Porous titanium dioxide photocatalyst film and preparation method thereof

A technology of porous titanium dioxide and photocatalytic thin film, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor bonding firmness between membrane and substrate, complex preparation process, and difficulty in scaling up. , to achieve the effects of stable photocatalytic activity, simple preparation process, and easily controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Sand the size to 42cm 2 The surface of the titanium sheet is polished smooth to remove the surface oxide layer; use 1:1 volume ratio of ethanol and isopropanol solution to ultrasonically wash, then ultrasonically wash with deionized water, and finally wash with N 2 Purge to dry.

[0020] The treated titanium sheet was soaked in 50mL of 15wt% H 2 o 2 In a mixed solution with 0.10mL ionic liquid 1-butyl-3-methylimidazole tetrafluoroborate (the concentration of hydrogen peroxide in the mixed solution is 15.0wt%, and the ionic liquid 1-butyl-3-methyl-imidazolium tetrafluoroborate The concentration of fluoroborate is 0.2wt%), placed in an oven and reacted at 80°C for 8h. The reacted titanium sheet was rinsed with deionized water three times, dried at 100°C, and then calcined at 450°C for 1 hour to obtain the target product.

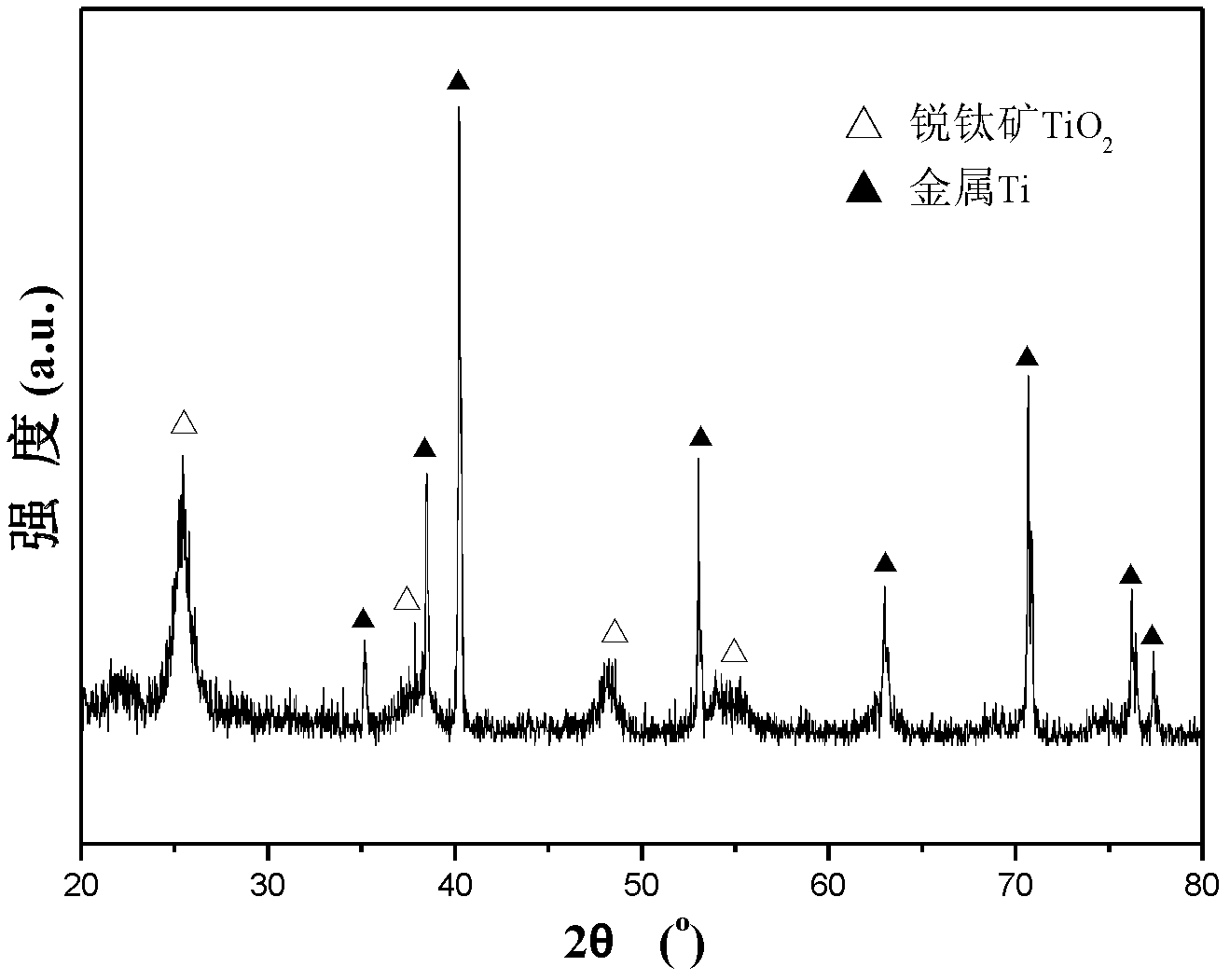

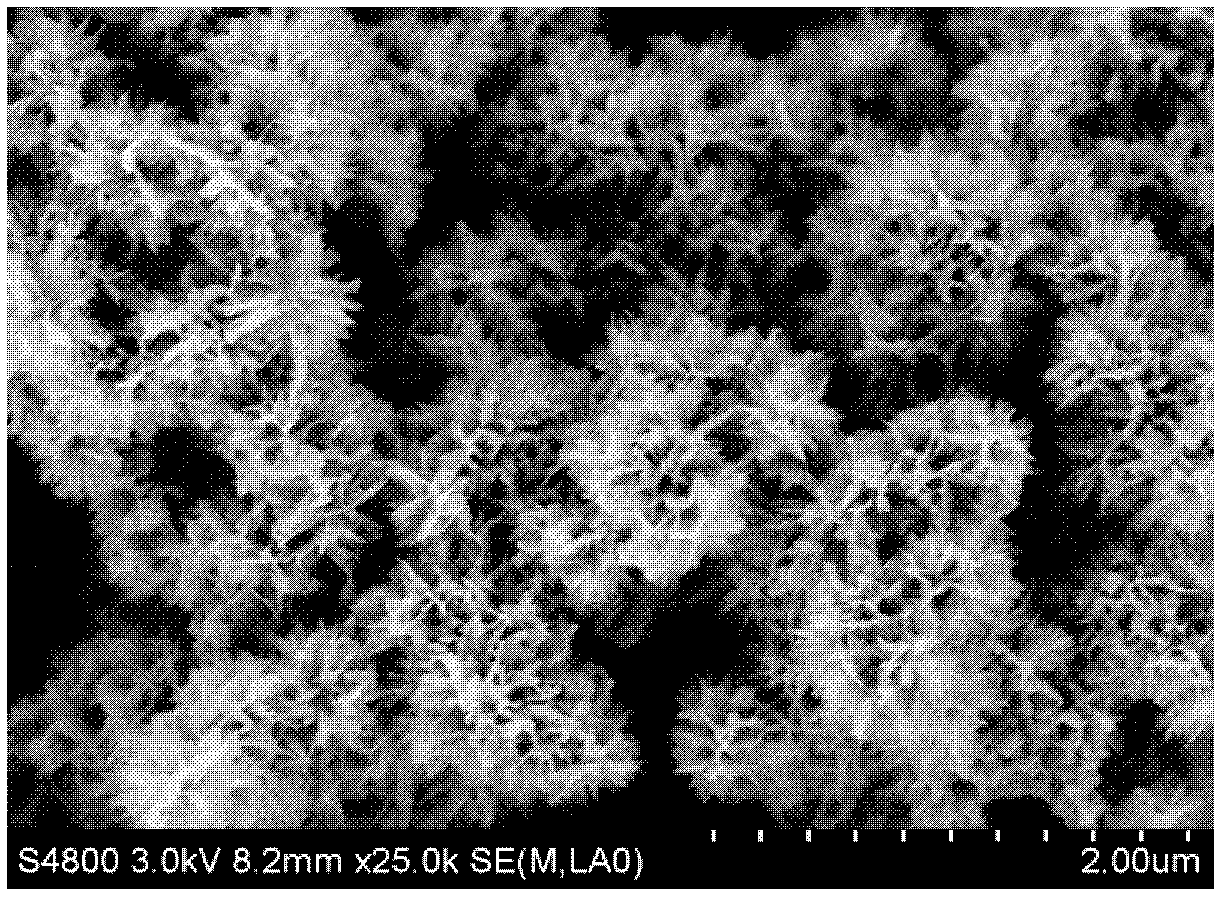

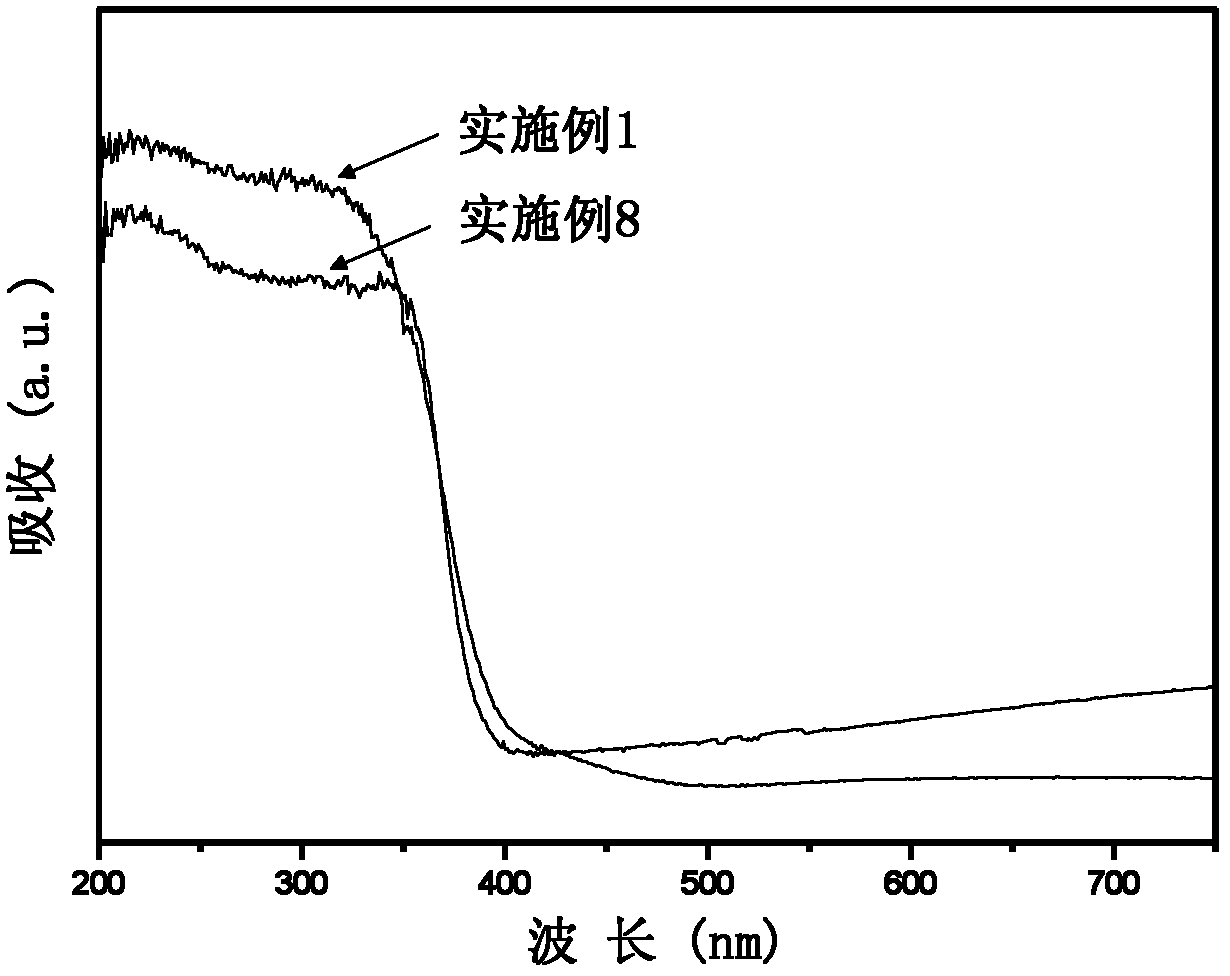

[0021] figure 1 For the X-ray diffraction spectrum of the sample prepared in this embodiment, it can be determined from the spectrum that the film...

Embodiment 2

[0024] The ionic liquid consumption is changed into 0.05mL, and all the other contents are the same as described in Example 1 (the concentration of hydrogen peroxide in the mixed solution is 15.0wt%, the concentration of ionic liquid 1-butyl-3-methyl-imidazole tetrafluoroborate is 0.1wt%). The X-ray diffraction spectrum of the sample prepared by this embodiment can confirm that the film on the surface of the sample obtained is anatase TiO 2 , it can be seen from the SEM photo that it is a porous random sheet structure.

Embodiment 3

[0026] The ionic liquid consumption is changed into 0.15mL, and all the other contents are the same as described in Example 1 (the concentration of hydrogen peroxide in the mixed solution is 15.0wt%, the concentration of ionic liquid 1-butyl-3-methyl-imidazole tetrafluoroborate is 0.4wt%). The X-ray diffraction spectrum of the sample prepared by this embodiment can confirm that the film on the surface of the sample obtained is anatase TiO 2 , it can be seen from the SEM photo that it is a porous structure with flower-like microspheres, and the diameter of the microspheres is about 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com