Solar cell assembly substrate automatic sealing-tape machine

A solar cell and tape machine technology, which is applied in the directions of sending objects, thin material processing, transportation and packaging, can solve the problems of uneven thickness of glue, high labor intensity of workers, low production efficiency, etc., to save material costs and shorten the The effect of curing cycle and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

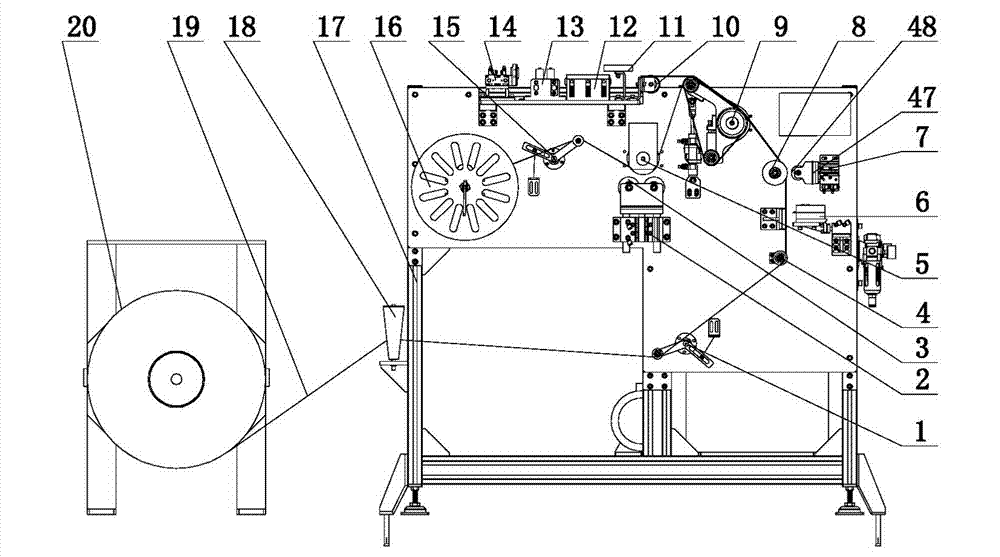

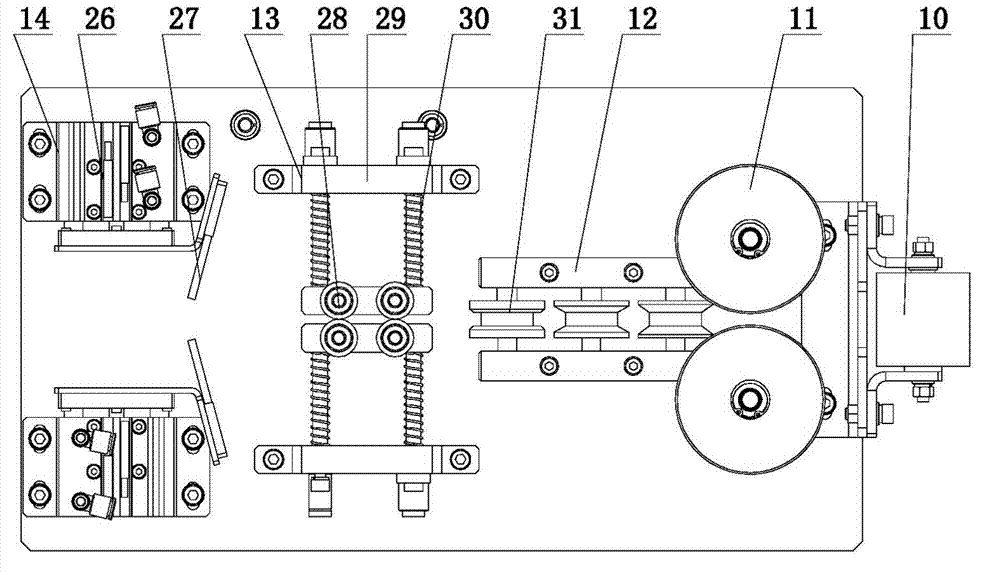

[0018] The present invention comprises an unwinding device 20, corresponding to the unwinding device 20 is provided with a hemming device, the hemming device described in its structural points includes a frame 17, the frame 17 is provided with a guide device corresponding to the unwinding device 20, The frame 17 is provided with a tape cutting device 6 corresponding to the guiding device; the upper end of the frame 17 is provided with a wrapping part 12 , and the frame 17 below the wrapping part 12 is provided with an active tape pulling device 5 .

[0019] Described guiding device comprises the first guiding wheel 18 corresponding to unwinding device 20, is provided with the second guiding wheel 4 corresponding to adhesive tape cutting device 6, is provided with tension force between the first guiding wheel 18 and the second guiding wheel 4 Regulator 1.

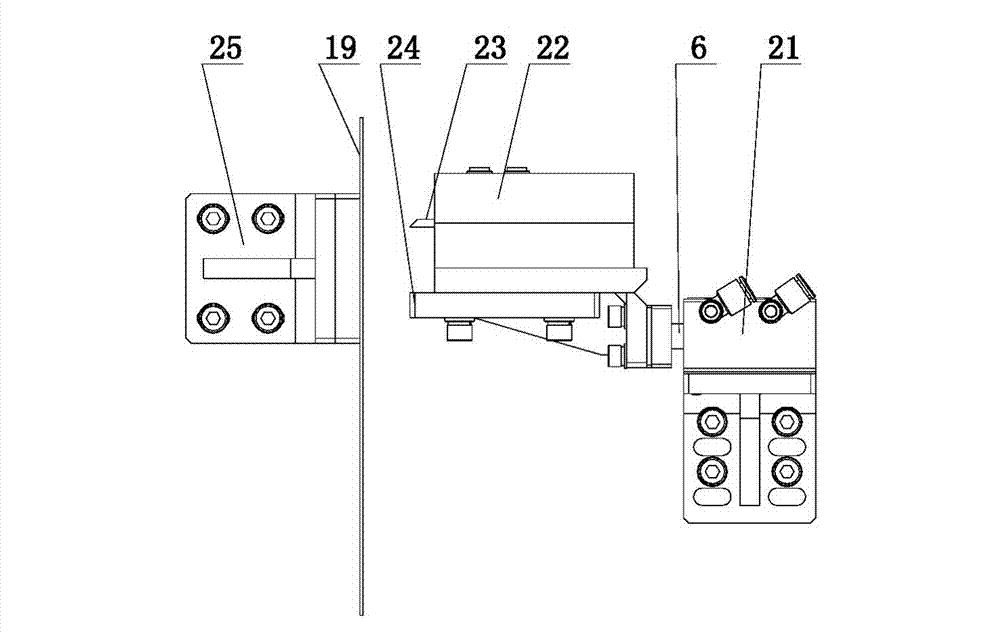

[0020] The tape cutting device 6 includes a baffle 25 arranged on the frame 17 and a cutting cylinder 21 , and a cutting k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com