Catalyst for preparing 2,3-dichloropyridine and preparation method and application of catalyst

A dichloropyridine and catalyst technology, which is applied in the preparation of 2,3-dichloropyridine catalyst and its preparation field, can solve problems such as easy corrosion, equipment corrosion, and increased operating costs, so as to avoid dechlorination side reactions and slow down Effect of dechlorination speed and selectivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

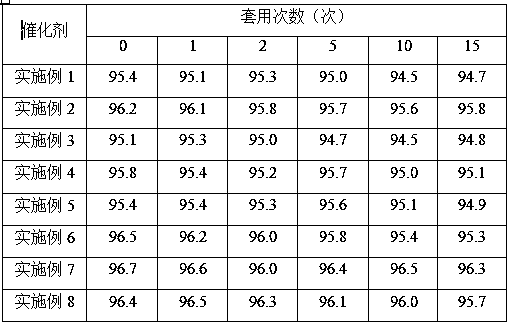

Examples

Embodiment 1

[0030] 1. A method for preparing a catalyst, which can be used to prepare 2,3-dichloropyridine, the method comprising the following steps:

[0031] (1) In the lined tetrafluoro reaction kettle, the bottom of the reaction kettle is provided with a discharge valve, and the upper end of the discharge valve is provided with a 200-mesh filter screen, and 0.5g of sponge Pd and 0.2g of sponge platinum are added into the In a tetrafluoro-lined reaction kettle, add 20 mL of aqua regia, stir for 30 min, add 4 times the volume of deionized water of aqua regia, and then add 19.1 g of activated carbon, the particle size of the activated carbon is 100-150 microns, and continue to stir for 30 min , drop the sodium hydroxide solution with a mass concentration of 5% until the pH value of the reaction system is 10-11, continue stirring for 30min, open the discharge valve, connect the negative pressure suction filtration to remove the liquid in the reaction kettle, and then close the discharge va...

Embodiment 2

[0041] 1. A method for preparing a catalyst, which can be used to prepare 2,3-dichloropyridine, the method comprising the following steps:

[0042] (1) In the lined tetrafluoro reaction kettle, the bottom of the reaction kettle is provided with a discharge valve, and the upper end of the discharge valve is provided with a 200-mesh filter screen, and 0.8g of sponge Pd and 0.3g of sponge platinum are added to the inside. In the tetrafluoro reaction kettle, add 20mL aqua regia, stir for 40min, add 80mL deionized water, then add 18.8 g of activated carbon, the particle size of the activated carbon is 100-150 microns, continue to stir for 40min, the mass concentration of dropwise addition is 6% potassium hydroxide solution to the pH value of the reaction system is 10-11, continue to stir for 40min, open the discharge valve, connect the negative pressure suction filtration to remove the liquid in the reaction kettle, and then close the discharge valve;

[0043] (2) Add 100 mL of an ...

Embodiment 3

[0052] 1. A method for preparing a catalyst, which can be used to prepare 2,3-dichloropyridine, the method comprising the following steps:

[0053] (1) In the lined tetrafluoro reaction kettle, the bottom of the reaction kettle is provided with a discharge valve, and the upper end of the discharge valve is provided with a 200-mesh filter screen, and 0.7g of sponge Pd and 0.1g of sponge Au are added into the In the tetrafluoro reaction kettle, add 20mL of aqua regia, stir for 50min, add 80mL of deionized water, and then add activated carbon, the particle size of the activated carbon is 100-150 microns, continue to stir for 50min, the mass concentration of dropwise addition is 10 % sodium hydroxide solution to the pH value of the reaction system is 10-11, continue to stir for 50min, open the discharge valve, and close the discharge valve after removing the liquid in the reaction kettle by suction filtration;

[0054] (2) Add 100 mL of an aqueous solution of sodium borohydride wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com