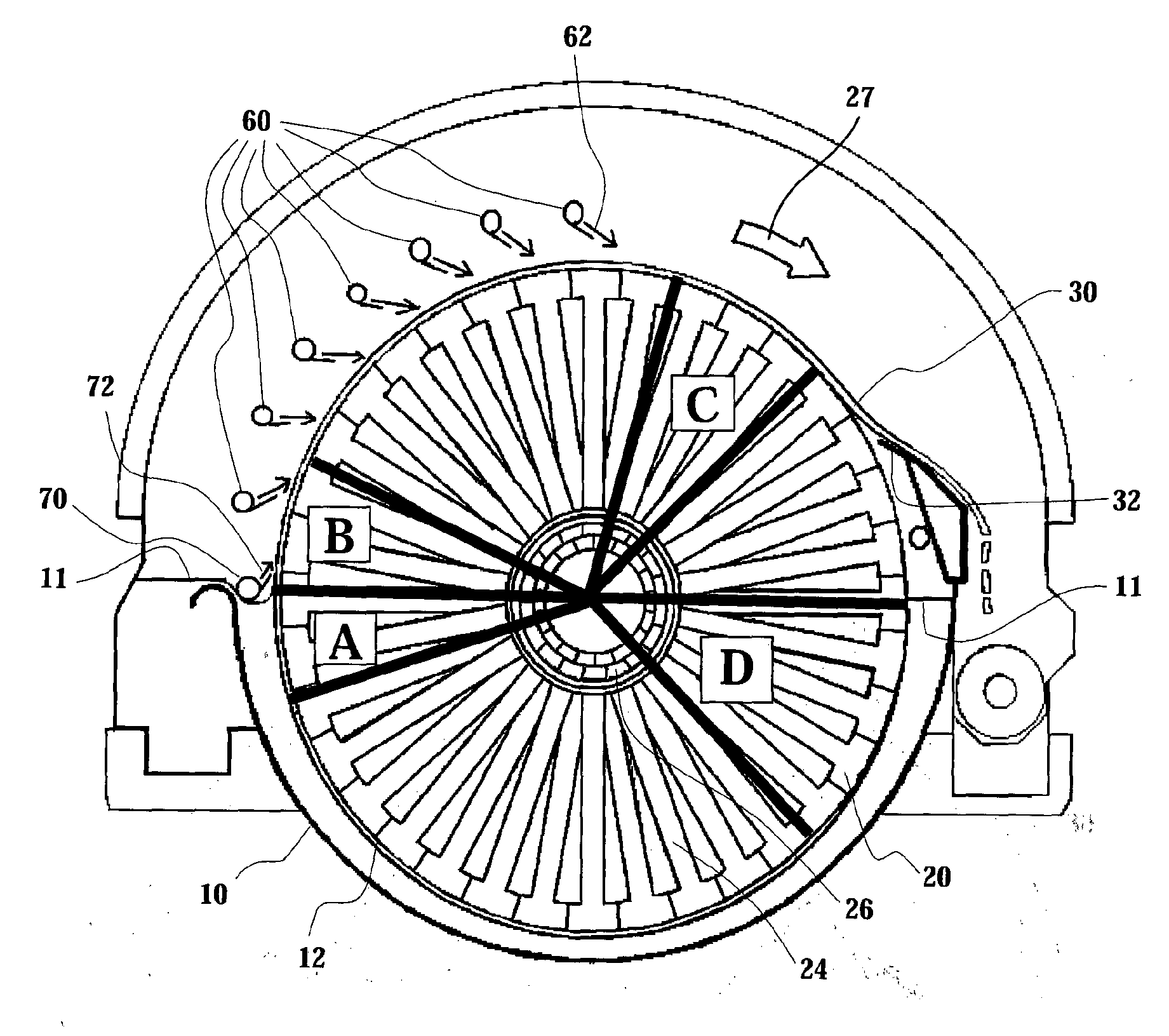

A method and an apparatus for washing a solids-containing suspension by means of a suction drum washer comprising a drum provided with a filtration surface, a main vacuum source such as a drop leg and washing tubes connected to the frame of the suction drum washer. A washing liquid stream is introduced by a first washing tube is directed to contact the pulp layer on the surface of the drum in a point below 10 degrees after the surface of the suspension and a vacuum of at least 0.1 bar greater than the main vacuum source, i.e. intensified suction is applied by means of a separate vacuum source to filtering surface at the contacting point of the first liquid stream and the pulp layer or maximum of 10 degrees before the contacting point. The intensified suction may be utilized also for boosting end of filtration stage (II) and drying stage (IV). Filtrate from the drying stage (IV) can be used at the same washer as a washing liquid at the first or the second washing tube.

Owner:ANDRIZ OY

Bearing Ring, Electrically Insulating Coating and Method for Applying an Electrically Insulating Coating

ActiveUS20150380124A1Less brittleLayers is relatively thickMolten spray coatingLayered productsMaterials scienceCoating

The invention discloses a bearing ring. The bearing ring, with a body, has an electrically insulating coating made up of a ceramic layer with pores and a plastic for filling the pores and coating the ceramic layer. According to the invention, the pores have a proportion between 10 and 50% in the ceramic layer. The invention furthermore defines an electrically insulating coating, made up of a ceramic layer with pores and a plastic for filling the pores and coating the ceramic layer. The invention further still discloses a method for applying an electrically insulating coating to a body of a bearing ring.

Owner:COATEC GMBH & CO KG +1

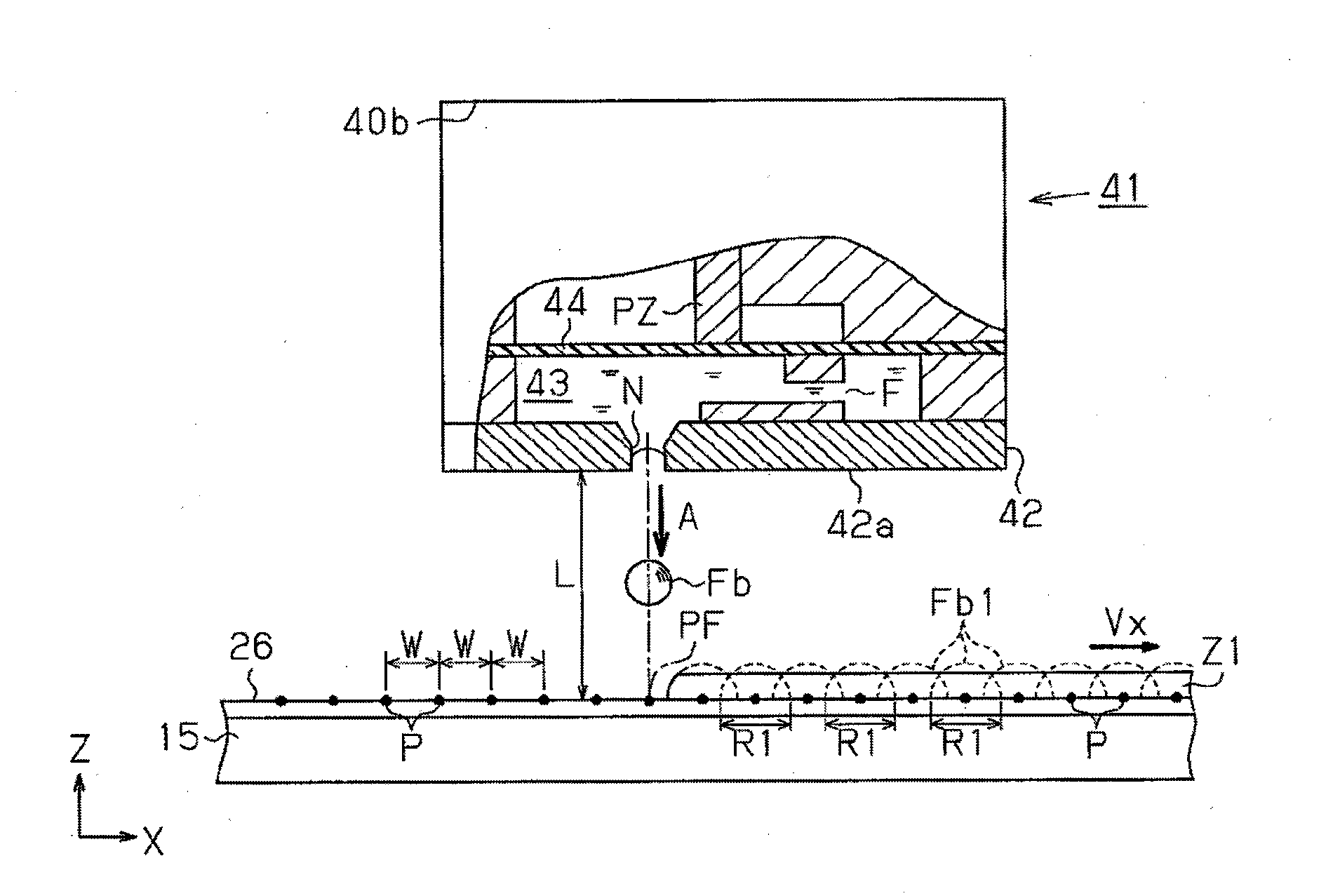

Pattern formation method

InactiveUS20080175981A1Pattern formation is simplifiedWell formedSolid-state devicesSpecial surfacesEngineeringPattern formation

A pattern formation method includes forming a plurality of concave parts adjacent to each other on a substrate, and discharging droplets including a functional liquid material on the substrate to form a prescribed pattern of the functional liquid material that straddles over the concave parts on the substrate.

Owner:SEIKO EPSON CORP

Etchant, display device and method for manufacturing display device using the same

ActiveUS8785935B2Improve featuresLayers is relatively thickSolid-state devicesSemiconductor/solid-state device manufacturingOrganic acidPersulfate

An etchant includes: 5 to 20 wt % of persulfate, 1 to 10 wt % of at least one compound of an inorganic acid, an inorganic acid salt, or a mixture thereof, 0.3 to 5 wt % of a cyclic amine compound, 1 to 10 wt % of at least one compound of an organic acid, an organic acid salt, or a mixture thereof, 0.1 to 5 wt % of p-toluenesulfonic acid, and water, based on the total weight of the etchant. A copper-titanium etchant further includes 0.01 to 2 wt % of a fluoride-containing compound. A method of forming a display device using the etchant, and a display device, are also disclosed.

Owner:SAMSUNG DISPLAY CO LTD +1

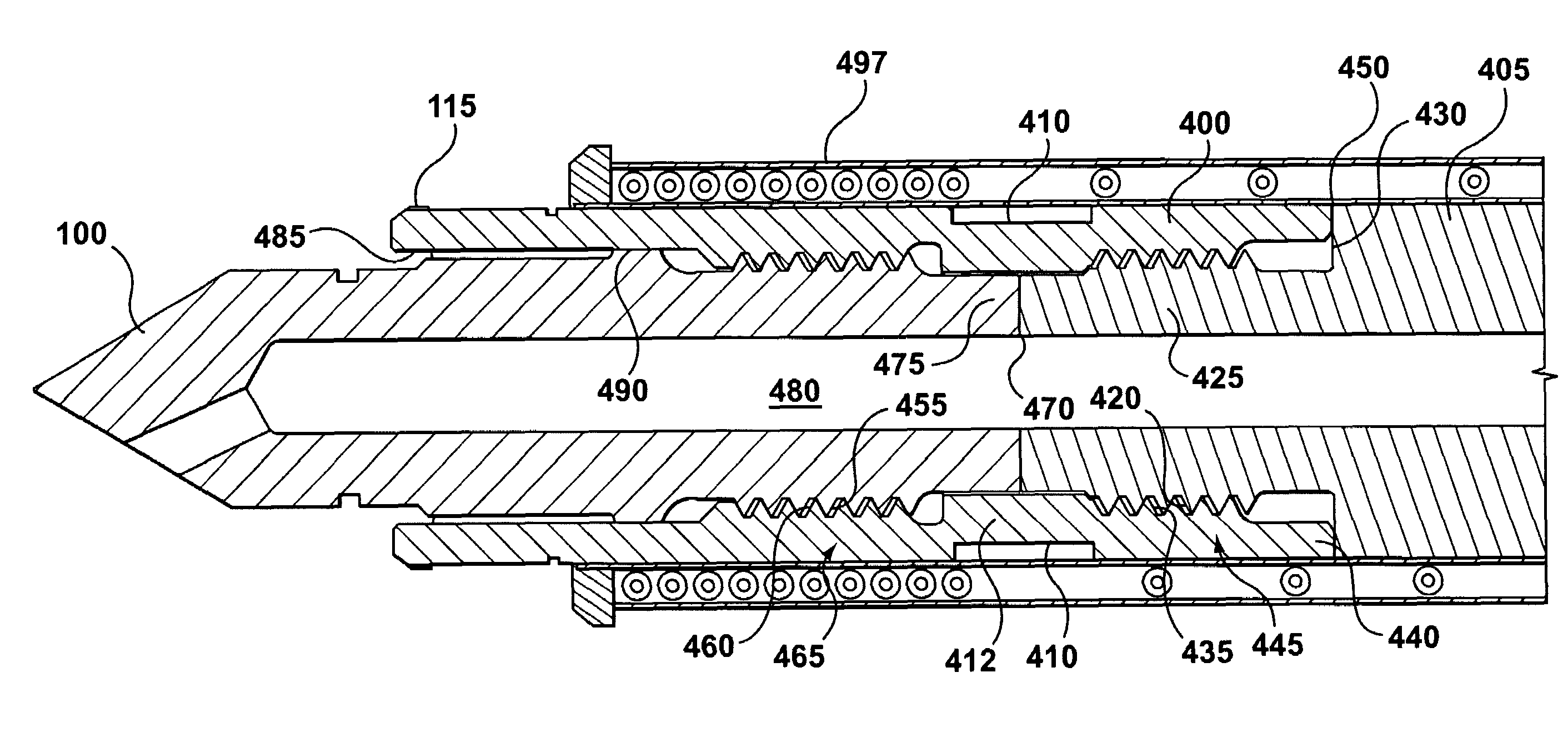

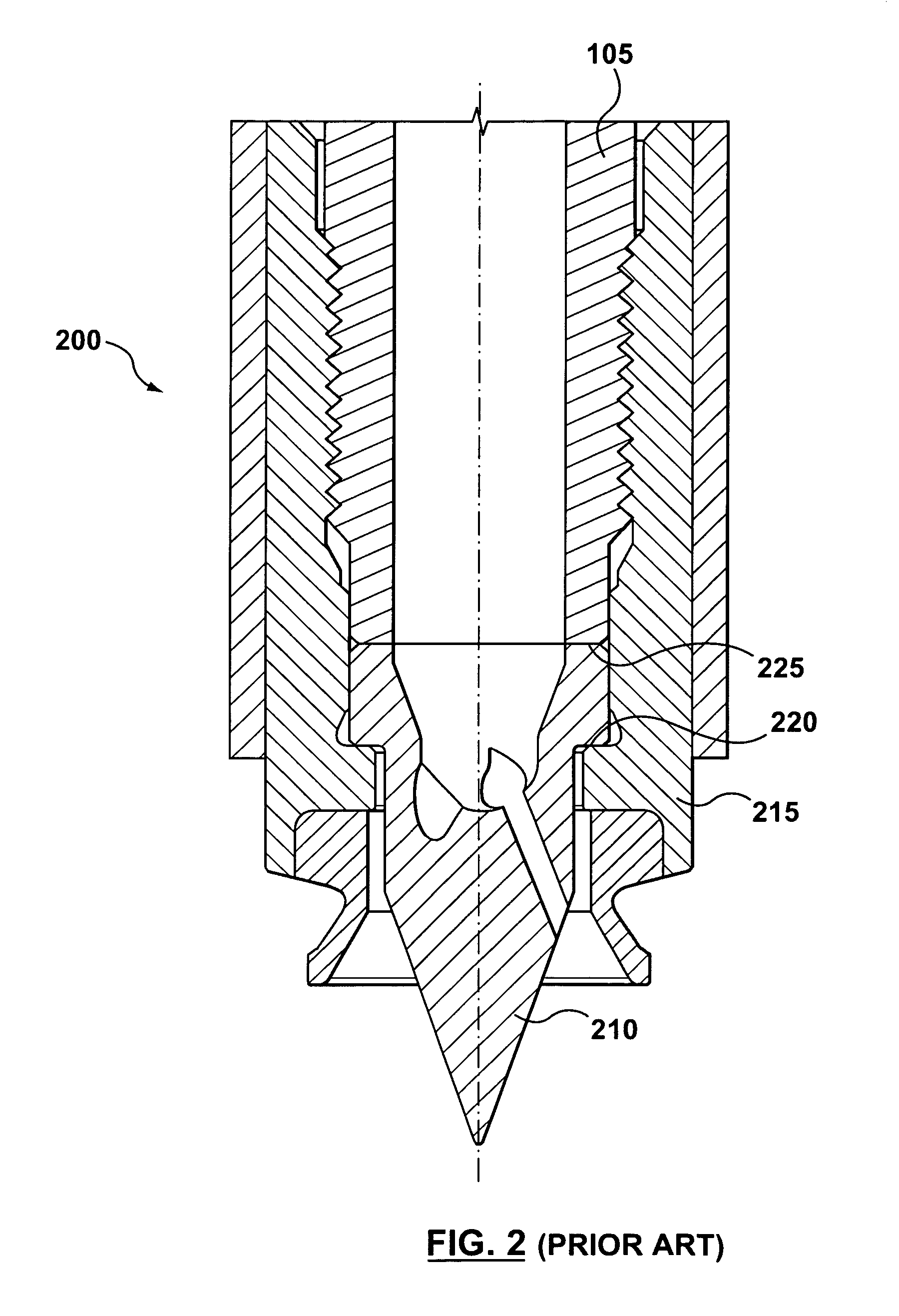

Hot runner nozzle system

A hot runner nozzle system (500) comprising a nozzle tip (100) adjacent to a nozzle (405) in series, and a retainer (400) adjoining both the nozzle tip (100) and the nozzle (405) in parallel, the retainer (400) having a first retainer thread (435), for connection to a nozzle thread (420) to form a first seal (450) between the nozzle end (440) of the retainer (400) and a nozzle shoulder (430), a second retainer thread (460), for connection to a tip thread (455) to form a second seal (470) between the inlet end (475) of the nozzle tip (100) and the gate end (425) of the nozzle (405), a seal ring (115) for creating a gate seal (496) with a gate insert (120), and a plurality of flats (410) thereon to facilitate torquing of the retainer (400) to the nozzle (405), the torque value applied to the retainer (400) being about two to four times of that applied to the nozzle tip (100) to facilitate removal of the nozzle tip (100) independent of the retainer (400).

Owner:HUSKY INJECTION MOLDING SYST LTD

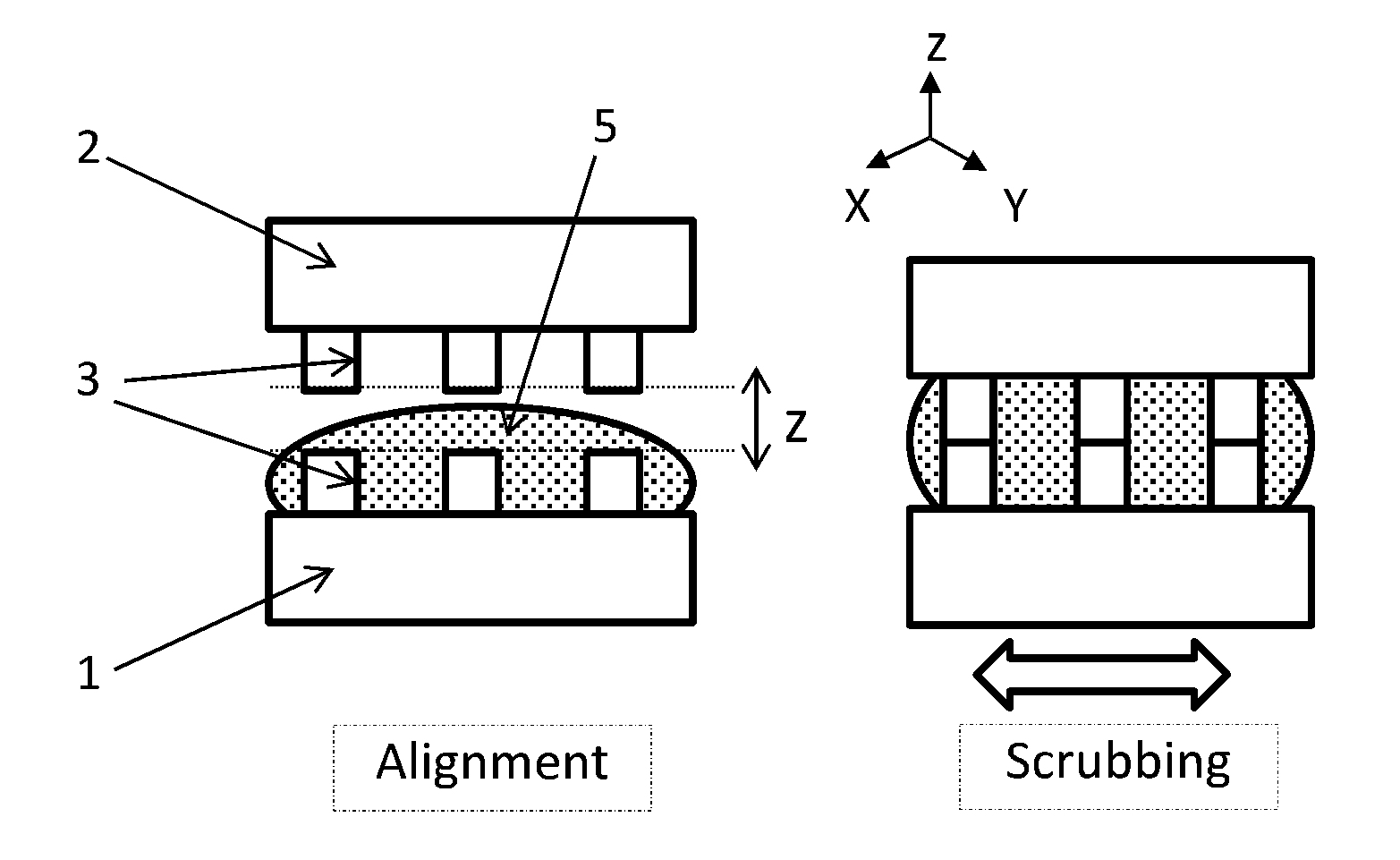

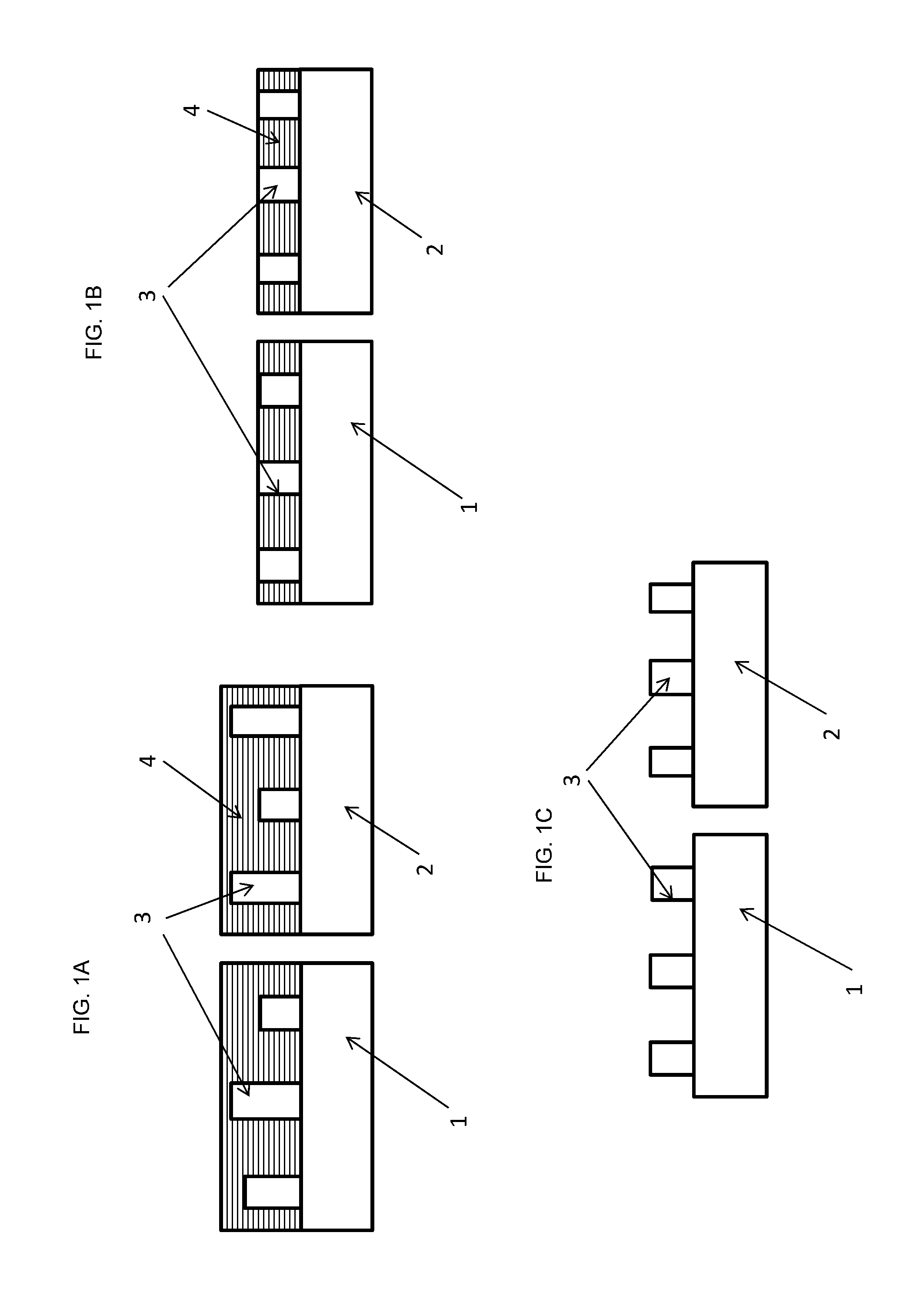

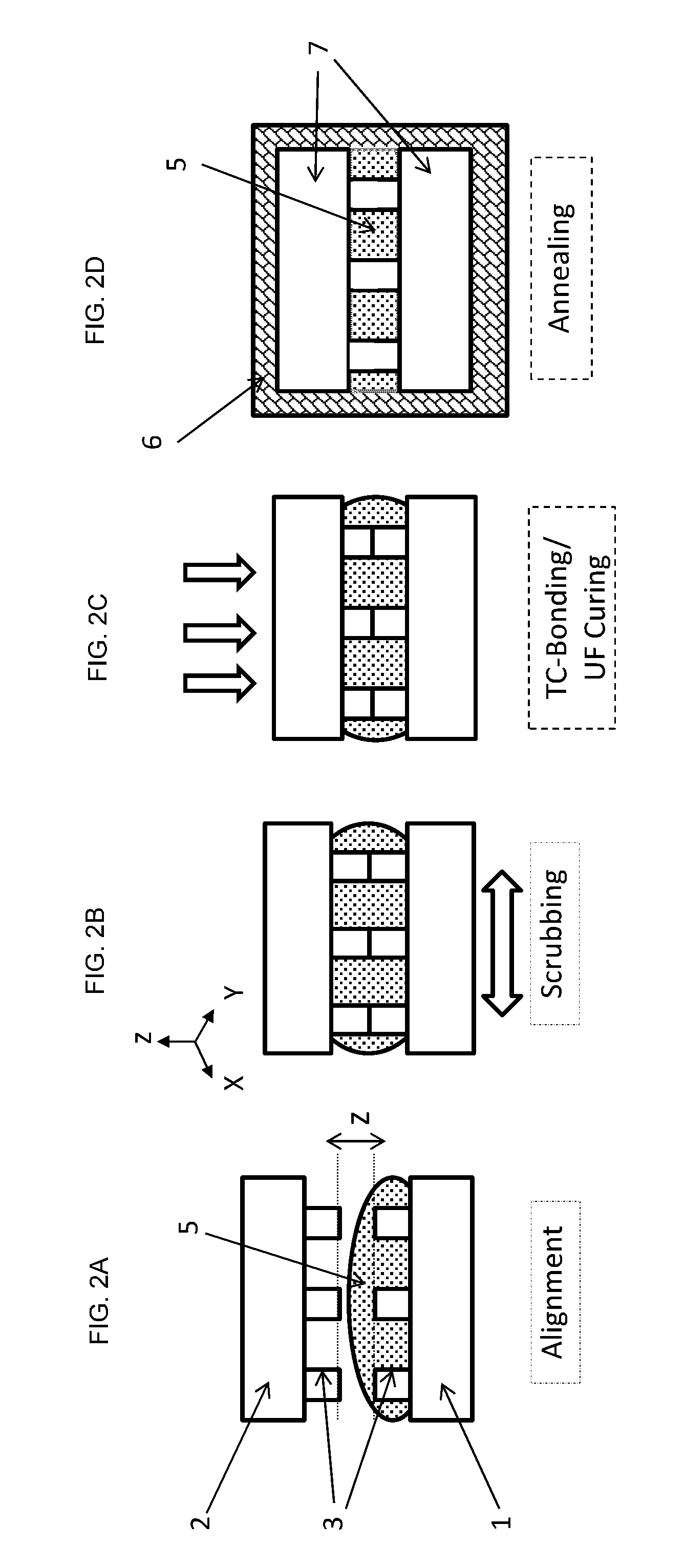

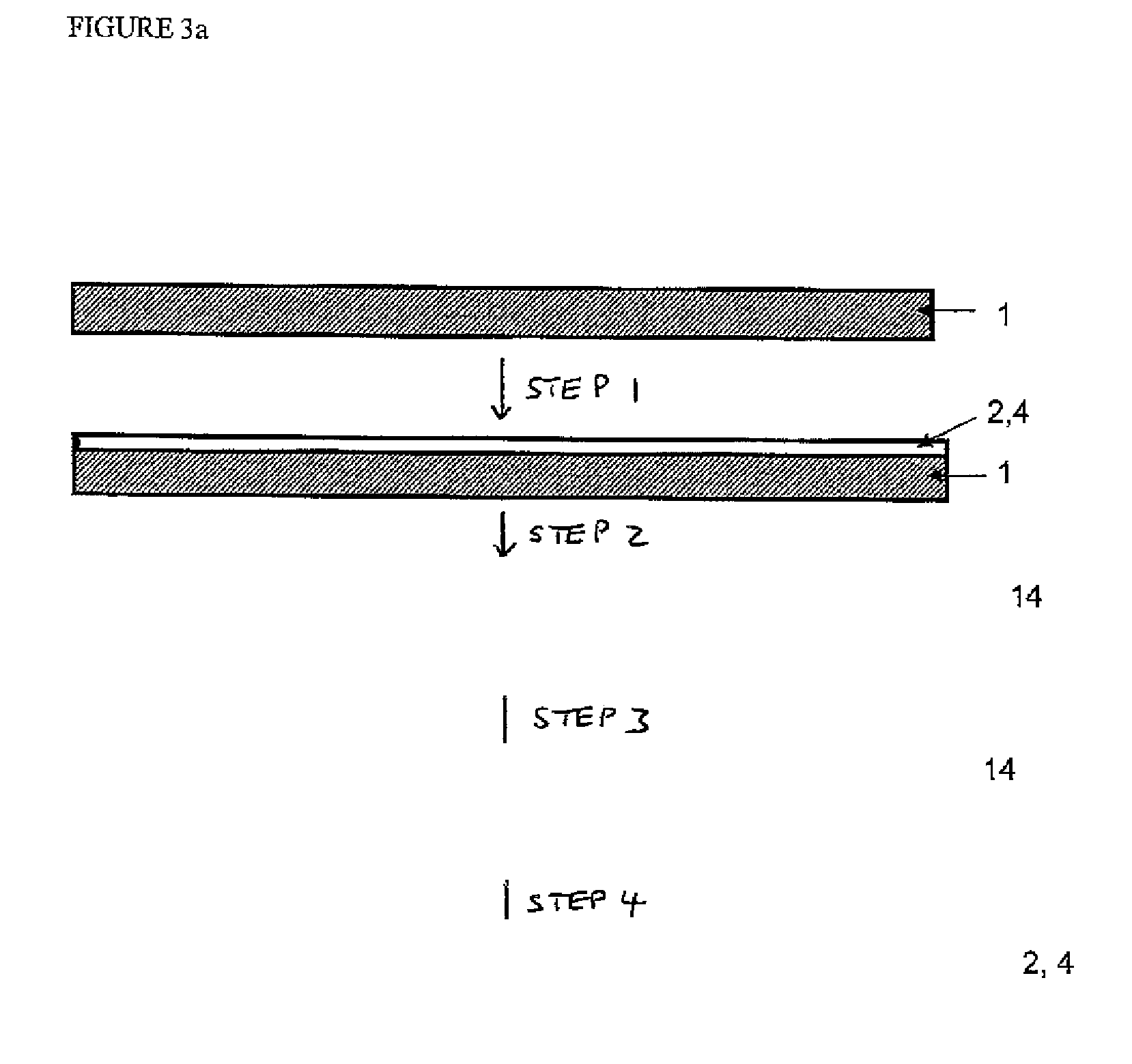

Method for bonding semiconductor substrates and devices obtained thereof

ActiveUS20140170813A1Reduce stressShortening duration of timeSemiconductor/solid-state device detailsSolid-state devicesSemiconductorMaterials science

A method is provided for bonding a first semiconductor substrate to a second semiconductor substrate using low temperature thermo-compression. The bonding method comprises the step of in-situ mechanically scrubbing the metal contact structure surfaces prior to thermo-compression bonding step, thereby planarizing the removing the oxides and / or contaminants from the metal contact structure surfaces. The thermo-compression bonding step is followed by a thermal annealing step for creating interface diffusion between the metal contact structure of the first and second semiconductor substrates

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

Method of manufacturing semiconductor device featuring formation of conductive plugs

InactiveUS6933229B2Improve toleranceReduce aspect ratioSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

A semiconductor device and method of manufacturing the same are disclosed. A conductive structure, spacers and a dielectric layer are formed on a substrate. Thereafter, a portion of the cap layer, a portion of the spacers and a portion of the dielectric layer of the conductive structure are removed to form a funnel-shaped opening. The shoulder section of the conductive layer exposed by the funnel-shaped opening is removed to form a shoulder recess. A liner layer is formed on the sidewall of the funnel-shaped opening and then a bottom plug is formed inside the funnel-shaped opening. Another dielectric layer is formed over the substrate. A top plug is formed in the dielectric layer such that the top plug and the bottom plug are electrically connected. Finally, a wire line is formed over the substrate.

Owner:NAN YA TECH

Method of Fabricating Flash Memory Device

InactiveUS20090163015A1Improve performanceImprove film qualitySolid-state devicesSemiconductor/solid-state device manufacturingBack biasNitride

The present invention relates to a method of fabricating a flash memory device. According to a method of fabricating a flash memory device in accordance with an aspect of the present invention, a semiconductor substrate over which a tunnel insulating layer and a first conductive layer are formed is provided. A first oxide layer is formed on the first conductive layer using a plasma oxidization process in a state where a back bias voltage is applied. A nitride layer is formed on the first oxide layer. A second oxide layer is formed on the nitride layer. A second conductive layer is formed on the second oxide layer.

Owner:SK HYNIX INC

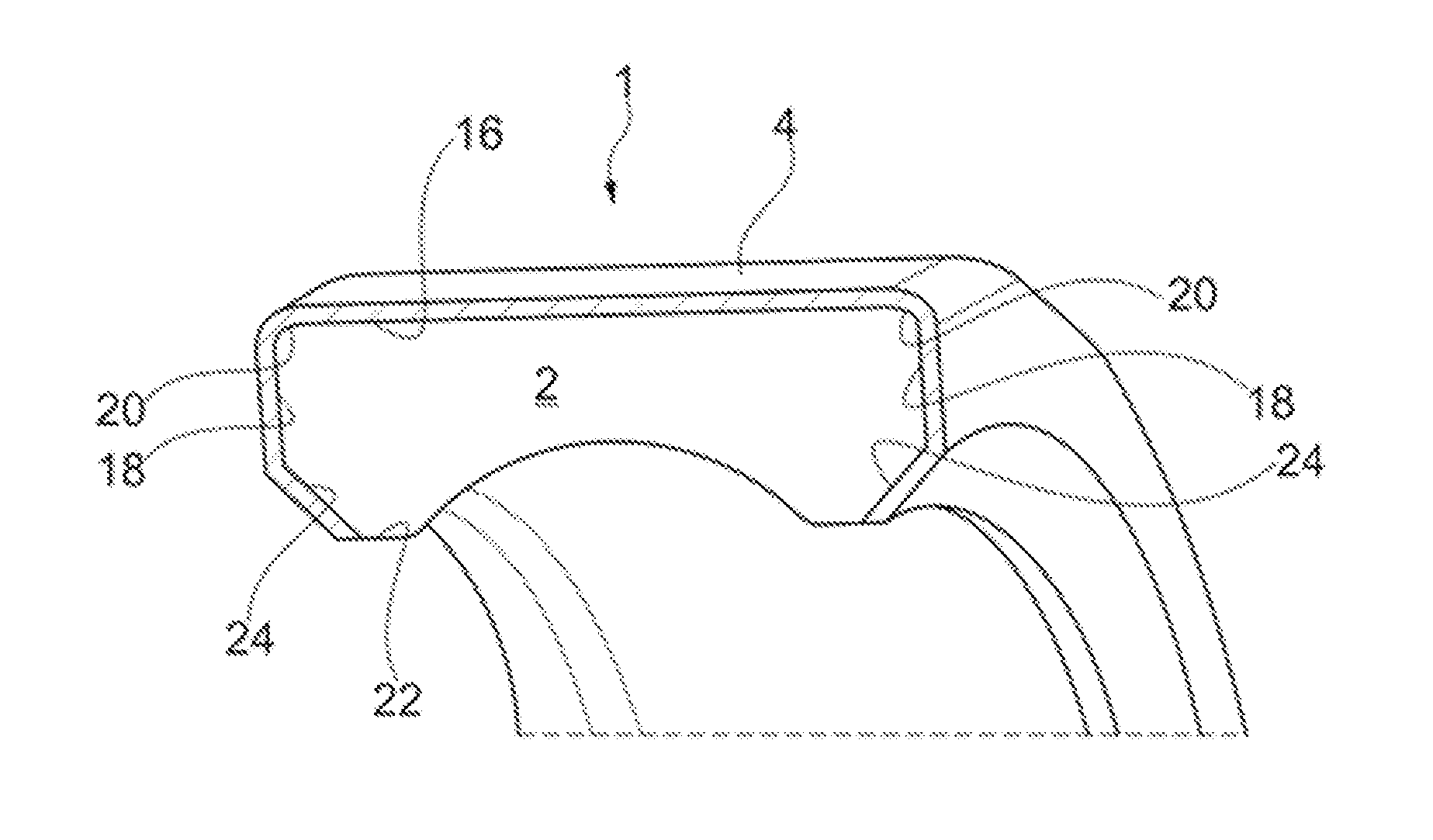

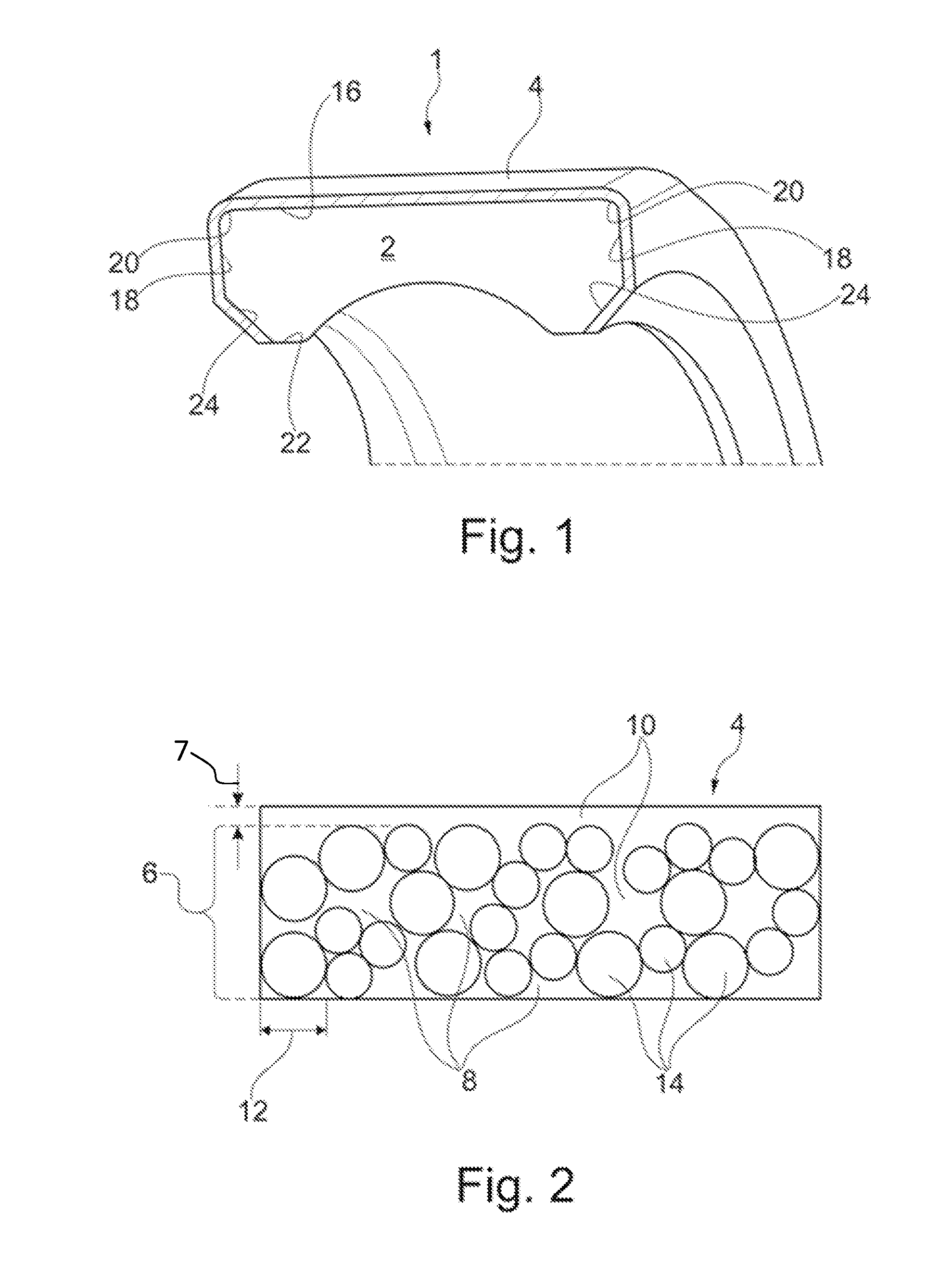

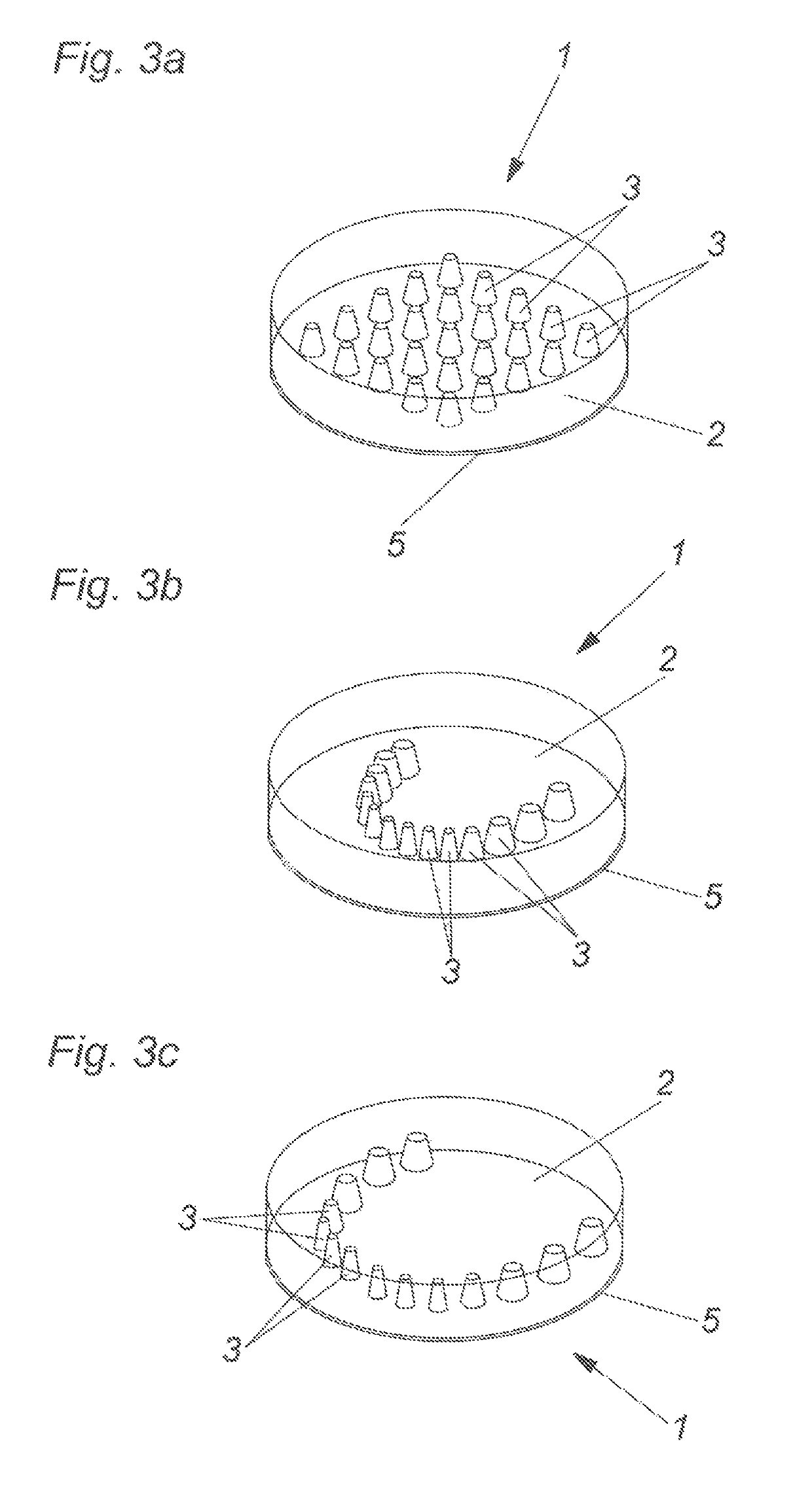

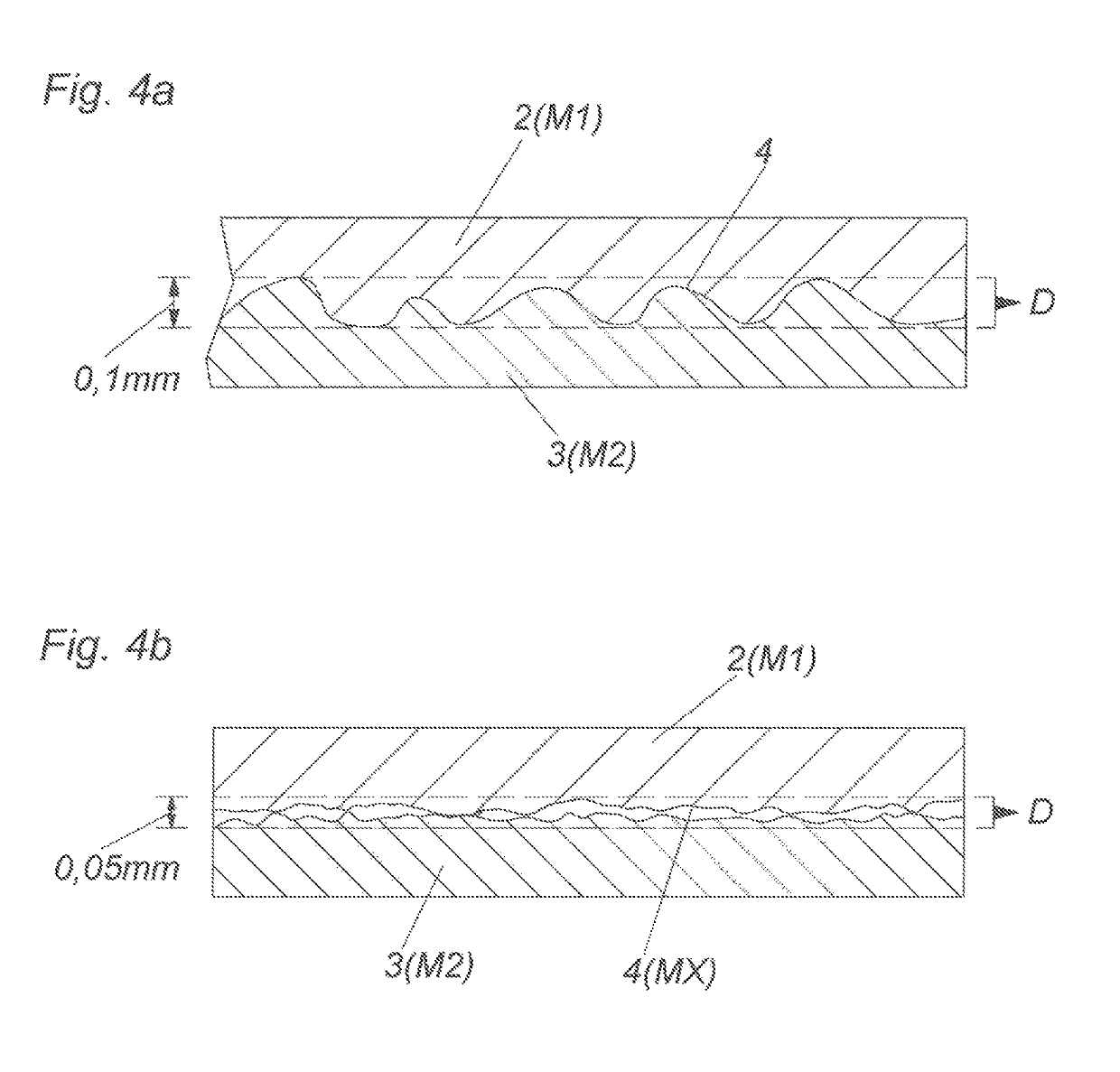

Blank for the production of a tooth prosthesis

A blank, in particular a dental blank, for the production of a tooth prosthesis, includes a bed of a first material, and at least one core region which is embedded in the bed and which has a different color from the bed and includes a second material. The core region has a surface directed in the direction of the bed, and a boundary layer delimiting the bed relative to the surface of the core region is directed in the direction of the bed. The boundary layer simulates a dentine boundary between a dental enamel and a dentine, and the blank has at least two separate core regions with separate surfaces directed in the direction of the bed.

Owner:STEGER HEINRICH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[semiconductor device and fabricating method thereof] [semiconductor device and fabricating method thereof]](https://images-eureka.patsnap.com/patent_img/9a854566-b472-4b63-b178-96e1c0a5e8d1/US20050012218A1-20050120-D00000.png)

![[semiconductor device and fabricating method thereof] [semiconductor device and fabricating method thereof]](https://images-eureka.patsnap.com/patent_img/9a854566-b472-4b63-b178-96e1c0a5e8d1/US20050012218A1-20050120-D00001.png)

![[semiconductor device and fabricating method thereof] [semiconductor device and fabricating method thereof]](https://images-eureka.patsnap.com/patent_img/9a854566-b472-4b63-b178-96e1c0a5e8d1/US20050012218A1-20050120-D00002.png)