Nanometer porous CuZnAl shape memory alloy and preparation method and application thereof

A nanoporous copper, memory alloy technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of hindering the diffusion of internal Zn and Al, low capacity of negative electrode materials, easy oxidation of copper, etc. problems, to achieve excellent superelastic properties, ease volume expansion, and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Weigh the pure copper block, pure zinc block and pure aluminum block according to the mass percentage of 60:34:6, and then obtain copper-zinc-aluminum alloy ingots by induction melting.

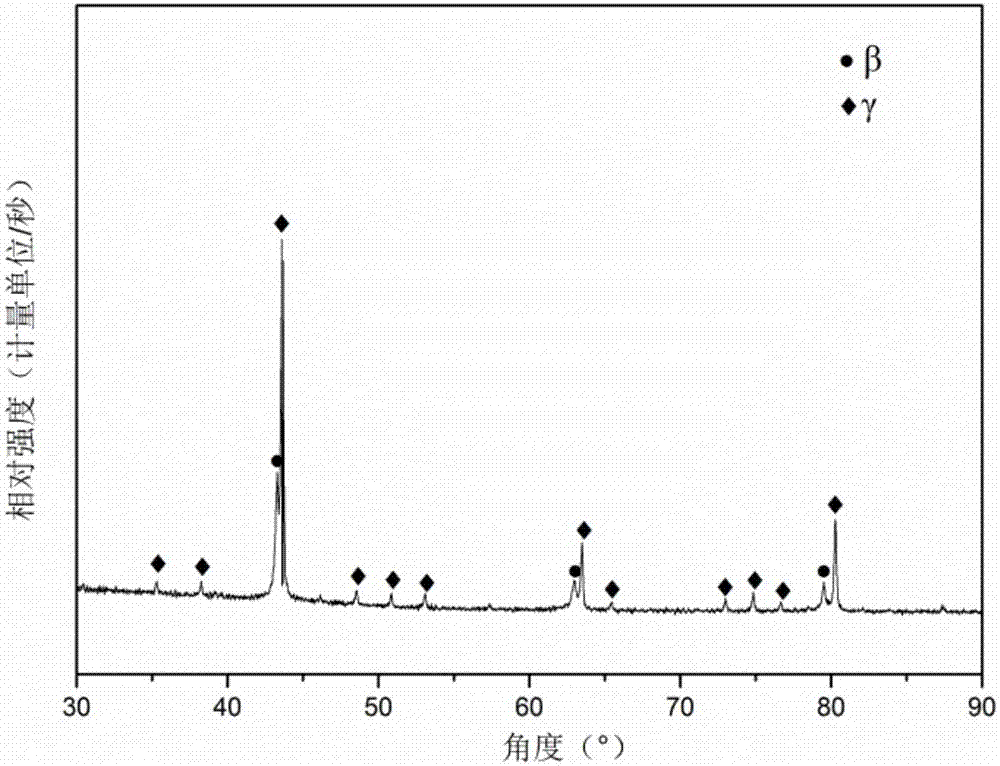

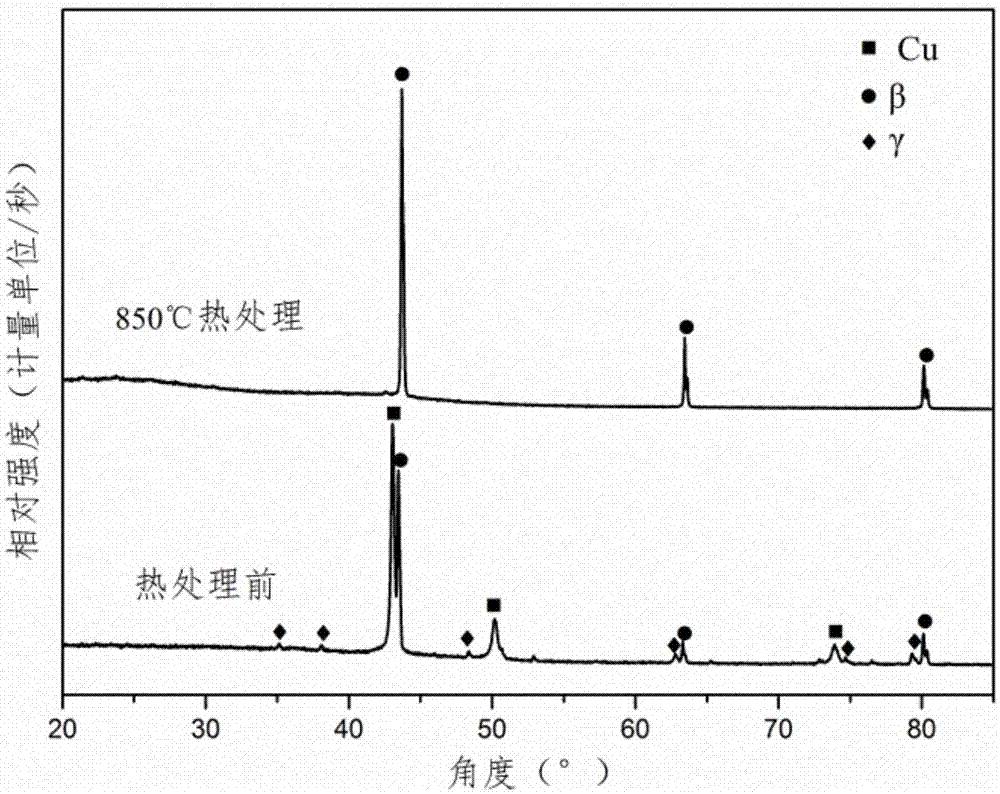

[0043] (2) Carry out the copper-zinc-aluminum alloy ingot of step (1) gained to carry out the quick quenching method of copper roller, under the protection of vacuum, spin strip and obtain to have gamma phase (characteristic peak 43.2, 62.7 and 79.2 degrees) and a small amount of beta phase (characteristic peak 43.5, 63.0 and 79.6 degrees) of ultra-thin tape CuZnAl precursor, its XRD diffraction pattern is as follows figure 1 shown. The vacuum degree during the rapid quenching of the copper roller is 0.1 Pa, the rotational speed of the copper roller is 4000 rpm, the thickness of the strip is 20 μm, and the material width is 5 mm.

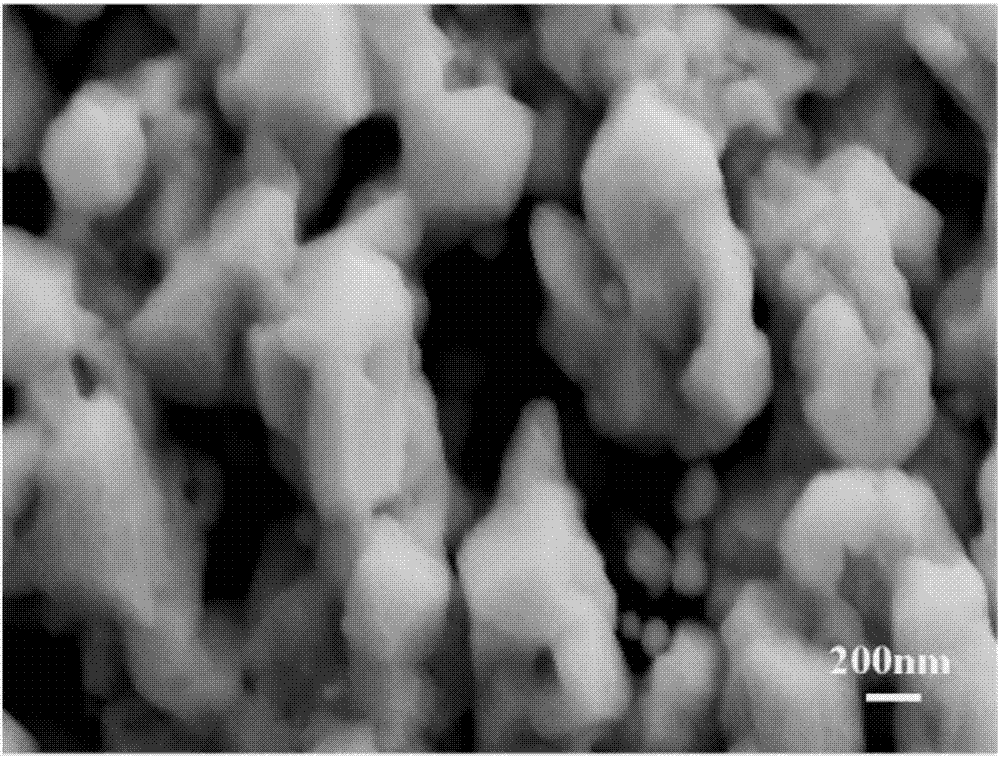

[0044] (3) the ultra-thin strip CuZnAl master alloy with β+γ two-phase that step (2) gained is in the ferric chloride hydrochloride aqueous solution (5...

Embodiment 2

[0049] (1) Weigh the pure copper block, pure zinc block and pure aluminum block according to the mass percentage of 61:32:7, and then obtain copper-zinc-aluminum alloy ingots by induction melting.

[0050] (2) The copper-zinc-aluminum alloy ingot obtained in the step (1) is subjected to a copper roller quenching method, and strips are thrown under vacuum protection to obtain an ultra-thin strip CuZnAl master alloy with a γ phase and a small amount of β phase. The vacuum degree in the rapid quenching process of the copper roller is 1 Pa, the rotational speed of the copper roller is 3000 rpm, the thickness of the strip is 40 μm, and the material width is 10 mm.

[0051] (3) Corroding the ultra-thin tape CuZnAl master alloy with β+γ two-phase obtained in step (2) in an alcohol solution with a chloride ion concentration of 3%, the corrosion time is 240min, and the corrosion temperature is 80°C.

[0052] (4) Seal the porous Cu / CuZnAl composite material with nano-aperture obtained i...

Embodiment 3

[0054] (1) Weigh the pure copper block, pure zinc block and pure aluminum block according to the mass percentage of 60:35:5, and then obtain the copper-zinc-aluminum alloy ingot by electric arc melting.

[0055] (2) The copper-zinc-aluminum alloy ingot obtained in the step (1) is subjected to a copper roller quenching method, and strips are thrown under vacuum protection to obtain an ultra-thin strip CuZnAl master alloy with a γ phase and a small amount of β phase. The vacuum degree during the rapid quenching of the copper roller is 0.5 Pa, the rotational speed of the copper roller is 2000 rpm, the thickness of the strip is 60 μm, and the material width is 3 mm.

[0056] (3) corroding the ultra-thin CuZnAl master alloy with β+γ two phases obtained in step (2) in an aqueous hydrochloric acid solution with a chloride ion solubility of 1wt.%, the corrosion time is 120min, and the corrosion temperature is 50°C. A nanoporous Cu / CuZnAl composite material is obtained.

[0057](4) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com