Ti-Zr-Nb-Fe-Al-Ce super elastic alloy and products thereof

A superelastic alloy, ti-zr-nb-fe-al-ce technology, applied in the field of titanium-based shape memory alloys, can solve the problem of no shape memory performance, etc., to improve shape memory performance, improve welding performance, high resistance The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

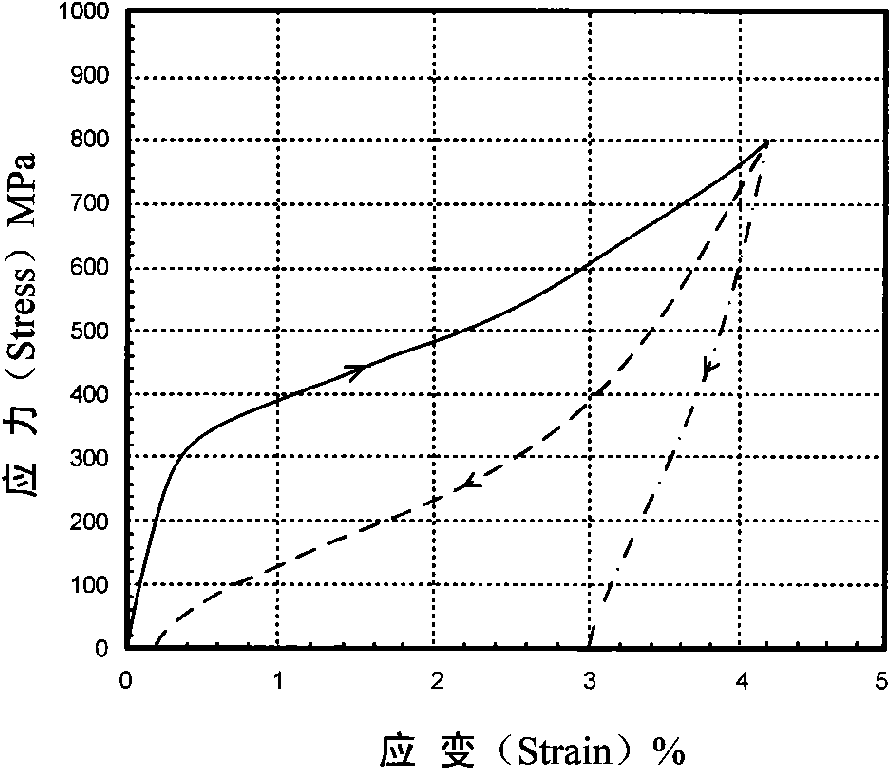

[0042] Example 1 : Ti-22Zr-18Nb-1.5Fe-1.2Al-0.6Ce alloy

[0043] According to the chemical composition scope of the alloy of the present invention, Zr: 13-26wt%; Nb: 13-26wt%; Fe: 0.5-3.2wt%, Al: 0.3-2.8wt%; Ce: 0.1-1.3wt%, Ti and Unavoidable impurity elements: balance, the unavoidable impurity elements mentioned here mainly include: H, O, N, C and other elements; alloy preparation.

specific to Embodiment 1

[0044] Specifically to embodiment 1, the alloy composition obtained after smelting is:

[0045] Table 1: Chemical composition of the Ti-22Zr-18Nb-1.5Fe-1.2Al-0.6Ce alloy of Example 1

[0046] the element

[0047] The alloy of Example 1 was subjected to solution treatment: (temperature 850°C, heat preservation for 30 minutes, water cooling) to make a tensile sample, and tested by a tensile testing machine at room temperature (25±2°C). Set the maximum strain at 4.2%, measure and record the stress-strain curve when it is loaded and unloaded, refer to figure 2 . Experiments prove that the alloy of Example 1 has good superelasticity.

Embodiment 2

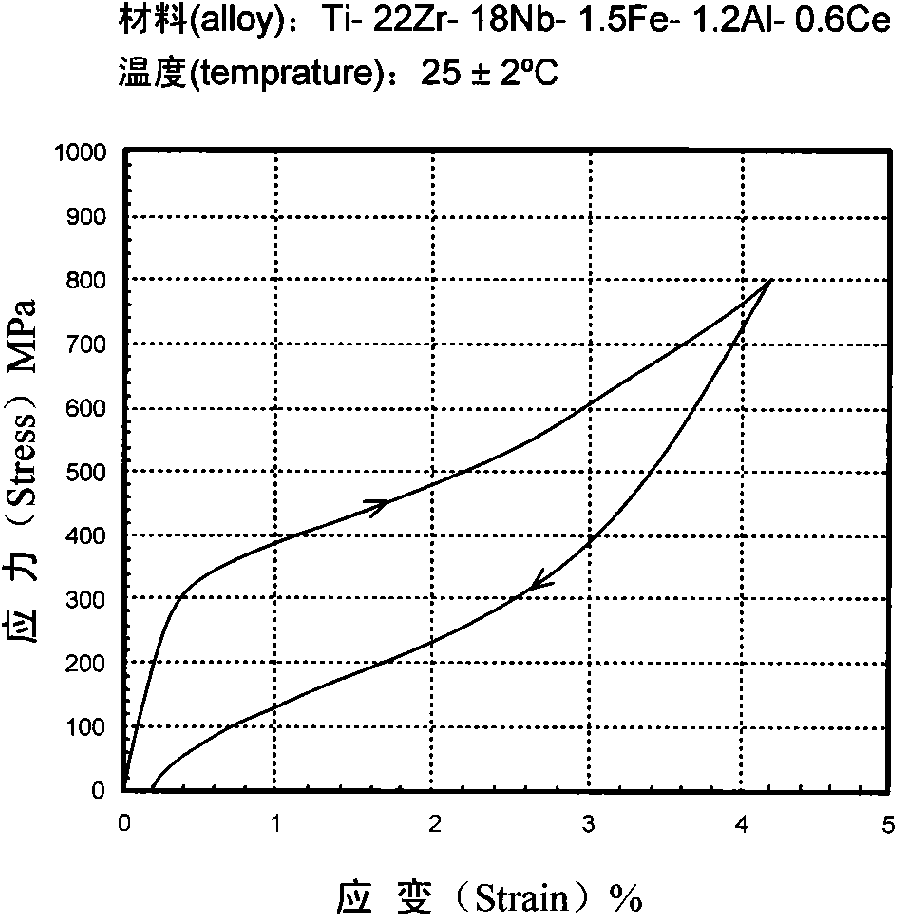

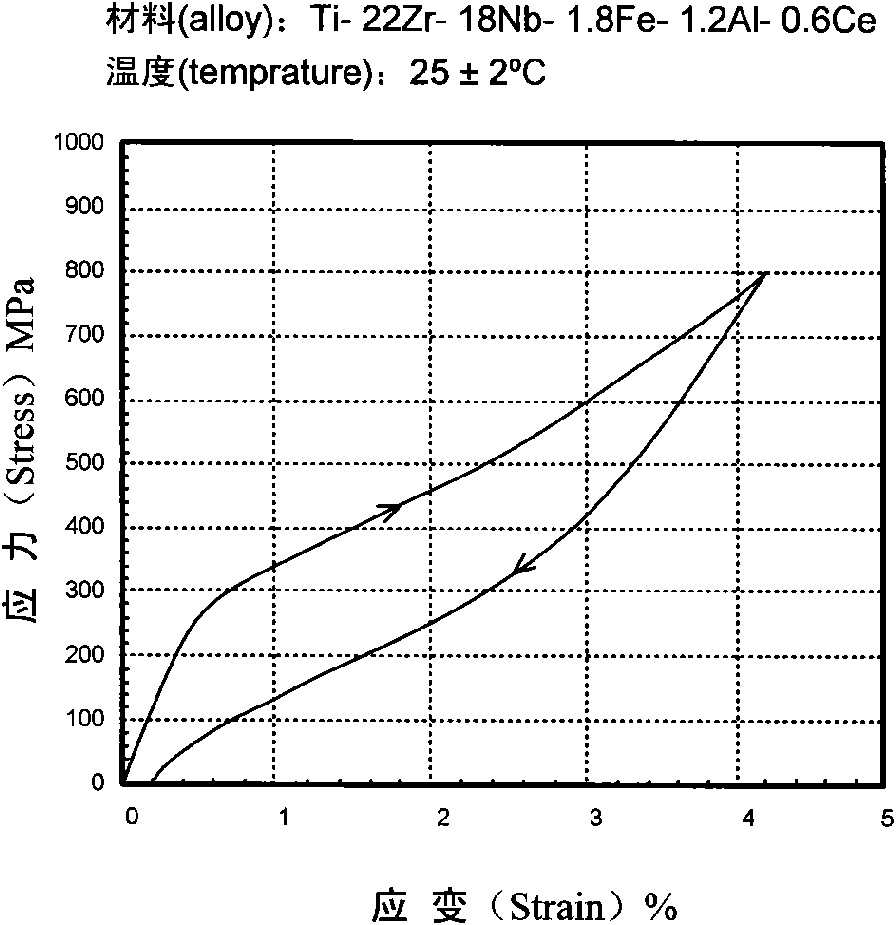

[0048] Example 2 : Ti-22Zr-18Nb-1.8Fe-1.2Al-0.6Ce alloy

[0049] Prepare and smelt titanium alloys according to the following Table 2. The obtained alloys are subjected to solution treatment: (temperature 850°C, heat preservation for 30 minutes, water cooling) and then made into tensile samples. Stretching test machine experiment. Set the maximum strain at 4.2%, measure and record the stress-strain curve when it is loaded and unloaded, refer to image 3 . Experiments prove that the alloy of Example 2 has good superelasticity.

[0050] Table 2: Chemical composition of the Ti-22Zr-18Nb-1.8Fe-1.2Al-0.6Ce alloy of Example 2

[0051] the element

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com