Different-well asynchronous CO2-injecting oil extracting method adopting symmetric-type crack distributing

A symmetrical CO2 technology, applied in wellbore/well parts, production fluid, earthwork drilling and production, etc., can solve the problems of reduced oil production, easy formation of water channeling, limited range of single well stimulation, etc., to increase the swept volume, The effect of reducing operating costs and improving the displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

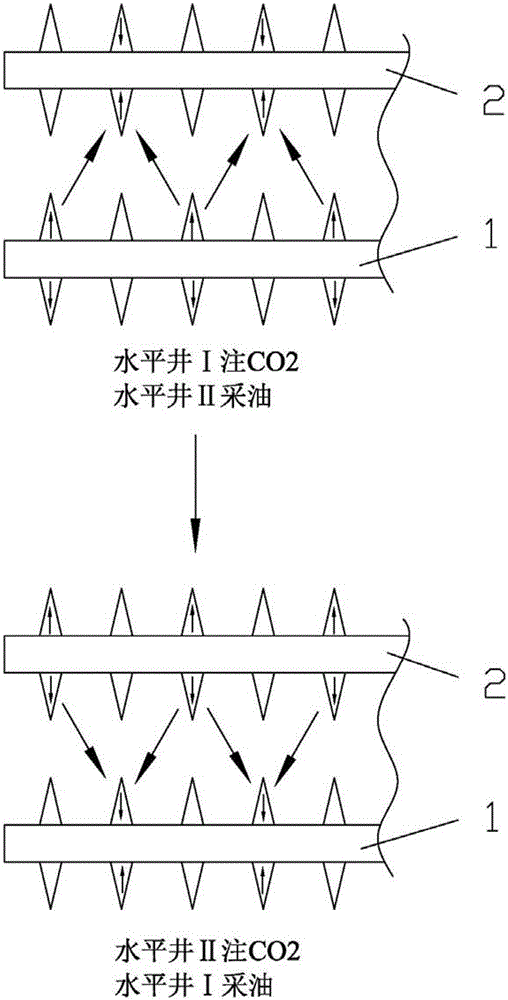

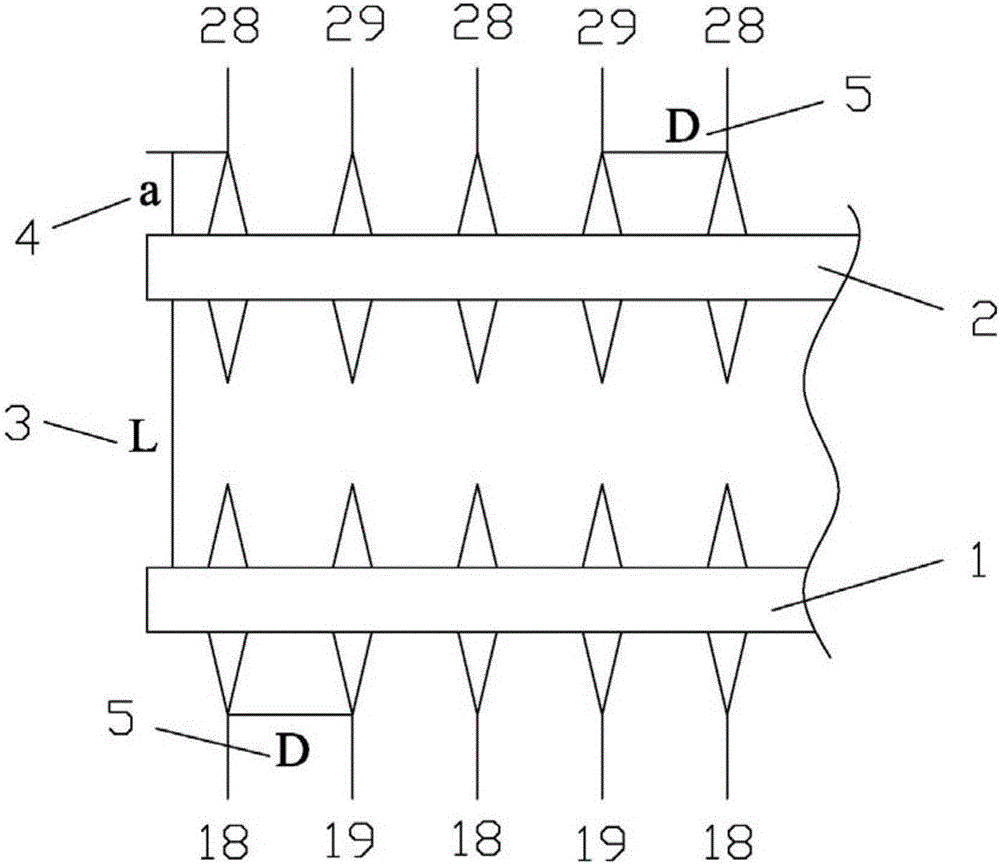

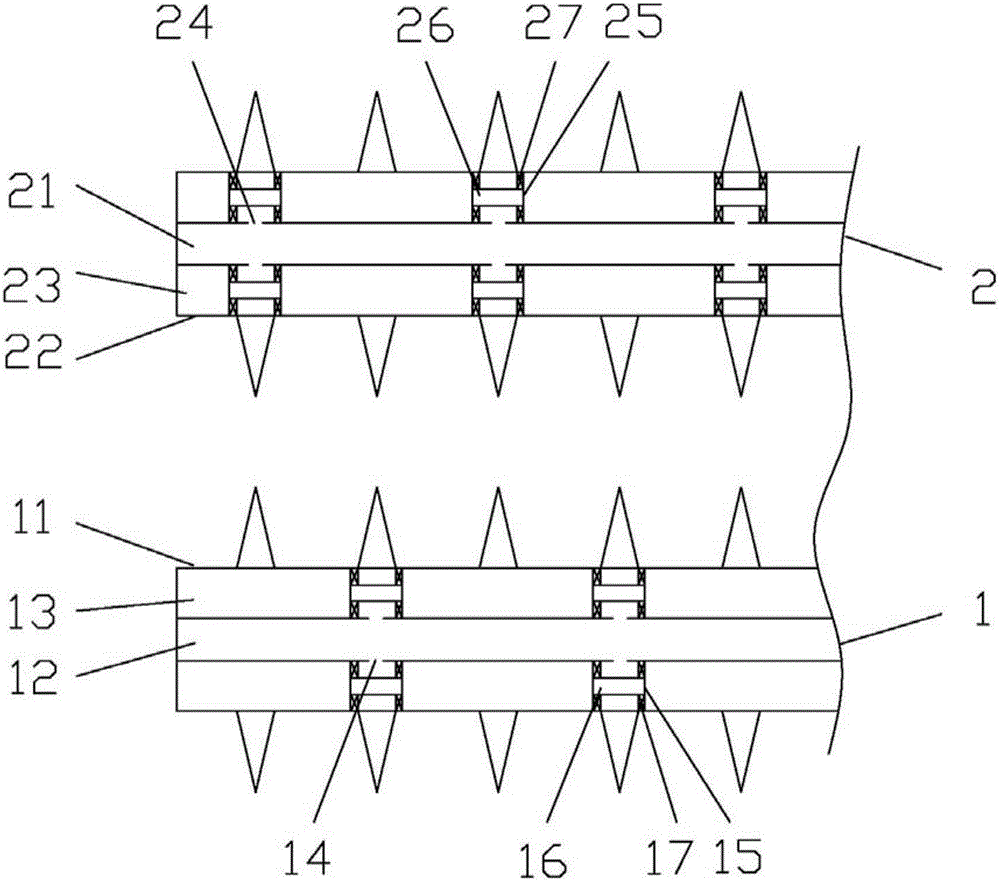

[0045] Such as Figure 1-7 As shown, the asynchronous injection of CO into different wells according to the symmetrical fracture layout of the present invention 2 An embodiment of the oil recovery method, which comprises the following steps in sequence:

[0046] Step 1: Arranging horizontal well I1 and horizontal well II2 in parallel in the formation, and performing symmetrical fracturing on the two horizontal wells to form a plurality of fracturing fractures perpendicular to the wellbore of the horizontal well and distributed symmetrically;

[0047] Step 2: At the initial stage of production, use natural energy to simultaneously exploit horizontal well I and horizontal well II for a period of time until the bottom hole pressure of both horizontal wells drops to the bubble point pressure;

[0048] Step 3: Take out the tubing I12 from the casing I11 of the horizontal well I1, and install a diversion device I15 at the position of each even-numbered fracture 19; The positions o...

Embodiment 2

[0066] Asynchronous CO injection in different wells according to the symmetrical fracture layout of the present invention 2 Another embodiment of the oil recovery method, its injection and production steps, fracture layout, principle and beneficial effect are the same as the first embodiment, the difference is: the distance between the horizontal well I and the horizontal well II is L=2.3a, and the fracturing fracture The spacing D=0.8a, where a is the half length of the fracture. This embodiment has been proved by a large number of experiments. Compared with the prior art, the CO injection in this embodiment 2 Oil recovery method, the oil recovery increased by 23%.

Embodiment 3

[0068] Asynchronous CO injection in different wells according to the symmetrical fracture layout of the present invention 2 Another embodiment of the oil production method, its injection and production steps, fracture layout, principle and beneficial effect are the same as the first embodiment, the difference is: the distance between the horizontal well I and the horizontal well II is L=2.5a, and the fracturing fracture The spacing D=a, where a is the half length of the fracture. This embodiment has been proved by a large number of experiments. Compared with the prior art, the CO injection in this embodiment 2 Oil recovery method, the oil recovery increased by 27%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com