System and method for evaluating the effect of CO2 emulsion on oil reservoir displacement

An emulsion and oil reservoir technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the rare, unusable displacement mechanism, and cannot clearly reflect the heavy oil and gel/high temperature steam system Interaction mechanism and other issues to achieve the effect of improving the displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094] The present invention does not specifically limit the preparation method of the heterogeneous core model, and conventional preparation methods in the field can be used, whichever can simulate the actual rock conditions. In the specific implementation process of the present invention, a suitable permeability heterogeneous core model is obtained by selecting suitable mesh size quartz sand and filling sand.

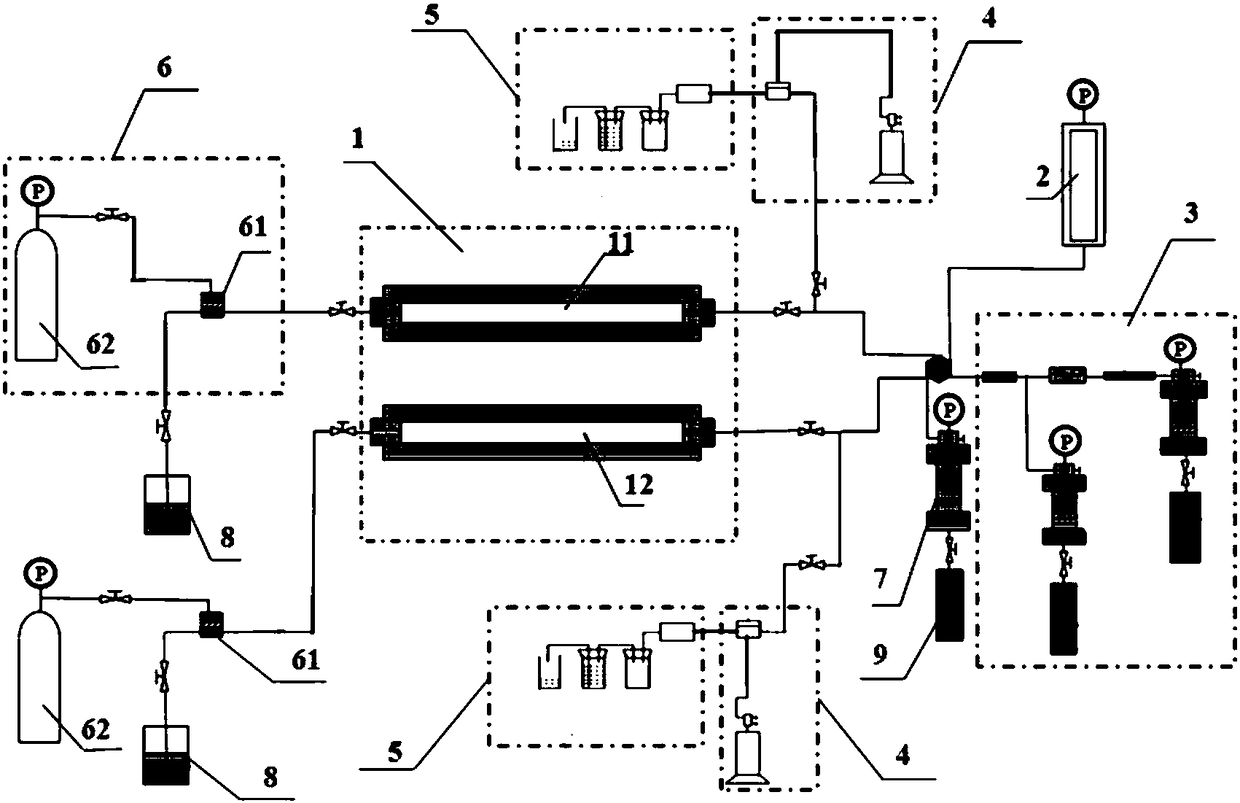

[0095] The present invention does not specifically limit the number of simulated heterogeneous core molds 1 , it can be one or more, and can be reasonably set according to specific experimental purposes. In a specific embodiment of the present invention, please refer to figure 1 The simulated heterogeneous core model 1 includes a first simulated heterogeneous core model 11 and a second simulated heterogeneous core model 12 connected in parallel. Specifically, a heterogeneous core model with relatively high permeability and a heterogeneous core model with low permeabi...

Embodiment 1

[0118] This embodiment provides an evaluation CO 2 Methods for the displacement effect of emulsions on reservoirs, including:

[0119] First, two heterogeneous core models with different permeability were prepared, among which the gas permeability of the high permeability heterogeneous core model was 1019mD, and the gas permeability of the low permeability heterogeneous core model was 201mD. The specifications of the two heterogeneous core models are the same: inner diameter 2.51cm, length 10.06cm.

[0120] Secondly, the above-mentioned heterogeneous core model is adjusted to simulate the heterogeneous core model 1, which specifically includes the following steps in sequence:

[0121] 11) Adjust the temperature in the heterogeneous core model to 80°C;

[0122] 12) The pressure in the heterogeneous core model is adjusted to 20MPa;

[0123] 13) Inject saturated water into the heterogeneous rock core model, so that the gap between the rock cores in the heterogeneous rock core ...

Embodiment 2

[0132] This embodiment provides an evaluation CO 2 Methods for the displacement effect of emulsions on reservoirs, including:

[0133] First, two heterogeneous core models with different permeability were prepared, among which the gas permeability of the high-permeability heterogeneous core model was 1052mD, and that of the low-permeability heterogeneous core model was 196mD. The specifications of the two heterogeneous core models are the same: inner diameter 2.49cm, length 9.98cm.

[0134] Secondly, the above-mentioned heterogeneous core model is adjusted to simulate the heterogeneous core model 1, which specifically includes the following steps in sequence:

[0135] 11) Adjust the temperature in the heterogeneous core model to 80°C;

[0136] 12) The pressure in the heterogeneous core model is adjusted to 20MPa;

[0137] 13) Inject saturated water into the heterogeneous rock core model, so that the gap between the rock cores in the heterogeneous rock core model is filled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com