Process for high-efficiency molding of composite plate spring

A composite material plate and process method technology, which is applied in the production field of composite material leaf springs for automobiles by molding process, can solve the problems of inability to achieve mass production, long time occupation of molds, and high labor intensity of paving, etc., to achieve Automated mass production, high production efficiency, and shortened preheating and curing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

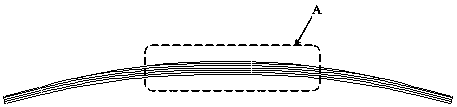

[0030] As shown in the figure, this embodiment provides a process for efficiently forming a composite material leaf spring, including the following steps:

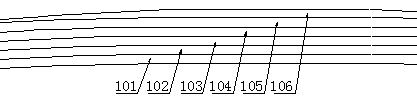

[0031] (1) Model the leaf spring, and model the leaf spring model hierarchically from bottom to top to form N (2, 3, 4...) single-layer models stacked together, that is, the first single-layer model , the second single-layer model...the Nth single-layer model, the first single-layer model, the second single-layer model...the width of the Nth single-layer model is equal, and the curvature of the contact surface of the upper and lower adjacent single-layer models corresponds; The principle of determining the number of layers is based on the maximum cutting depth of the ultrasonic cutting equipment, that is, in order to make the maximum thickness of the layered single-layer model less than the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com