High-purity helical carbon nanotubes and preparation method thereof

A carbon nanotube and helical technology, which is applied in the field of high-purity helical carbon nanotubes and its preparation, can solve the problems of difficult control of catalyst particle size and morphology, difficult control of HCNTs helical purity, and difficulty in ensuring catalyst size and uniformity. To achieve the effect of complete morphology, simple preparation method and uniform parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of α crystal form nano-iron oxide catalyst precursor: ferrous chloride tetrahydrate and potassium sodium tartrate tetrahydrate were respectively configured into solutions with a concentration of 0.2mol / L, two solutions of the same volume were taken, and stirred at room temperature. The ferrous chloride tetrahydrate solution is slowly added dropwise to the sodium potassium tartrate tetrahydrate solution, then left to stand, filtered, washed, dried, and ground to obtain ferrous tartrate powder, and then mixed with citric acid in a material ratio of 1:1 Mix in 100mL absolute ethanol to form a suspension, stir at 80°C for 6 hours to form a dark green gel, dry at 100°C, place in a tube furnace, and bake at 400°C for 2 hours in an air atmosphere , so that it can be fully oxidized, and after grinding, the precursor powder of the α crystal nano-iron oxide catalyst can be obtained.

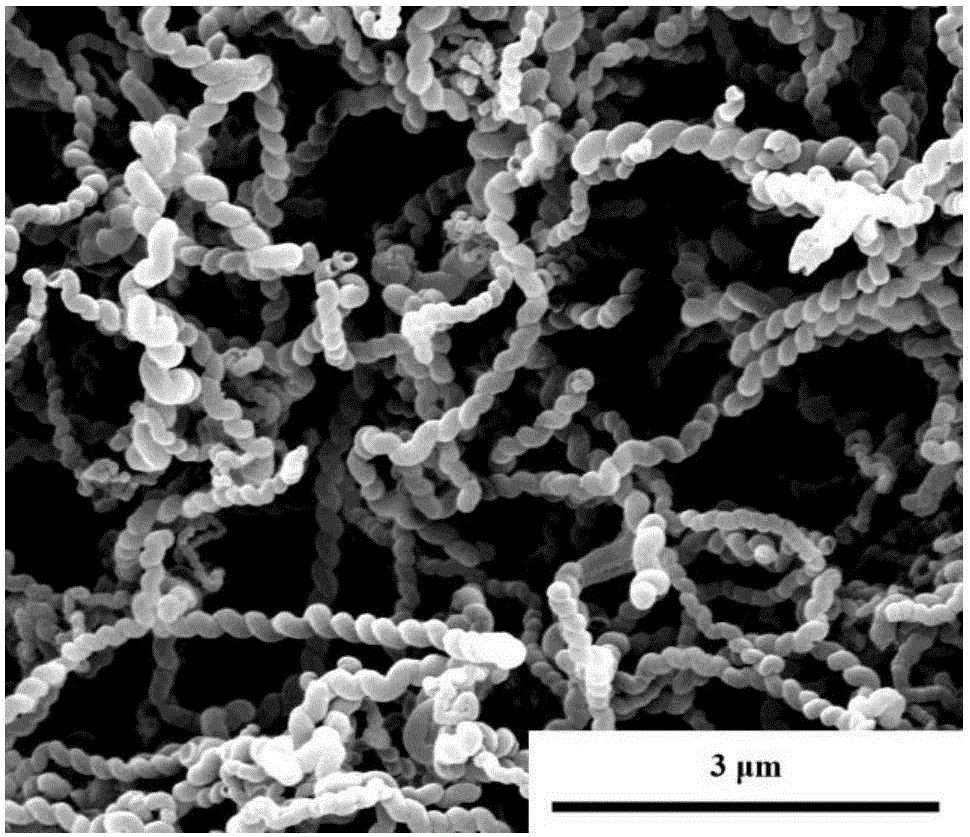

[0037] Preparation of high-purity helical carbon nanotubes: Take an appropriate amou...

Embodiment 2

[0039]Preparation of α crystal form nano-iron oxide catalyst precursor: Ferrous chloride tetrahydrate and potassium sodium tartrate tetrahydrate were respectively configured into solutions with a concentration of 0.1mol / L, and two solutions of the same volume were taken, and stirred at room temperature. The ferrous chloride tetrahydrate solution is slowly added dropwise to the sodium potassium tartrate tetrahydrate solution, then left to stand, filtered, washed, dried, and ground to obtain ferrous tartrate powder, and then mixed with citric acid in a material ratio of 1:1.5 Mix in 100mL absolute ethanol to form a suspension, stir at 60°C for 8 hours to form a dark green gel, dry at 90°C, place in a tube furnace, and bake at 600°C for 1 hour in an air atmosphere , so that it can be fully oxidized, and after grinding, the precursor powder of the α crystal nano-iron oxide catalyst can be obtained.

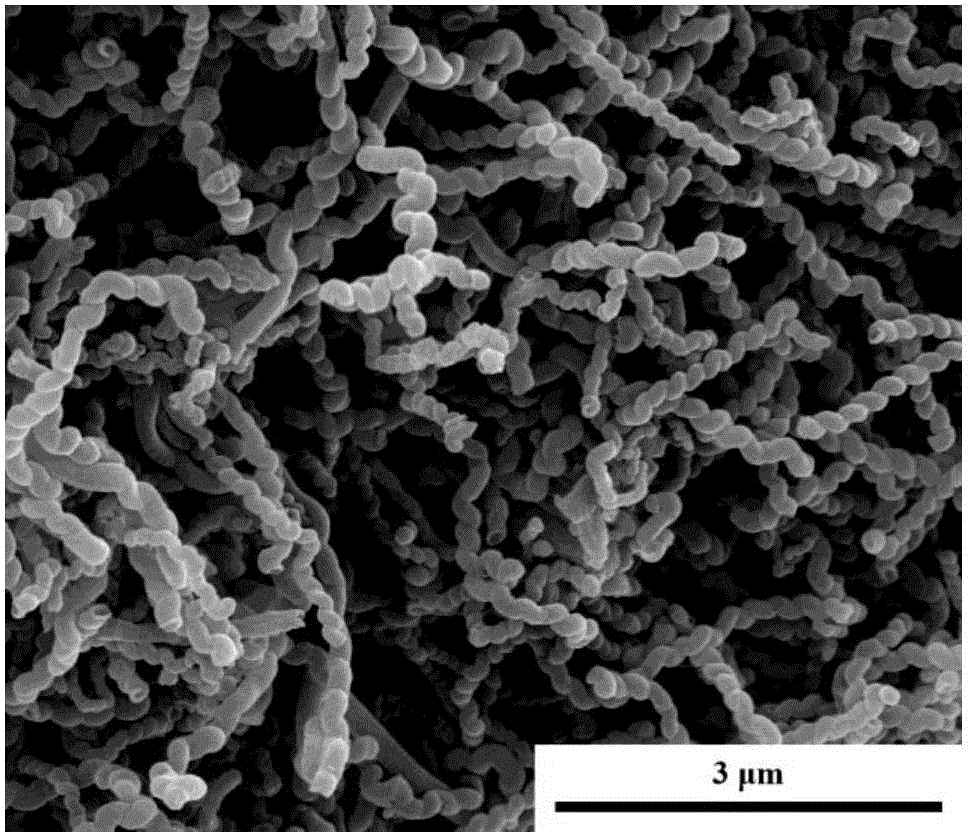

[0040] Preparation of high-purity helical carbon nanotubes: Take an appropriate a...

Embodiment 3

[0042] Preparation of α crystal form nano-iron oxide catalyst precursor: ferrous chloride tetrahydrate and potassium sodium tartrate tetrahydrate were respectively configured into solutions with a concentration of 0.3mol / L, two solutions of the same volume were taken, and stirred at room temperature. The ferrous chloride tetrahydrate solution is slowly added dropwise to the sodium potassium tartrate tetrahydrate solution, then left to stand, filtered, washed, dried, and ground to obtain ferrous tartrate powder, and then mixed with citric acid in a material ratio of 1:2 Mix in 100mL of absolute ethanol to form a suspension, stir at 100°C for 3 hours to form a dark green gel, dry at 95°C, place in a tube furnace, and bake at 500°C for 3 hours in an air atmosphere , so that it can be fully oxidized, and after grinding, the precursor powder of the α crystal nano-iron oxide catalyst can be obtained.

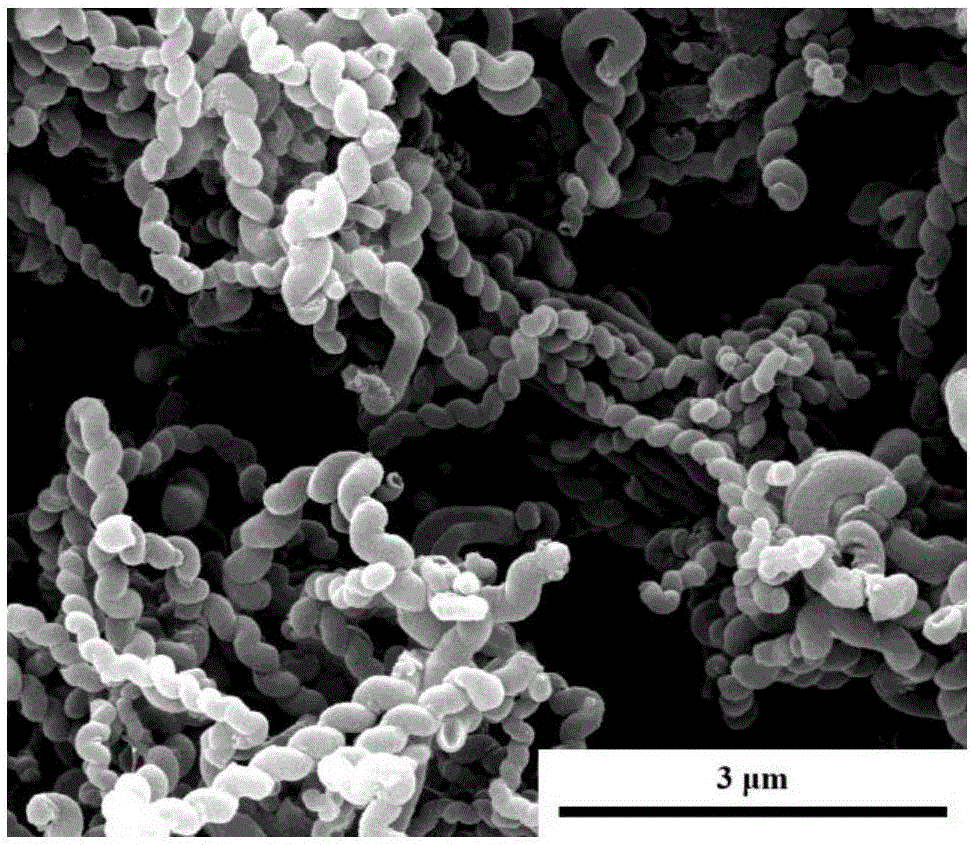

[0043] Preparation of high-purity helical carbon nanotubes: Take an appropriate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com