Cu-Al-Mn shape memory alloy damping device for precise instrument and manufacturing method of Cu-Al-Mn shape memory alloy damping device

A cu-al-mn, damping device technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of low superelasticity, high strength and high superelasticity difficult to obtain at the same time, low strength, etc., to achieve excellent damping performance and optimal reduction Shock energy absorption performance, strong energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

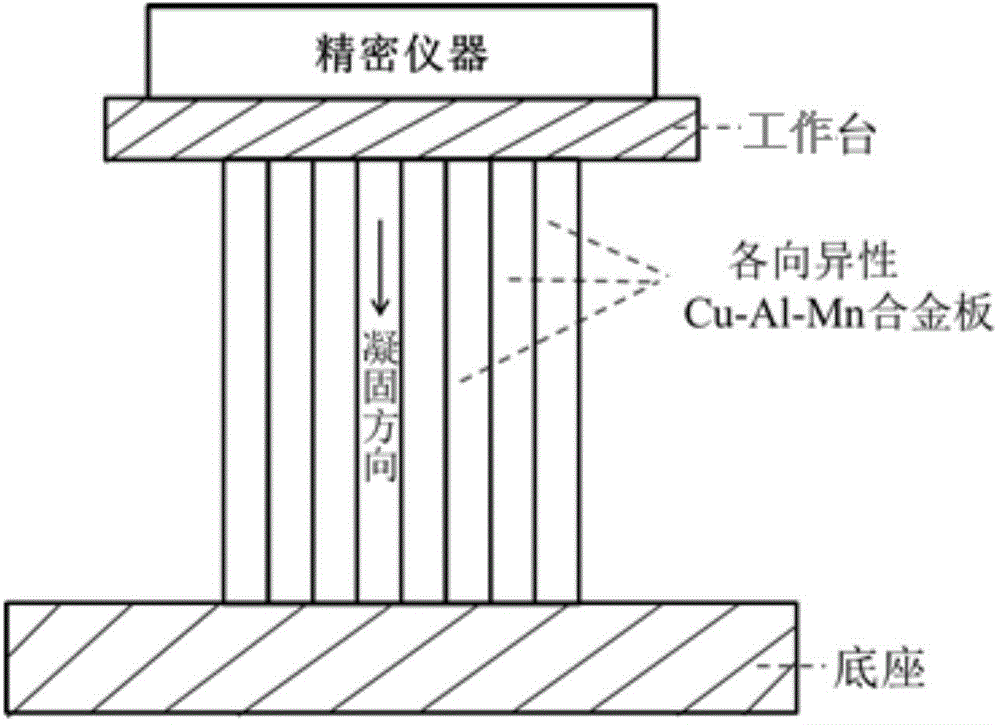

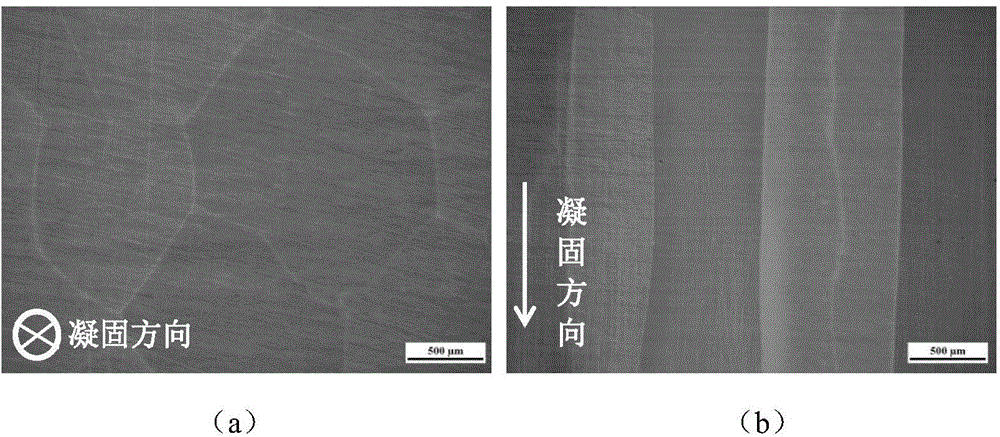

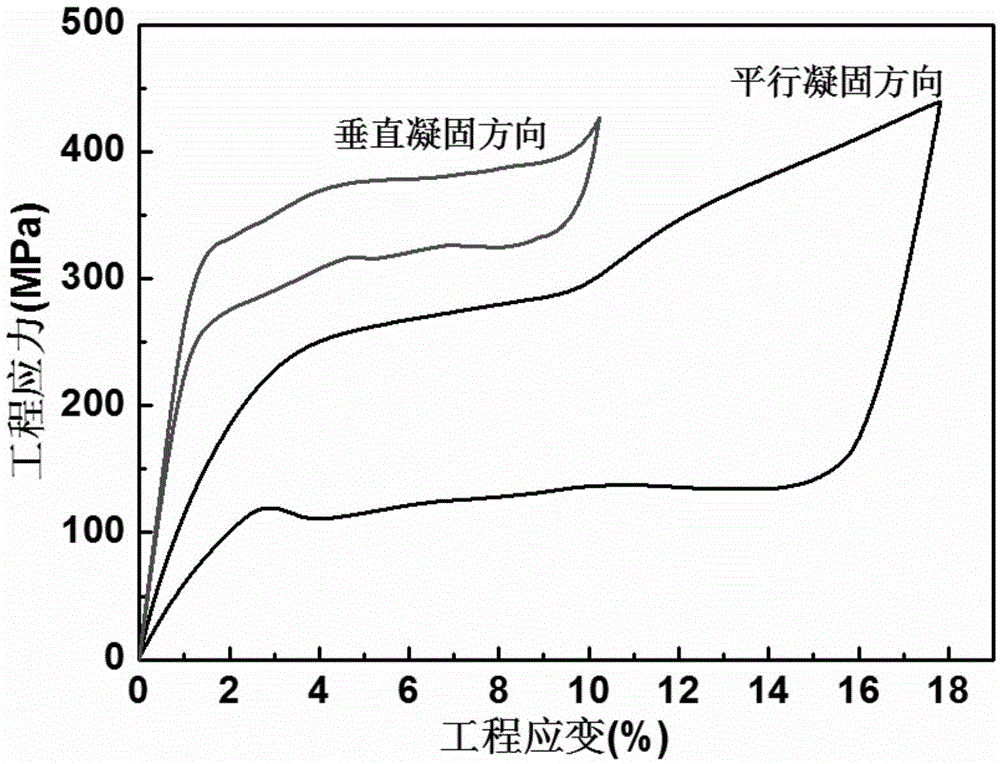

[0042] Adopt preparation process described in the present invention to prepare wide 50mm thick 5mm Cu 72 Al 18 mn 10 (at.%) alloy plate, the properties along the parallel and perpendicular solidification directions are shown in Table 1, the superelastic recoverable strain in the parallel solidification direction reaches 18%, the yield strength is 228.5MPa, and the superelastic recoverable strain in the perpendicular solidification direction reaches 9%, the yield strength is 312.1MPa. Cut the plate with a length of 150mm, the length direction of the plate is along the solidification direction, press figure 1 The shock absorber is made as shown. The maximum bearing pressure of the shock absorber is 228MPa.

[0043] Table 1 Columnar grain structure Cu 72 Al 18 mn 10 Performance parameters of alloy plates parallel and perpendicular to solidification direction

[0044]

Embodiment 2

[0046] Adopt preparation process described in the present invention to prepare the Cu of wide 40mm thick 4mm 72 Al 17 mn 11 (at.%) alloy plate, the properties along the parallel and perpendicular solidification directions are shown in Table 2, the superelastic recoverable strain in the parallel solidification direction reaches 16%, the yield strength is 268.9MPa, and the superelastic recoverable strain in the perpendicular solidification direction reaches 8.5%, and the yield strength is 349.3MPa. Cut the plate with a length of 130mm, the length direction of the plate is along the solidification direction, press figure 1 The shock absorber is made as shown. The maximum bearing pressure of the shock absorber is 268MPa.

[0047] Table 2 Cu columnar grain structure 72 Al 17 mn 11 Performance parameters of alloy plates parallel and perpendicular to solidification direction

[0048]

Embodiment 3

[0050] Adopt preparation process described in the present invention to prepare wide 50mm thick 4mm Cu 71 Al 20 mn 9 (at.%) alloy plate, the properties along the parallel and perpendicular solidification directions are shown in Table 3, the superelastic recoverable strain in the parallel solidification direction reaches 10%, the yield strength is 298.9MPa, and the superelastic recoverable strain in the perpendicular solidification direction reaches 7.5%, and the yield strength is 382.1MPa. Cut a plate with a length of 140mm, the length direction of the plate is along the solidification direction, press figure 1 The shock absorber is made as shown. The maximum bearing pressure of the shock absorber is 298MPa.

[0051] Table 3 Columnar grain structure Cu 71 Al 20 mn 9 Performance parameters of alloy plates parallel and perpendicular to solidification direction

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com