Shape memory alloy web friction self-reset steel frame joint

A memory alloy and steel frame technology, applied in building components, earthquake resistance, construction, etc., can solve the problems of poor performance, dissipation, and hindering safe application of shape memory alloys, and achieve the effect of strong practicability and clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

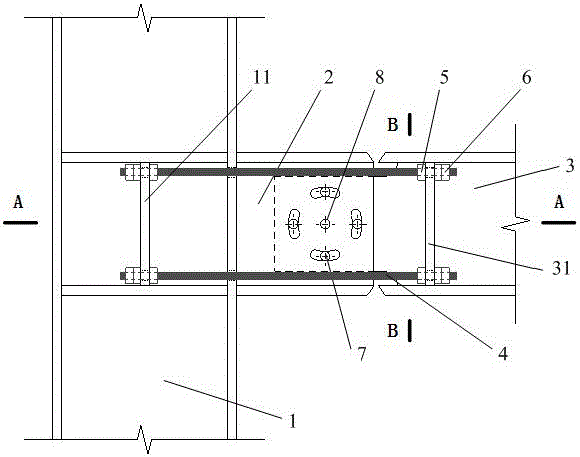

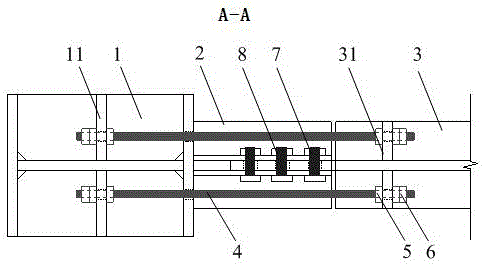

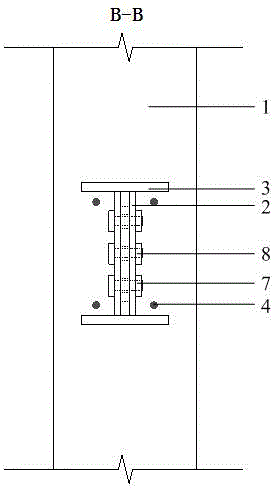

[0024] refer to Figure 1 to Figure 4 As shown, a shape memory alloy web friction self-resetting steel frame joint, the joint includes a column 1, a corbel 2 and a beam 3, and a corbel 2 is fixedly connected to one side of the column 1, which is welded in this embodiment. A beam 3 is arranged at one end of the corbel 2, the web of the corbel 2 and the web of the beam 3 are connected by high-strength bolts, and the upper and lower parts of the beam 3 are respectively connected by shape memory alloy cable units 4 Connect to column 1.

[0025] The corbel 2 is in the form of a double-web structure, and the protruding part of the web of the beam 3 is inserted between the double webs of the corbel 2 and connected by high-strength bolts. The flange of the corbel 2 and the beam at the joint 3 leaves a gap between the flanges.

[0026] Des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com