Surfactant complex-based high temperature-resistant solvent

A technology of surfactant and high temperature resistance, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of narrow use concentration range, deterioration of production conditions, poor surface activity, etc., to improve steam transfer efficiency, improve The utilization rate of heat and the effect of improving the permeability of water phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

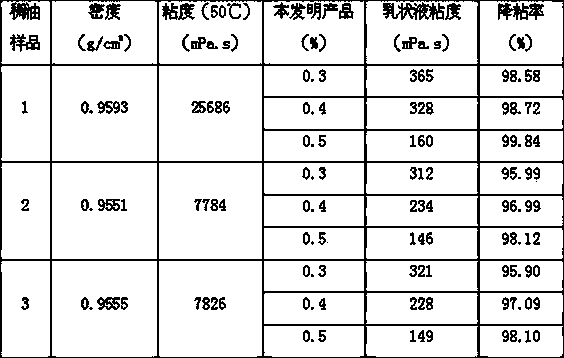

Embodiment 1

[0014] Embodiment 1: A kind of high-temperature-resistant solvent based on surfactant compounding of the present invention is made according to the following raw material weight parts: 5 parts to 10 parts of dispersant, 10 parts to 30 parts of compounded surfactant, inorganic salt 5 to 10 parts, 80 to 50 parts of water.

Embodiment 2

[0015] Embodiment 2: A kind of high-temperature-resistant solvent based on surfactant compounding of the present invention is made according to the following raw material weight parts: 5 parts or 10 parts of dispersant, 10 parts or 30 parts of compounded surfactant, inorganic salt 5 or 10 parts, 80 or 50 parts of water.

Embodiment 3

[0016] Embodiment 3: A kind of high-temperature resistant solvent based on surfactant compounding of the present invention is made according to the following raw material weight parts: 5 parts of dispersant, 10 parts of compounded surfactants, 5 parts of inorganic salts, 80 parts of water .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com