E-surface superconducting diaphragm millimeter wave waveguide filter

A waveguide filter and superconducting film technology, which is applied in waveguide devices, electrical components, circuits, etc., can solve the problems of difficult filter assembly, difficult to fix the specific position, and easy breakage of superconducting substrates, etc., and achieve performance improvement , easy to assemble, solve the effect of large insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

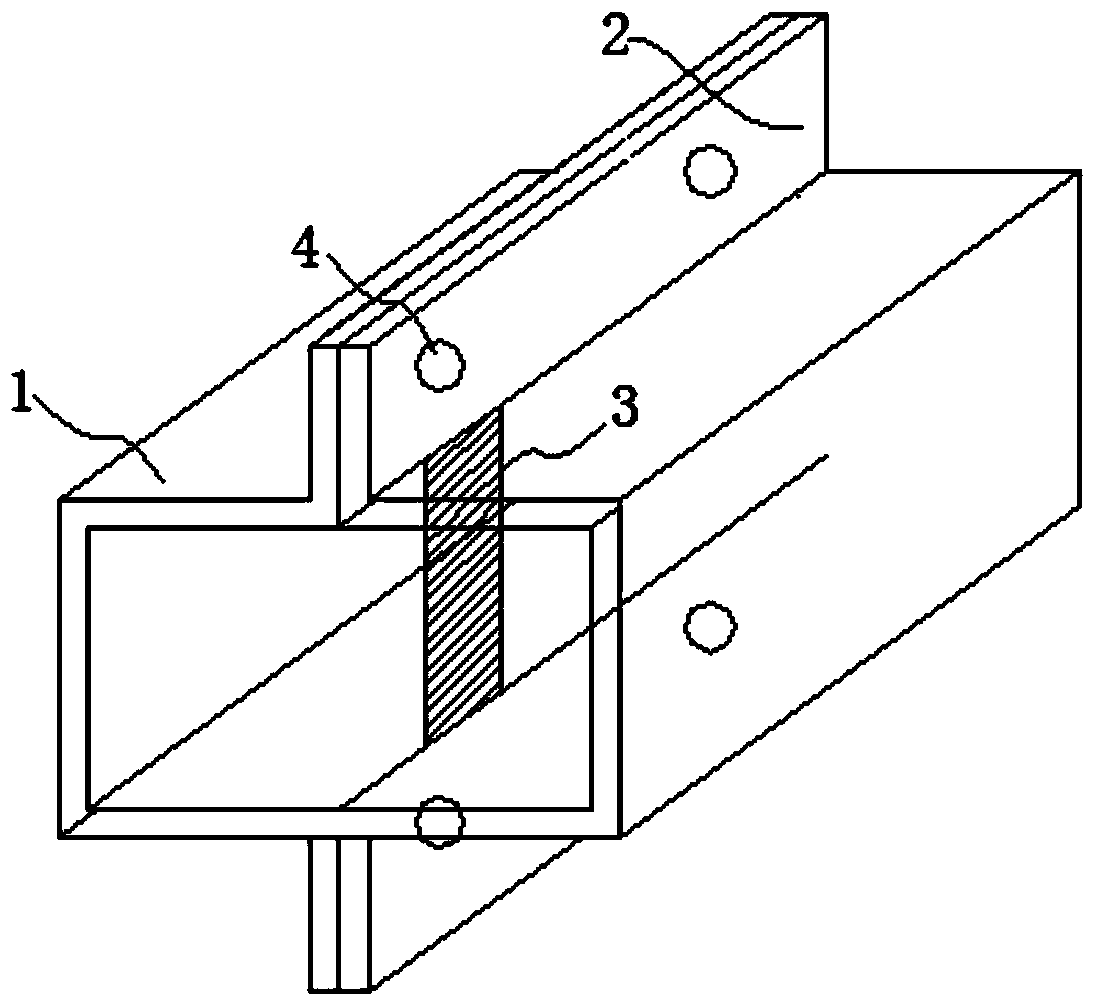

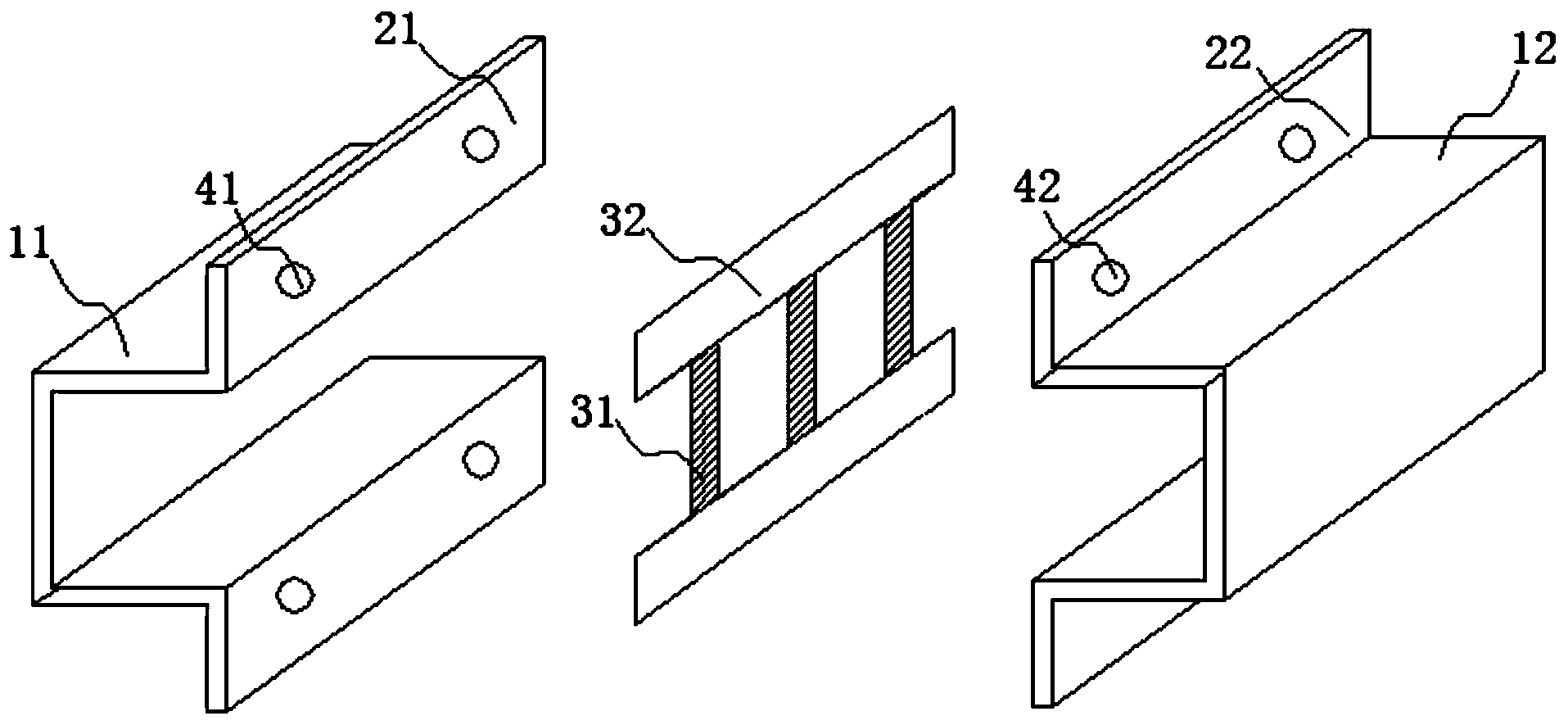

[0023] The following is a preferred embodiment of the present invention: it includes a rectangular waveguide with a superconducting film grown on its inner wall, and a diaphragm with a superconducting film grown on the central E plane of the rectangular waveguide cavity. The rectangular waveguide is composed of two U-shaped waveguide cavities with superconducting film grown on the inner wall facing each other. The metal diaphragm with superconducting film inserted on the E surface is pressed against each other by the 匚-shaped waveguide cavity and fixed through the screw hole. The diaphragm and the rectangular waveguide work together to form a resonant cavity. The number of designed resonant cavities and the coupling coefficient between the resonant cavities are determined by the design indicators of the filter (such as operating bandwidth, ripple coefficient, insertion loss, out-of-band suppression, etc.) get. The size of the resonant cavity is determined by the center freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com