Platinum-based composite carbon aluminum catalyst and method for continuous production of 2B oil

A technology of catalyst and composite carbon, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. High chlorine and other problems, achieve the effect of maintaining the reaction temperature, improving adsorption and activation, and less dechlorination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

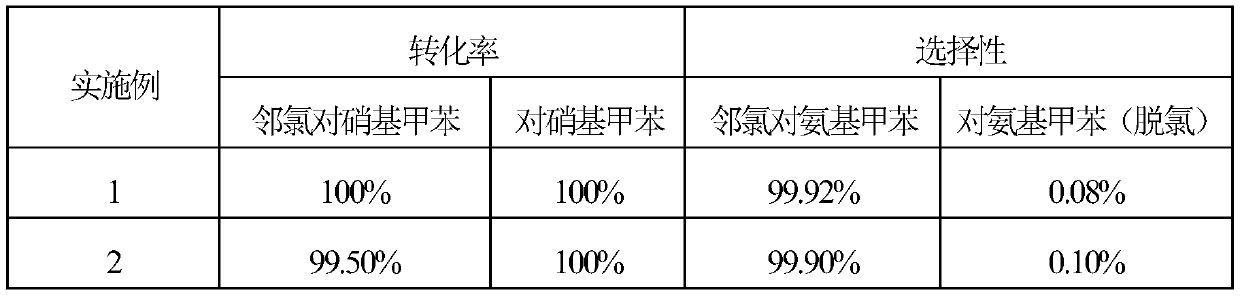

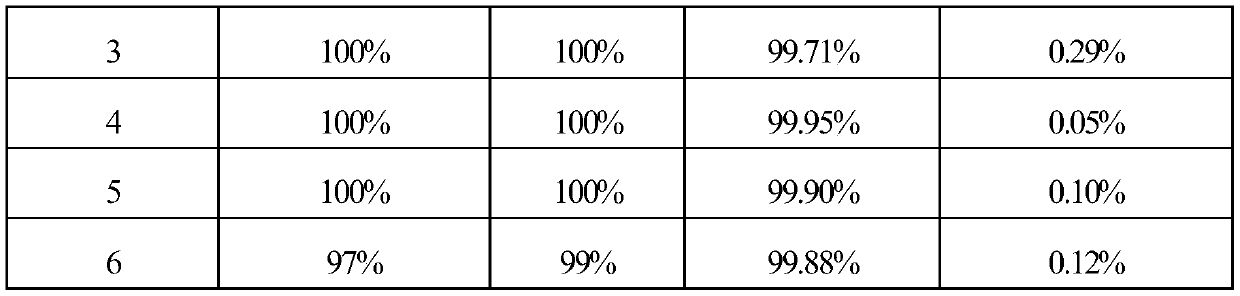

Examples

Embodiment 1

[0027] 1. Preparation of catalyst

[0028] (1) After washing and drying 200g of 10-20 mesh granular aluminum foam, place it in a muffle furnace and bake it at 400°C for 1h.

[0029] (2) After 200g of dried corn granules are ground into powder, stir and mix evenly with 100g of polyethylene glycol 4000 powder and 1000g of aluminum sol with a solid content of 20%, then place the foamed aluminum after roasting in 100g of step (1) Immerse in the obtained mixed solution for 1 hour, take it out, place it in a tube furnace, and treat it at 400°C for 3 hours under the protection of nitrogen, then add water vapor in the nitrogen, control the volume ratio of water vapor and nitrogen to 12:88, and at the same time use The temperature was raised to 800°C at a rate of 2°C / min, the treatment was continued for 2 hours, and the temperature was lowered to obtain a carbon-coated aluminum foam carrier.

[0030] (3) Add 2.03g of dinitrosodiammine platinum into 40g of deionized water, heat and sti...

Embodiment 2

[0036] 1. Preparation of catalyst

[0037] (1) After washing and drying 200g of 10-20 mesh granular aluminum foam, place it in a muffle furnace and bake it at 400°C for 1h.

[0038] (2) After 200g of dry corn granules are ground into powder, stir and mix evenly with 100g of polyethylene glycol 4000 powder and 1100g of aluminum sol with a solid content of 20%, then place the foamed aluminum after roasting in 100g of step (1) Immerse in the obtained mixed solution for 1 hour, take it out, place it in a tube furnace, and treat it at 400°C for 3 hours under the protection of nitrogen, then add water vapor in the nitrogen, control the volume ratio of water vapor and nitrogen to 12:88, and at the same time use The temperature was raised to 800°C at a rate of 2°C / min, the treatment was continued for 4 hours, and the temperature was lowered to obtain a carbon-coated aluminum foam carrier.

[0039] (3) Add 1.86g of dinitrosodiammine platinum into 35g of deionized water, heat and stir ...

Embodiment 3

[0045] 1. Preparation of catalyst

[0046] (1) After washing and drying 200g of 10-20 mesh granular aluminum foam, place it in a muffle furnace and bake it at 400°C for 1h.

[0047] (2) After 200g of dried corn granules are ground into powder, it is uniformly mixed with 100g of polyethylene glycol 4000 powder and 1200g of aluminum sol with a solid content of 20%, and then the foamed aluminum after roasting in 100g of step (1) is placed Immerse in the obtained mixed solution for 1 hour, take it out, place it in a tube furnace, and treat it at 400°C for 2 hours under the protection of nitrogen, then add water vapor in the nitrogen, control the volume ratio of water vapor and nitrogen to 10:90, and at the same time use The temperature was raised to 800°C at a rate of 1°C / min, the treatment was continued for 3 hours, and the temperature was lowered to obtain a carbon-coated aluminum foam carrier.

[0048] (3) Add 1.69g of dinitrosodiammine platinum into 32g of deionized water, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com