Product prepared from amorphous alloy and heterogeneous material and preparation method thereof

A technology of amorphous alloys and heterogeneous materials, applied in the field of products formed by amorphous alloys and heterogeneous materials and their manufacturing, can solve the problems of limited wide application, high material cost, high material cost, etc., and achieve low manufacturing cost , reduced requirements, high yield strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

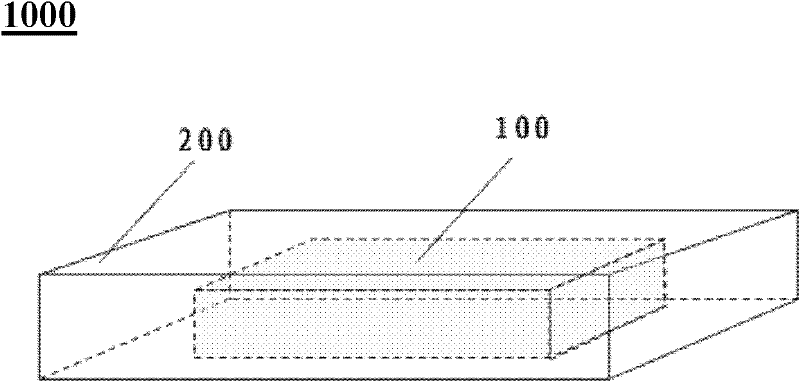

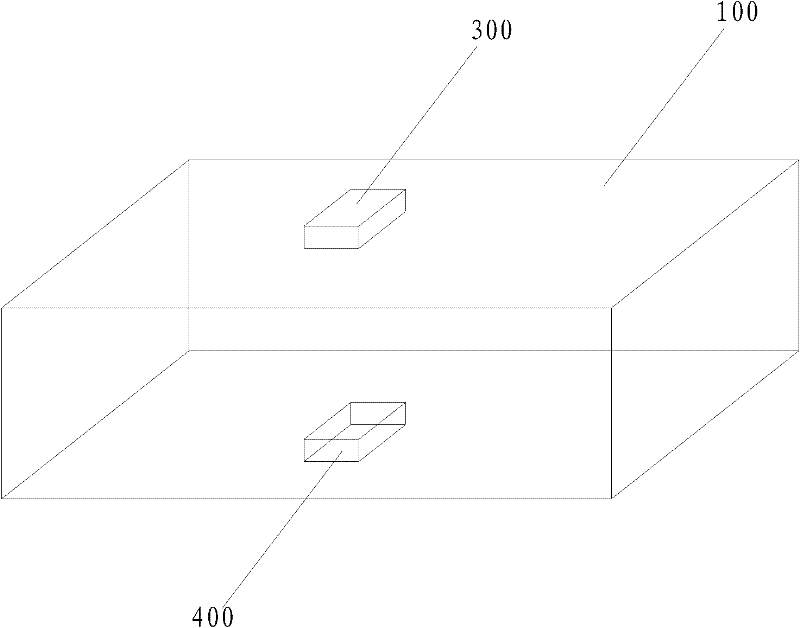

[0070] Examples 1 and 2 respectively use plastics and zinc alloy as cores to obtain products in which the entire outer surface of the core is covered by an amorphous alloy. The outer wall of the amorphous alloy can be obtained by using an amorphous alloy with a critical dimension of 3mm. This is because the thickness of the outer wall formed by the amorphous alloy is reduced, so the critical dimension of the amorphous alloy can also be reduced. Further, due to the reduction of the critical size, it is not necessary to contain precious metals in the chemical formula of amorphous alloys to improve the formability of the alloy's amorphous alloys. At the same time, the use of low-cost plastics and metals also allows the use of amorphous alloys from more than two hundred Grams are suddenly reduced to tens of grams. Although the mechanical strength of amorphous alloy products will be lower than that of products formed entirely of amorphous alloys, the hardness and corrosion resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com