Bulk acoustic wave filter and electronic equipment

A bulk acoustic wave filter, main body technology, applied in electrical components, impedance networks, etc., to achieve the effect of improving out-of-band suppression and offsetting adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

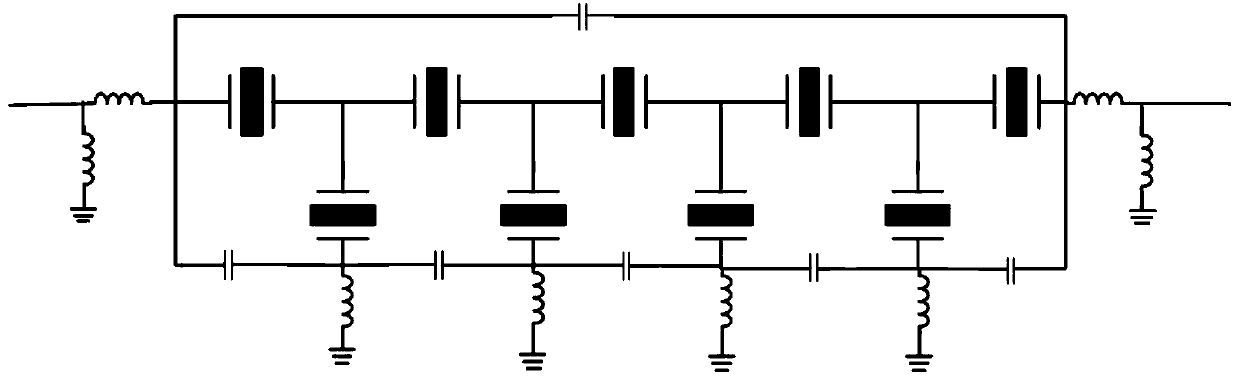

[0039] This embodiment provides a bulk acoustic wave filter with improved near-stop band suppression, and the sealing ring is connected to the reference ground plane of the carrier board through a metal ball, thereby eliminating the coupling between each resonator and between each resonator and the sealing ring , thereby improving near-stop-band rejection.

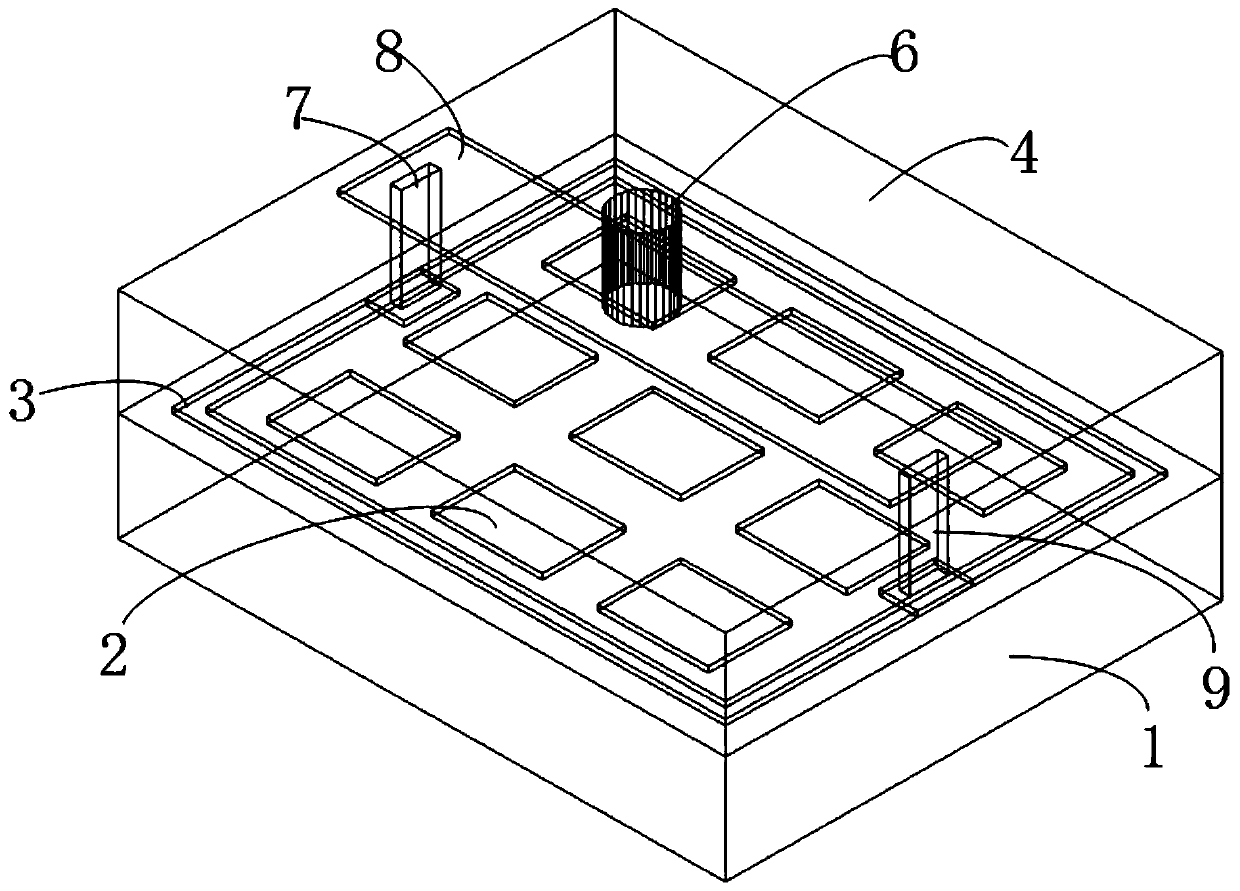

[0040] Please refer to the attached image 3 , the bulk acoustic wave filter includes:

[0041] chip body 1;

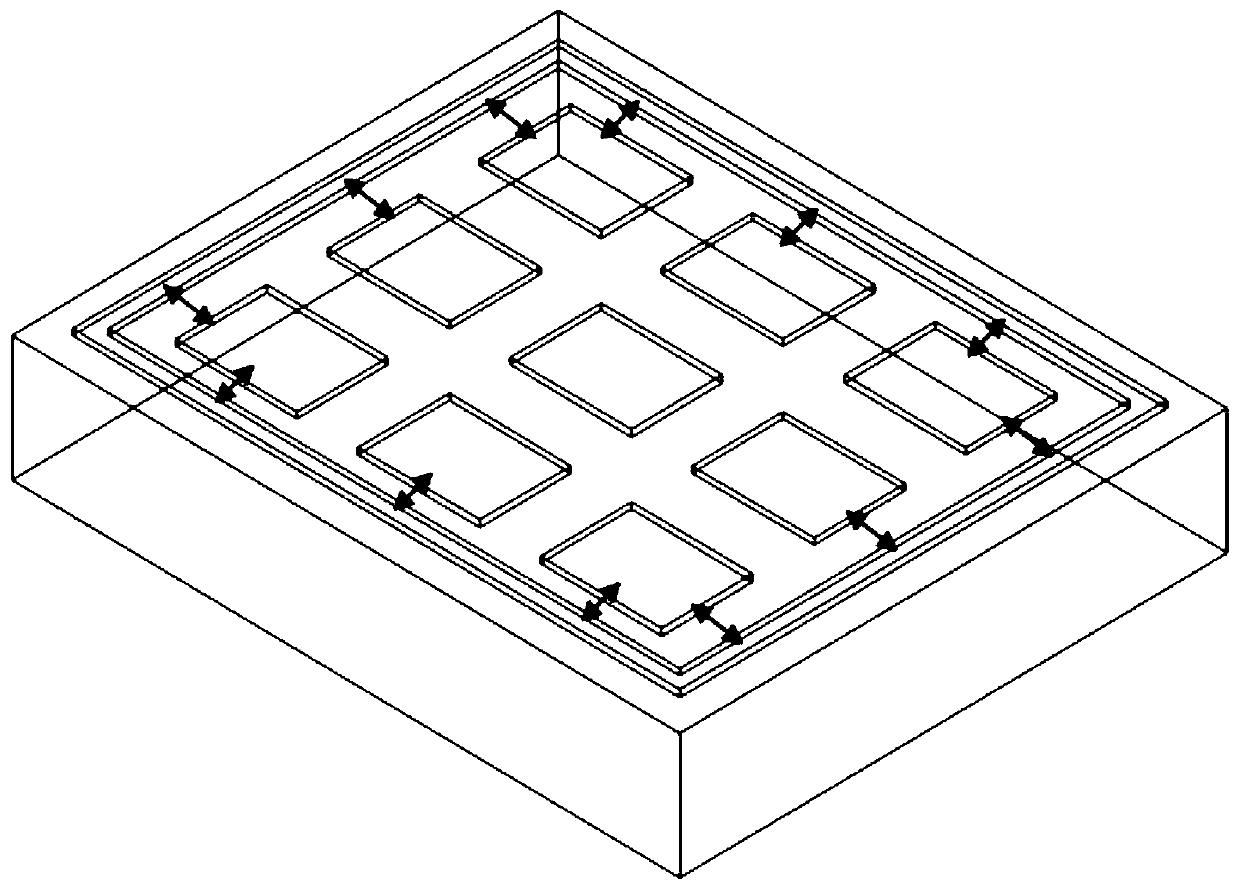

[0042] A plurality of resonators 2 are sequentially arranged on the surface layer of the chip main body 1, and the periphery of the resonators 2 is surrounded by a sealing ring 3;

[0043] The protective cap 4 is arranged on the chip main body 1, and the two sides of the sealing ring 3 are respectively connected to the surface layer of the protective cap 4 through the first metal post 7 and the second metal post 9, between the first metal post 7 and the second metal post 9 connected by a metal strip 8;

[0044...

Embodiment 2

[0054] This embodiment provides a bulk acoustic wave filter, please refer to the attached Image 6 , the bulk acoustic wave filter includes a chip main body 1 , a protective cap 4 and a carrier plate 5 .

[0055] The chip body 1 is arranged on a silicon substrate; a plurality of resonators 2 are arranged in sequence on the chip body 1, and the periphery of the plurality of resonators 2 is surrounded by a sealing ring 3, and the two sides of the sealing ring 3 pass through the first metal pillar 7 and the second metal post 9 are connected to the surface of the protective cap 4, the first metal post 7 and the second metal post 9 are respectively connected to metal strips 8, and the two metal strips 8 are respectively connected to the ground plane of the carrier board through metal balls.

[0056] In this embodiment, the internal resonator 2 is jointly protected by the protective cap 4 connected with the sealing ring 3 .

[0057] In the bulk acoustic wave filter proposed in this...

Embodiment 3

[0059] This embodiment provides a bulk acoustic wave filter, please refer to the attached Figure 7 , the bulk acoustic wave filter includes a chip main body 1 , a protective cap 4 and a carrier plate 5 .

[0060] The chip body 1 is disposed on a silicon substrate; a plurality of resonators 2 are arranged in sequence on the chip body 1, and the periphery of the plurality of resonators 2 is surrounded by a sealing ring 3, and one side of the sealing ring 3 passes through the first metal pillar 7 is connected to the surface of the protective cap 4 , the first metal post 7 is connected to a metal strip 8 , and the metal strip 8 is connected to the ground plane of the carrier board 5 through the metal ball 6 .

[0061] In this embodiment, the internal resonator 2 is jointly protected by the protective cap 4 connected with the sealing ring 3 .

[0062] In the bulk acoustic wave filter proposed in this embodiment, one side of the sealing ring 3 is connected to the surface layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com